Finishing the facade of a building with siding allows you to protect the structure from the negative influence of external factors. This finishing material has a large list of advantages:

- attractive appearance;

- practicality;

- low cost;

- ease of installation work;

- durability;

- wide selection of colors and shapes.

The installation process is relatively simple and consists of creating a supporting frame, onto which panels of finishing material are subsequently mounted. A smooth, solid wall can be covered in literally a few days, but you will have to tinker with window and door openings.

The finishing of siding on windows and doors is not particularly different from each other. The only difference is the presence of a low tide to remove precipitation when covering the windows. When covering doorways, the function of low tide is performed by a threshold or a threshold.

Basic principles of cladding

Taking into account three important principles determines the direction that is set when covering doors with modern siding:

- Siding may only be attached to prepared sheathing. This allows you to use additional options for insulating the facade. Moreover, a ventilated gap is provided, which is required for complete condensate drainage.

- Compliance with a clearly defined sequence of work during installation activities. For this reason, the surface is first thoroughly prepared, two strips (starting and finishing), corners of the internal and external structure, and finishing strips are installed. In each case, siding is used only with platbands, so it will not be possible to do without them. After proper preparation, you can install the siding.

- Taking into account the temperature effect on siding. Panels can expand and contract under the influence of temperature. In this regard, it is recommended to take into account the temperature regime when installing elements with the optimal tightening force of the fasteners used.

If you take into account the three principles described above, there is a chance to guarantee a successful siding finish. These aspects are classic, so they play an important role in both interior and exterior decoration using the material in question. Otherwise, completing the assigned tasks is greatly simplified.

Preparatory stage

High-quality window finishing from the outside requires certain preparation. Such work includes:

- removal of decorative elements;

- cleaning the surface from old plaster;

- removal of old wooden parts;

- dismantling of communications.

In addition, technical devices and fixtures - antennas and air conditioners - are also removed. The surface is cleaned and dried. It is better to carry out such preparation if it is planned to cladding the entire façade of the building.

Siding storage and transportation options

In order to decorate your home with siding, every person must remember the rules for storing and transporting the material. Otherwise, you cannot count on a positive result. Panels are allowed for use only if their quality has been maintained optimal:

- Packaging materials with siding should always lie on a flat surface. Support along the entire length of the material is required.

- You can only stack up to fifteen packs on one stack. Otherwise, the material will be subjected to excessive pressure, which will be dangerous for its quality.

- The temperature inside the packaging material cannot exceed 60 degrees Celsius. If you leave packaged siding under the hot scorching rays of the sun, it risks losing its original characteristics, despite its resistance to external factors.

Proper storage allows you to successfully use the siding in the future.

Finishing a door with siding, platbands, dermantin: video instructions, photos

Every owner wants his front door to look beautiful, since it is considered the hallmark of the house, it can say a lot about its owners and catches the first glance of guests. Today, metal or wood products with different decorative finishes are used as entrance doors.

However, the ready-made models on the market are not particularly diverse, and many decide to transform the entrance structure to their liking and with their own hands.

Finishing the door with faux leather is a fairly simple solution.

In some cases, the old front door may be of good quality and to give it freshness, it is enough to simply update the cladding, which will serve not only as decoration, but also provide additional sound insulation.

Rules for caring for siding

What should be the proper care for siding? What aspects are recommended to be taken into account?

- The panels can be washed with water using a classic hose.

- To remove heavy dirt, use a brush with soft bristles or a soft cloth.

- Abrasive cleaners or brushes with stiff bristles can cause scratches on siding. For this reason, it is recommended to avoid such materials. Pure chlorine, organic solvents, varnish removers, grease stains, and furniture surface polishing agents can be negative.

- The most serious remedy that is allowed to be used consists of water and vinegar. In this case, it is mandatory to observe the proportions: 70% - water, 30% - vinegar.

Proper care is guaranteed to extend the life of the cladding.

Arched windows

Such designs look great, but finishing them is fraught with some difficulties. Installing siding on arched windows is complicated by the presence of a curved part in the upper part of the structure.

