When installing sealed double-glazed windows made of metal-plastic, the microclimate in the room may be disrupted. This leads to an increase in moisture concentration, lack of oxygen, and the appearance of stale air. To improve the situation, a supply valve for plastic windows was invented. This device helps to normalize ventilation, as well as stabilize air exchange, providing normal living conditions in the apartment.

Is it necessary to install a supply valve?

Many apartment residents do not think about the fact that constant air circulation is necessary in the apartment. The correct microclimate in the room is formed due to the normal organization of ventilation, and this is not always possible. Then a supply valve on metal-plastic windows comes to the rescue, which normalizes the freshness of the air in the apartment.

Normally, clean, fresh air should enter the apartment, and stuffy air should leave it. Its output can be provided by an exhaust hood or a natural ventilation system in multi-apartment buildings. The valve will become an additional device that helps remove stale air outside, and instead fill the room with freshness. In windows with wooden frames, ventilation occurred spontaneously through cracks in the structure. This will not happen on PVC windows, so a ventilator is necessary.

Disadvantages of the system

The disadvantages of such ventilation include the following:

- Some types of structures require milling a window profile to create an opening for air channels. After dismantling the valve, it is quite difficult to seal such slots.

- Not all types of systems are suitable for rooms; for example, a built-in valve in the leaf handle will not be able to provide an air exchange function for large rooms.

- When closing the ventilation valve at low temperatures (below -15 degrees), the gap may freeze, blocking the air supply.

- There is no filtration system, and fine dust will enter the room with fresh air.

- In the summer, forced ventilation systems (exhaust) are needed for operation, otherwise the installed structure will not work.

However, such disadvantages are less significant than simple ventilation with unlocking the doors. But ideal systems do not exist.

Operating principle of the inlet valve

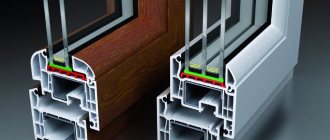

Externally, it looks like a small horizontal strip mounted in the upper part of the sash. To understand how the device functions, you need to know the mechanism of its operation. The product consists of:

- outer part;

- telescopic channel;

- internal part.

The part that takes in air is located on the outside of the window frame. A protective visor is always placed above it to cover the valve from bad weather. The ventilation duct runs through the frame and is built into the window frame. The control part is located indoors and is equipped with a nozzle with a mechanism for adjusting the flow rate.

IMPORTANT. You can check the operation of the ventilation yourself. To do this, close the door to the room, opening the window sashes in the room. A paper sheet is applied to the ventilation grille: if it holds, then everything is normal with the ventilation system.

The essence of the valve's operation is to suck air masses into the room, as well as release warm air from the apartment through exhaust ventilation ducts. The circulation itself occurs due to the difference in pressure between the two media. The valve will work independently if the temperature outside the window is no higher than +5 degrees, so in summer its operation is possible under the condition of forced exhaust.

Tags

AUBIDouble-sided handle on the balcony doorhacking of plastic windowssoldered sealant sealant for plastic windowschild lock blowing from the windowjammed balcony doorjammed window handlereplacement of window fittingschild protectionwinter modehow to choose plastic windowswhen to install windowscondensation on windowscoextruded sealantmosquito netssetting up plastic windowsbalcony door does not closewindow slippage windows storiesplastic windows plastic windows are whistling, plastic windows are crying, the window does not close well, the plastic balcony door is sagging, blowing out plastic windows, adjustment plastic windowsadjusting fittingsknobs with a keybalcony door creakslubricating plastic windowswindows leakingsealing rubberinstallation of pvc windowswindow insulationcaring for the sealsound insulation of pvc windows

Which valve to choose

The ventilation valve market offers a large selection of different devices. In stores you can find folded models, slotted, overhead, as well as automatic and manual. Each model has a number of features and is suitable for a specific case.

Types of ventilators by design type

Ventilation valves installed on window frames can be divided into several types, according to their design:

- Seam - ventilation is carried out using a small cut in the frame.

