The most common and noticeable defects of plastic windows arise due to poor-quality installation of the window and its low-quality components (sealants, sealants, polyurethane foam). Replacing old wooden windows that literally whistled with a huge number of holes at the joints, we want to see the quality of the new double-glazed windows, but, chasing cheapness, we risk buying low-quality material. And if you turn to an unknown company, about which there are not even any reviews, you risk being deceived by poor-quality installation of plastic windows. And if at first you don’t even notice it, as you use them all the defects will “come out” to the surface.

Defects of plastic windows. Causes of their occurrence and tips for eliminating them

The most common and noticeable defects of plastic windows arise due to poor-quality installation of the window and its low-quality components (sealants, sealants, polyurethane foam). Replacing old wooden windows that literally whistled with a huge number of holes at the joints, we want to see the quality of the new double-glazed windows, but, chasing cheapness, we risk buying low-quality material. And if you turn to an unknown company, about which there are not even any reviews, you risk being deceived by poor-quality installation of plastic windows. And if at first you don’t even notice it, as you use them all the defects will “come out” to the surface.

- Types of defects

- Causes of these defects and their elimination Condensation and mold

- Defects on slopes

- Blowing or leaking from a window

- Defective mosquito nets

- Scratches, chips on the profile

- Incorrect window measurement and installation

- Clogged drain holes

- Hardware defects

- Cracks on the seklopacket

A few words in conclusion

Now you know about the most common defects of double-glazed windows and will be able to independently identify them during the acceptance of the window into service. Timely detection of a defect will save money and have it fixed under warranty.

2 Why does a double-glazed window sometimes sweat inside?

A double-glazed window does not need painting or additional insulation, but the appearance of condensation inside the chambers brings a lot of problems. It cannot be removed manually, translucency deteriorates, and with a large amount of moisture, mold and microorganisms can appear that destroy the window unit.

Types of defects

- Formation of condensation on double-glazed windows indoors, in the space between the glass, on the window sill, profile, sashes.

- The appearance of mold on slopes.

- Icing of windows in winter.

- Defects on slopes.

- Leaking from a window or blowing.

- Damage to the profile (cracks, chips, etc.)

- Inaccurate measurement of the window opening.

- Unsightly joint with window sill, slopes, ebbs.

- Untidy appearance from the outside.

- Leaking glass unit.

- Clogged drainage holes.

- Problems with the operation of the fittings.

- Sagging of the sashes.

- Cracks in the glass unit.

How to repair rotten sections of a frame

A rotten section of frame can be replaced or restored. For restoration, epoxy wood putty is required. The damaged area must be freed from paint and dust removed. Then apply putty, carefully filling all the recesses and cracks. Form the missing part. It should be slightly larger than the required size, since the excess will be removed during subsequent grinding.

If the rotten area cannot be replaced, the defect is eliminated using putty

Leave the frame to dry for at least a day. Sand the repaired area with sandpaper or a grinder.

It is worth understanding that such repairs of old wooden windows help restore the appearance, but do not provide the necessary reliability, especially in areas of active use. But on a blind or rarely used window, this method will allow you to restore the structure without a radical replacement.

Putty and primer for small defects

Before carrying out this operation, it is necessary to identify cracks, chips and other defects in wooden windows, mark them with a marker and treat them with sandpaper. Then cover the marked areas with latex or oil putty. The work is carried out with a rubber spatula, immediately removing excess material. If necessary, after the first layer has dried, apply a second one. Finally, the wooden surface is treated with fine-grained sandpaper. The primer is applied in 2 layers.

Impregnation of wooden windows

In order for repaired antique and Soviet windows to last as long as possible, they need to be covered with drying oil. It will block the development of new rot germs and, if possible, restore the structure of old wood.

Coating with drying oil will extend the life of the window frame and prevent the formation of rot.

The drying oil is applied with a brush in 3-4 layers: the next one - after the previous one has been completely absorbed and dried. This treatment will last for 2-3 years (until the next repair). Impregnation for many decades is carried out in a piece of iron pipe 10-12 cm thick, sealed at one end. All actions must be performed only on the street, away from residential buildings.

