Kinds

Window fittings consist of the following elements:

- window handle - it controls the operation of the fittings from a certain point;

- corner element - it serves to connect other elements of the window structure;

- a locking bar, which uses rollers to press the window against the sash;

- scissors - this element is necessary when opening the sash;

- window hinges - they are used to secure the window to the window frame for its smooth opening and closing;

- additional scissors and corner strip to enhance the work of the structure;

- a pin or roller to ensure that the sash is pressed tightly against the window frame.

Window fittings often include additional elements. This could be a child lock that will securely fix the handle and prevent the child from opening the window and looking outside. When installing a child latch, you don't have to worry about your child falling out of the window. The child lock can be built into the handle or attached to the sash and frame. Such locks allow you to open the window for ventilation, but prevent it from being opened completely by a small child.

In addition, for children's safety, it is worth installing a mosquito net with special grilles that can prevent them from falling out. Using a metal flag, you can quickly install and also quickly remove the mesh.

Fittings can be classified:

- by the method of opening it;

- towards;

- by weight.

If for old wooden windows only a regular handle for opening, a latch and hinges were enough, then for double-glazed windows the set of fittings can be much larger.

Situations often arise when the window handle becomes unadjustable. Then you should find out the cause and fix the breakdown. Sagging is possible if the window sash is sagging, that is, when it moves, it begins to cling to the window frame or other elements.

When choosing handles and hinges, you should pay attention to the following points:

- The handle must be made of metal, the top of which is covered with plastic or other material. If the plastic is painted with short-lived enamel, it means the fittings are of low quality.

- The hinges must be steel, with screws that are screwed into the frame with a metal reinforcement. If you screw screws into plastic, they will soon become loose.

The main function of hinges for plastic windows is ease of opening and closing the window. Thanks to them, the mechanical load is distributed evenly and the geometry of the windows is maintained. Hinges for windows may differ in their location, size, and manufacturing methods. They can have a standard size, be large or small.

The screw-in loop is secured using special threaded pins. The reliability of the design depends on the number of pins. The loop can hold up to six pins. If previously screw-in hinges were used for wooden structures, today they are made for PVC windows.

For wooden structures, hinges according to GOST can be overhead, mortise or combined. Loop groups can be lower and upper. The lower universal loop can be adjusted in several dimensions.

Manufacturers pay increased attention to the design of window structures. This is how hidden fittings appeared, which have a number of advantages:

- hinges for plastic or aluminum windows are mounted in the folds of the sash, so they are not visible;

- thanks to the original design, hidden hinges look elegant;

- there is no need to select plugs for canopies;

- hinges prevent cold air from entering from the street;

- due to good tightness, additional pressing of the valves occurs.

According to the opening method, fittings can be divided into the following types:

- Rotating with vertical suspension. This type of fittings can be considered the most common.

- Rotating with horizontal suspension. This type of fittings is also called transom fittings. When opening a window, the sash can remain open for ventilation at any angle.

- Tilt and turn fittings. When using it, you can reduce the load on the sash.

What to do if the main lock gear is broken?

If the sash gearbox is broken, you need to contact a plastic window repair company and call a specialist. He will select the necessary fittings and repair the window. If the windows were recently installed, then it may be possible to get by by replacing only the main lock. But experience shows that the gearbox breaks when the window is more than 10-15 years old. Therefore, it will be difficult to choose exactly the same fittings, since many manufacturers periodically update their products and stop producing old models. We also wanted to draw your attention to the fact that after 10-15 years, if one of the fittings elements breaks, then most likely other elements will soon begin to break as well. Therefore, for the sake of economy and practicality, it is advisable to immediately change the entire window trim.

How to adjust the hinges of a plastic window?

In addition to seasonal adjustments to the degree of pressure, plastic windows are also adjusted by tightening/loosening the screws in the hinges that secure the sashes to the frame. There are two of them - one below, the second above. They differ in design, so they are pressed differently.

Options for plastic window mechanisms

Hinges on plastic windows have to be adjusted due to:

- initially poor, illiterate settings of the window unit during installation;

- natural wear of the seal;

- inaccurate and rough closing of the valves;

- window structure shrinkage;

- wear of parts of the tilt and turn mechanism.

