Changing the location of the opening is a common occurrence in the redevelopment of a residential space. To do the job correctly, you need to know many parameters. Let's take a closer look at how to make an opening in a brick wall. First of all, this is the legal part of the issue, because you can’t just do such actions. We will also study the features of brick walls, varieties of the material itself and types of masonry. All this can affect the progress of work. Plus, we’ll figure out what the process of work itself should be like.

Opening in a brick wall Source 04563.com.ua

How to make an opening in a brick wall - legal specifics of the issue

The legal part of the redevelopment issue involves the preparation of a number of documents. The main paper here is permission, which is not so easy to obtain. The procedure consists of agreeing on a new house project with an interdepartmental commission.

It is important to know! If a person lives in an apartment building, the neighbors’ official consent will be required to carry out such repair work, in accordance with the social tenancy agreement.

It should also be remembered that such issues are resolved through multifunctional centers. The difficulty of the procedure is that it will not be possible to do it all at once.

You will have to visit the MFC more than once Source poligraftorg.ru

3 steps on how to make a doorway in a brick wall from a legal point of view:

- SRO approval - a specialist or organization that will punch/cut an opening in the wall is required to have this document - if it is not there, then a work permit will not be issued;

- permission – here we mean obtaining permission directly to work, which is issued after agreeing on all the nuances;

- registration of the result - upon completion of the redevelopment work, it is important to make changes to the documentation (here you should correct the information in the floor plan, and also obtain a new technical passport of the premises with the changes made).

The paperwork can be completed retroactively if the builders did not make a mistake in the calculations and did everything correctly. Otherwise, authorized persons will be required to block the doorway back. Plus, you will have to pay a fine.

Some people do the process in reverse - first make the doorway, and then go for the relevant papers. If something is done wrong, the consequences will be sad Source prorab78.ru

Attention! If we are talking about a doorway in a load-bearing wall, then things are much more complicated. It is possible to obtain such permission. But for this it is necessary to fulfill a number of norms and requirements.

3 cases when it is impossible to obtain permission in principle:

- joint of slabs - here its width plays a role in relation to the location of the new doorway;

- emergency condition of the house - work is planned on the first floor of a multi-storey building, which is in a condition close to emergency;

- ventilation ducts - if there are any at the place where the doorway is planned, work will be prohibited.

There are situations when local authorities impose a ban on the redevelopment of houses of a certain type - here no nuances are considered (for example, buildings that have cultural and historical value). But if everything is done correctly, then most of those who wish to obtain permission without problems.

It is important to obtain permission for redevelopment Source solreg.ru

On a note! We must remember one more restriction - when carrying out work, you cannot violate the time limits for noisy construction work (until 23:00).

Using beacons

The next stage is placing beacons on opposite ends of the brick partition and laying the first row. This is a very important job, since the correct start will later facilitate the laying of the main mass of the wall.

You have clear pencil lines on the walls. Along them it is necessary to lay out brick beacons to a height of 4-6 rows. Then a nylon cord is stretched between them. Its task is to help the mason raise a perfectly flat wall.

After the first row is laid out, the nylon cord rises one row higher. Having laid it with bricks, the cord rises again to a new height. We do not recommend raising the thread several rows at once. This is usually what masons - specialists - do in order to save time on throwing the cord.

For those raising walls for the first time, it is best to have a reference point on each row. With this approach, the bricks will lie horizontally more evenly and beautifully. As a result, the strength of the partition will increase.

How to make an opening in a brick wall - specifics of the material

In the construction of houses, brick is one of the most frequently used and studied materials. When working with it, it is important to consider a number of points. A doorway, for example, can weaken the structure of the entire building. It is also necessary to choose the right work technique.

Attention! Incorrect actions can damage the wall itself, which means additional financial costs. To understand how to make an opening in the wall for a door in a brick wall, you need to at least familiarize yourself with the general information.