For finishing, a J-profile is usually chosen, which is quite flexible. However, its cost is significantly higher than that of a regular one. For this reason, its standard counterpart is often chosen. To do this, several cuts should be made in a regular profile, which are made on the mounting part. It is then bent to give the required radius of curvature.

Attention! In some cases, cuts are created on the front side of the product. If carried out carefully, this solution will become an effective design technique.

An alternative option is to replace the arched opening with a polygonal opening. The design of such a window is performed using the same technology. However, the profile cutting will be large.

The ease of bending a regular J-profile will depend on the material from which it is made. In the case of metal, it will yield much harder than plastic. To create an arc of the required radius of curvature, you should choose vinyl siding. To make bending easier, it should be warmed up well. However, you should not overuse this - the plastic can easily melt.

Taking into account these rules and recommendations, you can decorate windows with siding quite quickly and effectively. This will save time and effort. If the facing material is installed correctly, the window will look very attractive.

How to carry out winter installation

Covering doors with siding is permitted even in the cold season. To eliminate unwanted risks, it is recommended to take into account important aspects of the planned event:

- The siding should rest for several hours. A mandatory requirement is compliance with a suitable temperature regime. The material must be cured at outdoor temperature, which at the same time should not be lower than +15 degrees Celsius. Otherwise, the cold will have a negative impact on the material that has not yet been installed on the door.

- It is advisable to use a suitable cutting technique for cutting. The best options would be a saw with small teeth or a grinder with an angular design. Scissors designed for cutting metal will not be desirable.

- It is recommended to remember the tolerance that affects the compression - expansion of the material. The optimal tolerance is eight to ten millimeters.

Carrying out work in winter

When performing work at subzero air temperatures, the fragility of the plastic increases. The brought material should not be stored near heating appliances. Vinyl panels should be cut in a heated room. Since the material contracts when cooled, a thermal gap of 6 mm is provided between the ends. Other actions are performed by analogy with the work algorithm described above. If the technology is followed, the siding strips will not warp when the air temperature rises.

How to install siding on a door surface

Mandatory requirements - taking into account the basic rules that determine the result of installing siding on the door surface:

- Satzding panels can become wider or narrower. Such changes depend on temperature exposure. In this regard, strong screwing of screws or nails is not recommended. It is best to leave about one millimeter between the siding and the head of the screw or nail. One millimeter will be enough for the panels to successfully move from one side to the other and vice versa.

- The vertical profiles of the sheathing used cannot be placed more often than every thirty to forty centimeters.

- It is recommended to leave about 6 millimeters at each side gap. This will be enough for natural compression and expansion of the panel. If installation is carried out at low air temperatures, the distance is always increased to eight to ten millimeters.

- During installation, do not apply strong upward or downward pressure on the panel when securing it. Otherwise, the radius of the installed panel will shift, and the locks will actively rub against each other. Light force may only be applied in one direction: from bottom to top. Such force is allowed only until the connection between the lock and the lower part occurs.

- A nail or self-tapping screw may be driven into the central part of the perforated hole. The main task is to remember that forceful hammering is not recommended. Otherwise the panel will be damaged.

Recessed structures

Window trims are great in cases where the window is not very deeply recessed into the wall. Thanks to the use of planks, the slopes are closed.

Then the window strip is placed in the hole of the finishing profile. When joining the planks on the vertical elements that connect to the slope, it is necessary to make special cutouts. Horizontal elements are cut and bent.

Now finishing the window with siding can be considered complete. For different design solutions used when installing windows, there are specific features of siding installation.

If the window is recessed quite deeply, the use of window strips is not required. For such structures, small pieces of wall panels are used. During the installation process, a corner is used.

Installation can be carried out using a special ebb. Its edges must be trimmed and folded under the vertical elements. To increase the reliability of fastening the ebb, a sealant is used.

Installation of siding on windows is carried out in the following order:

- first, a J-profile is attached around the perimeter of the structure;

- then the installation of pre-prepared elements of the frame panels is carried out;

- At the final stage, the corner profile is installed.

During installation, you must follow the same rules as for the general installation of siding panels. Each connection should be created with a gap of 5 mm.

Attention! When performing work in autumn or winter, the gaps should be increased to 10-12 mm.

