Correct installation of the door structure will provide the proper level of protection. This will also guarantee optimal heat and sound insulation. Let's figure out how to install the front door, what is needed to achieve the best result. We will familiarize ourselves in detail with all stages of work - from dismantling to finishing. We will also consider how to soundproof a metal entrance door.

A door installed according to all the rules always looks beautiful Source potapenkov.com

Dismantling operations

Installation of the front door begins with dismantling work. During the work, you don’t have to worry too much about the integrity of the canvas (when its further use is not planned). But it is important to take care of the safety of the opening. The less it suffers during the process of removing the frame, the easier it will be to install a new door.

Dismantling work is carried out in the following sequence:

- Removing the door leaf . To remove it from its hinges, you need to lift it a little using a crowbar. The collapsible hinges are untwisted, after which the canvas is removed from the opening.

- Removing a threshold . For ease of removal, it is cut into two parts, after which it is knocked out with a heavy hammer.

- Removing the box . This process starts from the side. To make the box easier to dismantle, several horizontal cuts are made. If the side elements of the box have been removed, the upper part will be removed very easily.

Dismantling the old box Source prom.st

- Cleaning the opening . In order for the subsequent installation of a metal door to be successful, the old opening is cleared of plaster and foam. Fasteners are removed.

Dismantling work becomes more complicated if the door frame is metal. First, determine the location of the fasteners. They are removed, after which the box is removed from the installation site without significant effort.

Dismantling a metal door frame Source tildacdn.com

Measuring and ordering a door

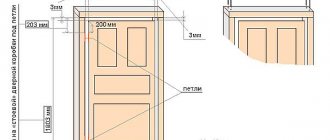

The speed and quality of work on installing the front door depend on the accuracy of the measurements taken. In terms of height, they must be carried out in two places; the width is measured at the bottom, in the middle and at the top. To calculate the dimensions of the door frame, the smallest vertical and horizontal values are taken, after which 40-50 mm are subtracted from them - for technological gaps.

Scheme of doorway dimensions measurements.

Before going to the store, you need to decide on the location of the hinges, i.e. decide which way the doors will open. The standard option is to the wall of the corridor. If the corridor is through, then in the opposite direction from the entrance - it’s easier to bring in furniture.

The openings of old houses are mostly non-standard. Therefore, you need to choose: expand the opening or order doors according to existing sizes. Experience shows that the second option loses a little financially, but is otherwise preferable (the customer avoids the noisy, dirty and labor-intensive process of adjusting the opening to the size of the door block), especially since the order in almost all companies is completed the next day.

Another important point when ordering is that the insulation must be not only in the door leaf, but also inside the door frame.

Preparing the opening

When studying the recommendations of experts on how to properly install a metal entrance door in a private house, you should not neglect the stage of preparing the opening. If there are pieces of plaster that may fall off, it is better to get rid of them. If large voids are identified, it is recommended to fill them with bricks set on sand-cement mortar. Small potholes can be skipped as they will later be filled with polyurethane foam.

The condition of the floor must be assessed. If necessary, a wooden block treated with impregnation is placed in the opening. Brick can also be used to level the base; minor defects are filled with mortar.

Preparing the opening for subsequent installation of the box Source ytimg.com

Dimensions of a new door: important nuances

In order for installation work to proceed as quickly as possible and with minimal inconvenience, even at the stage of choosing a new metal door, carefully take the necessary measurements.

Before you go to the store, measure the doorway. This work is complicated by the presence of a rather thick layer of mortar around the perimeter and, of course, the door frame. Because of them, it is quite difficult to clearly determine the boundaries of the opening, which causes a number of inconveniences during the measurement process and can distort its results.

Scheme for installing an entrance door under a flat platband

To ensure that your measurements are as successful and accurate as possible, please read the following recommendations:

- Before directly installing the structure, we clear the lower part of the opening down to the floor. The material used to raise the chute, as well as the thresholds and other elements will be dismantled;

- increase the top of the doorway, i.e. lifting is prohibited;

- the side parts can be slightly expanded if necessary. Here it is important to determine the width of the supporting transverse element, which is also the upper edge of the doorway. The width of the installed door should be approximately 2-2.5 cm less than the same parameter of the supporting element.

