This is primarily due to the high degree of sealing of the latter. Despite the wide range and functionality of ventilation fittings, they will not work properly in the absence of air access channels into the room from outside.

Leading hardware manufacturers

Maco. An Austrian manufacturer, it specializes more in the manufacture of rotary or tilt-and-turn modifications. The company's assortment includes products with five levels of burglary protection.

Roto. Manufacturer of quality products from Germany. Provides a ten-year warranty on its products. The main distinctive features: tight connection of the sash to the frame; flat tongue of the locking mechanism.

Winkhaus. Long-lived in the market of accessories for metal-plastic structures (the company has existed for more than 50 years). Simple and easy to install products.

Documentation

Here we discuss terms that are described in documents such as SNiP and GOST. Specialized documentation makes it possible to get acquainted with the most detailed information about what locks and hardware are used to create window blocks, about methods for determining noise insulation and determining the overall light transmission coefficient.

It is also possible to find out information about standard sizes:

- a block measuring 470x470 mm is installed in an opening of 500x500 mm;

- a block measuring 1470x870 mm is installed in an opening of 1500x900 mm.

a block measuring 870x770 mm is installed in an opening of 900x600 mm;

Let's get to the bottom of it

What are window blocks according to GOST 23166-99? Let's get a look:

Definition

Only installed PVC window block

According to generally accepted rules, a window block is a light-transmitting structure, the purpose of which is to provide natural lighting and ventilation of rooms. That is, in fact, this is a window that is familiar to us, so why is it called a block? In order to clarify this issue somewhat, I would like to draw attention to the structure of the object in question.

Device

Window block elements

So, what does a window block consist of? Let's figure it out:

- Frame . The frame profile encircles the perimeter of the entire object, playing the role of a kind of frame;

- Sash . But the frame already contains one, two or even three, depending on the window model, sashes;

Photo of window sash

- Accessories . Includes hinges and handle-locks, which are equipped with some sashes. This improvement allows for ventilation of the room. It is noteworthy that if a sliding glass unit is installed, the fittings will look different;

Handles in different colors

If a small child lives in the house, I recommend immediately equipping the window unit with an additional lock that the child will not be able to open. This will protect it from accidentally falling out of the window, which can have dire consequences even on the first floor, not to mention the rest.

An example of a window lock that prevents unauthorized opening of the sash, but does not interfere with ventilation

- Impost . This internal vertical profile enhances the window's resistance to pressure acting on it from above;

The impost continues to support the top of the window even when the sashes are open

- Glass . Separates the space of the room from the outside world, without interfering with the penetration of sunlight and the view of the surroundings;

Transparent glass sheet

If you are installing a window unit on the south side of the house, then it makes sense to think about applying tinting film to the glass. This will make your stay in the room much more comfortable even at midday.

The bright sun will not disturb you through tinted windows

- Glazing bead . It is a bar that holds the glass in place.

Beads for wooden frames

You can also include slopes and a window sill here, but they are still desirable components, but optional, so I will limit myself to just mentioning them.

Documentation

The term in question is not “pulled out of thin air” and is described in detail both in SNiPs and GOSTs. You can find detailed information in the specialized documentation:

- On acceptable coating options - GOST 9.303-84 ESZKS;

- On technical operating conditions for sheet glass - GOST 111-90;

- About what kind of locks and hardware are used when creating window blocks - GOST 538-88;

- On methods for determining heat transfer resistance - GOST 26602.1-99;

- On methods for determining sound insulation - GOST 26602.3-99;

- On methods for determining the total light transmittance - GOST 26602.4-99.

Even standard sizes according to GOST can be found out, for example:

- A block measuring 470 by 470 mm is installed in an opening 500 by 500 mm;

- A block measuring 870 by 770 mm is installed in an opening 900 by 600 mm;

- A block measuring 1470 by 870 mm is installed in an opening 1500 by 900 mm.

Therefore, if you have any questions regarding the technical characteristics of window units, you can always find the values recommended by official bodies in the relevant literature.

Profile system

The basis of plastic windows is considered to be a profile system. In essence, the profile is a hollow PVC bar, equipped with galvanized metal reinforcement for rigidity. To provide the required thermal insulation and strength characteristics, the internal cavity of the profile is divided into the appropriate number of compartments (chambers). The more there are, the more resistant the structure is to deformation and the higher the overall energy efficiency of the window unit.

According to the wall thickness, there are three classes of profile systems - “A”, “B” and “C”:

- The highest quality ones have an outer wall thickness of at least 2.8 mm. Internal partitions – from 2.5 mm.

- Middle class with an outer wall of 2.5 mm, an inner wall of 2 mm.

- There are no strict requirements for this category. The walls are thinner than those of the classes listed above.

Depending on the place of use, the following profile types are distinguished:

- Frame. Used to make the outer frame of a window block. Its plane facing the opening has small protrusions for better adhesion to the polyurethane foam and proper fixation. On the reverse side there is a special overlay for the sash rebate, or for supporting the glass unit in blind blocks. The lower profile of the frame is made with a recess for mounting the window sill on the inside and the ebb on the outside. In addition, it may have drainage holes if the design includes sashes. The holes are located in such a way that water flows from the sash at low tide.