Features of using siding

Recently, finishing doors with siding has become widespread. Often this option for finishing door structures is used in commercial and industrial premises:

Siding is an ideal option for both the exterior and interior. In addition, the material is ideal for covering large doors.

Siding can be wooden or metal. Even if you plan to decorate a metal door with your own hands, a successful event is recommended. In addition, success is guaranteed. Metal siding is ideal even for finishing large doors on the outside, because any precipitation or temperature influences cease to be dangerous.

conclusions

The overall impression of the facade of the house depends on how well the windows are finished. That is why such work should be treated with the utmost caution. The installation technology is determined by the shape of the window, as well as the degree of its recess into the wall. Such work will be simple even for a novice builder.

If you follow the suggested tips, finishing a window with siding will not be difficult, and the result will be pleasing to the eye.

Before cladding, it is better to take care of the proper preparation of the opening. It should be cleaned thoroughly. To protect the interior from the cold, it is necessary to create a thermal insulation layer. It is made from polystyrene foam boards.

If windows are properly covered with siding, decorative elements will not be deformed under the influence of temperature changes and weather conditions. The process of finishing a window with siding can be learned from the video:

- Liquid glass and its application

- How many boards in a cube

- Fiberboard or hardboard

- DIY bark beetle plaster

There are many options for facing a house, one of which is finishing the windows with siding on the outside. This process does not require special skills and can be done independently. The work is carried out in conjunction with the installation of the main covering. The main thing is to correctly select and install additional elements taking into account the specific situation.

Advantages of siding panels

Why is this material becoming more and more popular?

- optimal resistance to moisture, which loses any negative properties;

- a decent level of fire safety, thanks to which any risks associated with a fire in the premises are successfully eliminated;

- optimal resistance to any impact;

- long-term operation and guaranteed durability;

- frost resistance and heat resistance. Only before carrying out installation activities is it recommended to protect the material from the negative influence of temperature;

- eliminating the need for special processing: impregnation, painting, maintenance.

The above advantages fully explain why the material is becoming popular.

How to decorate the inside of the apartment?

Slopes protrude from both the outside and inside of the door. Accordingly, there are two types of finishing - external and internal. The external one, as a rule, is less variable. The main focus is on the design of the door leaf, and the slopes echo either it or the decoration of the walls. More often these are practical and concise options that do not attract attention.

Inside an apartment or house, the finishing of slopes becomes part of the interior. It plays a decorative role, so the types of materials and methods of decoration are of great importance.

Finishing with facing materials from the inside can be of the following types:

- Plastering the surface.

- Gluing finishing materials.

- Frame sheathing.

- Coloring.

For the first type, plaster, primer, water and all the necessary tools are used. This process takes a lot of time, but makes it possible to fill up all the unevenness, insulate the structure, and make a layer of the required thickness. Decor from other materials is often applied on top of the plaster, but in itself it is already considered a finished finish, and therefore refers to the basic techniques in repair.

“Clean” slopes after plastering can be easily painted in any suitable color, while they are sanded until smooth or, on the contrary, left in relief.

The following materials can be used for decoration:

- Ceramic tiles (tiles). It is distinguished by its rigidity, moisture resistance, hygiene, low price and a wide range of colors, shapes and textures. The ceramic surface is easy to care for, but the tiles can crack or break off due to mechanical damage, and during the replacement process you will have to work hard to avoid damaging neighboring elements.

The undeniable advantage of tiles is the many possibilities for design. The mosaic looks especially original. It can be made from whole small tiles or from small pieces. Mosaic fragments are obtained artificially from tiles by cutting them into pieces of the required size, and handymen can use broken tiles, which are considered unsuitable, for this purpose. The result is original and unique, and the cost of materials is minimal.

Any construction adhesive is suitable for gluing tiles. Apply it evenly with a plastic spatula, and the seams are rubbed down after a day with a rubber spatula.

- Porcelain tiles. This material is often confused with ceramic tiles. Indeed, in the manufacture of porcelain stoneware, the same composition of the substance is used as for tiles, but the production technology is very different. As a result, the tile has a colored coating only on top and becomes unsightly when chipped, while porcelain stoneware has a uniform color throughout the entire thickness of the slab and damage to it is less noticeable. Also, its structure is denser, so it is more resistant to damage. In addition to being moisture-resistant, environmentally friendly and durable, it is also frost-resistant. In appearance, this material is more noble, but the color spectrum is very limited and its cost is higher than for ceramic tiles.