- Slotted - air saturates the room through a hole with a width of 17 to 40 cm and a height of 12-16 mm.

- Overlays are similar to slotted models, but they are installed before installing the double-glazed window.

Modern valves look like a gap with curtains in a window. The quality of the device varies depending on the manufacturer and the correct installation. Operational efficiency will be determined by the technical characteristics of each model.

Seam models

Seam type valves are a common type of supply ventilation. The main advantage is that there is no loss of sound insulation during their use. The installer does not need to make a hole in the window, so apartment residents will enjoy silence. It is believed that the rebated type is not easy to install, as it requires partial dismantling of the window. Experienced installers avoid this procedure and do not remove the window to install the ventilation device.

Many apartment owners refuse to install a rebate valve. They believe that the device provides insufficient air exchange. Metal-plastic windows do not fog up, as happens in the absence of ventilation, but air circulation is considered imperfect. The choice is always up to the apartment dweller: seam models are more affordable, retain heat, provide sound insulation and have the ability to be automated.

Slot climate devices

As already noted, in such devices there is a gap, which is an opening for air circulation. Such a valve is equipped with an inlet and control block separately, and in modern models these two blocks are combined into one. The inlet block is always covered with protective structures that prevent precipitation and small insects from seeping into the room. The device is installed in a horizontal impost or on the top bar located in the sash.

Advantages of slot type valves:

- Ease of use;

- ease of installation;

- high throughput;

- ensuring natural air exchange without forced ventilation;

- protection from exposure to bad weather, insects.

Slotted models are not without their drawbacks. Device owners note the difficulty in installing models consisting of two blocks. In this case, you will need to groove the window block. The problem can be solved by purchasing cheaper models that provide fresh air through the space between the frame and the sash.

Overhead valve models

The use of overhead ventilation window valves is more suitable for industrial premises. A peculiarity of the installation is the dismantling of the window frame, due to which noise and heat insulation is lost. It is not recommended to use such an inlet for residential premises - there is a risk of illness due to the constant circulation of cold air masses.

The main advantage of an overhead inlet is to ensure maximum air circulation, but there are several nuances in installing the device. The size of the frame and window opening must be adjusted to the dimensions of the valve itself. Because of this, installing the valve on an existing window is not advisable. Installation of the overhead model must be carried out before installers build metal-plastic products into the window opening.

Methods for controlling a window inlet

Ventilation valves can be controlled in several ways - manually and automatically. Manually operated air valves are inexpensive, but many owners of such devices claim that adjustment is difficult. It is difficult to adjust the necessary microclimate in a room when several people are constantly there at once. Operation of a manual air inlet consists of opening and closing a damper or curtain.

Automatic valves are more sophisticated in design and operation. They have the following features:

- They stabilize the air flow due to the pressure between the room and the street. The user independently regulates the permissible air flow, and the device will operate within the specified range.

- The air flow is regulated thanks to a polyamide sensor. The cross section of the valve will increase with excessive humidity, and with normal indicators it will decrease.

It is impossible to completely block ventilation in some modern automatic devices - this is a significant disadvantage. Also, the user will have to spend a sufficient amount to purchase the device.

Varieties for windows

There is a wide range of supply window valves on the market, which differ according to different criteria. Below is a detailed classification of this ventilation equipment.

According to the method of air entry into the room

Depending on the configuration and operating principle, there are several types of supply valves for windows.

Seam system

The simplest and most affordable design. Can be installed at any stage of window operation. Supply air enters through an extended slot in the profile seal.

Installation principle: at the lintel level of the window block there is a gap with overlays on both sides of the profile.

Features: to increase the air exchange rate, it is recommended to calculate this indicator in advance based on the volume of the room, and then select the required number of valves.

Advantages:

- low price;

- minimal labor costs during installation;

- possibility of installing an automatic module.

Flaws:

- low productivity;

- the power of the valve mechanism does not exceed 5 m3/h.