As a result of all this, the sash sags and does not close tightly or does not close at all. However, to return it to its place, you just need to tighten the hinges. Moreover, you can perform such a pull-up on your own. There is no need to call the experts from the company that installed the window. All you need to do is have a screwdriver and a hex key on hand. This is not repairing gasoline generators for the home or a submersible pump for dirty water; with window structures everything is much simpler.

Plastic window adjustment points

Upper

The top hinge is adjusted from the side using a hexagon when the sash is fully open. After turning the screw there clockwise, the window leaf moves away from the frame, and when tightened counter-clockwise, it is pressed so that there is less of a barrel on top.

For more precise adjustment, there is also another bolt on the upper tilt and turn mechanism. But to get to it, you will have to press the blocker (set it strictly vertically) and turn the handle to the top ventilation (also in a vertical position). As a result, the sash on top should pull away from the frame, hanging on the lower hinge and opening full access to the upper one.

Adjusting the top hinge

It is important here not to over-tighten the adjustment bolts. There should be a small empty space between the sash and the frame, where, when closing the window, a tilt and turn device made of steel will be placed

Lower

The bottom hinge also has two adjustment screws. One of them is located on the side at the very bottom. He is responsible for horizontal adjustment - he presses the sash against the frame or pulls it away from it.

The second is located directly in the rotating mechanism itself. To get to it, you need to remove the plastic cap from the loop. This screw allows you to adjust the opening window leaf vertically (height). Turning it clockwise makes it go up, counter-clockwise means it goes down.

Bottom Hinge Adjustment

Manipulations when independently tightening the hinges on a plastic window should be done extremely carefully and without applying excessive force. Do not immediately tighten or unscrew the adjusting screw all the way.

It is better to turn it a quarter turn first and close the sash to check to see how smoothly it has become in the frame. And only then, if necessary, can the bolt be tightened further.

Top corner won't close

The upper part located above the handle may not close for the following reasons:

- The door sagged. In this case, the sagging is not as critical as in the case described above, and the lower part can fall into place. However, the upper pins will touch the striker, which is usually accompanied by a characteristic knock when trying to close the window. The adjustment is made depending on the installed mechanism. In some cases, it is enough to slightly adjust the position of the strike plate: release the fasteners, lower it slightly and fix it. Roto fittings allow you to adjust the angle of the sash.

Plank

Those who have never dealt with plastic windows professionally do not know what kind of fittings there are for plastic windows other than standard well-known elements. But there are many more different parts in the kit.

The bar allows the sash to fit more tightly to the profile. Often the bar can also provide additional security against burglary. Most manufacturers often use only two strips per window, however, the more of these parts, the better.

For those who do not know what the best fittings for plastic windows are, there are counters that are responsible for burglary protection, as well as tilt-and-turn ones. In addition to its main tasks, the bar is also the fulcrum for the swing-out sash.

Conclusion

The reliability of window fittings is as important as a good engine in a car. To make sure of its quality, you need to come to the office of the window company and test the presented samples. Open and close the sash several times, feel the ease of movement of the handle, listen to the sound of movement. You should refuse the purchase if the fittings crack and crunch, and the handle turns too tightly or, conversely, too easily.

When ordering a window, you should choose a package that takes into account the needs of all family members for many years to come. Preference in purchasing should be given to a reliable and time-tested brand of fittings.

*The article contains contextual and visual advertising

| The WINDOWS MEDIA portal recommends: Which window fittings are best? |

Hidden hinges on windows trend No. 1

A plastic window has long ceased to be a means of natural light and protection from bad weather. Designers are actively interested in this part of the room; windows are no longer covered with tulle or curtains, but are turned into interior decoration.

Photo: ordinary hinges without overlays do not decorate the window - their surface does not have a decorative layer on the protective coating. All elements used in the window must match the style and color, just like on expensive furniture.

It is with the choice of color solutions for window hinges that designers most often have problems. The range of overlays often does not allow you to choose the required color and the appearance deteriorates.

Photo: most often, manufacturers offer dark brown hinge covers for colored windows. It doesn’t look good on all laminated windows.

Hidden hinges are an original engineering solution that made it possible to hide the hinges inside the window and at the same time significantly expand the decorating possibilities and durability of the windows.