Based on the above, the frame of a new metal door should be 4-5 cm lower and narrower than the opening.

After taking the necessary measurements, proceed to preparing the working tools.

Installation

To figure out how to install a metal entrance door, start by leveling the frame. The prepared structure is installed in the opening. The lower part of the box is installed on special pads. By adjusting their thickness, they ensure that the structure stands level. When the loot is aligned horizontally, it is aligned vertically. This process is also controlled using a building level.

The position of the door frame is checked in all planes Source goodoors.ru

Once the box is in the optimal position, it is wedged. Use plastic or wooden wedges. Three fixing elements are installed vertically, and two horizontally. The wedges are placed close to the fastening points.

When the box is exposed, they proceed to fixing it. There are several methods for installing a metal door:

- For the eyes . The simplest and most popular method. A hole is made through the eyelet. An anchor is inserted into it, which is subsequently tightened.

- Through the canvas . The structure can be fixed through special holes that are provided in its design. The wall is drilled through them with a hammer drill, after which anchors are installed.

Fastening through the canvas Source rabotai-sam.ru

See also: Catalog of companies that specialize in doors, windows and related work

- Grips . The method is used when performing installation in a house with reinforced concrete walls. The structure is held inside by special hooks.

After securing the box, install the canvas. If there is a non-separable mechanism, it is simply hung on the hinges. It may also be necessary to adjust the door so that the process of closing and opening it occurs as smoothly as possible.

Installation of metal doors

Steel (metal) doors are most often used as entrance doors. The door frame, door frame and outer surface of the door leaf are made of metal. To ensure the required degree of heat and sound insulation, the canvas is laid with soundproofing material. On the side of the room, the entrance doors can also be covered with metal, or with sheet material (a budget option).

Metal door structure

Rubber insulation is laid on the frame along the perimeter of the vestibule (sometimes on the door leaf). It performs two functions: it serves to seal and reduces the strength of the sound that occurs when the door slams. The result is a reliable, warm and “quiet” entrance door.

Preparing the door

Since it is problematic to embed a lock into a metal door, doors are ordered immediately with a lock. You receive a kit that includes a pre-installed lock. Handles come separately. Here they need to be installed in place, screwed with self-tapping screws. Before installation, you need to check the operation of locks and latches. Everything should work smoothly, without effort or problems. If everything is fine, you can begin installing the metal entrance door.

Preparing a steel door for installation: checking the operation of the lock, insulating the frame with mineral wool

If the doors are installed with access directly to the street (in a private house, for example), the outside of the door frame is lined with insulation. You can use rock wool cut into strips. It is inserted into the frame and held in place by elastic force. It has a significant disadvantage: it is hygroscopic, which is why the doors can rust from the inside (if they stand as an exit to the street and are not tightly sealed). In multi-storey buildings this is not critical: here there is no precipitation in the entrance. Another solution is to install polystyrene foam or fill the frame with foam. They are not afraid of moisture, and the thermal insulation is normal.

To ensure that the paintwork of the box is not damaged during installation and subsequent finishing work, it is covered with masking tape around its perimeter. It is removed after the door slopes have been made. If there are any wires coming through the door frame, it’s time to install the inserts - a piece of plastic pipe or corrugated hose through which these wires will get inside.

Installation of interior doors is described here. Read about installing sliding doors here.

Installation in brick and concrete walls

It is more convenient to install doors in which the panel can be removed. Before installation, it is removed from its hinges. The door frame is inserted into the prepared opening. At the bottom it is placed on mounting pads 20 mm high. She should stand in the opening freely.

We place the door frame on mounting pads

By changing the thickness of the pads, we ensure that the lower frame is strictly level. This is checked using a building level. Having set it horizontally, we set it vertically: so that the racks do not deviate either forward or backward, but stand strictly vertically. This is also checked using a level, only the device with a bubble is located on the short part of the tool. Another option is to check with a plumb line.

Checking whether the door frame is aligned vertically

After the box is level, it is wedged using prepared wedges. They can be cut from wood, or you can buy plastic ones. The wedges are inserted on long posts, three in number, two at the top. They should be placed close to the fastening points, but without blocking them.

Example of wedge installation

After installing the wedges, check once again whether it is positioned correctly: in the horizontal and vertical planes. There should be no deviations.