Selection rules

First of all, you need to decide on the optimal material. For example, finishing an iron door with your own hands should only be done using reliable metal siding. Understanding the technical properties of the material used ensures that there is no risk of disappointment in the achieved result.

Wood siding is losing popularity as it gives way to metal and vinyl varieties. Metal products are susceptible to corrosion, so they often require special anti-corrosion treatment. Otherwise, vinyl becomes the most worthy material.

The choice of high-quality, beautiful and suitable material in color and texture, and proper installation guarantee successful door trim.

The requirements for the front door are always much higher than for the interior design. It is necessary not only to decorate the entrance to a house or apartment, but also to reliably protect the home from the penetration of cold and external noise.

- Selection of material for slopes

- Combined finishing

- Plastic panels

- Siding on the entrance door slopes

- Plastered slopes

Insulation

Finishing windows during siding installation involves creating an insulating layer that will protect the window frame and the room behind it from the effects of cold. Insulation is best done with polystyrene foam boards. It is mounted on dowels with wide heads.

Advice! To protect the insulation from moisture, a film should be laid on top.

Since cracks cannot be avoided during installation of the window frame, it is necessary to prepare the sealant in advance. Thanks to the use of this material, it is possible to increase the hydro- and thermal insulation properties of the structure as a whole.

Selection of material for slopes

Entrance doors can be made of wood, metal sheets or plastic panels. The finished slopes should complement the door design and be combined with the design of the walls. Almost any finishing materials are suitable for work:

- Plastering is a simple and reliable method of leveling the surface. This can be a finishing decorative option or preparing the base for a mixed finishing method.

- Plastic panels are installed without first leveling the base. Lathing is used to secure them. The appearance of plastic slopes always pleases with its neatness.

- Siding is used for both internal and external decoration of doorways. A variety of sizes and colors of the material allows you to choose the most suitable option.

- MDF panels are used for a combined finishing method, which makes it possible to make slopes warm, durable and beautiful.

- Decorative stone requires preliminary preparation of the base.

We suggest considering the option of finishing entrance door slopes using a combined method. The rough finish will be plaster or putty on the base, and the final finish will be MDF panels.

Features of finishing doorways

The front door of a private house or cottage also needs to be framed with siding. Although the procedure is almost identical, there are some differences:

- The simplest option is to move the iron frame with external platbands into the same plane as the facade. In this case, the panels are mounted under the protruding fragment of the frame.

- For slopes less than 5 cm, you can use a regular corner trim: they frame the entire perimeter with trimming at the corner joints.

- Deep slopes can be made by placing the siding vertically or horizontally, taking into account the frame.

Upon completion of the work, all joints are sealed. For these purposes, compositions matching the color of the cladding are used.

Still have questions? Watch this video:

Combined finishing

To work you will need tools and materials:

- Brush, spatula.

- Perforated corner.

- Building level.

- Polyurethane foam.

- Primer, putty.

- Liquid Nails.

- Glue, dowels.

- MDF panels.

Installation of slopes on the front door begins after its installation is completed. Start with standard surface preparation:

- Check the strength of the wall around the door and clean the work surface from dust with a brush.

- Fill the gaps between the wall and the door frame with foam. Let it harden and remove the excess with a knife, carefully leveling the surface of the base.

- To ensure that the plaster mixture adheres better to the base, treat the cleaned surface with a primer.

- Install the beacon profile for plastering.

When the preparation of the base is completed, proceed to the main stages of work.

Stage No. 1. Applying plaster or putty

For rough finishing, use cement-sand mortar or starting façade putty. Both types of solution perfectly level and insulate the surface. Prepare a mixture of lime mortar, sand and cement yourself. Dilute the putty to the desired consistency.

Apply the solution from top to bottom. First level the surface above the door, and then start plastering the sides. The layer should be thick. Remove excess with a wooden strip. To keep outside corners strong and neat, install perforated corners by pressing them firmly into the plaster. Leave the surface to dry completely.