There are only 3 types of walls:

- Bearers . They rest on the foundation and support the total weight of the upper floors (interfloor partitions rest on openings in the load-bearing walls). Obtaining permission to construct a doorway in a supporting structure is the most difficult, as this may affect the integrity of the building. Many nuances will be taken into account here.

- Self-supporting . Like load-bearing walls, these are external walls, but do not support the upper floors. Interfloor ceilings are supported by internal fastenings.

- Partitions . Not designed to support any significant load. The optimal thickness of brick partitions is 1/20-1/25 of the floor height.

It is clear about the difference between load-bearing and self-supporting walls Source infosort.ru

See also: Catalog of companies that specialize in internal redevelopment

Features of brick walls for doorways

Before constructing doorways, you must first become familiar with the specifics of the material itself. There are many types of bricks that differ in various parameters - texture, density, weight, etc. To learn how to make a doorway in a wall, it is important to familiarize yourself with all the properties of the brick in advance.

Brick as a building material has certain dimensions - it is 250 mm x 120 mm Source stroyshans.ru

It is important to know! If you compare a regular brick with a ceramic one (double brick, in other words), you should note the difference in height. For a regular one it is 65 mm (88 mm if it is an ordinary thickened one). In terms of height, ceramic wins over both - 138 mm.

2 types of bricks are used for laying walls:

- solid – can be used for any construction needs;

- hollow - due to the presence of air in the cavities, it has high thermal insulation properties - can be used for laying outer walls.

Brick and ceramic stone are made using similar technology, but the materials used are different. For example, sand-lime brick is made from lime, and ceramic brick is made from clay, the surface of which is fired.

On a note! Various brands of brick have frost resistance ranging from 25 to 300 freeze/thaw cycles. According to GOST, this characteristic is displayed as F 25 - F 300.

Other characteristics of brick depending on its frost resistance Source stroyinform.ru

Coverings for window and door openings

When building a brick wall and leaving openings for doors and windows, you need to think about how best to cover them after the masonry is raised. For these purposes, various materials are used, and their choice is regulated by the thickness of the walls and financial capabilities.

The simplest option is to install a steel profile or corner. It is simply installed on top of the brickwork, reinforced with iron rods on both sides, and then the wall continues to be laid out. Simple and angry. Reinforced concrete lintels are very convenient. They are selected according to the thickness of the brick, and their installation covers one masonry row. This method is convenient, but loses in decorative terms. A lintel made of a reinforced concrete block will look unsightly between the facing bricks, and plastering the walls will ruin the whole look. Therefore, if you plan to use such a stone, consider another method.

Technology for punching doorways in a brick wall

Each work on redevelopment of an apartment or house has its own specific technology. It is important to adhere to the specified sequence so as not to disrupt the overall design and obtain the desired result.

4 steps on how to make a doorway in a brick wall with your own hands:

- Preparing the necessary tools and dismantling the finish.

- The punching process itself consists of several steps (described in the paragraph below).

- Strengthening the site.

- Exterior finishing of the finished doorway.

Another important detail is the door frame, which will fit into the future opening. If one is not planned, this simplifies the task. Otherwise, you need to take into account the rules for its installation in advance.

It is important to know! Installing a door frame requires meeting certain conditions. It is extremely important to maintain the distance here - there should be a gap of 1 to 2.5 cm between the wall and the end.

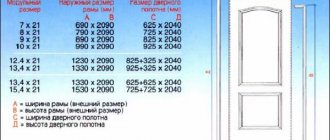

Most doorways are standardized. However, if you are working on your own, it is best to think through this point in advance and make the door frame to order. Then you don’t have to worry about its size.

Required Tools

To work, you will need to prepare the following list of tools and equipment:

- Trowel for throwing mortar.

- Pickaxe for cutting bricks.

- Durable nylon cord.

- Two medium length nails for fastening the thread.

- Household or professional hammer drill.

- Mixer attachment for mixing the solution.

