There are several different technologies and many building materials for repairing and finishing slopes. Let's consider how to plaster a doorway after installing the door, taking into account their condition. Let's get acquainted with the characteristics of the most commonly used mixtures, with detailed instructions for carrying out installation work, with recommendations from specialists. Read to the end and you will learn about common finishing methods.

Doorway after installing a new door Source remontnik.ru

How to seal a doorway after installing the door

After you have installed the door, a sad picture will certainly appear before your eyes - the gap that has formed between the new door frame and the doorway. But don’t despair that your opening doesn’t look entirely attractive. Filling up an ugly, damaged area will not take you much effort or money.

Doorway trim

And you can watch how the work on improving the opening is carried out on the Internet in a video. Despite the fact that you do not have much work experience, finishing with your own hands is possible for any person, because the work is not very voluminous and will require from you not so much experience as accuracy and a creative approach.

With the help of doorways, the entire room is perceived, and the perfect finishing of slopes and filling of cracks adds a finished look to your new door structure.

Cost and duration of services

If you order the services of a private master who does not work according to the price list, you get the opportunity to personally agree on tariffs.

All specialists and companies registered on YouDo offer reasonable prices for services. Craftsmen can inexpensively trim and finish the slopes of the front door - the price is determined taking into account the following factors:

- total volume of restoration of door structures

- cost of finishing materials (slopes on doors, thresholds, extensions, corners)

- work experience, rating on YouDo of a repairman or organization

Preliminary calculations allow you to find out how much it will cost to install structures with plastering.

Sometimes prices are influenced by the rating of a specialist or company on YouDo. Performers with many professionally completed orders behind them occupy higher positions than newcomers.

It is often cheaper to order the restoration of door trims, thresholds, corners and internal slopes with metal or steel panels from novice craftsmen.

How to work with different types of walls

In addition to the standard situation in which the concrete opening of a panel apartment building needs to be sheathed, there are other options. The wall can be:

- Concrete;

- Brick;

- Made from rounded timber;

- From laminated veneer lumber;

- From cinder blocks (and other types of blocks);

- Made from sandwich panels.

All these types of materials differ in their aggregate properties and size. For example, rounded timber is much more “movable” than laminated timber, and cinder blocks have a lower density compared to concrete. That is why you need to work with each type of wall individually.

The easiest way to install door trim is on a concrete wall. It is dense and thin, it is difficult to damage it with a handy tool.

Brickwork is wider than concrete, so the standard addition that comes with the kit will clearly be out of place here. The width of a brick wall can reach 50-60 centimeters. A concrete wall is rarely thicker than 10 centimeters. Moreover, brick crumbles under strong mechanical stress from both sharp and blunt objects. You need to work with it delicately.

Rounded timber shrinks. Therefore, during the installation of the door, a support structure is pre-fabricated from bars. In this case, the sheathing should be attached to them, if possible. This is done to avoid the opening from deforming over time. Moreover, the width of the timber also does not allow the use of a standard extension. Glued laminated timber does not shrink, but is also much wider than a standard concrete wall.

Cinder blocks, sandwich panels, foam blocks and other materials with minimal density require gentle fastening of the sheathing. In this case, it is better not to get carried away with self-tapping fasteners and choose, for example, polyurethane foam.

Non-standard solutions

In addition to the above standard methods using popular materials, you can use more original options that will highlight the interior, decorate the front door and surprise your friends:

- Artificial stone is a non-standard finishing of slopes. The main advantage is resistance to mechanical stress (if it is not a plaster model, it is fragile). Not a cheap option, requires the participation of a specialist.

- Tile. A type such as clinker (imitation brick or stone) is suitable.

- Plastic panels are an affordable but unreliable finish.

- Decorative plaster – in terms of aesthetics and durability, it has no equal. But you will need to work hard to find a good specialist in this field, because this work requires a creative approach and professionalism.

Materials can be combined if their properties are similar (sandwich panel parts + stone, laminate + tile and others).

Technology

Plastering the slopes begins after the surface of the main walls is leveled. The work ahead is dirty, so it is advisable to cover the door leaf, floor and door frame with film, oilcloth or other similar materials. You can cover the jamb with masking tape - it will be easier to clean.