- Sash. A window part designed to be opened or rigidly fixed inside the frame. The profile of this element is most often made in the form of the letter “Z”. One protrusion is necessary to support the glass unit, the other for an overhead connection to the frame. The weight and dimensions of the sash beam are somewhat smaller than the frame beam, and moreover, it can use lighter reinforcing elements.

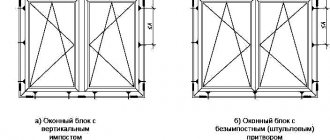

- Impost profile. A T-shaped frame element, with the help of which the decoupling (division into separate sections) of the window block is realized. The protrusions of the profile are located on the street side and serve as a stop for the sashes or double-glazed windows. A false impost is installed to close the sashes together without frame imposts, for example, if the customer needs a large window clearance.

- Bead profile. A structural element of PVC windows, through which the glass unit is tightly fixed in the frame or sash. Its shape and dimensions differ depending on the base profile and type of glazing. Reliable fastening and easy replacement are possible thanks to special grooves in the frame and corresponding protrusions (legs) on one side of the bead.

Important! Both the frame and sash profiles have special grooves for installing rubber seals, which allows them to be replaced in case of destruction or loss of elasticity.

The profiles described above are used directly for the manufacture of window blocks. In addition to them, there are a number of additional parts for fixing the frame in the opening.

As for color and texture, the white profile is most often used due to its availability and fairly respectable appearance. However, if desired, you can choose products in color.

The combination of surface lamination and coloring of the polymer in the mass gives the best result. For example, a film with a wood texture is glued to brown PVC. Thanks to this approach, the difference between the decorated surfaces of the profile and the areas where it is impossible to apply a lamella is almost invisible.

Wood lamination of plastic windows in bulk

Best Profile Manufacturers

The majority of plastic window manufacturers work with the same profile manufacturers. Most of them have been on the market for decades. However, it should be remembered that even the most famous manufacturer has budget options for profile systems that are not always suitable for use in certain conditions.

- Rehau. The budget three-chamber profile is called “Euro Design”. Equipped with two sealing circuits, light U-shaped reinforcement, two sealing circuits. Installation depth – 60 mm. The most expensive in the line is Brilliant. Six chambers, 80 mm deep, designed for large double-glazed windows.

- KBE. The initial model - Engine - is also three-chamber with two sealing contours and low thermal insulation. The frame profile reinforcement is closed (square pipe). Premium products – KBE-Select. Five chambers, thick walls, more advanced design features, produced only in Germany.

- Veka. The cheapest option in the line is L-Line. Glossy surface, three cameras, the most affordable price and acceptable quality among competitors. Premium segment products - Softline Seven chambers, closed reinforcement, large installation depth (82mm), the glass unit is recessed deep into the profile, which reduces the likelihood of condensation.

Adviсe

Experts recommend using the following tips when installing window units:

- if there is a small child in the family, it is recommended to immediately equip the window units with special metal or plastic locks, which he will not be able to unlock, since a fall from a window, even from the height of the first floor, can cause serious injuries to a small child;

- When installing window units on windows facing south, it is worth considering the possibility of using a dark tinting film.

To learn how to make a window block with your own hands, see the following video.

Last time it was mentioned that window units can be single, paired, split-paired and split. We should dwell on this in a little more detail.

Single window units. The simplest type with glass is used only for unheated buildings (country houses, warehouses) or as windows in interior spaces, for example, between partitions. Single pane windows can be found in most modern buildings, and they are also most often installed as a replacement for outdated plate glass split windows.

Image 1. Single window units (sectional drawing above, example below): a – with one glass; b – with single-chamber double-glazed windows; c – with double-glazed windows.

Paired window units. They come with glass or with glass and double-glazed windows. They have a joint opening, therefore they are called paired. A design with a double-glazed window saves heat better, but is more difficult to manufacture.

Image 2. Paired window units: d – with double glazing (example below); d – with glass and double-glazed windows (on the right is an example of such a block where blinds are installed in the space between the glasses).

Separate-paired block. It only comes with triple glazing; this is a transitional look between paired and separate. It is rarely used, as it retains heat worse than structures with double-glazed windows, and also has less noise insulation.

Image 3. Separate-paired window unit: g – drawing with a section (next to it is a fragment of a window with a separate-paired window).

Separate window units. Soviet double-glazed windows do not need any special introduction; they make up the bulk of dilapidated windows, which with regular repairs would be in much better condition. They were replaced by separate blocks with glass and double-glazed windows, which undoubtedly have an advantage over their predecessors. A rare occurrence, these are separate blocks with two double-glazed windows; this window design is the most labor-intensive and expensive; it should be used for additional protection from noise, low temperatures, and when installing shockproof or bulletproof windows.

Image 4 (can be enlarged). Separate window units (sectional drawings above, examples below): e – with double glazing; h – with glass and single-chamber double-glazed windows; and – with glass and double-glazed windows; k - with two double-glazed windows.