- A pair of buckets for preparing a cement-sand mixture.

- Measuring tape 3-5 meters long.

- Plumb line to check the quality of masonry.

- Building level - serves the same purpose.

- A simple pencil for drawing lines.

Video description

Watch in this video how to cut a doorway of a non-standard shape:

Stage 1 - how to properly prepare for punching an opening under the door

Before breaking through a wall, you need to examine the space under the ceiling. You need to be especially careful when working with a load-bearing wall. Floor slabs must be supported.

On a note! Telescopic stands can be used as a supporting structure. This is an ideal option, which is used on professional construction sites of monolithic buildings. If it is not possible to purchase them, you can use ordinary sub-products - wooden logs. However, they cannot be placed on a clean floor. Here you should use overlap.

What you need to prepare before making an opening in the wall:

- universal hammer drill;

- welding machine;

- Bulgarian;

- a set of keys.

During redevelopment work, you will need to cut the reinforcement. To do this, you need to acquire special scissors.

Scissors for cutting reinforcement Source mixtools.com.ua

Masonry methods

The device should begin with determining the type of masonry, which can be:

- Lozhkova . The brick is laid with the spoon facing outwards.

Spoon masonry

- Chain.

Chain masonry

- Cross . In the chain and cross cases, alternating masonry is used: one row is laid with a spoon facing outwards, the other - with a butt joint.

Cross masonry

- Kolodtseva.

Masonry well

In this case, the masonry is carried out in two rows, forming a well-type structure. Its space is filled with gravel, slag or construction waste.

Video description

Watch the video for details of dismantling a brick wall under a doorway:

Stage 2 – a guide to action in 5 steps

In order not to get unnecessary cracks in the wall and not to disrupt the overall structure, it is important to consistently adhere to the technology presented below.

Step-by-step instructions on how to make an opening in the wall for a door:

- Installation of a new jumper. A place is made in advance for it in the brick on both sides of the wall. Most often, channels of suitable sizes are used as jumpers.

- Preparing holes for tie bolts . Holes are drilled between the jumpers into which threaded rods will be inserted.

- Jumper tie . The main thing here is to achieve an even distribution of effort.

- Marking and cutting the opening . Marking is done using a regular black stationery marker. A level and tape measure will help you make accurate calculations. Then you need to cut a hole along the contour using a grinder or a gas cutter. We must not forget about accuracy. The smoother the cut, the simpler the external finishing.

- Wall dismantling and adjustments . When the outline is cut, the wall is dismantled. A hammer drill is used here. The final stage of adjustment involves working with a small spatula to knock out small defects.

After the drilling process, a place for the second jumper is punched Source kskconstruction.com.ua

Preparation of the solution

Once the markings have been made, you can begin preparing the cement-sand mortar. It is most convenient to mix the ready-made dry mixture with water using a hammer drill with an attachment. This is the fastest way to make a solution without much physical effort.

Fill the bucket about one-third full with water. Then pour the dry mixture into the container. Using a puncher with a nozzle, stir the solution until smooth. It is important to follow this sequence. If you add water to the mixture, it will not mix completely and dry lumps will remain at the bottom.

Briefly about the main thing

Many owners of private buildings and commercial buildings are thinking about remodeling the interior space, so punching a new doorway is one of the most popular construction procedures. To work independently, knowledge of the correct technology is required. It is better for beginners in construction not to undertake such experiments, especially since such work requires special permission.

To make an opening in a brick wall, you need to complete all legal documents. The most important thing is to obtain permission from local authorities. If redevelopment work was once prohibited, it is almost impossible to obtain the papers.

When all requirements and standards are met, and the house is not in disrepair, documents are issued fairly quickly. Although you will have to return to the MFC more than once with reports.

Another point is the study of the parameters and properties of the building material. To make the process easier for yourself and speed up the time of constructing a new hole for the door, you need to understand the type of masonry, its density, etc. The choice of tool, as well as methods of work, depend on this. It is also important to study in detail the technology of the work itself.