Next, the installation of the metal door frame in the opening begins. There are two types of mounting holes: steel eyes welded to the box and a through mounting hole (there are actually two of them: in the outer plate with a slightly larger diameter and in the inner plate with a smaller diameter).

Two types of mounting holes

There is no difference in the installation method. Simply frames with holes in the body of the box can be installed on thinner walls. This may be important if the entrance door is installed in a panel house: it is not always possible to install doors with lugs in them.

Through-hole mounting

Iron entrance doors are secured to anchors or to pieces of steel reinforcement with a diameter of 10-12 mm. The diameter of the fastener is selected to match the existing holes. If anchors are used, their head should fit into the outer hole and “get stuck” in the inner one. The diameter of the fittings must match the diameter of the holes. In any case, holes are pre-drilled for them.

We take a hammer drill, a drill and an anchor. The drill is of the same diameter as the fastener. Its length should be at least 30 cm. To more accurately determine the depth to which you need to drill, masking tape is attached to the drill. It marks a distance that is slightly greater than the required depth.

Mark the drill according to the length of the anchor

The installation of fasteners begins on the hinge side. When drilling, it is important not to move the installed box. First they drill from the top.

Drill holes at the top, on the hinge side

Install the anchor, finishing it off with a hammer. To recess it to the inner edge of the box, insert a screwdriver into the slots and tap the handle of the screwdriver with a hammer. Then, when the anchor is driven in, it is tightened a few more turns with a screwdriver. We check whether the box has been moved during work - take a level and check everything.

Driving the anchor deeper

We install the fasteners below in the same way. We also check verticals and horizontals. If the door leaf is not heavy, you can already check at this stage how correctly the frame is positioned. To do this, hang the doors and check how smoothly they “sit”, whether there are any distortions, cracks and other troubles, how well the locks and latches match and work properly.

If the canvas is made of thick sheet steel and weighs about a hundred kilograms, two fasteners are clearly not enough. Then install all the fasteners on the hinge side, as well as one on the lock side. After installing each fastener, the verticality and horizontality of the box is checked. Then they carefully hang the canvas and check how it “moves”. If everything is fine, continue installing the fasteners. No - you will have to remove the already installed fasteners and re-position the frame.

We place the anchor in the door frame of the front door from below, checking the verticality of the post

After checking, the canvas is removed again, and the already installed anchors are finally tightened. Then they put everything that is needed on the hinge side, then on the lock side. When everything is finally installed, the door leaf is hung in place again.

Now you need to fill the installation gaps with foam. To install an entrance door with your own hands, it is better to take one with a low expansion coefficient: it is easier to work with. In order for the polymerization of the foam to proceed normally, the cavities that will be filled are moistened with water from a spray bottle (ordinary household). Then everything is slowly filled with foam.

You need to blow it across the entire width of the door frame: then there will be no blowing and the sound insulation will be better. When installing a door with iron, you don’t have to worry about the frame breaking apart: the rigidity of the metal is such that the expansion force of the foam is far from insufficient. Therefore, you can foam generously.

We fill the installation gaps with foam

Only if foam gets on the canvas should it be removed immediately with a damp cloth. After 5 minutes, you just won’t be able to wipe it off. While wet, it can be removed without leaving a trace. Then you will have to scrape, but this is not painless: traces will remain. Polymerization of the foam will end after 24 hours. Then we can consider that installing the front door with our own hands is completed. All that remains is to make the slopes on the door.

Installation of a box with lugs

If there are welded plates on the box - lugs - the box is placed in the same way: on pads. Then it is leveled and wedged. Then there are two options:

- The lugs have mounting holes. Then holes are drilled for them. Cut a piece of reinforcement, insert it into the hole and hammer it in.

Installation using fittings - There are no holes in the lugs, but they are made of thick metal - 3 mm thick or more. Then two pieces of reinforcement are driven in near the plate (after drilling holes), and the plate is welded to them.

Weld to two pieces of reinforcement driven into the wall

When installing using this method, you need to control the position of the box even more carefully: it is easy to move it from its place. If not corrected, the doors will not work well.

Read how to adjust an entrance door made of metal and plastic here.