Mortise

An effective ventilation device, the adjustable flaps of which are located inside a wide profile.

Installation principle: the glass unit and profile must be dismantled, installation is carried out at the factory, the window is delivered to the client with the valve already installed.

Features: the visible part is covered with a louvered grille on the interior side and a low tide on the outer edge of the profile.

Advantages:

- does not take up much space;

- effective regulation of the amount of incoming air;

- up to complete blocking of the valve, if necessary.

Flaws:

- high retail cost;

- complex installation; if it breaks or gets clogged, you need to contact a professional.

Slotted

The inflow is carried out through the gap between the rotary sash and the main profile of the window block, onto which a block with a control damper is additionally mounted.

Installation principle: sold in a single case, dimensions range from 150 x 10 to 400 x 16 mm.

Features: just like the rebated version, it is possible to install the device without dismantling the profile or glass unit.

Advantages:

- high air exchange rate – up to 15 – 25 m3/h;

- The control unit reliably protects the room from dust and precipitation.

Disadvantages : increased complexity during installation - fastening a double-sided structure entails serious interference with the profile design.

Invoice

One of the most advanced ventilation devices, the installation of which provides an increased air exchange rate.

Installation principle: by analogy with slot models. The difference lies in the design of the air flow control system inside the overhead box.

Features: designed for sales areas, production facilities, workshops and other public or industrial facilities.

- Advantages : inflow up to 90 – 120 m3/h.

- Disadvantages : operation of the product is accompanied by significant deterioration in the thermal properties and sound insulation of the window structure.

Wall

It is installed in the wall between the windows, has a circular cross-section, the external deflector is insulated with mineral wool along the entire perimeter of the product.

Installation principle: through drilling of the outer wall is required to install a plastic valve tube with a diameter of 110 mm.

Features: the possibility of installation anywhere on the external wall; before installation, it is necessary to study the working design for the location of load-bearing structures.

Advantages:

- no violation of the window structure is required;

- can be completely blocked in the cold season.

Flaws:

- complexity of installation;

- the presence of dirty processes when drilling a wall;

- weakening of building structures;

- risk of freezing due to poor quality insulation.

Before installing the valve, you need to make sure that the PVC profile does not contain a reinforcing channel, which will interfere with both cutting the slot and milling the plastic.

Material of manufacture

According to the material of manufacture, all valves to ensure air flow into the premises are made into 3 basic categories:

- Plastic models are inexpensive, can be quickly installed, but have low strength and must be replaced if they fail.

- Metal – made of black, galvanized or stainless steel. Designs from the higher price category can be made of aluminum. They have an attractive appearance and are not subject to corrosion. The main disadvantage is that thin metal is deformed under rough mechanical influence.

- Combined - plastic parts of control dampers are covered with a metal body of the valve block. They are considered the most advanced models.

If there are additional wishes from the customer, the outer surface of the overhead structure can be covered with a laminated film that matches the shade and texture of the window profile.

By window type

Depending on the design of window units and profile materials, the following types of valves are used :

For PVC windows. If there is a plastic reinforcement profile in the body, the best solution would be to install an overhead inlet valve.- For wooden windows. Such designs require minimal intervention into the structure of natural wood. The most suitable valves are wall or slot valves.

- For aluminum windows. The device requires a powerful milling cutter that does not cause metal deformation. It is permissible to use a mortise, slotted or overlay part.

- For blind structures. The type of supply valves used depends only on the air exchange rate and thermal requirements.

- For swing structures. The shape and configuration of the valve block depends on the width of the leaf. The use of an overhead product is not recommended, as it may prevent the window from being fully opened.

- For sliding structures. Considering that with such a system the profiles of window blocks intersect with each other, only rebated and mortise products are suitable for such structures.

Supply valves are universal products that can be used for almost every window contraction. In this regard, the classification below is advisory in nature.