Tree

The windows of a private house, made of natural wood, look harmonious; they fit perfectly into the lifestyle outside the city, surrounded by nature. The main advantages of such windows are environmental friendliness and beauty. Frames for them are made from larch, pine, as well as more valuable species - beech, oak or mahogany.

The disadvantage of such structures is their high cost, which is determined not only by the type of wood chosen, but also by the quality and quantity of fittings, the size of the structure itself and the methods of opening it.

The standard thickness of a wooden window sash is 7-8 mm. This allows you to install double-glazed windows, as well as, at the customer’s request, energy-saving, armored or bulletproof options. In addition, such window designs can be tinted, colored, patterned; many prefer triplex.

Wooden frames also have other disadvantages, such as a relatively short service life. This is due to the fact that the material is susceptible to the negative effects of moisture, which collects in microcracks, as well as damage by insects. However, such negative consequences can be prevented if the wood is impregnated with special compounds that protect against moisture and pests.

Kinds

It should be said that today there is a colossal number of diverse variations that have different technological features.

Based on their differences, they are formed into subsections.

Number of sashes

Options for the number of valves can be different, which, in turn, can be divided into certain groups.

- Single door block. Such a window is usually small in size, since it does not have reinforcing imposts. These windows are most suitable for auxiliary non-residential premises, since they are not very convenient to use and do not let in a large amount of sunlight. These are just small single-glazed windows.

- Double block. These are undoubtedly the most common types of window units, which are found in the vast majority of residential premises. We can say that the double-leaf block is a classic option.

- Multi-leaf block. The most obvious example of such a block, without a doubt, is a plastic balcony door combined with a window in an ordinary apartment built in the Soviet period or later. In other words, during the construction process one door was simply expanded and turned into a door leading to the balcony. Window and balcony blocks do not have less than three sashes. In this case, a large window block has several sashes and more than one impost, which serves as a support for the upper frame profile, which gives the prospect of being able to withstand increased pressure on the window openings.

According to the presence of valves

There are several basic options here - single-leaf (these are elementary structures because they have no reinforcement and are used in small buildings) and double-leaf. These are the most common types. They are found in almost all rooms of residential buildings and offices. Multi-leaf doors are most often window blocks made of PVC profiles, where one of the doors acts as an entrance door, for example, from a balcony.

It is clear that when a window increases in size, the number of sashes also increases. To do this, it is necessary to strengthen the structure - the imposts are fixed. They help support the upper frame profile, which withstands different pressures on the window opening. The choice is made depending on the external data and the size of the room itself.

Device

Sash design

The sash can have a variety of designs and fastenings.

- Single. It is a regular single-leaf profile with glass. There are no excesses in this design.

- Paired. Here you can observe the inner and outer sash, connected into a whole structure that withstands mechanical stress quite well. One of the sashes is usually equipped with hinges that allow the window to be opened.

- Separate. Here you can also see both doors, but the peculiarity is that they are not connected to each other, and each has its own fittings. Thus, they can open in both directions.

- Separately-paired. This design is a combination of the above types: twin sets are installed inside, and single sets are installed on the outside. A feature of this block is its very high rigidity, as well as ease of use. The price of this design is quite high.

Number of glasses

Another classification method can be used when referring to the number of glasses in a double-glazed window frame. The number of air pockets formed between each pair of glass sheets increases thermal insulation. Accordingly, a direct proportionality is formed: the greater the number of glass sheets in a double-glazed window, the warmer the room will be, and the better the sound insulation.

It is necessary to take into account that double-glazed windows will have a higher cost.

- Single layer of glass. Such a window can only be used for rooms without heating where people do not live. The cost of such double-glazed windows is the lowest.

- Double layer of glass. Most often, the most obvious example of such a design is an old window with a wooden frame. Today these windows are also used, and this type of glass unit is called single-chamber.

- Triple layer of glass. In this case, two unique air-filled pockets are formed inside the glass unit, which guarantees a high level of sound insulation, as well as excellent thermal resistance.

- Four layers of glass. As a result of installing four glass panels parallel to each other, the effect of a three-chamber window block is achieved. This provides an excellent degree of insulation and sound insulation, although the cost of such a design is very high.

Sash opening direction

The most familiar to our eyes are windows equipped with swing mechanisms, although in reality a much wider variety of options is offered.

- Turn on yourself. This is the most popular type of opening the internal sash - its hinge joints are the simplest and most reliable to handle.

- Turn away from yourself. This mechanism is mainly used when handling external doors.

- Two-way rotation. Its use is possible with single-leaf window units, however, this type of mechanism wears out greatly during operation.

- Suspension. A rather specific and not very common mechanism of operation of the structure. A window of this type is mainly installed in the attic - where opening the window to the side is not very comfortable, since the surface of the roof is inclined.

- Folding. As a rule, it is implemented for use with vents. Samples of its fittings are made of aluminum alloy or stainless steel.