Preparation

The first stage of work is surface preparation. First, poorly adhering plaster, pieces of brick, and other building material are removed. If the doors have been replaced, the old plaster may stick out a lot. In this case, even if it holds up well, it gets beaten up.

If the old plaster sticks out a lot, it is refinished

Then, grease or oil stains, if any, are treated with neutralizers. Old paint is also removed: plaster does not adhere well to it. Afterwards, remove dust and dirt.

If the cracks were not foamed when installing the door, you will need to do this now. Polyurethane foam is applied to the wetted surface in a volume of no more than 1/3 of the required amount. First, clean out all the dust, then moisten it with a spray bottle. In a few minutes it will greatly increase in size, filling all the empty spaces. After waiting for the foam to polymerize (harden), the excess is cut off with a knife. It’s more convenient to do this with regular stationery paper.

If plastering is to be done with cement-sand mortar, the surface is moistened. This can be done from the same spray bottle or using a brush or roller.

Setting up the guides

It is more convenient to plaster slopes with your own hands, as well as walls, using guides. On the outside of the doorway, to obtain a smooth and rigid edge, a perforated paint corner is usually placed. Once secured well, it can be used as a guide.

It is cut to the height of the doorway. The upper edge of the corner, which will be adjacent to the main wall, is cut down at an angle of 45°. It is better to do this, since during work this edge for some reason always lifts up and causes a lot of inconvenience.

You can fix the corner in several ways:

- Gently apply the solution inside the corner, then press it into the corner. You need to apply the solution carefully: the walls are made very thin and even with a small mass it breaks. Therefore, it is better to use the second method.

- The solution is applied to the corner, and the corner is pressed into it.

There shouldn’t be too much mortar, but there

shouldn’t be any voids either. Having pressed the corner in well, it is leveled so that its edge is flush with the main wall. The solution that protrudes through the holes is removed with a spatula. Then they take a level bar (you can use a building level or a rule), apply it to the corner, checking how level the corner is. They check both from the side of the main wall and from the side of the slope.

The procedure is repeated on the other side, and then on top. At the junction of the corners, the absence of differences can be checked by running your finger along the joint.

There is another way to attach the corners - with nails or self-tapping screws. This method is good when working with drywall, but it is not used when plastering: the caps get in the way.

When plastering door slopes it is convenient to use a template

The second guide is the door jamb. When installing the doors, they were aligned straight, so this is a good guide. But since the solution should not cover the entire surface of the jamb, a template is cut out of some dense material, which is then used to level the solution. It is better to cut it out of a piece of plastic: the edge is smooth, glides well, and is quite dense. You can use a piece of flat wooden plank. Only the edge that will cut off the excess mortar should be perfectly smooth. The part of the template that will slide along the jamb is made in the form of a step. This protrusion will remove excess solution.

You can work with a spatula or a rule, but then a beacon is installed and secured along the jamb at the required distance. The tool rests on it when cutting off excess mortar.

In this video tutorial on plastering slopes, the technology for attaching perforated corners is explained in detail, and explanations are given regarding the technique of applying putty during finishing.

Start and finish finishing: how to level a doorway

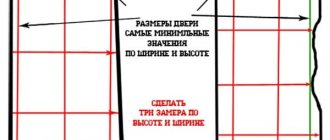

The process of aligning the opening is labor-intensive, complex, takes time and is carried out in several stages. Therefore, you should adhere to technology so that cracks do not appear at the junction, as they will require restoration.

If the door has not yet been installed, then metal corner profiles should be installed on both sides of the opening. They are able to protect corners from external influences and strengthen them. The profile should protrude to the thickness of the plaster layer. The distance should be measured with a level or plumb line. Then they take the solution, throw it on the slope and level it. This is done with special graters.

At the beginning, use the starting mixture. It is grainy. After it dries, the finishing is applied. To give the doorway a finished look, you need to putty it at the very end. For this purpose, special solutions are used that have little or no granularity. Using putty you can make the opening perfectly smooth.

The starting mixture allows you to level the opening, but not completely. To ensure that the opening has a smooth surface, it is necessary to apply plaster in several layers. Then use the finishing solution.