Place the pipe at an angle of 300, fill it ¾ full with drying oil and heat it from below with hot air from a hairdryer or electric stove. As the temperature rises, the drying oil will begin to swell - this will release moisture and air. If the smell suddenly increases, you need to move the heater away and wait a little. Impregnation begins after the bubbles disappear:

- Prepare an iron hook with a sharp end 5-6 mm thick;

- Place the part in the pipe and press down with a hook for 4-5 minutes;

- Hook the bar with the point of the hook, remove it and lay it to dry;

- It is forbidden to touch the parts with your hands (even with gloves), since the temperature of the hot drying oil exceeds 130 degrees.

Such treatment allows you to extend the service life of wooden window frames by more than 100 years, and if they are coated with an oil composition, repainting will be required no earlier than after 15 years.

Causes of these defects and their elimination

Condensation and mold

Condensation on the double-glazed windows and mold on the slopes are formed as a result of improper installation of the window, a violation of the tightness of the sash with the frame and the absence or insufficient ventilation in the room.

To eliminate condensation and mold, if necessary, you should:

- install ventilation equipment;

- replace the glass unit with the required heat transfer parameters;

- insulate the installation seam of the window;

- install plastic slopes with insulation;

- repeat the installation of the window in compliance with GOST requirements.

Defects on slopes

The reason for the formation of defects on slopes is non-compliance with the requirements of installation and finishing work.

Defects are eliminated by replacing slope elements and re-installing new slopes with insulation.

Blowing or leaking from a window

Incorrect window installation technology and insufficient seal seals can cause leakage from the window or blowing.

This can be eliminated by adjusting the sash pressing elements and replacing the seals. Unprofessional installation is repeated again (partially or completely).

Defective mosquito nets

Breakage of mosquito nets is caused by wear or poor installation of fasteners.

To fix this, it is necessary to reupholster the mesh fabric and install fasteners.

Scratches, chips on the profile

If the product is handled carelessly during transportation or installation, scratches, chips on the window profile, etc. may occur.

To eliminate them, grind (for large scratches) or replace parts of the product that cannot be restored.

Incorrect window measurement and installation

Incorrect measurements of the window opening are corrected by taking exact dimensions and manufacturing a new window.

Inaccurate installation work, resulting in unsightly joints with window sills, slopes, and ebbs, is corrected by making new window elements and partially redoing the work. Inaccurate installation also causes an unaesthetic appearance of the window from the outside.

It can be eliminated by carrying out additional work to bring the external assembly seam to the required form.

A leaking glass unit should be replaced.

A violation of the manufacturing technology of window structures leads to sagging of the sashes. To eliminate this, adjustment work is performed.

Clogged drain holes

This happens due to failure to follow the recommendations for caring for plastic windows. To fix this, you need to clean the window drainage holes.

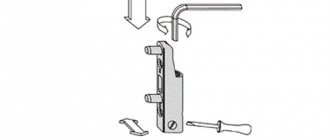

Hardware defects

They arise as a result of its wear and violation of operating recommendations. To eliminate this, window fittings are repaired, replaced or adjusted.

Cracks on the seklopacket

Incorrect glass production technology, as well as mechanical stress on it, lead to the appearance of cracks. To remove these defects, the glass unit is replaced, and spacer substrates are installed correctly to evenly distribute the load on the glass.

It is very important that breakages and defects of plastic windows are repaired by specialists who have sufficient knowledge and skill to do this. As you can see, in many cases, defects can be corrected only by installing a new high-quality window, so do not skimp on your comfort, it is better to order a plastic window once, but one that meets all the requirements and rules.

Assembling the sashes

The prepared sashes are placed on the shield and carefully aligned to a rectangular shape. The details of the window require special attention: a 1 mm difference in diagonals will provide a 0.7 mm gap.

The leveled area is secured with glue or nails, carefully driving them into the shield near the sash. They look through the old dowels (“chopiki”).