Finishing work

If after installation of the main structural elements no problems are identified, proceed to finishing work:

- Polyurethane foam . All remaining space between the box and the enclosing structure is filled. Polyurethane foam acts as filler and insulation, preventing the penetration of cold air and extraneous sounds from the street into the room. To ensure that the material fills all the voids, the opening is cleared of dirt and moistened with water. The remaining foam is cut off after it hardens.

The entire contour of the doorway is filled with polyurethane foam Source krovati-i-divany.ru

- Finishing . The gap between the box and the wall is carefully leveled. Putty is used, which is applied in several layers.

- Installation of platbands . Such decorative overlays significantly improve the appearance of the opening. The trims are attached to the outside of the door structure.

- Slope finishing . Plastic strips and drywall are used. The slopes can also be puttied and painted.

Opening before and after finishing Source rabotai-sam.ru

- Handle and lock . After installation, functionality is checked. If necessary, the opening mechanism is lubricated with special oil.

Final stage

At the final stage, the finishing work of the technological process of installing the door is carried out, as well as the finishing of the slopes and the economy class door leaf.

After installing the frame, you need to foam the gap between the wall and the door block. Foam performs several functions at once:

- is an additional fastening of the door frame;

- serves as insulation;

- protects the apartment from corridor noise.

Before filling the gap, the box on the apartment side is sealed with masking tape to prevent foam from getting in, and the wall is moistened with water to remove dust. The foaming process is carried out in two stages. First, a thin layer of foam is applied from the inside to the outer casing through a technological gap.

The technological gap is foaming.

This operating procedure will not allow the foam, when expanding, to escape between the wall and the metal trim in the corridor. After 15 minutes, when the expansion process is complete, you can fill the remaining part of the gap with foam. After it dries, the excess is cut off with a knife. Remove the masking tape from the box.

Instead of foam, you can close the gap between the block and the wall with cement mortar or putty. But this is more expensive financially and more difficult to implement. The installation process is completed by removing the protective film from the door leaf and installing decorative plugs on the holes with anchors.

Features of installation in a wooden house

When installing a door in a building with wooden enclosing structures, it is unacceptable to attach the frame directly to the wall. Be sure to use a frame in the form of a beam. It is attached movably, which leaves the possibility of moving the log house as a result of drying out. In this case, the tongue-and-groove connection type is used. The pigtail is held in a given position due to elastic force.

Rigid fastening of a door in a wooden house is unacceptable. At first, the openings in such a building are not filled at all due to too much deformation. To install the door, a groove is cut out in the selected location. Perform a T-shape. The width of the groove is slightly less than the thickness of the tenon. This ensures reliable fixation without the use of additional fasteners. During installation, the casing is inserted into the tenon and driven in with a sledgehammer until it stops.

Casing in the opening Source dvervdome.ru

Where can I buy entrance doors to my apartment?

Entrance doors are bought in a construction hypermarket, at the market, and in a specialized salon. Convenient to buy through the online store. The online store presents the entire assortment and sorts it according to the desired parameters. The optimal solution would be the official online store of the manufacturer, where they offer competitive prices and quality products. All you have to do is choose a manufacturer who makes door blocks conscientiously. Select a factory for the production of steel entrance doors, study the prices and products presented. The quality must comply with GOST standards. The company provides a guarantee, exchanges and returns are made in accordance with the law. When placing an order in the official factory store, use the services of professional door installation.

Features of work in a building made of aerated concrete

Aerated concrete blocks are not as strong as brick. Therefore, when installing a door structure in such a building, it is necessary to additionally strengthen the opening with a corner.

Strengthening the doorway with corners Source roomester.ru

The fastening of two corners installed at the edges of the opening occurs with vertical jumpers. They should be located in the places where the door frame fasteners will be placed.

Door mounting options

Fixing the door to the frame can be achieved based on three methods:

- Recessed method. The essence of the process is to screw the door directly into the wall with anchor bolts, for which holes are pre-drilled taking into account the technological gaps. Finally, the ears of the bolts must be masked with plastic plugs of the appropriate color.

- On mounting plates. Fastening is carried out on 3 or 4 plates protruding from the door block, in which there are holes for mortgages. If the door frame is placed correctly, there should be a gap of 10–20 mm on all sides. Then steel guides are threaded into the provided holes, the second ends of which are either welded or riveted. As an alternative to replacing guides, anchor bolts or reinforcement are used.