Siding installation: step-by-step instructions for covering a house with your own hands

For cladding the facades of residential buildings, plastic, metal or wooden slabs are used, painted in different shades or imitating natural finishing materials. Siding installation involves installing a frame and insulation. The home owner can do the work himself, reducing the cost of construction or repairs. The durability and strength of the finish depend on the quality of preparation of the wall surface and the correct assembly of the sheathing.

Plastic panels

For work, prepare:

- Starting guides.

- Screwdriver and wood screws.

- External and internal corners made of plastic.

- Wooden bars.

- Plastic panels

- Sealant, building level.

Level out unevenness in the base using putty - this is necessary for high-quality fastening of the sheathing. Proceed with assembling the base for mounting the panels immediately on the surface of the slopes. Connect the wooden blocks together with self-tapping screws. Check the fastening with a level.

Attach the starting strip to the finished sheathing with a construction stapler, having first checked the level of its installation. When using two or three strips of panels for wide slopes, fasten them together using locks installed at the ends, and treat the joints with sealant.

Insert the panel cut to the required size into the starting strip and attach it with a stapler. When all the elements are installed and secured, begin installing the inner corners.

Recommendation! When using plastic panels, wall finishing should be done after completing work on the doorway.

Install external decorative corners only after finishing work on the wall. This will hide the transition between two different finishing materials and make your front door neat and beautiful.

Siding is often used to finish internal and external slopes. Let's find out how to make front door slopes from this material.

Frame installation

When deciding to decorate a window opening with siding, it is worth considering that before such work, lathing should be done. It will be needed for the following reasons:

- so that the material is securely fastened;

- cladding will be much easier;

- to level the surface of the wall.

The following options are suitable for lathing:

- wooden beam with a cross-section of 4x6 cm.

- metallic profile.

Advice! When using wooden beams, before starting cladding, it is necessary to treat the elements with an antiseptic. This will help prevent the wood from rotting and being damaged by insects.

The frame parts are attached at a distance of 20 cm from each other. This step is optimal. If it is larger or smaller, the strength or aesthetics of the structure will decrease.

Siding on the entrance door slopes

Select siding of a suitable color from a construction supermarket to make the entrance to your home look beautiful and harmonious.

For work, prepare:

- Starter stripes and the siding itself.

- Corners for interior and exterior decoration.

- Wooden bars for sheathing and self-tapping screws.

- Construction stapler and staples to match the color of the siding.

Finishing slopes with siding is similar to working with plastic panels. The only difference is that siding can be installed in two ways - horizontal and vertical. With the first method of fastening, material consumption increases due to scraps, so most consumers prefer fastening siding along slopes.

With minimal financial investments, but labor-intensive and requiring professional skills, finishing slopes with plaster from the rough to the finishing stage is considered.

Basic requirements for the design of slopes

In order to do everything correctly, you should consider some recommendations:

- It is better to fasten the elements with galvanized self-tapping screws with a press washer, this will prevent damage to the parts and will make it possible to adjust the gap (unlike nails).

- The technological gap is a mandatory element. It is necessary to compensate for thermal expansion. When working with plastic products, the distance will be greater.

Since plastic and metal are prone to thermal expansion, the panels must be fixed with a mandatory technological gap - To avoid fitment problems, all materials should be made by the same manufacturer.

- The technology assumes that the screws will be screwed into the center of the mounting hole at a right angle.

- To ensure visual appeal and create proper drainage of excess moisture, some parts should be cut at an angle of 45 degrees.

- Accuracy is of great importance. It is better to take measurements at several points to determine the curvature.

When measuring window fittings, it is necessary to take into account the thermal expansion of the material - Although siding can be installed even in sub-zero temperatures, it is advisable to carry out the process in the warm season with stable humidity.

Everything must be done correctly, because any defects that arise during the work will lead to undesirable consequences.

Plastered slopes

This type of finishing is suitable for external and internal work. To work, you will need starting and finishing plaster, spatulas of different sizes, a building level, and a primer. Decorative plaster or paint can be chosen as a finishing layer.