When assembling the sashes, it is necessary to strictly observe the rectangularity

Drill them in the middle of the corner using a larger diameter drill. If one of the dowels is shifted to one side, then you need to:

- Secure it along the border with a few drops of “Super Glue”;

- Drill the correct location;

- Pass the saw blade through the gap between the fixing lugs and saw through the old dowel.

After assembling all the corners, you should get a fairly rigid structure. Now you can take the frame and install the sashes into it. They will fit more tightly if plywood strips of the appropriate width and thickness are glued to the frame.

Place all parts on a leveled surface and press down with a weight (approximately 100 kg). Leave to dry and level for 2-3 days.

DEFECTS IN PLASTIC WINDOWS

1. Formation of condensation on windows and mold on slopes. Icing of windows during the cold season.

The cause of condensation on windows and mold on slopes:

- Violation of window installation technology

- Violation of the tightness of the window sash to the frame

- Lack of ventilation or insufficient ventilation of the room

Eliminating condensation on windows or mold on slopes:

- It is necessary to diagnose the formation of condensation on windows or mold on slopes.

Depending on the results of the diagnostics and identification of the cause of condensation on windows or mold on slopes, the following work is carried out:

- Recommendations are given for proper ventilation of the room.

- If necessary, equipment is installed to ventilate the room.

- A glass unit with the required heat transfer resistance characteristics is being replaced.

- Additional insulation of the window assembly seam is carried out.

- The window is re-installed in compliance with the GOST 30971-2002 standard.

- Plastic slopes with insulation are installed.

2. Formation of defects on slopes.

Cause of defects on slopes:

- Violation of window installation and finishing technology.

Elimination of defects on window slopes:

- Slope elements with defects are being replaced.

- Visible slope defects are eliminated.

- New plastic (gypsum plasterboard) slopes with insulation are being installed again.

3. Blowing or leaking from the window.

The reason for the occurrence of blowing or leaking from the window:

- The seals do not fit tightly enough.

- Violation of window installation technology.

Elimination of blowing or leakage defects from the window:

- Performing adjustments to fittings and window sash clamping elements.

- The window seals are being replaced.

- Window installation defects are corrected: partial or complete window reinstallation.

4. Breakage of mosquito nets.

Reasons why mosquito nets fail:

- Wear and tear of mosquito nets

- Incorrect installation of mosquito net fasteners.

Troubleshooting mosquito nets:

- Reupholstering mosquito nets

- Installation of mosquito net fasteners.

5. The occurrence of scratches, cracks, chips and other damage to the window profile.

The cause of defects (scratches, cracks, chips) on the window profile:

- Careless handling of the product during transportation or during window installation.

- A crack in the window profile could also be caused by an incorrectly selected bead length.

Elimination of defects (scratches, cracks, chips) on the window profile:

- Grinding minor scratches on the profile.

- Replacement of plastic elements of a window product that cannot be restored (large scratches, cracks and chips).

6. Incorrect measurement of the window opening.

Cause of the defect:

- An inaccurate measurement of the window opening was made and the corresponding size of the installation seam was calculated.

- The exact dimensions of the window opening are taken taking into account the calculation of the size of the installation seam.

- A new window is made to the correct dimensions.

7. Unsightly joint with window structures (window sill, slopes, ebbs).

Cause of the defect:

- The window installation work was carried out sloppily and does not correspond to the aesthetic appearance.

- New window elements are being manufactured

- Partial reinstallation is in progress.

8. Unaesthetic appearance of the window from the outside.

Cause of the defect:

- The window installation was done carelessly.

- Additional work is being carried out to bring the external assembly seam to the required form.

- In case of destruction of the installation seam, the window is re-installed in compliance with the GOST standard.

9. Violation of the tightness of the double-glazed window.

The reason for the seal failure of the glass unit:

- Mechanical damage to the double-glazed window due to improper installation of the lock with push-button fitting.

Elimination of glass unit leaks:

- Replacing a double-glazed window or reinstalling a lock with a push set.

10. Clogged and dirty window drainage holes.

Cause of the defect:

- Failure to follow recommendations for the care and operation of plastic windows.

- Cleaning window drain holes.