European window manufacturers have adopted an ideal offer for designer windows from hardware manufacturers - hidden hinges. In the Russian window market, the share of hidden hinges is about 1%-2%, but the trend for their installation is only gaining momentum.

How to repair the main lock reducer yourself?

Let us say right away that it is impossible to repair the gearbox on the main window lock. It is necessary to completely replace the constipation. Choosing the right window fittings on your own is also very difficult; we have already written about this several times on the pages of our website. It is more economical and profitable if the repair of the plastic sash is carried out by a specialist. Since in addition to the brand of fittings, you need to know its series and overall dimensions. The hardware manufacturer also plays an important role. Properly installed German fittings will serve you for decades.

Next, you need to remove the broken fittings from the sash and install new ones. Even for an experienced craftsman, replacing window fittings takes an hour. We have had cases where clients tried to fix the window themselves. It all ended at the stage of removing the sash from its hinges and disassembling it. Almost no one was able to install the fittings independently and correctly. Or it took more than a single day. Therefore, we strongly recommend that you save your nerves and seek help from specialists.

You can call a technician if the main locking gear of a plastic window breaks down by phone every day from 9:00 to 21:00. A specialist repair visit is free!

Source

Plastic windows - description, pros and cons

The main material used in the production of plastic windows is polyvinyl chloride. It refers to thermoplastics, that is, plastics that, after initial molding, retain the possibility of subsequent processing. When producing profiles for windows, various modifying, stabilizing and other additives are added to PVC to achieve the necessary properties of strength, light resistance, colors and shades, as well as resistance to atmospheric factors from the material.

The scope of application of plastic windows is extremely wide - they can be used in almost any residential, public or industrial buildings. In this case, it is simply necessary to select a type of design that meets the specific requirements.

Advantages of plastic windows

The rapidly gaining popularity of the design in question is largely due to its undoubted advantages:

- tightness of the structure. Plastic windows provide high levels of both sound and heat insulation;

- environmental friendliness. Despite the fact that polyvinyl chloride is a product of the chemical industry, as a finished material it is absolutely harmless, at least the variety that is used in the production of window profiles;

- variety of sizes, options, types and appearance of the structure. The modern technological level allows us to produce almost any design of a plastic window, taking into account individual characteristics and wishes. Even manufacturing a window of non-standard sizes rarely takes more than 1-15 weeks. In addition, it is possible to obtain any frame color, including various shades of wood;

- reliability, strength and durability of the structure. The properties of plastic allow windows made from it to guarantee trouble-free operation of the product for several decades;

- ease of maintenance and operation. Plastic windows do not require special care or maintenance, additional painting or other similar measures;

- relatively low cost. The price for different types of plastic windows varies quite a lot. But we can say with confidence that it is quite competitive in comparison with wooden ones, if we take products of similar properties and characteristics.

Disadvantages of plastic windows

Like any building structure or material, plastic windows also have a number of disadvantages:

high installation requirements. Despite the fact that the installation of plastic windows is not a very complicated technological process and can be done independently, it still has a number of nuances and features that can seriously affect the quality of the work and the resulting design. Therefore, it is better to entrust the work to specialists, but even at the same time control its implementation;

An example of installation of structures is shown in the following video:

https://youtube.com/watch?v=qMBqdgWXysU

tightness of the structure. It’s a little paradoxical that this property of plastic windows has both advantages and disadvantages. However, most residential buildings built earlier do not have a forced ventilation system. In such conditions, even the slight ability of wooden windows to provide air circulation turns out to be a generally favorable factor.

This must be taken into account when renovating old houses, in which wooden windows often played the role of the only supplier of fresh air. Of course, the best way out of this situation is regular ventilation of the premises, but this is sometimes difficult in winter conditions

As can be seen from the above lists of advantages and disadvantages, plastic windows have extremely attractive properties and characteristics that ensure their frequent use and popularity

Part 2. Glazing

Double-glazed window installation

Since a window is, by definition, a translucent structure, almost exclusively glass filling is installed in it. The exception is the side windows of balconies, the lower parts of balcony doors, etc. – there, as I noted above, a sandwich panel can be used as filling.

Double-glazed window design

The most common glazing option is to install double-glazed windows:

- A double-glazed window is a structure of two (or more) glasses, which are hermetically connected to each other using a spacer frame.