- Tilt-and-turn. This design has come into use for a long time due to its popularity and prevalence. To completely open the window, you need to turn the handle at a right angle and set it horizontally. If you need to open the window slightly, you need to turn the handle 180 degrees.

- Sliding. This option is quite popular for country houses. It replaces the loops with a roller. The main advantage of this type is the release of free space that would otherwise be occupied by the opening sash. In this design, the sash “slides” to the left or right, and not into the room. But such space savings can easily be negated, because if you slightly disturb the geometry of the double-glazed windows, it will be completely impossible to move the sash from its place.

- Lifting. This option is almost similar to the previous one with the only difference - the sash does not go to the right or left side, but rises vertically.

- Deaf. In this version it is impossible to see any hinges, rollers or handles. It will not be possible to ventilate rooms through a window equipped with such a mechanism, but nothing will be broken here, since there are completely no seams through which heat can escape. We can say that this window design will appeal to its high degree of simplicity and reliability, even despite serious limitations in operation.

Ventilation function

Ventilation of rooms using window units can also be organized in different ways, and this depends on their equipment.

- Windows. This is a fairly common part of the window that can be opened.

- Tilt and turn sashes. This is a structural solution, which is implemented on most versions of opening double-glazed windows and is the most functional of all metal-plastic windows used.

- Transoms. We can say that a transom is a window that occupies a large (usually upper) section of double-glazed windows.

- Ventilation valves. Allows for moderate intensity ventilation, even if the doors are in the closed position. This option is also good for double-glazed windows that are structurally unable to open.

Single-chamber double-glazed window formula

Post on the forum https://www.notrefenetre.ru:

Balcony glazing with single glazed windows

– I replaced ordinary wooden frames in my rural house with single-chamber double-glazed windows. It has become warmer, but the northern rooms are still cold. The company advised installing thicker 32 mm bags instead of the usual 24 mm thick bags. Is there any reason?

Since there was no response to this request on the forum, we will take on the role of an expert:

– Both types of double-glazed windows consist of two glasses 4 mm thick and the space between them. In one case - 16 mm, in the other 24 mm.

But since the relationship between the thickness of the air layer and its heat transfer capacity is not linear, increasing the gap between the glasses above 16 mm from the point of view of heat conservation has practically no beneficial effect.

An encyclopedic article on our website is devoted to “Two-chamber double-glazed windows.” Find on our website also materials about three-chamber double-glazed windows. Which double-glazed window should you choose? Find expert advice at https://oknanagoda.com/balkony-lodzhii/osteklenie/luchshe-osteklit-balkon.html

Single-chamber double-glazed window 4-24-4

The advantage of a thicker bag is its greater rigidity. Therefore, double-glazed windows with a thickness of 32 mm are usually installed where, say, wind load falls on them - on the upper floors of high-rise buildings and similar places.

Without further ado, specialists use the so-called single-chamber double-glazed window formula, which indicates the thickness of the glass and the thickness of the air gap between them. So, 4-16-4 is the formula for a conventional single-glazed window with a thickness of 24 mm.

Materials

Today, only two main materials can be considered.

- Polyvinyl chloride (PVC) or, as it is also called, metal-plastic. It is quite reliable and has an inexpensive price. Its disadvantage is that it “does not breathe,” and as a result, some owners return to windows made of wood.

- Tree. It is a natural material, it “breathes”, has low weight and an aesthetic appearance. But this material also has known disadvantages: high price and tendency to deform when used for a long period of time.

What you need to know about modern designs

Plastic windows began to conquer the mainstream market several decades ago. People understood that these designs have their own characteristics and are convenient to use. In addition, they have a long shelf life, which is of great importance for many.

But such structures do not breathe and cannot create the desired indoor microclimate. But installing them is not as difficult as it seems. To begin with, it is worth making accurate measurements, and then ordering a window unit from the manufacturer.

When the element is ready, you can begin installation work. Initially, the frame is attached, after which double-glazed windows are inserted. And then they move on to the fittings. You need to purchase a sufficient amount of polyurethane foam and reliable fastening devices. Plastic window blocks have good sound insulation and do not release heat. That is why their popularity has become so great.

When purchasing components, you should not do so from unfamiliar manufacturers who have a dubious reputation. It is clear that the modern market is overflowing with offers, and these are unlimited opportunities for the home owner and architects. Everyone has the chance to purchase ready-made designs or place an individual order. From this it is worth noting that window units, selected and installed correctly, make it possible to create an attractive appearance for the entire building, as well as protect it from natural influences and sounds.

When making a choice, pay attention to many things:

- Material for production. These are wood, aluminum window blocks and PVC.

- Glazing – glass or double-glazed windows.

- Availability of doors - one, two, etc.

- The opening process is present or absent.

- In shape - rectangular, round, arched and curved.

- Opening of elements - swing, folding, rotary, tilt-and-turn, sliding, blind.

It is clear that the most reliable design is double-glazed windows. If you live in the house permanently, you should pay attention to these options. In private houses, and even in apartments, it is better to have hinged structures with several doors. This makes it easier to bring in fresh air. If the premises are non-residential, then there is no need to spend a lot - standard glazing is quite suitable. Do not forget what the window block consists of. This:

- Frame.