11. Errors in window design.

The reason for errors in window design:

- Unprofessional design of the window structure (features of the opening, etc. are not taken into account).

Troubleshooting window design errors:

- Re-design of the window and production of a new window.

12. Difficulty opening and closing PVC entrance doors.

Cause of the defect:

- Wear and tear of window parts and mechanisms.

- Window parts and mechanisms are being replaced.

- The window hinges are being adjusted.

- Installation of the closer.

13. Defects in window fittings or lack of additional functions for the window.

- Additional installation or replacement of fittings (limiters, combs, remote transom openings) is carried out.

14. Sagging window sashes.

Cause of the defect:

- Violation of the production technology of window structures.

- The geometric dimensions of the window sashes are measured by reinstalling the spacer glass unit substrates.

- Carrying out adjustment work.

15. Breakage of window fittings.

The cause of defects in window fittings:

- Wear and tear of window fittings.

- Violation of recommendations for the use of window fittings.

- Repair or replacement of window fittings.

- Adjusting window fittings.

- Consulting on the correct operation of window fittings.

16. The appearance of cracks on the glass unit.

The reason for the appearance of cracks in the glass unit:

- Violation of glass production technology.

- Mechanical impact on the glass unit.

- The glass unit is being replaced.

- The correct installation of spacer underlays under the glass unit is carried out in order to evenly distribute the loads on the sash.

Replacing paintwork: recommendations

In order to carry out restoration work most effectively, it is first necessary to remove the old paintwork from the frames. The work begins by removing the frames from their hinges and removing all metal parts and glass from them. If these works are carried out in full, the restoration work itself is significantly reduced.

To remove old paint from frames, there are several methods, most of which will require the involvement of a team of professionals with special chemical compounds. But if all the work is done independently, then mechanical cleaning methods are used: scrapers, spatulas or abrasive materials are used.

When the surface is cleared of paint, dust is removed from it and washed with an alkaline solution, which is purchased at hardware stores. After this, the remaining paint comes off and is easily removed with a spatula.

If you have the skills to cut glass, you can do all the work yourself. Otherwise, it is better to use the services of specialists, who will simply need to take measurements.

When the glass of the required dimensions is cut, a layer of putty or sealant is applied to the frame folds, which will ensure a tight fit of the glass to the frame. When the glass is installed, all cracks are also coated with sealant.

How to adjust the handle and solve other problems with it?

Situations often arise when the handle of a plastic window does not turn well. As a rule, the reason for this is sagging of the valves or when there is no lubrication. In the latter case, you just need to lubricate the moving elements of the structure with any penetrating oil. It is also recommended to change the lubricant once a year for preventive purposes.

Related article: Simple platbands for windows in a wooden house

If the problem is not a lack of lubrication, then it is necessary to adjust the sash hinges.

If the handle has fallen off or deteriorated and should be replaced with a new one, then dismantling the old one looks like this:

- lift the protective cover over yourself;

- rotate to horizontal position;

- Unscrew the mounting screws with a screwdriver;

- remove the old handle;

- put on a new one and replace the protective pad.

What to do if the sash is open but the handle is blocked?

There is a situation when the handle turns down, but the window sash is open. The lock is activated and the window cannot be closed.

The solution to the problem depends on what kind of fittings the plastic window is equipped with. In some cases, first there is a thin metal plate and a spring on the handle, which must be turned, pressing these elements more tightly to the seal.

The sash must have a strictly vertical position; if it is tilted at an angle, the upper lock will work and it will be impossible to turn the handle. And when it is positioned vertically, the bar will press against the seal and the handle will turn, so the window can be closed.

Also, some models are equipped with a metal tongue slightly below the handle at an angle to the profile; it is adjustable in the same way as the bar. Press the tongue at the bottom until it is parallel to the profile level, so the handle will turn and the window will close.

If the window has been deformed due to temperature changes, the adhesion may be impaired and the tongue will slip when closing the window. This way the handle will be blocked and the plastic window cannot be opened. To do this, find the metal part of the lock with the sash open and install a spacer between it and the frame, this will improve the grip on the tongue and the handle will work normally.