- The distance frame (distance) is made of plastic or aluminum and filled with a special composition that absorbs moisture. Thanks to the action of this composition, condensation does not form on the glass unit from the inside.

Single and double chamber products

- An important parameter is the width of the spacer frame. In the production of PVC windows, frames from 10 to 20 mm are usually used (standard is 16 mm). If you make the distance smaller, then the thermal insulation characteristics will decrease due to the air layer being too thin, and if it is larger, then convective heat transfer will begin inside the double-glazed window, and this will also negatively affect energy efficiency.

- Another purpose of the gap between the glasses is sound insulation. The best result in this case is provided by the use of two spacers of different widths (for example, 10 and 16 mm) - this way the sound passes through the most heterogeneous medium and loses a lot in volume.

Factors influencing energy saving efficiency

Glass types

And yet, the main characteristics of a double-glazed window are ensured through the use of different glasses. You can view the configuration options using the table below:

The operating principle of energy-saving glass

This is how multifunctional glass works

| Glass | Function |

| Standard | The cheapest and most common type of glass. For the manufacture of double-glazed windows, products with transparency M0 and M1 are used. Thickness – 4, 6 or 8 mm. There are no additional properties. |

| Energy saving (low emission, Low-E) | On the inside, such glass is covered with a thin film of metal oxides - tin or silver. The oxide film effectively reflects infrared radiation, due to which a significant part of the heat generated by heating devices remains indoors. When in contact with oxygen, the energy-saving coating quickly collapses, so it is placed inside a double-glazed window. |

| Sun protection | To protect against excess sunlight, either glass tinting is used or lamination with a film (tinted or mirrored). Both options provide effective absorption in the visible spectrum. The disadvantage of this solution is directly related to its advantages: both tinted and film-coated glass transmits very little sunlight (shading up to 40 - 45%), so on a cloudy autumn day you will have to turn on the lighting much earlier. |

| Multifunctional | Multifunctional glass, in fact, is an advanced energy-saving glass: a multilayer coating based on silver oxides allows not only to retain heat in the room, but also to prevent the penetration of infrared rays from the outside. In summer, this allows you to save on air conditioning, and in winter – on heating. The disadvantages of multifunctional glass include significant (up to 25-30%) shading. Well, their price is much higher than that of standard options. |

| Shockproof | Protection of the outer glass from damage and the premises from unauthorized entry can be achieved by installing special glass:

|

The photo shows the results of attempts to break the triplex

Well, and finally – filling the glass unit chambers. There are two options here:

- By default, the space between the glasses is filled with dried air. This option is the cheapest, but in terms of thermal insulation it is not the best.

- For the most effective heat conservation, an inert gas - argon or krypton - is pumped into the chamber. These gases have reduced thermal conductivity; in addition, the absence of oxygen has a positive effect on the service life of the energy-saving coating.

Using valves similar to these, argon is pumped into double-glazed windows.

To fill the glass unit with inert gas, special valves in the spacer frame are used. Over time, these valves begin to “poison”, so argon losses range from 5 to 10% per year.

Hardware details

From the above classification of fittings it follows that manufacturers offer a wide variety of locking mechanisms, hinges, handles and additional option parts.

It is difficult for an unprepared buyer to understand what is required for a particular window. Let's fill the gap and understand each element of the fittings: their name and role in the window structure, as well as the installation diagram (shown in the photo).

Scheme of fittings installation.

1. Handle. One of the most important parts of the fittings that controls the locking mechanism. It can be aluminum, plastic, steel, brass and wood, have various shapes and a wide range of colors. It consists of a strip that is attached to the sash, a decorative overlay on it and a handle.

Pens.

Several types are available:

- Standard ones are the most common and at the same time the cheapest variety. Opens the window in the vertical and horizontal plane or moves the sash;

- Removable - easily detached from the locking mechanism. This function is indispensable if there are small family members in the apartment;

- With a lock - the locking mechanism blocks the handle, which does not allow children to open the window on their own (compared to the previous option, this is a more reliable system);

- With a button blocker, which is not always a hindrance for the child.

2. Main corner strip. Transmits the movement of the handle through the corner of the sash for simple (pivot) opening of the window. It consists of 2 parts: a fixed one - attached to the sash and a movable one, which switches the position of the locking bar. It is made of spring steel, which ensures smooth operation of all elements of the locking device. There is a groove in the sash profile for its fastening.