The process of punching through a doorway itself consists of 4 stages - preparing the wall, drawing the outline and cutting, strengthening the door and external finishing. The penultimate stage is mandatory only for load-bearing and self-supporting walls. If an opening is being cut in a partition, there is no urgent need for the third stage.

How to seal a window tightly

You can seal the window tightly. In this case, some suitable wall material is used. You can use bricks or blocks of various types for this.

It is also necessary to take into account the material from which the walls are built. If the facade of the house is made of brick, then the outer layer should also be made of brick. Moreover, it is better to choose a brick that will be as similar as possible to the existing one in order to hide the place where the window used to be.

Subsequent layers of masonry can be made from other materials, for example, from foam blocks, which have low thermal conductivity. This is important because the window area is still quite large, so it makes sense to make the masonry warm.

How to seal cracks in plastic windows inside an apartment

To insulate plastic windows from the inside of the room, it is better to choose a lightweight and effective sealant. Lightweight and elastic materials lie flat on the inside of the plastic surface, quickly adhere to the materials and last a long time.

- Silicone – suitable for exterior and interior use. It repels water, is not destroyed by precipitation, and lasts longer in direct sunlight. The mass remains plastic after cooling, so it tolerates shrinkage and expansion and contraction of the gap.

- Acrylic – adheres to PVC, wood, metal and glass. Suitable for indoor application on drywall. It is easy to paint and does not have a strong toxic odor. The material hardens, so it can crack due to deformation of the glass unit.

- Thiokol - the degree of plasticity can be adjusted independently. The mixture will withstand temperatures of -48 +128℃.

- Polyurethane - quickly adheres to textured surfaces and glues any materials. Dries quickly and is easy to paint. Elastic after drying, does not shrink.

- Acrylate - applied with a gun or spatula. After drying, the surface is rubbed down, which is important when insulating slopes. Repels moisture and withstands low temperatures. Option “Stiz-A” is best found for outdoor work, and “Stiz-B” for interior decoration.

Work order:

- Remove debris and dirt from the inside of the gap, degrease the area, and wipe dry.

- Cut the tube with sealant at an angle and cover the gap with a thin layer.

- Align the seam in one motion and remove excess sealant from the frame.

You can perform alignment using the edge of a coin. The composition ensures tightness of seams for about 1-2 years. When cleaning or washing, the sealing putty begins to separate from the frame and window sill material, darkens and becomes dirty.

Recommendations from professionals

- Block jumper. Installed if the house is built of similar material. The width of the opening should not exceed 1.2 meters, the height - no more than two-thirds of the previous indicators. For reinforcement, reinforced rods with a cross-section of 6-8 mm are placed under the blocks. The ends of the reinforcement are bent upward and inserted behind the laid blocks. The blocks are laid using an adhesive solution. The outlet on the sides must be at least 115 mm.

- Ready-made concrete lintels. The material of the building does not matter. The choice of beams depends on the height of the row of walls of the building. If it is brickwork, make sure that the height of several rows together with row seams is equal to the height of one lintel laid on the mortar. In the case of blocks, select beams according to the height of the block. Installation is carried out with an overlap of at least 25-30 cm on each side. If 2-3 parallel beams are laid, the space between them is filled with adhesive, cement mortar.

It is unacceptable to drill holes, make grooves, or carry out other mechanical operations with concrete lintels. This will lead to a decrease in the strength of the structure.

- Corner jumpers. To strengthen brick and concrete window openings, metal corners are used. The elements are laid on the inside and outside, flush with the outside of the wall. Installation of the first row of purlins is carried out with trimming of block elements. The margins along the edges are at least 10-13 cm. For an opening no more than 1 meter 20 centimeters wide, the size of the corner flange is 50 mm. Before installing metal elements, treat with anti-corrosion agents.