Air flow control method

There are two types of supply valves based on the method of regulating the flow of air entering the room:

- Manual - inflow limitation is carried out by driving louvered grilles or blocking dampers, which have a lever drive on the surface of the product.

- Automatic - a complex design with internal flexible dampers independently regulates the amount of outside air, depending on its pressure and speed. The flow intensity changes due to the response of the built-in sensor to changes in humidity in the room, which indicates the need for ventilation.

In a standard apartment with ceilings up to 2.7 m high, the consumer can save money and install a manual valve in private homes, or when organizing a two-story space, it is recommended to install only automatic devices.

Manufacturers of ventilation devices

Among all the manufacturers presenting ventilation equipment in this category on the market, consumers identify the following brands.

Air box

One of the first Russian companies, founded in 2005, which began producing supply ventilation equipment for window units.

Advantages:

- in the company’s catalog you can find many models with built-in filters and external visors,

- developed network of sales points;

- own online store;

- availability of service centers in most regions of the Russian Federation.

Disadvantages : consumers note long wait times for orders during the summer season.

Aereco

French company founded in 1983. For more than 10 years, a branch of the brand has been operating in our country. The brand's products are sold throughout the country. Each product has a state certificate; the valves are installed by design and are part of the adaptive ventilation system of apartment buildings.

Advantages:

- excellent quality;

- increased productivity;

- the ability to continuously adjust the flow intensity, including in automatic mode.

Flaws:

- standard products;

- small model and size range;

- not suitable for all translucent structures;

- high retail price.

Ventec

A joint German-Russian production association from Smolensk. The company's products are in demand in the Russian Federation. All types of valves described above are available, with manual or automatic adjustment options.

Advantages:

- compact dimensions;

- ease of installation, possibility of insertion without dismantling the window unit;

- On sale are acoustic valves that are mounted on windows facing busy city streets.

Flaws:

- insufficient air exchange – for effective ventilation of a room with an area of 15 m2 or more;

- 2 or more items are required.

Norvind

The plant of this brand was founded in the Russian Federation in 2010. The product immediately took a leading position in the market. The company is distinguished by its own innovative developments and cooperates with many scientific institutes specializing in aerodynamic research.

Advantages:

- stylish design;

- high performance;

- excellent sound insulation.

Flaws:

- high retail cost;

- The humidity sensor must be periodically serviced when condensation occurs in winter.

Selection of main valve characteristics

The supply air valve is an indispensable device for city apartments where metal-plastic windows are installed. In order to choose a device according to all the rules, you need to pay attention to the list of criteria - they will help you understand the efficiency and performance of the models.

Performance range

Since the normal operation of the inlet requires a difference in pressure indoors and outdoors, the throughput will be one of the main indicators of modern devices. This indicator is taken into account based on pressure, therefore, in the description of the purchased device, it is necessary to take into account the performance range. The standard differential value, which is calculated by manufacturers, is 10 Pa.

FOR REFERENCE. If the device is designed for use in apartment buildings with a warm indoor climate, then the pressure will be equal to 2.4 Pa.

With different pressure drops the performance characteristics will change. For example, with a pressure drop of 2 Pa, the productivity of some models is 73 cubic meters of air per hour. Moreover, if the pressure drop is 10 Pa, the productivity will increase to 160 cubic meters of air per hour. For an apartment in a high-rise building, it is better to choose a device with an indicator of 30-40 cubic meters of air per hour, with differences of 10 Pa.

Providing sound insulation

The average noise insulation is 35-40 dB. The valve that needs to be installed in the window must comply with these data. After installation of the device, the noise level should not change. In this case, slotted valves are inferior to seam valves; they do not provide sound insulation. To operate them, it is necessary to organize an oblong hole through which natural air circulation will occur.

In some modern models, the design is designed in such a way that there are special soundproofing channels inside. When the device is operating, it additionally absorbs noise, preventing extraneous sounds from entering the room. Such a device would be appropriate if there are small children in the apartment.