- Glass.

- Accessories.

- Seals.

- Fasteners to load-bearing structures.

- Flashings, window sills and strips (to hide the installation seams of window blocks).

Sample quality certificate for PVC structures

d.). Certification includes the following stages: Below are the requirements for certification of window and balcony door units.

The general system of standards of the Russian Federation requires the registration of certain technical documents during the manufacture (production) of goods, their processing and disposal, including quality certificates for products. A quality passport is a document that is part of the design documentation that is attached to manufactured goods.

As a rule, this document is developed in relation to non-food products and contains their technical and operational properties.

To ensure the operation of the product quality control system, the Steko Plant has created a service - the Technical Control Department, which monitors and tests the supplied raw materials for the production of metal-plastic structures. The incoming control system covers not only glass and PVC profiles, but also all materials and components entering production.

Compliance with samples (standards), functional serviceability, absence of defects are integral requirements of the incoming control system.

GOST 30673-99 PVC profiles for window and door blocks

GOST 26433.1-89 System for ensuring the accuracy of geometric parameters in construction.

Having decided to install a plastic window, you carefully choose a company: having your own production and certified products guarantees that the window will be of high quality. But 70% of a durable window is its installation.

In advertisements and advertisements you can often find a phrase like “Installation of plastic windows according to GOST.” Theoretically, such installation is a guarantee of quality, reliability and durability of installation work, but.

is a company with valuable experience earned over years of confident work in the market of metal-plastic windows and doors.

The capabilities of Austrian and German equipment of the 2013 model allow us to produce high-quality windows and provide a guarantee unique for Ukraine - 12 years. Confirms the warranty - a passport for the windows, which indicates: product characteristics and warranty conditions, as well as useful tips and recommendations for caring for them.

PVC windows (plastic windows)

Do you want to know who produces and sells them? Do you need information about plastic windows Aluplast, Gealan, LB-Profile, Kbe, Montblanc, Rehau, Salamander, Veka?

Here you will find answers to your questions! This section of the portal www.winport.by presents the entire range of plastic windows, PVC windows and doors produced in Belarus, their prices, warranty periods, as well as samples of finished products.

GOST 23166-99 “Window blocks

The standard does not apply to translucent façade systems, skylights, or special-purpose products (burglar-proof, bulletproof, fireproof, etc.). Note - If a reduction in the airborne noise level of urban traffic flow is achieved in the ventilation mode, the letter “P” is added to the designation of the sound insulation class.

Window block installation

Scheme for securing window blocks in the opening: 1-wooden wedges; 2-mooring line; 3-plumb

- Sealing and insulating tapes are prepared to size on a prepared cutting table, board or any other installation site directly from the roller. To the required size (for a horizontal ceiling joint - 5 mm plus the width of the opening, for vertical joints - the size of the full height of the opening) add 1-2 cm to create an overlap in the corners. After this, the protective tape is removed 3 cm from the material on both sides.

- During the first stage of insulation of the inner layer, it is necessary to stick a vapor barrier tape on 3 sides of the slope. It is necessary to do everything in the following sequence: first on the vertical surface of the slope, then on the horizontal ceiling surface of the window. You need to carefully seal the overlapping areas of the tapes. A 60 mm wide tape for insulation from steam is pasted with a sticky wide layer; it is necessary to retreat from a quarter of the opening at a distance of 30-35 mm, while using a limiter bar.

Window block fastening scheme: 1-window sill board; 2-tow; 3-antiseptic wooden liner; 4-ruff crutch; 5-protrusion (quarter) of the wall; 6-external weir; 7-window box If there is a need to prevent the impact of moisture coming from the side of the wall opening on the foam thermal insulation, a tape up to 100 mm wide can be installed over the entire width of the slope. When gluing the tape, the protective paper strip is removed from the adhesive layer. In this case, it is necessary to preserve the protective strip, which covers the adhesive layer made for attaching the tapes to the window block.

When gluing sealing and sealing tapes, do not pull the tape over the joints. The tape must be rolled and pasted so that the entire surface of the tape is smooth, without swelling, air bubbles or folds. The size of the joint must be at least ½ the width of the tape; there should be no more than one joint on one side of the seam.

Before the window (door) blocks are installed in the opening, a sealing vapor-permeable tape PSUL is installed. It is attached both to the surface of the quarter opening and directly to the frame of the window block. First of all, the PSUL tape is glued to the vertical surface, and then to the horizontal top surface with an overlap at the intersection of the tapes. The protective paper tape on the side of the adhesive layer is removed with an advance of 5-7 cm. The cross-section of this tape should be such that the size of the tape being compressed by the block is at least 70% of the thickness.

Possible mistakes

When constructing openings, many beginners often encounter a number of difficulties. To avoid problems, and to ensure the result meets your expectations, you need to listen to the following expert advice :

- The opening is arranged exclusively in accordance with the design solution.