If the slopes are severely damaged after installing the door, apply the starting plaster in several layers to properly level the surface. Let each previous layer dry before continuing. Be sure to apply a primer between layers of plaster - the slopes will be strong and reliable.

Apply the finishing solution in a thin layer and, after complete drying, treat with a fine mesh. Paint smooth slopes or apply decorative plaster to them.

We introduced you to different ways of finishing entrance door slopes. Typically, homeowners perform such work themselves. Choose the method you like and try to apply the acquired knowledge in practice. You will succeed.

We recommend watching this video:

Finishing the facade of a building with siding allows you to protect the structure from the negative influence of external factors. This finishing material has a large list of advantages:

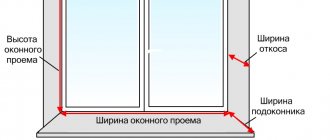

- Material calculation

Before installing siding around windows and doors, it is necessary to calculate the number of necessary components, which include near-window strips, J-profiles, ebbs, trims, corner strips and finishing strips.The use of certain components depends on the configuration of the window or doorway. If they have wide slopes, then it is necessary to use near-window strips. If doors and windows are flush with the wall, use platbands.

As a rule, the length of the components for siding is 3 meters. When calculating the required amount of material, you should divide the total perimeter of all doors and windows by 3. The length of components may vary depending on the manufacturer; this feature should also be taken into account when making calculations.

What siding is used for finishing window and door openings

To frame any opening, several main types of material can be used:

- Vinyl. This siding is made from a mixture of PVC and special additives and is very popular. This is due to the excellent qualities of the products, including resistance to precipitation, temperature changes and low weight. The undoubted advantage of the product is its affordable price, which is significantly lower than other types. When choosing a plastic material, take into account that products often available on sale are made from recycled PVC and are characterized by low performance properties.

- Metal. This type is superior to the previous version in many respects: the metal siding surface has better resistance to ultraviolet radiation, which significantly increases the durability of the coating, the material imitates the wood structure well and is classified as fireproof. Disadvantages include a higher price and the possibility of corrosion in damaged areas.

- Wood. This siding is also suitable for decorating openings. The cladding has an excellent appearance. Disadvantages: high cost and the need to apply a protective and decorative coating, since the production treatment gradually wears off.

In theory, metal and plastic slopes can be mounted on any siding, but in practice it is desirable that the slope material and the siding material match.

To decorate the house, different types of materials can be used: wall (facade) and basement, having different decorative coatings. Each option is suitable for framing a window or doorway.

Attention! For work, it is recommended to use only high quality panels and additional elements. Although the cost of such material is noticeably higher, this is compensated by durability.

Accessories

In order to cover window and door openings with siding, you will need special components and galvanized profiles.

How to cover a window with siding

Installation of siding around the window differs depending on the depth of their planting:

the window is flush with the plane of the wall;

This division is associated with the use of various standard elements. The industry offers several design options depending on the linear dimensions of the profiles for installation: external corner profiles and starting profiles (you can find the name J-profile or universal profile).

Before framing the windows with siding, it is necessary to create a sheathing. It is best to use metal profiles as a material, since wood does not have sufficient durability and resistance to external destructive factors.

If wooden slats are chosen as the frame, then before installation it is necessary to treat them with special protective compounds that increase the moisture resistance, fire resistance, chemical and biological resistance of the wood.

The frame must be mounted at an angle of 90 degrees, regardless of the direction of the slopes of the window opening.

Window siding trim with slope

If the seating depth of a window or door is up to 20 cm, then for cladding you can use a standard J-strap, which can have a width of up to 22 cm. Taking into account the overlap of structural elements, this method can cover an opening up to 20 cm. A finishing strip is attached to the plane of the window frame , into the groove of which the J-profile is inserted.

You can also replace the near-window strip with a system for fastening the outer corner, a universal strip and cutting strips of siding, which are laid horizontally in the grooves of the universal strip, and the outer edge is covered with an outer corner trim. This method can also be used if the window seating depth exceeds the permissible dimensions of the J-chamfer (20 cm).

The outer corner and J-profile are mounted, and the space between them is filled with siding panels cut to the required length.