Before leveling, it is necessary to clean the surface from dirt, dust, paint, and get rid of protrusions on the working plane.

Materials for work

Wood panels, laminate, veneer, MDF, plasterboard, plastic and other materials are used for embedding. You need to prepare:

- Screwdriver Set;

- screwdriver with a set of bits;

- drill for metal.

You will also need:

- level to check;

- polyurethane foam;

- wooden slats;

- putty knife;

- fastening means.

Plaster

Plastering is the most common method. It is used to eliminate defects after the door has been installed. You will need to set the guide beacons and mix the solution. A vapor barrier is carried out on the foam seam of the door block to avoid the appearance of moisture on the internal slopes in the future. This will also help prevent the appearance of fungus and mold.

For external and internal work, a special hydro- and vapor barrier sealant is used, which can be bought at any hardware store (Stiz A, B, etc.). We seal the openings with a plaster mixture (sand-cement mortar) and carefully level them. For basic sealing, tile adhesive is sometimes also used.

Plastering work begins when both adjacent walls are already plastered and the opening is covered with a primer compound. If sounds are heard from the stairwell, the gaps are first filled with soundproofing materials. Excess plaster mortar is cut off with a float or a regular lath. When the material dries, you will need to grout it.

This video shows the plastering work of a doorway:

Drywall

Finishing with plasterboard, which is installed in the doorway, leads to an ideal result. The surface of the sheets is treated with putty.

Plasterboard sheets are mounted:

- on glue;

- guides.

For doorways it is better to use glue. This option is preferable for interior doors, but for entrance doors it is better to use a different finishing method. After processing, the plasterboard sheets can be plastered, painted or covered with wallpaper or ceramic tiles.

This video shows how to finish a doorway with plasterboard:

Gluing

Gluing finishing panels made of different materials can also be a way to solve the problem:

- First, we fill the guide strips on the edges of the openings according to the level, then we apply the platband on the outside of the slope, and measure the distances.

- They cut blanks for the slopes with a jigsaw, glue a decorative corner on the top and sides of the opening, which is covered with a platband.

- The top crossbar of the panel is secured to the frame, then they begin to finish the side parts of the slopes, while the protruding parts will need to be cut off.

- Small cracks are filled with putty.

- The slope on the side of the frame is secured with glue or small nails.

The photo shows several options:

This video shows how to design a doorway:

Plastic finish

Defects can also be repaired with plastic overlays. This is a lightweight, waterproof material that simply sticks on and lasts a long time:

- Sheathing with PVC panels is carried out after leveling with wooden blocks and installing the sheathing flush.

- Then the platband is mounted on top and secured with a stapler to a wooden batten.

- Insert the plastic into the starting panel and lay a layer of cotton wool for insulation.

Install the side panels with an overlap (the excess is cut off with metal scissors). The result is perfectly sealed slopes made of white plastic, which can match the color of the balcony door. This option is practically not used for entrance doors.

Fastening the laminate

Door slopes can be finished with laminate. The material is fastened using a gusset, into the grooves of which the strips are inserted. The linings have high wear resistance and a service life of up to 20 years.

- It is necessary to cut the laminate into strips, insert the elements into the grooves of the corners and starting levels. The color of the laminate panels is chosen to match the color of the door itself and the floor.

- The finished plates are usually glued onto liquid nails or another adhesive mixture. The surface will first need to be plastered and primed for good adhesion. The laminate is cut to size and the panels are attached starting from the bottom.

- The joining edge will need to be cut with a jigsaw.

This video shows how to attach laminate flooring to doorway slopes:

Using wood

For finishing you can also use:

- tree;

- chipboard;

- moisture resistant plywood.

Wooden panels are attached as before. For better fixation, you can fill the gaps with foam.

Sequencing:

- The doorway is treated with putty.

- Level and add thermal insulation material if necessary.

- Strengthen the wooden panels and seal the seams with sealant.

The photo shows wood paneling:

This video shows how to sheathe a door slope with wooden panels:

MDF sheets

- The most popular type of finish is MDF (medium density fiberboard) sheets. This is due to the low price of the material and its similar color to the door. To finish, you need to put wooden guide strips on the edges of the openings, and then attach MDF trims to the outside of the slope.