Main corner strip.

3. Locking plate. It is a movable rod with hooks that fit into latches and fix the sash in a pressed position to the frame. They can be basic - located on the handle side and open/close the window in all planes, medium - installed on the hinge side and ensure a tight fit of the sash to the frame in this area, and additional - increase the number of hooks.

Locking plate.

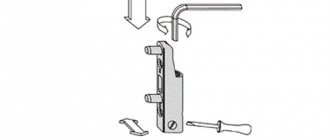

4. Scissors. Allows you to smoothly tilt the sash in a vertical plane. The design resembles classic scissors, which is why they received the same name.

They consist of a movable and a fixed bar, which are connected to each other by a bolt and nut. The fixed part of the scissors is attached to the frame profile at the top, next to the hinge, and the movable part is attached to the window sash.

Scissors.

5. Loops. Window hinges have two functions:

- hold the sash with glass unit on the frame;

- ensure smooth movement of the sash when opening/closing the window.

There are:

- by design features: rod and planar;

- purpose: for windows made of PVC, aluminum and wood;

- installation method: overhead, screw-in, mortise.

Overhead hinges make it possible to open the window in several planes. They have a variety: anti-burglary, where special plates do not allow them to be disassembled when the door is closed.

Screw-in hinges are attached to the frame profile using threaded pins. Mortise - all hinge elements are hidden in the sash. They have a long service life. Allows you to open the window 100o. Due to the installation features, the sash receives additional pressing density of its profile to the frame.

6. Auxiliary scissors. They are placed to help the main scissors, marked in the photo with the number 4.

7. Auxiliary corner strip. Provides tilting of the sash.

8. Striker plate. Facilitates the process of connecting the sash and frame.

Mounted strike plate.

9. Trunnion. One of the elements of the locking mechanism. Adjusts the tightness of the sash against the frame.

10. Additional parts of the kit that allow you to increase the degree of fit of the sash to the window structure. In addition, the kit includes:

- decorative overlays for hinges;

- latches - attached to the frame, holding the sash in the closed position.

Decorative elements of loops.

Stuck in ventilation mode

The cause of jamming is usually the exit from the grooves or the breakdown of the so-called “scissors”.

In case of such window breakdowns, the main thing is not to apply excessive force to the handle and not to try to forcefully close or open the sash.

To restore the unit's functionality, you must do the following:

- Remove the sash. To do this, you first need to remove the top canopy cover, pull the special rod down and remove the hinge.

- When the top is detached, the sash is easily removed from the bottom hinge - just lift it a little.

Bottom loop

Sometimes you can do without dismantling the sash. This will require certain skills and enough free space at the top of the window, since if the slopes get in the way, it will be quite difficult to push the “scissors” into place.

Jamming in the ventilation mode can also occur due to broken fittings, the presence of foreign objects in the mechanisms or grooves, misalignment of the sash and incorrect operation of the lock.

Additional equipment

As a matter of fact, what I describe in this section does not apply to the window itself. However, all these small details are very useful, and therefore their existence is also worth remembering. The minimum set, from my point of view, includes the following positions:

The two most popular methods of attaching a mosquito net

- Mosquito net is a net on an aluminum or plastic profile that is fixed outside the window. To attach the mesh, loops, plastic pockets, hooks, plungers and other devices of varying degrees of reliability and convenience are used.

Varieties of mosquito nets are anti-dust and anti-cat products. The first are designed to protect against plant pollen, the second - from pets falling out of the window. They differ primarily in the structure of the canvas and fastening to the frame.

Installation diagram and principle of operation of the ventilation valve

- Supply ventilation valve. Built into the upper part of the window, it provides fresh air in automatic or semi-automatic mode. For the valve to function effectively, the exhaust must be working in the room, i.e. air must be removed through ventilation ducts - otherwise the inflow will be clearly insufficient.

- Blinds and roller blinds. They are used to adjust the light, installed either on the top of the frame, or (if you have so-called mini-cassettes) directly on the sash. In the second case, the presence of a curtain does not interfere with opening the window in a rotating or tilting position.

Cassette roller shutters on each sash