Door closers are installed on almost all entrance doors. They can have different designs: from a simple spring to a modern mechanism. As a rule, closers are durable, but nevertheless, breakdowns are possible during their operation. The type of door closer repair depends on the cause of its malfunction, which may occur due to exposure to precipitation, incorrect selection of the mechanism, or due to lack of maintenance. Whatever the reason, you can fix it yourself. Here you can learn how to repair a door closer.

Closers for entrance doors: types of mechanical devices

Considering the method and place of fastening of door closers for entrance doors, they are divided into the following groups:

- overhead closers;

- bottom (floor) closers;

- hidden (frame) closers.

Overhead closers are fairly common and universal door closers. These types of door closers are mainly used for building entrance doors. They are distinguished by simple installation: the sliding rod and lever are fixed on the lintel of the door frame, and the body is fixed on the inner upper surface of the door leaf.

The design of top-mount door closers offered by different manufacturers may differ in their operating principle. A mechanism with a lever drive and a toothed gear is popular. Another current option is a door closer with a sliding rod and a cam gear.

As for hidden closers for interior doors, they are installed at the production stage of the doors themselves; lower closers are installed in the floor, making them almost invisible.

Design and principle of operation of a door closer

The door closer device includes a lever rod and the housing itself with a mechanism that allows the door to take a closed position. The mechanism consists of a fairly powerful spring, compressed due to the force of the piston drive. The spring, usually made of steel, is enclosed in a special capsule. The capsule contains oil, which, when the spring returns to its original position, moves through hydraulic channels into the working container. This technology ensures smooth and soft closing of the door. The door closer is adjusted using specially designed screws located at the end of the housing. As the screws rotate, they change the cross-section of the channels, which affects the speed of oil movement and, accordingly, the rate at which the door closes.

Lever closer design

Improved models of door closers have an additional closer valve that allows you to hold the movement of the door leaf. This happens when the door opens already at 70 degrees before closing, and just before closing (when up to 15 degrees remains), the movement accelerates, which helps to press the door tightly. Thanks to this design, the closer copes with the force of the latches on the doors and overcomes the air resistance formed when closing.

There are door closer models equipped with the additional function of blocking door movement. This system regulates the spontaneous closing of the door. It is very convenient when large items (furniture, household appliances, etc.) need to be brought into the room. The door opens 90 degrees or more and is fixed until it is pushed to close, after which the closer mechanism will ensure its smooth and silent closing. Door closers can perform a number of additional functions, including a door delay for 30 seconds, a door closing coordinator for door models with more than one leaf, and a sudden swing shock absorber (damper).

Design Features

Before you repair a door closer, it is worth getting acquainted with its design features and the principle on which it works (see Door closer: design options and requirements for them).

Inside the device there may be a mechanism of the following design:

- Spring-loaded. It lacks control over opening and closing the door;

- Geared. Provides soft movement of the door leaf when closing;

- Eccentric. A shaped cam is used, which allows you to set any torque parameters to the mechanism.

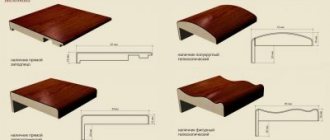

Spring

Gear

Eccentric

The rotation of the door leaf can be transmitted in several ways:

- Using hinges or levers. This device is quite durable, and if it breaks, you can repair it yourself.

- Through a sliding channel. In this case, voltage transmission occurs by sliding - the lever moves with a free ring along the sliding channel. Opening a door with such a mechanism is more difficult and requires great effort. Cam technology eliminates this disadvantage.

- Built-in mechanism in the floor.

Lever system

Slip transmission

Mechanism built into the floor

Sliding door closer

Causes of door closer breakdowns

The main causes of malfunctions in the operation of the door closer are:

- negative impact of various atmospheric phenomena. This cause of failure is especially relevant if the device is installed on an access door, gate or gate. Constant temperature changes, rain, snow, dust, and so on lead to the destruction of the external parts of the device;

- incorrect selection of a door closer for a specific door. This factor negatively affects the operation of the entire mechanism. When choosing a device, it is recommended to take into account such parameters as the weight and width of the door leaf;

Door closer selection table based on door parameters

- improper use of the device. Fixing the door leaf in the open position, exceeding the permissible door opening angle, the use of force when opening or closing most often become the causes of malfunctions in the operation of the closer;

- deformation of the door leaf;

- lack of maintenance of the mechanism. Failure to carry out the preventive maintenance specified by the manufacturer of the closer. Like any working mechanism, the door closer requires constant care.

Troubleshooting.

The most common breakdown is the failure of the folding lever; this is the main problem for door closers installed in walk-through areas. Frequently occurring shock loads, such as gusts of wind, unbalanced visitors, also contribute to failure; it is not possible to hide this element of the closer, so it often becomes a victim of vandalism. The lever may be deformed or broken; the rod's attachment to the door or the door closer itself is often broken off. Such malfunctions can be easily eliminated by welding; in extreme cases, you can purchase a lever assembly; they are commercially available. You can even use rods from other modifications, provided that the attachment point to the device is compatible.