Operating temperature

Climate valves have another important characteristic - each model is designed for operation at a certain temperature. Normal natural ventilation will occur at a temperature of +5 degrees outside the window. Then the valve can independently take in fresh air, releasing it inside. All water vapor is removed through the existing ventilation hole, but do not forget about strong temperature changes.

For example, in winter, at sub-zero temperatures, the supply valve may freeze and become covered with a layer of ice. This affects his work, making it difficult or impossible. Therefore, modern systems use the “thermal break” technique. Then a special plastic strip is placed between the inner part, made of metal, and the outer part. There is no temperature transfer, so the device operates as usual.

Adjustable

When choosing a supply valve for your home, you should pay attention to the possibility of accurately regulating the intensity of air intake and exhaust. This criterion is necessary when the user needs to independently set parameters for operation. The valve is controlled manually or automatically. If the latter option is selected, the device independently selects the optimal humidity and temperature parameters. The valve itself creates the necessary climatic parameters in the room.

The manual valve can be adjusted mechanically:

- At the top of the structure there is a special slider.

- The device is responsible for opening and closing the ventilation curtain.

- By turning the slider in different directions, you can reduce or increase the size of the holes for air flow.

Owners find it inconvenient to manually regulate the air flow, so they purchase automatic devices. They are more expensive, but they work independently, depriving apartment residents of problems with unorganized ventilation.

No. 2. Metal pipes for ventilation

This group includes pipes made of stainless steel, galvanized and black steel. General advantages include the following qualities:

- resistance to high temperatures, pressure and aggressive environments;

- a wide choice of shapes and sizes, in which metal pipes are significantly superior to plastic ones;

- rigidity and strength;

- durability.

High weight, considerable price and complexity of installation are the reasons why many prefer to abandon metal pipes in favor of plastic ones. In private homes today, almost no one uses metal air ducts anymore - there is no need for them. They are more suitable for organizing ventilation in industrial premises.

To the general disadvantages, let us add the disadvantages of different types of metal pipes. Although galvanized steel receives protection in the form of a sprayed layer of zinc, it is not particularly durable. The coating, of course, delays the onset of corrosion and slows down its development, but does not completely eliminate it. The weakest points in galvanized pipes are the joints. It is in these places that rust appears first, and as soon as it begins to develop, an unpleasant odor is formed. If we are talking about residential premises, then this is a very serious drawback.

Stainless steel behaves much better in operation. It is more resistant to corrosion and therefore more durable. This material has increased fire resistance and is suitable for transporting aggressive air masses. For production this is an ideal option, but at home it is justified to use massive metal pipes only if you got them for free and will be hidden in the wall.

All metal air ducts have one more unpleasant property. Air passing through such a pipe and forming currents can cause significant noise. To reduce the amount of air turbulence, it is necessary to minimize the number of turns of the pipe and avoid 90-degree angles. In addition, the metal walls of the channel will resist the passage of air flow.

Review of popular ventilator models

To install a truly high-quality and functional air supply unit, you need to find out which models and manufacturers currently occupy the market. The following manufacturers can be distinguished:

- A company from France that produces valves in various colors. The assortment includes products in white and gray, as well as wood-look options. To protect the valve, the buyer can separately purchase a special visor. There are several models: EHA2, EMM, EMF. The models are made of reinforced plastic, ENA2 has a throughput capacity of 35 cubic meters per hour, while the noise insulation is 37 dB. The EMM is equipped with a movable external block, and the EMF is manually switched.

- Air-Box. Ventilators made in Russia with manual adjustment. They are easy to use and maintain. The devices do not have automatic humidity control. There are no external units here, and the device itself is mounted on the window frame from the inside. The series are divided into Standard, Comfort, Comfort S.

- Products from a Belgian manufacturer. Produces slot-type inlets. The valves are equipped with filters, manual control is realized using a cord in the “open” and “closed” positions.

The installation method will vary according to the design of the device. Products made in Russia and abroad will be equally effective.

