Spraying metals and their oxides onto glass can either improve the quality of glass or give it additional useful properties. For example, there is energy-saving spraying on glass. Or tinted.

How complicated is this process - spraying? Is it possible to do it yourself, in a home laboratory? What beneficial properties are imparted to glass by spraying?

We will answer these and other questions in the article further on our portal.

Technological features of glass spraying

The principle of this effect is based on the fact that a darkened room is quite difficult to see against the backdrop of brighter reflections.

Today there are no translucent mirrors that would be able to transmit light in one direction and not in the other. In order to make such glass, people began to use special methods that allow products with a one-sided effect.

Thus, simple mirrors can be glass with an extremely dense and thick reflective coating applied to the back surface. Mirrors that have one-way transparency are made in a similar way, but a thinner coating layer is used that also transmits light.

As an alternative, today some use a mirror film, which will be applied to the surface of the product. This mirror type film can be easily applied to a finished product.

There are two main spraying methods:

- Pyrolytic method (it is carried out during manufacturing).

- Vacuum type of spraying (applied to finished types of products using a special type of installation).

Today there are several types of vacuum-type sputtering, and the most popular are high-speed magnetron and ion-plasma.

Glass manufacturers

The world's largest silicate glass manufacturers offer almost a complete range of original types of flat glass processed by the glass industry.

Glaverbel - AGC

Glaverbel

(AGC Flat Glass Europe), Brussels, Belgium, is a European subsidiary of the world's largest flat glass manufacturer, Asahi Glass Company (AGS). The largest production of coated glass.

Main brands:

- Transparent and tinted Planibel

: polished transparent, colorless (Planibel Clear) or colored in the paste: bronze, gray, green, blue (Planibel PrivaBlue and Planibel Dark Blue), light blue (Planibel Azur and Planibel Planibel Linea Azzurra), coated float glass. Tinting in bulk with metal oxides when the glass is in a molten state. Low color reflection, solar protection. - Sun-reflective StopSol

- sun-protective reflective (reflective) glass, based on transparent or body-dyed Planibel glass by pyrolytic application of a thin transparent layer of metal oxides to the surface when leaving the furnace, Classic (strong reflective properties, amber tint: transparent, bronze, gray or green) , Supersilver (highly reflective, bluish tint, better light transmission than Classic), Silverlight (less reflective, silver-blue or blue-green), Silverlight PrivaBlue (dark blue, silver-blue and deep blue). - Low-emissivity Planibel Top N+

- polished Planibel glass with a rigid Top N coating applied on one side by vacuum deposition. - Frosted

:

Matelux

(acid etched),

Artlite

(silk-screen printed),

Lacomat

(matte varnish coated),

Imagin

(patterned frosted glass),

Stratobel

(laminated safety glass with matte adhesive polyvinyl buteral PVB film). - Mirror Mirox 3G

(without copper and pharmaceuticaldehyde),

Sanilam

(triplex with mirror glass 3+3mm). - Anti-reflective (low haze: Glamatt

,

Matobel

,

Satinluxe

), painted with opaque enamel (

Colorbel

), painted with varnish (opaque

Lacobel

or matte

Lacomat

), antibacterial (with silver ions near the glass surface:

Planibel AB

- transparent glass,

Lacobel AB

- painted glass,

Mirox AB

– mirror).

Pilkington

Pilkington

, UK is part of the Nippon Sheet Glass group.

Main brands:

- Tinted Optifloat Tinted

(bronze, gray, green),

Arctic Blue

(rich blue). - Low-emission Suncool Brilliant

(soft coated with maximum energy control),

Suncool HR Titan

(soft coated with high light transmission),

K-Glass

(hard spray),

Optitherm

(hard spray with high degrees of insulation). - Self-cleaning Pilkington Activ

. - Enlightened OptiWhite

. - Matted Optifloat Opal

. - Anti-glare OptiView.

Guardian

Guardian Industries

(formerly Guardian Glass Company), USA is an American glass manufacturing company, primarily for automotive glass.

Main brands:

- Coated Design Glass

(cleanliness level is average between standard glass and OptiWhite). - Low-emissivity Sun-Guard

(soft coating with high mechanical and chemical resistance),

ClimaGuard N

(soft coating with high light transmittance),

SunGuard High Performance

(with magnetron hard coating based on silver).

Saint-Gobain

Saint-Gobain

, France, one of the largest manufacturers and distributors of glass, construction and high-tech materials.

Main brands:

- Tinting sggParsol

(transparent or dyed heat-absorbing float glass in bronze, grey, green and pink tones),

sggDiamant

and

sggPlanilux

(chemically cleared colorless float glass). - Low-emissivity

hard coated

sggAntelio

Clear, Silver, Emerald, Havana,

sggCoolLite

, sggCoolLite K and sggCoolLite SK (various shades and degrees of reflectance: neutral, silver, bluish), sggPlanitherm Futur Neutra (color close to regular glass, soft coating).

Previous: Contents

Details. Types of glass spraying

Magnetron sputtering

This type of processing will involve applying different types of metals and their compounds to glass surfaces using the magnetron sputtering method. Products are processed in a closed space. This type of processing is carried out at the molecular level, due to which the products obtain high performance and quality characteristics. To obtain the desired effect, various Gases are often used - nitrogen, oxygen or even argon. During the reaction process, layers of metals are formed on the surface of products. This will provide the ability to produce glass with different specified characteristics.

Glass tinted using magnetron sputtering technology has a number of advantages:

- Excellent reflective characteristics.

- Excellent thermal reflection characteristics.