- Before cutting, precise markings are required using modern metrological equipment.

- The cut is made only with a diamond disc so that there are no burrs left on the brick.

- If an opening is made in a multi-layer wall, it should be remembered that the internal and external cuts may not coincide. To do this, you should make 4 through holes in the corners of the future opening to check the correctness of the markings.

- When dismantling part of a wall, only serviceable and powerful power tools are required, especially if we are talking about a monolith.

Making an opening in an external wall is a responsible and complex procedure. The best solution for performing such work would be to turn to professional builders.

The best manufacturing brands

Germany is considered the leading country in this area. Their designs are distinguished by high-quality materials and the latest assembly technologies. The appearance of such frames is preserved for a long time; over time, the plastic does not change color and looks beautiful. This also applies to colored material; it does not fade. Some leading companies have factories in Russia, so the price is not too high and is affordable for most citizens.

Rehau

The products of this company are of excellent quality, have the best characteristics, and the profiles look beautiful. It has existed for more than 50 years, regularly updating production technology, improving build quality.

There are 6 types of Rehau profiles on the Russian market. They have from 3 to 6 cameras installed, width from 60 to 80 mm. The latest models have a reduced frame height, which means more light penetrates the room, without affecting the quality of the structure. Prices are average and affordable.

KBE

One of the most widespread companies in Russia. Uses durable materials that can withstand temperatures from -50 to +50 degrees. The plastic used is environmentally friendly; KBE products are recommended for use in medical and educational institutions. The width of the frames is from 58 to 70 mm, there are expensive and economy class models, produced using German technologies.

Proplex

A young Russian company that works using innovative technologies. Successfully applies the developments of Austrian specialists. It pleases customers with high-quality assembly of structures, uses the best materials and tries to keep prices reasonable. Width from 58 to 127 mm. Constantly working on modernizing production technology.

VEKA

Another company from Germany that has proven itself over decades of impeccable work. It produces traditional and multi-colored frames that are not susceptible to changes in outdoor temperature, do not turn yellow and do not lose color over time, and are painted according to the RAL scale. The design uses a rubber seal that is not deformed or destroyed under the influence of atmospheric conditions. Frames can be installed in any Russian regions. Width from 58 to 90 mm.

Trocal

Appeared on the market in 1954. One of the first companies to engage in the production of PVC windows. It produces many models with decorative finishes, laminates frames, covers them with acrylic paint, etc. In the manufacturing process, it uses innovative Greenline technologies and materials. The products provide high-quality thermal insulation, do not allow noise from the street, dust and moisture to pass through. Width 70 mm.

Salamander

They are produced directly in Germany, hence the price is slightly higher than that of analog companies with production in the Russian Federation. The materials and build quality are no worse than Veka or Rehau. Width from 60 to 76 mm.

Knowing about the structural features of PVC profiles in detail, making a choice is much easier. Now there are several hundred manufacturers, among which there are many worthy ones.

How to insulate a single-chamber double-glazed window

Ways to insulate single-chamber double-glazed windows should be sought not in increasing their thickness, but in various kinds of technological tricks.

Trick No. 1: single-chamber double-glazed windows with energy-saving glass.

Glazing with energy-saving packages

Energy-saving glass works the same as a mirror. It only reflects infrared radiation rather than visible light.

As in the case of a mirror, the effect is achieved by sputtering silver ions or oxides of some other metals onto the surface of the glass.

This does not reduce the transparency of the glass, but the heat flow coming from the heated room is reflected back by such a sprayed layer.

What does this give? If the heat transfer resistance of a single-chamber double-glazed window with a thickness of 24 mm is 0.33 watts per sq. meter, then for a single-chamber energy-saving double-glazed window of the same thickness this coefficient reaches 0.70 watts per square meter. meter. That is, more than twice as much!

To make it clearer: if with a temperature difference between indoors and outdoors of 46 degrees (+20 degrees indoors, -26 degrees outdoors) the temperature on the surface of a conventional double-glazed window is only 5 degrees Celsius, then on the surface of an energy-saving double-glazed window it will be +16 degrees Celsius.

How to distinguish energy-saving glass from regular glass

The thermal conductivity of a single-chamber double-glazed window is lower than that of a standard (three glasses of 4 mm each with two gaps of 12 mm and 14 mm between them) double-chamber double-glazed window. Therefore, it makes sense to use energy-saving packages for installation where reducing the load on the package mounting infrastructure is essential.

So, if the weight of a single-chamber double-glazed window with a standard size of 1700 x 1400 mm is 47.6 kg, then the weight of the same two-chamber double-glazed window will already be more than 70 kg. The gain, as you can see, is significant - one and a half times.

Consumers choose plastic windows

What profiles are used to fasten single, double and triple glazed windows? Get help in the article “All brands of plastic windows - choose according to your taste!” Why and why is it necessary to replace cold glazing of balconies with glazing with heat-saving double-glazed windows? Read the analysis on our website! How to cut glass when installing glazing on a balcony yourself? Secrets of mastery - follow the link https://oknanagoda.com/balkony-lodzhii/osteklenie/kak-narezat-steklo.html

When purchasing, it is quite easy to distinguish an energy-saving double-glazed window from a regular one. To do this, you need to bring a burning match (lighter light) to the metal-coated glass. In energy-saving glass, the reflection of this light will be doubled.