Ventilation control

The ventilation clinker can have automatic or manual opening mode. In the latter case, the user, by changing the position of the curtain, independently achieves stabilization of the flow of air masses. He also monitors the duration of ventilation (if neglected, it is quite possible for the room to freeze out).

In the automatic mode of opening the curtains, action is possible according to two schemes:

- The adjustment of the curtain position is determined by a polyamide sensor - in conditions of high humidity the flow area increases, and in conditions of low humidity it decreases;

- The air supply level is set based on the difference in pressure inside and outside the room, while the opening range of the curtain is determined by the user.

With all the advantages of smart automatic flow valves, they often simply do not have the function of completely blocking ventilation. Moreover, their prices are far from low.

Example of installation of a ventilator with perforation

The ventilator installation process will vary depending on its design features. Often the frame may need to be milled, but sometimes this is not necessary.

Carrying out preparatory work

It is recommended to install the perforated valve at the top of the window. When planning the insertion of a device, it is recommended to take into account the following nuances:

- installation will be faster and easier if the sash is initially opened;

- It is better to carry out installation in the summer - then bad weather will not interfere with the work;

- When making holes for slot ventilation, you must act carefully so as not to damage the sealing devices on the window.

IMPORTANT. The main preparatory stage will be removing the sash from its hinges and placing it in a vertical or inclined position. To remove the sash carefully, you need to enlist the help of a partner.

List of required tools

To install the air supply unit on the frame yourself, it is important to prepare a list of tools. Milling is not complete without an electric drill. It is necessary to select drills of the correct diameter, for example, 5 and 10 mm. Also useful:

- Fine-grained file.

- Electric jigsaw.

- Prepared template - you can make it yourself, from cardboard or metal.

- Silicone sealant - useful for filling gaps after installation.

The marking template can also be made from hardboard - a small piece of material is drilled in several places at the same distance. This template can then be applied to the window frame and marks where the ventilation holes will go.

Step-by-step installation and fastening

When installing an exhaust valve, it is worth following the sequence of work, then the likelihood of error will be reduced to zero. The entire algorithm for performing the work:

- Marking. Place the prepared template on the vertical protrusion and mark the insertion location for the future supply valve.

- Milling. Use a large drill to make several holes in a straight line, use a knife to make slits, or use an electric jigsaw. Do the same on the frame float.

- Installation of strip and valve. Apply sealant to the back of the plank and apply it to the sash. To strengthen the structure, additionally use self-tapping screws.

- Installation of the visor. Fix the protective visor on the outside of the window and secure it with self-tapping screws.

- The final stage. At this stage, install the window sash in place and fasten all the fittings back.

To check how the supply valve functions, it is necessary to set the ventilation mode - fresh air will be taken in from the outside and released from the inside to the street.

Example of valve installation without milling

If the supply valve does not have perforations, then its installation will take much less time and effort. To work you need a knife, a screwdriver and a ruler. The ventilator kit includes the valve itself, seals, plugs, and fasteners. It is better to place the device in the center of the sash, so it is important to find the location in advance and mark it with a simple pencil.

The seal is removed from the grooves by making holes with a knife. Instead of a seal, a supply valve is installed and secured with self-tapping screws. All changes made should not affect the design of the sash.

Overlays

Their principle of operation has some similarities with folded models. They have high throughput. Such structures can be mounted on fixed and openable plastic window structures.

How to install such a supply valve? Installation of this model must be carried out before installing double-glazed windows. These types of products are widely used for ventilation of large office spaces and country houses.

Conclusions and useful video on the topic

A supply ventilation valve installed on a plastic window helps normalize the microclimate in the room. Valves come in several types and can be controlled manually or automatically. Manual options are difficult to set up, but they are cheaper; automatic models independently select the desired diameter of the air hole.

If there is constantly condensation on the windows in the apartment, then there is a need to install a supply ventilation valve. The device is easy to install, so you can install it yourself.