- Thanks to the ability to simulate the thickness of the metal layer that has been deposited, manufacturers are able to make glass with the required characteristics of light reflection and light transmission.

- This type of coating can even be used to process patterned glass.

- Relatively small and also affordable cost.

Let's consider the second processing technology.

Ion plasma sputtering

In order to apply ion plasma sputtering to glass, it is necessary to place the product under vacuum conditions. In a closed space there is an inert gas, cathodes that have a negative charge and a metal coating, an anode that is positively charged, and also a bearing with triple liners

. During processing, the spray layer is applied specifically to the bearing. The plasma method makes it possible to apply alloys of various metals, as well as their compounds, such as silver, titanium, aluminum, chromium, nickel, etc., to the surface of products. The quality of the applied coatings will always directly depend on the surface quality.

In such a matter, one should also take into account such points as the texture or roughness of the workpiece, the quality of preparation of the surface itself, and also the production culture. It can be noted that the limiting factor that will influence the spread of such methods can be called very stringent requirements for surface preparation, as well as the price of the equipment used.

Sapphire coating

Glass coated with sapphire deserves special attention. In the watch industry, this technology is often used to create dials. The material used for production is mineral glass, which, in turn, is artificially grown from silicon oxide crystals. For lovers of especially durable glass, Swiss craftsmen even made glass from artificial sapphire.

Such products will be characterized by high strength and no less high cost. A solution between price and strength was found after the invention of mineral glass, which was coated with sapphires. This type of spraying has the strength of sapphire and the price of simple mineral. The only drawback is the fast wear time.

Why us?

In our company you can order high quality glass and mirror panels. This will allow you to organize a private space and obtain a durable, wear-resistant structure. We produce canvases with different coatings depending on the tasks set by the customer.

Features of cooperation with our company:

- We will fulfill orders of any complexity;

- New precision equipment is used;

- Production allows for the production of small and large batches;

- You can choose a design for any interior;

- Our employees will perform a full range of work - from design to installation.

The price of our glass and mirror structures is quite low, because we manufacture the structures ourselves. The cost is calculated for each project separately, taking into account customer requirements, operating conditions, etc.

Characteristics

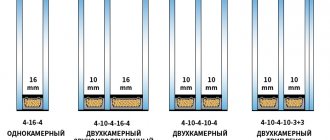

An energy-saving design can have one or several air chambers; there are also those that are filled not with air, but with argon - which better protects against the penetration of cold.

But the packages themselves are characterized by the composition of the spray:

- I - with completely transparent glass, which is obtained by applying a silver composition of tiny particles of just a few microns;

- K - with a darkened, thin film coating of hundredths of a micron. The film consists of an oxidized metal coating; their cost is much higher, but their ability to reflect heat flow is less.

Solar radiation

The spectrum of solar energy consists of electromagnetic waves with different lengths:

- Gamma rays, X-rays and short ultraviolet (UV-C) radiation up to 280 nm are blocked by the earth's atmosphere.

- 280-380 nm - ultraviolet (UV-B, UV-A) radiation reaching the earth's surface. Provides about 5% of all incoming energy. In everyday life, it affects the photosynthesis of plants and negatively affects various materials in the room. The purpose of protective glazing is to reduce the amount of UV-B and UV-A entering the room.

- 380-780 nm - visible light. About 50% of all energy. Determines the illumination of the room. The purpose of solar control glazing is to reduce brightness.

- 780-2480 nm - short (IR-A) and medium (IR-B) waves of infrared radiation. About 45% of all energy. Provide heating of objects directly from the sun. The purpose of solar control glazing is to reduce heating of the room from direct sunlight. The spectral range of radiation from 280 to 2480 nm falling per unit surface directly from the sun is called directed solar energy.

- 2480 nm and more - long-wave (IR-C) infrared radiation. Undirected (scattered) solar energy obtained from radiation absorbed by the atmosphere. The purpose of solar control glazing is to reduce heating of the room from the air, surrounding objects, etc.

Marking of double-glazed windows

At first glance, it may seem that the labeling of double-glazed windows is understandable only to their manufacturers. In fact, almost everyone can decipher the marking formula.

Sheet glass

- M0 (M1; M2, etc.) – transparent, colorless, obtained using a hood;

- 4 or 6,8,10 and so on. – glass thickness;

- 4float or 4F - float glass is used, 4 mm in thickness;

Float glass is a flat, colorless glass produced by continuously casting a silicate mixture onto a layer of tin that is in a liquid state (with cooling).

- 6Fjumbo - 6 mm float glass. thick; Jumbo - maximum dimensions of float glass (6000x3210 mm.)

This is interesting: Types and installation of geared motors: Instructions

Standardization according to GOST 32565-2013

However, the decision on the method of applying glass tint is made by the car owner. If the dimming indicators comply with GOST, self-tinting is not prohibited by law. It should also be taken into account that most service centers do not use vacuum chambers when tinting car windows.

The percentage of light transmission is determined according to GOST 32565-2013

- at least 70% for windshields and front side windows;

- If there are side mirrors on the right and left, the remaining glass is not standardized.

Violation of tinting standards will inevitably lead to penalties.

Service price

The cost of the service affects the specific performance of the work and its technological complexity. As mentioned earlier, self-tinting will lead to the coating becoming unusable very quickly.

A professional one will cost an order of magnitude more than applying a regular film, which will last much longer.

Table 1. Prices for spray tinting.

As can be seen from the information presented, spraying prices depend on the model and design features of the car. However, many salons provide discounts when ordering comprehensive tinting of the entire car.