Single-chamber energy-saving double-glazed windows, reviews:

Vadim: I live in a new building. The house is uninhabited and cold. For the sake of experiment, I placed a bag with energy-saving glass in the bedroom. Now I regret that I did not have time to change all the windows before the cold weather began. Now I have to do the “spraying” myself: I cover the glass with foil. There’s still nothing to look at outside the window: there’s construction debris and unfinished construction all around. And it's warmer!

Manufacturing and repair

It is better to entrust the installation of PVC windows to professionals who already have the necessary skills.

If necessary, a person who has tools can strengthen the block themselves.

- First of all, you need to find a drawing - it is available on the Internet.

- In accordance with the diagrams, corner profiles are cut out and processed on a milling machine.

- After this, the locking system is glued according to the tongue-and-groove pattern, and all the elements are connected into a whole structure, and each corner must be properly controlled.

- Then the glass is inserted and secured with glazing beads.

- The next step is to install the block. Here you need to understand that the old window will have to be dismantled. During the process, you must try to avoid damage to the wall and window openings.

- It is advisable to treat the frame with antiseptic agents and insert it into the opening, fixing it with wedges and pads.

- The sashes should be hung only after the frame has been completely fixed and there are no distortions.

Basic elements

A window made of metal-plastic is significantly more complex than its traditional wooden counterpart. But in fact, it is easy to study such a product if you understand the principle of operation and the main principles: what the window consists of, how the basic elements are placed.

The key feature of a product with a PVC profile is its modular structure. It is assembled from independent blocks with their constant number and location. But these parts themselves may vary within technology standards.

Basic elements that make up the structure of window blocks.

- Profile frame with internal metal reinforcement. The design of the window frame is the base into which “solid” glazing or opening sashes are inserted.

- Filling the openings: double-glazed windows or single glass. In some cases, opaque materials are used, an example of which is a sandwich panel. This option has low thermal conductivity and provides excellent thermal insulation.

- The fittings are a set that represents the mechanism of a plastic window. With its help, products are closed and opened. In this case, various modes can be set. Composition: handle, hinges, shut-off valves, drive parts, ventilation system components.

- Necessary details such as window sill, strips, drainage strips. In some cases, slopes and various profiles are used: basic, connecting, extensions. The set of parts depends on the design, as a result of which significant differences may be observed in different models.

- Accessories. Ventilation valves, insect screens, blinds or roller blinds. They are not included in the main set; they can be dismantled if desired.

In addition to the list of main parts, their detailed description, which is discussed below, is also important.

Profile

The basis is a PVC profile, inside of which a reinforcing belt is provided to ensure strength.

A special feature is the presence inside the cavity, hollow channels along the entire length.

Precisely calculated technical parameters determine their number, location and size. These several air-filled chambers increase the thermal insulation of the structure.

Other grooves are intended for fastening, fittings, and bead installation. The product is selected based on specific tasks. For example, this is improved thermal insulation and reduced noise levels.

Depending on the type of premises, the specific case applies.

- In apartments - with the maximum possible number of chambers to preserve heat.

- In buildings with temporary residence, this amount is minimized to save money.

- A country cottage with permanent residents requires protection from wind and cold, therefore it is optimally insulated.

If we take 2 chambers as an example, the heat will not be retained sufficiently even in the south of the Russian Federation, not to mention Siberia. But this is determined not only by their number, but also by the mounting width of the profile. Another criterion is the thickness of the outer walls.

If you save on its optimal value of 3 mm, even a multi-chamber design will not save heat.

Frame

Manufacturers mainly make profiles using metal. Namely, inside each there is galvanized steel - a reinforcing component.

This is a rectangular pipe with a U-shape. Thanks to it, the plastic window structure is stably located in the opening.

That is, it is a frame that provides rigidity. In multi-chamber systems it takes on the main load.

There are structures without reinforcement. The product is not fragile even under such circumstances, and its strength is enhanced by inter-chamber partitions.

According to one opinion, metal creates heat loss, representing a bridge of cold. But profiles without frames are made of fiber material, which provides the entire block with the proper rigidity.

According to the reduced heat transfer resistance

According to the given heat transfer resistance, products are divided into classes (see table)

| Class | Reduced heat transfer resistance, R0, (m*2 C)/W |

| A1 | More than 0.80 |

| A2 | 0,75-0,79 |

| B1 | 0,7-0,74 |

| B2 | 0,65-0,69 |

| IN 1 | 0,6-0,64 |

| AT 2 | 0,55-0,59 |

| G1 | 0,5-0,54 |

| G2 | 0,45-0,49 |

| D1 | 0,4-0,44 |

| D 2 | 0,35-0,39 |

| Note: products with heat transfer resistance below 0.35 (m*2 C)/W are not assigned a class | |

How to choose depending on the material?