- Combined. This method involves parallel operation of the two methods described above at the same time.

Increasing door sound insulation

Failure to comply with installation technology leads to the fact that the sound insulation of the front door is very low. This problem occurs if gaps occur while filling the gap with polyurethane foam. Noise insulation is reduced if the seal is placed incorrectly (different degrees of tension). Also, the ability of a door to transmit sounds is influenced by the material from which they are made - the type and thickness of the filler, the type of cladding.

To solve the problem, you can choose several options:

- Replace the seal or install it along two contours, which will improve the fit of the door to the frame.

- Install special threshold slats.

- Take care of slope insulation. This will prevent sound waves from penetrating through microcracks in the wall or gaps in the foam.

Door slope insulation Source stroy-podskazka.ru

Finishing

When the door is installed, the slopes and the adjacent part of the wall remain uncovered (platbands are needed). In addition, for economy class doors, the inside of the door leaf requires further finishing: powder painting or paneling made of veneer or plastic.

Slopes can be installed from gypsum plasterboard (the process is described in detail in the work: “How to make slopes on plasterboard windows?”), plastic, or sealed with putty. But the most popular option is to finish it with additional trim. The manufacturer can supply the accessory complete with the door.

Attention: for more information about installing the additional strip, see the following material.

Soundproofing process

The door is soundproofed after it is removed from the frame. It is necessary to remove the external fittings and lay the canvas on a vertical surface. The subsequent technology for performing the work depends on the design of the door - collapsible or not. In the first case, all decorative elements of the product attached with nails, rivets, and screws are carefully removed. The metal panel from the room side is removed. The internal space of the canvas is first filled with vibration-damping materials based on bitumen (Guerlen), after which sound insulators are laid.

Laying insulation Source aviarydecor.com

To soundproof a non-removable structure, a frame is installed on the surface of the door for subsequent fixation of soundproofing materials. Subsequently, the product is covered with decorative panels. Soundproofing of interior doors is carried out using a similar algorithm.

To perform these works, the following types of fillers are used:

- Minvata . The material is affordable and durable. The filler is fireproof, but when wet it loses its insulating properties.

- Foam sheets . Easy to install, do not absorb moisture, and insulate well. Polyfoam is inexpensive and has a long service life. Disadvantage: flammability.

- Polyurethane . It is not afraid of moisture and is lightweight. Effectively absorbs noise and safe. The disadvantages include the relatively high cost of the material.

- Foampropylene . It is lightweight and works effectively as a sound insulator. The material is resistant to various chemicals, but is classified as flammable.

The variety of insulating materials on the market is encouraging Source krovlyaikrysha.ru

Conclusion

We will not say that installing iron doors is a cakewalk, but if you follow all the above recommendations, then a person who knows how to hold a drill and a hammer in his hands can cope with such a job.

Doors installed by yourself will be your pride.

If you need to purchase spotlights, then on the page https://ledin.kz/ru/catalog/prozektora today every modern consumer has the opportunity to get acquainted with one of the most practical, reliable and attractive solutions.

Briefly about the main thing

Door installation begins after the opening is cleared. The installation of the box is carried out strictly according to the level. The structure is fixed in the design position through special holes, behind linings or grips. After installing the canvas, the resulting gap is filled with special foam, finishing and fittings are installed.

In a wooden building, doors are installed after preliminary installation of the frame. In an opening made of aerated concrete, it is necessary to carry out additional reinforcement of the structure. When installing doors, it is also important how well they cope with sound insulation. If necessary, the canvas can be additionally insulated using polystyrene foam, polyurethane and other materials.

We meet the door fully armed

Installing an entrance door with your own hands may require the following tools and auxiliary materials:

- perforator;

- drill;

- sledgehammer;

- hammer;

- chisel;

- construction level;

- welding machine;

- Grinder;

- protective glasses;

- cement mixture or foam;

- asbestos fabric;

- screwdriver;

- mount;

- concrete drill with a diameter of 12 mm;

- set of socket wrenches;

- sprayer with water;

- wooden blocks (wedges, gap plates).

When everything is prepared, you can inspect the ordered door block and get to work.

How to care for a wooden door?