Window trim without slope

If the doorway coincides with the plane of the wall, then when covering the building with siding, you can use standard elements in the form of platbands. Platbands come in several sizes, which vary depending on the width and shape: narrow (about 4 cm) or wide (about 6 cm), and a flexible platband is also used to frame arched openings.

In this case, all elements can be matched to the color of the siding or, conversely, you can highlight the door or window opening by using trims that differ in color from the main color of the siding.

The sequence of finishing windows with siding with your own hands: first install the platbands, then fill the gap with siding.

Arched window trim

To cover arched windows with siding, a standard flexible J-profile is used, but due to its high cost, many resort to using a standard rigid J-profile, the base of which is trimmed with the necessary increments. The cutting step is chosen depending on the radius of the rounding; the smaller the turning radius, the more frequent the cutting should be.

When bending an arched profile, you should be careful not to break the profile at the rounding point. Even if you managed to straighten out the bend, then, most likely, a noticeable mark will remain in its place.

Finishing a window with a slope greater than 20 cm

When finishing a window opening with a recess of more than 20 cm, external corners, J-profiles and siding panels cut to the required size are used.

At the initial stage of finishing, it is necessary to install the outer corner and J-profile, then in the gap between them, siding panels cut to the required size should be laid.

To finish the slope, you can use both the siding itself and the soffit. It is advisable to use a soffit, since the panel itself has a shape designed to drain water, and the soffit looks more aesthetically pleasing.

Particular attention should be paid to the methods of trimming and joining the corners of the window or door frame. The corners must be connected in such a way that there are no gaps or gaps through which water could penetrate under the finishing material.

Straight cutting can also be done, but cutting at 45 degrees is more attractive and has more functionality.

It is worth noting that the use of metal fittings will allow you to close slopes larger than 20 cm. This is due to the fact that it can be ordered according to the size of your home, i.e. if you have a slope of 25 cm, then they will make it for you and the area around the windows will be a single piece, and not an “assembled kit”. Another advantage of metal fittings is that they look more attractive when decorating the facade of a house than plastic ones.

Video instructions for finishing window and door openings with siding

Tools and materials

All processes for lining openings are done with your own hands, so the work is carried out using available tools available to every home craftsman:

- Screwdriver. This device can be replaced with a drill with the ability to control the speed.

- Grinder, scissors and metal saw. Trimming parts will require care, so it is advisable to provide electric and hand tools.

- Level.

- Measuring devices. Square, tape measure, ruler.

- A mallet and a simple hammer.

- Bits, drills and hardware.

To install all types of siding, the same set of tools is used.

To cover a window in a private or country house, you will need additional elements:

- finishing profile and starting bar;

- clypeus (narrow or wide);

- J-profile;

- internal and external corner;

- low tide;

- arched flexible J-profile.

All tools and components are prepared in advance, this will avoid delays during work.

Vinyl siding has the widest range of accessories for finishing windows, so it is easier to work with this material

How to choose the right design?

The design should match the style of the interior, especially the part of the room where the front door is located. Few people can boast of the design of an apartment, where everything is consistent with the popular style, but even an interior without pretensions, chosen by the household members themselves, should be harmonious.

When choosing a finish for slopes, you should take into account the prevailing colors, materials and textures in the room. So, to support a plastic door you should use siding and sandwich panels, for a wooden door - veneer, trim and laminate, and you can decorate a metal (steel, iron, aluminum) door using paint, artificial stone or plastic with imitation brick.

How to insulate?

Thermal insulation and sound insulation are the functions of the front door, which partly depend on the type of finishing of the slopes. To insulate a room, you don’t have to run to the store to buy a heater. First you need to take care of maximum tightness, and you should start with the front door. This will not only increase the level of comfort in the house, but will also help in the future to save money on utility bills.

Insulation of slopes from the inside is carried out step by step:

- Selection of materials. The leading positions are occupied by sandwich panels, plasterboard, polystyrene foam, mineral wool, and polystyrene. Experts recommend choosing polystyrene, which is superior to other materials in many respects. At a relatively low cost, it is capable of thermoforming and vacuum forming, is resistant to moisture and chemical treatment, does not smell, is environmentally friendly, and is amenable to various types of processing. If there is no polystyrene, it can be replaced with a mineral slab (wool).