It is not necessary to take many factors into account. There are two main directions here:

- Window blocks made of polyvinyl chloride profiles. Simply put, these are plastic structures that are reliable and low cost. But they often say that such structures do not breathe and many began to switch to a wooden window block.

- Tree. This is a high-quality material, breathable and environmentally friendly. But it is expensive, quickly deforms and requires additional care during operation.

Today, many people prefer plastic window blocks, as they look beautiful and at the same time the price is low. At the same time, the range of designs is varied, and everyone can choose an individual design for their building.

Description: what is it?

An opening in the wall for a window is a structural element that is installed in the outer wall for the purpose of further installation of a translucent element. There are two types of wall openings:

- Planned - laid down by the project, at the stage of creating the design diagram of the structure, as a result of which the designer sees the places that need to be strengthened during construction.

Thus, after the construction of the building, additional measures to ensure the load-bearing capacity of the structure are not required. - Punch-through windows - installed at the operational stage of the facility if the building owner requires the installation of an additional window. In such cases, a separate strength calculation is required with subsequent reinforcement of the structure with framing profiles or reinforcement.

The openings vary:

- according to form;

- dimensions;

- device location;

- elevation;

- the presence of framing elements.

What elements does it consist of?

All full-fledged openings in external walls consist of the following structural elements :

- The body of the opening, which is limited by the ends of the external walls intended for the installation of a translucent structure.

- Window sill block - a section of the wall directly below the opening, intended for fixing the heating device. The standard height of this element is from 700 to 900 mm.

- A lintel is a section of the enclosing structure located directly above the window. It works according to a beam scheme, most often, it is subject to reinforcement in the lower zone.

- Partitions are parts of the outer wall located on the sides of the window opening. Designed for rigid connection with perpendicular load-bearing structures, ensuring the rigidity of the structure.

Each of the listed elements absorbs part of the internal forces when organizing the opening, since the removal of a wall fragment contributes to the occurrence of stress concentration and a change in the deformation properties of materials.

How to make a wooden window

In addition, you will need equipment for cutting grooves, cutting chamfers and internal transitions, otherwise it will simply not be possible to make a high-quality wooden window. To build a window you will need:

- A circular saw;

- Wood milling machine and manual;

- Grooving and slotting machine;

- Hand drill, tape measure, set of carpentry clamps.

The window can be completely blind, for example, if you plan to glaze in a barn, garage or utility room. For residential premises, as a rule, a ventilation system is used using a window and an opening flap. A general view of the window structure is shown in the photo. If you have the tools, equipment and prepared material, you can make the main part of the window frame in a day, if you have a clear idea of how to make a wooden window with your own hands and drawings for making the main parts.

For your information! In order to make a window with an opening sash, you must first prepare a set of awnings and two window locks.

It is clear that before making a window out of wood, it is necessary to take the dimensions of the window opening and the box into which the window block will be inserted. In this case, a window with an opening sash will be made, measuring 130x110 cm.

Peculiarities

In accordance with accepted rules, a window block is a structure that transmits light. It is designed to provide natural light and supply the room with fresh air.

Structural elements of the block

- Frame. Frame profiles encircle the entire object and act as a kind of frame.

- Doors. The frame contains one or more sashes, depending on the window models.

- Accessories. This term refers to the hinge or handle-lock, similar to a door handle, that is included with each sash. Such improvements allow the function of room ventilation. If we are talking about installing sliding double-glazed windows, then the fittings will differ from windows that open in the usual way. Often, when there are small children in the family, it is necessary to take into account the danger that a child could easily fall out of an open window. Therefore, it is recommended to install additional window locks made of a cable with a locking device, which can prevent unauthorized opening of the sashes, but at the same time do not interfere with the use of free modes of ventilation of the room.

- Imposts. An impost is an internal vertical jumper that increases the resistance of the window frame to the pressure acting on them in the direction from top to bottom. Imposts also support window frames even when the sashes are open.

- Glass. Glass is the main insulator, separating the room from the external environment, but not preventing the penetration of sunlight into the room and external views. The thickness of the glass sheets themselves also plays an important role.

- Glazing beads. Glazing beads are the strips that hold the glass in the frame.

The slope and sill slabs could be added to this classification, although they are only optional and optional components.

How the doors open

Most often, people are accustomed to seeing swing structures, although today there are more of them:

- Turning in your direction is a simple option, and everyone has seen such designs.

- Turn in the opposite direction - for external sashes.

- Double-sided - also rotates, but is used in windows with one sash and has rapid wear.

- Suspended - used in attics, when creating a standard level is difficult due to its location.

- Folding ones - can be seen on the windows. Installation of window units of this type is made of durable materials.

- Tilt and turn - everyone knows this option, as it is installed on plastic windows. It is possible to open the structure in several positions.

- Sliding – the main feature is that there are no hinges. Instead, there is another mechanism - rollers. The advantage is its compactness, because it opens parallel to the structure and does not require much space. But in case of any violations it will not be possible to make a discovery.