Caring for wooden doors is easy. To maintain cleanliness, they must be periodically wiped with a viscose napkin or suede cloth. But wet materials may not be suitable, since wood is a capricious material that does not tolerate excess water well.

In order for the canvas to maintain its impeccable appearance for a long time, it is necessary to avoid impacts and other mechanical influences. If the house is undergoing renovations, it would be a good idea to cover the door leaf with oilcloth so as not to stain it with whitewash, paint and other building materials.

Articles on the topic

How to install a door in a brick house - options, installation, instructions, advice from masons

Staircase in a brick house - types, features of the foundation, instructions, advice from masons

Brick foundation for a wooden house - types, instructions, advice from masons

Electrical wiring diagram in a brick house - how to do the wiring, instructions, advice from masons

Ventilation in a brick house - diagram, purpose, instructions, advice from masons

How to decorate an arch with decorative bricks - stages of work, instructions, advice from masons

Brick ceiling - how to make, options, strengthening, instructions, advice from masons

The size of a standard window in a brick house - Brezhnev, Khrushchev, Stalin, instructions, advice from masons

Reviews ()

How to install fittings correctly?

Let's talk separately about installing door handles with your own hands. Installation of fittings requires attention, certain skills and knowledge. First of all, let's figure out what kind of door handles there are. According to their shape and principle of operation, they can be stationary (staples), halyard with pressing, and halyard with rotation (knobs). The first ones are attached to the canvas using screws and screws. Their shape can be round, U- or L-shaped, or in the form of a ball. Push-in hardware has a halyard latch that literally cuts into the door. Handles with a rotating mechanism are spherical. There is a keyhole in their center, but they can only be opened from one side with a key. Handles of this type are often installed in bathrooms and toilets.

The material of the handles varies. Metal fittings are made from steel, aluminum, brass. To increase wear resistance, their surface is treated with nickel and chromium. Quite often, brass products are on sale, due to the quality of this material and its appearance.

Wooden handles are also on sale. Wood of different species is suitable for their production. However, it is better to choose hard grades, as this will reduce wear on the product. A more affordable analogue is plastic fittings. However, due to its low wear resistance, it is installed on doors with low intensity of use, for example, on balconies. But one of the most expensive options is natural stone. With such fittings, doors and rooms in general take on a luxurious look.

What should you consider when choosing hardware for a wooden door? It must be remembered that the handles can be left- or right-handed. Knowing the thickness of the door leaf will also help in your choice. Before purchasing, you must make sure that all components of the fittings are in good condition. They must be reliable, since the fragile handle will not be able to withstand active use and, most likely, will fail. If you take these parameters into account, choosing suitable fittings and its subsequent installation will not cause problems.

Installing a door handle with your own hands consists of several steps. It starts with markings. And here it must be said that it is not at all necessary to adhere to the recommended 90-100 cm. The main thing is that the fittings are convenient for all family members to use. The distance from the edge must be at least 60 mm. All marks, for greater reliability, should be pierced with an awl. Next, they need to be drilled, but not through, but only on one side. On the other side, the same manipulations are performed. It is important to ensure that the holes on both sides match. You also need to drill a hole at the end, but here you will need a feather drill.

The next step is to punch out a niche using a chisel. The result should be a deep recess for the latch. If everything is done correctly, the latch sinks and ends up in the same plane with the end. This element is attached with screws. Following this, the two parts of the product are inserted and tightened with bolts. At the finish, a metal plate must be installed on the end of the box. To do this, cut holes for the plate and tongue, make sure that the frame is adjacent to the end and secure it with screws.

Types of door frames

Let's talk separately about the door frame. As a rule, it is presented for sale with accompanying elements that help to refine the opening. These include extensions, platbands, seals, and fittings. Door frames have different sizes, but the standard is the same. Let us add that the elements of door frames can be joined in different ways:

- Tenon and groove lock (tenon).

- Hardware (baguettes). The edges of the timber are pre-cut at 45°.

- Right angle. For such joining, grooves are formed at the end of the beam.

Depending on the type of onion, the box can be end, covering or corner. The latter consists of box timber and is often chosen in the manufacture of metal fire doors. The end panel is mounted in the opening itself, which is how it got its name. The telescopic one has a special groove for the platband and covers the entire opening.