Problems that can be corrected independently include violation of the closing and finishing speed. These violations can be eliminated by adjusting the corresponding screws, but remember, changing the position of the adjusting screws by more than two turns from the initial position is not allowed. And, as mentioned earlier, in the event of a hydraulic fluid leak, repairing the door closer is almost impossible. The tension force of the spring is regulated by the corresponding nut.

From all of the above, we can conclude - follow the rules for operating a door closer, select a model depending on the weight of the door leaf, then the device will serve reliably for a long time.

This simple device greatly simplifies life, as it eliminates not only the need to close the door behind you, but also from drafts, ensuring a tight press of the canvas. But even the most reliable mechanism has a certain lifespan, and sooner or later, the door closer will have to be repaired. As a rule, most of the possible malfunctions can be completely eliminated without the involvement of a specialist.

Types of mechanism breakdowns

The main failures of the device can be:

- Weather conditions – instantaneous changes in climatic conditions, rain, dampness, high humidity. Such causes of malfunction are most often found in boxes made of plastic.

- Uneven opening or closing of the door leaf. When the door is opened with effort or, on the contrary, closed despite the slow movement, despite the fact that the closer is not adjusted to this mode.

- Door movement is delayed for a short period of time or for a long period.

- Blocking the door with foreign objects without turning off the closer. Applies to models whose characteristics do not include the function of holding the doors open at 90 degrees or more.

Such models, when artificially holding the door for a long period, will inevitably require repair of the mechanism.

Heavy load on the mechanism, for example, if a closer is installed on a heavy door leaf that does not meet the functional characteristics.

The door closer on the kitchen unit door is broken: how to fix it

There are several typical failures of a spring door closer in a kitchen set. The main problems include deformation or damage to guide devices and rods. This may be caused by damage to the door or excessive opening of the leaf after the closer passes the dead center. A broken rod can be repaired relatively easily.

Damage to the closer rod may be associated with:

- By bending the lever in the opposite direction;

- Lever jamming;

- Breakage of fasteners.

If the lever is bent in the opposite direction, then you can fix the problem yourself. To do this, it will be enough to remove the cabinet doors from their hinges, disassemble the closer, and carefully bend it in the other direction with your hands. Disassembling and repairing the closer will not take much time. If it is not possible to return the lever to its original shape with such repairs, then it will be possible to replace the damaged element with a new one.

Typical types of repairs

All of the above reasons may lead to repair work on the door closer:

Curvature, corrosion, rupture of the rod - this part is in the field of view on a constant basis, so this problem can be noticed with the naked eye. It is worth periodically visually checking this part of the mechanism. If minimal damage is found, it should be repaired as soon as possible.

Curvatures and bends of the rod can be straightened, but you should be careful - with strong impact from the hammer there is a risk of breakage. Corrosion must be eliminated by stripping and exposed with a special anti-corrosion coating or simply painted.

The gap can be repaired by welding; it is important to remember about the seams - they also need to be cleaned and covered with an anti-corrosion coating. If the damage to the rod is maximum and eliminating it is labor-intensive and unprofitable, then it is best to replace the part with a new one.

Prevention measures

To maximize the service life of the door closer, you need to take care to maintain the serviceability of this mechanism. To this end, the condition of the main parts of the system should be checked regularly. If there is a problem of corrosion, treat the metal parts regularly and lubricate them for smooth operation.

You should also take care to adjust the settings according to the door parameters. This applies to setting the speed of movement, force and clap. It is advisable to change these indicators every six months, since the door closer is largely influenced by weather conditions and temperature conditions. This is the only way you can preserve it for the maximum period.

Oil leak

The main working element of the closer is a spring, which is housed in a special sealed housing filled with oil.

The main working element of the closer is a spring, which is housed in a special sealed housing filled with oil. If there is an insufficient level of lubricant in the housing, the spring will operate at high speed, which will lead to a sharp slamming of the door.

The current problem is leaking oil. During winter frosts, the main part of the oil mechanism, which is responsible for the smooth movement of the door, may break down. If the oil has leaked from the main mechanism, the closer will not lose its main function - closing the doors, but will work like a spring. If possible, this breakdown must be eliminated in the shortest possible time, because if you ignore it, you will eventually have to buy a new mechanism. Repair of the closer in this case is carried out using hermetic glue. Of course, before this, a leak is found and eliminated.

Rarely, there are episodes of negligent attitude of employees at the manufacturing plant - they simply forgot to add oil and the mechanism needs to be refueled. It is possible to refill with synthetic-based motor oil, and for a more economical option, shock-absorbing fluid is also suitable. Oil is charged through the hole in the adjusting screws.

If oil has leaked from the door closer housing, that is, traces of oil are found or the device is not operating correctly, you must:

- remove the door closer;

- carefully inspect the device body. If the crack through which the lubricating oil comes out is small, then to eliminate it you can use the usual

- If the crack can be eliminated, then the closer body is refilled with lubricant. To do this, unscrew the adjusting screws located on the end of the housing, and use a syringe or pipette to inject oil.

The most suitable lubricant for door closers is regular machine oil.

Linkage faults

How to troubleshoot the door closer rod yourself? First of all, you need to find out the type of breakdown. It could be:

the appearance of a crack, which leads to incorrect operation. A crack on the rod can be eliminated using sealant (if it is small) or by welding. After sealing the crack, it is recommended to thoroughly clean the treated area and coat it with any anti-corrosion compound;- lever deformation. This problem most often occurs as a result of improper operation or excessive load on the closer. If the device is made of a material that can be straightened, then using a hammer the lever mechanism is given the correct shape. If high-strength material is used to make the closer rod (for example, for street mechanisms), then the lever rod must be replaced; In specialized mechanisms, you can purchase the rod for the closer separately. When choosing a device, it is recommended that the operating parameters completely match

- lever fracture. The problem can only be resolved by replacing the device.

A door closer is one of those devices that requires careful and regular care, since constant loads and daily cycles of opening and closing doors lead to imbalance of the mechanisms of this device. Such troubles are corrected by a rather simple adjustment process. This is exactly what we will talk about in this article, in which we will talk about how to adjust the door closer with your own hands.

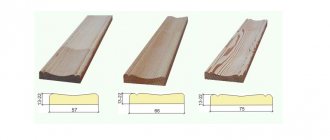

Bar deformation

It is much easier to notice changes in the lever assembly; we are talking primarily about the bar. This part is located in the most visible place, so from time to time you should pay attention to it and check the condition of the mechanism. If the slightest damage occurs, the lever must be repaired as soon as possible.

How to repair a damaged rod on a door closer:

- If the part is covered with rust, this indicates that ordinary steel was used for its manufacture. In this case, it is necessary to clean off corrosion formations and treat the mechanism parts with a special protective lubricant.

- If a break occurs, the defect can be repaired by using the welding method. The seams must be cleaned to a perfectly smooth surface.

- Curvatures and bends can also be eliminated yourself. To do this, the part is leveled using a hammer, but there is a risk that the rod will burst from the load on it.

- If the damage is too obvious and it is quite difficult to eliminate it, it is best to purchase a new spare part and replace the broken fragment.

In some cases, a complete replacement of the rod may be required

When purchasing, pay attention to such characteristics as the size of the part, the method of its fastening and the shape of the landing part; they must correspond to the closer model used.

What is regulated in the closer and what is not

Almost all modern door closers have two or three points that can be adjusted at your discretion - with their help you can not only adjust the operation of this mechanism, but do it in such a way that it is convenient for you to use the doors. That is why the question of how to adjust the door closer is solved not only during operation, but also immediately after installing this device on the door.

So what can be adjusted in this device? As a rule, this is the speed of closing the doors, the so-called closing (pressing the door leaf against the frame) and in some expensive models the door speed ranges from 80°-90° to closing. Let's talk about the purpose of such a division in a little more detail.

- Adjusting the door closer - overall closing speed. The closer can be used for doors for various purposes - with equal success it can be installed on both entrance doors and interior doors. You probably already guessed why the overall closing speed is important - for entrance doors it should be higher, since in the summer during this time flies can fly into the house, and in the winter it can get cold. For interior doors, slow closing is more suitable. In addition, one cannot ignore the personal preferences of each person individually and the so-called seasonality.

- Adjusting the intermediate stroke of doors. By adjusting this moment, two issues can be solved simultaneously: firstly, and importantly, for very frequently visited premises, it is possible to ensure the passage of several people in one opening. And, secondly, by fully tightening a special screw, you can ensure that the doors are constantly open.

- Dokhlop and its purpose. Everything is simple here, and it’s not so difficult to guess the purpose of the hit on your own. Agree, at the very least, it would be wrong if the doors hit the frame with all their might - not a single door block can withstand such treatment for long. That is why the finishing touch should be carried out more or less slowly - the manufacturer puts a certain allowable interval into the operation of the product, and you select from it those modes that meet your requirements.

Adjustment

Carrying out adjustments is a mandatory measure not only during operation of the mechanism, but also for prevention. The procedure is performed at least 2 times a year, and with seasonal temperature fluctuations this is done more often.

Adjusting the device consists of adjusting the speed of closing the door block using adjusting screws, pressing it against the frame, and smoothly decelerating when the doors are completely closed.

Repairing door closers is a simple technological process that, most often, even a novice master can do.