- You can also make guides from ordinary polyurethane foam. They cut out panels from MDF or take ready-made options for standard-sized entrance doors and attach them to foam or other adhesive.

The photo shows the department of MDF sheets:

What can slopes be made from?

Slopes can be internal or external, depending on their location relative to the room. When finishing them, two problems are solved: aesthetic and thermal insulation. To do this, you need to choose the right material.

MDF panels

Now for this type of work, in most cases, MDF panels are chosen, which have proven themselves in bathroom renovations. This wood fiber material comes in several types.

- Veneered is a material perfectly suitable for finishing a doorway; it is particularly strong and durable compared to other types of panels.

- Laminated is a water-resistant material that is slightly less durable than veneered MDF. But it is very attractive from the outside: it has a rich palette of colors, and there are also panels that imitate the texture of natural wood. Such MDF is also perfect for finishing a doorway after installing a metal entrance door.

- Painted is a material whose surface is less durable. It is not suitable for this type of work.

We make slopes from MDF with our own hands

If you decide to finish the doorway with MDF panels on your own, then the following materials and tools will be useful to you:

- MDF panels (3 pcs.);

- platbands (3 pcs.);

- decorative bending corner (3 pcs.);

- decorative rail (3 pcs.);

- guides (slats with a width of 10 mm and a width of 30 mm, the total length of the slats is approximately 9 m);

- screws (length 35 mm), approximately 30 pcs.;

- dowels (diameter – 6 mm), approximately 30 pcs.;

- watery nails;

- cement mortar;

- polyurethane foam;

- jigsaw;

- assembly knife;

- chisel;

- brace;

- bit;

- roulette;

- pencil.

Decorative plaster

A variation of point No. 2. “Decorative” is applied to a previously plastered surface. If the decorative plaster is textured, then the rough layer does not need to be laid out perfectly evenly. You can choose plaster with colored stone chips - it is very durable.

The disadvantages are the high cost of materials, labor-intensive and “dirty” work.

Frame from youtube.com

The adjacent wall can be wallpapered, painted or decorative plaster applied to it.

Frame from youtube.com

How to prepare for work

Tip: In order for more light to penetrate into the room, the slopes should be plastered at a slight angle, which is measured with a special square.

The instructions for preparing slopes for work suggest the following procedure:

- The surface is thoroughly cleaned of dirt and dust.

- Bitumen and grease stains, salts that protrude on the surfaces are removed.

- Particular attention should be paid to preparing the corners.

- Existing concrete deposits are removed.

- The masonry seams are cleared to a depth of one centimeter, which will ensure good adhesion of the material to the main surface, and the plastered corners of the walls will become durable.

- The walls are primed with a special primer solution (see Types of construction primers and their scope).

Tip: When plastering walls with sand-cement mortar, their surfaces must be moistened with water using household sprayers, rollers or brushes.

- Galvanized plaster profiles are attached to MP-75 or Rotband mortar.

- Profiles must be aligned in two planes:

- relative to the wall;

- without shifting the selected position relative to the slope.

- If there are several doorways on one wall, you need to simultaneously install the profiles on the outer slopes, and after the solution has hardened, install the intermediate elements, aligning them with respect to the previously installed ones. Aluminum slats are used for this. In this case, the outer profiles will protect the corners from damage and act as plaster beacons.

After preparing the surfaces, you can plaster the doorways.

To do this you will need to purchase:

- Ironing iron.

- Spatulas.

Tip: For high-quality plastering of surfaces, you need to make a template. To do this, you can use available material, for example, a piece of plastic. The main thing is to ensure that the working part of this structure is sufficiently smooth and sharp.

Seal the gap at the bottom of the door

As a rule, all entrance doors are equipped with a threshold. Blowing from the bottom is eliminated by increasing its height or decorating the area of contact with the canvas with a special seal. Given the constant contact with water and cold air, it is recommended to use reliable rubber as a seal. An excellent option are special threshold slats of a combined type, equipped with nylon brushes. The presence of a special groove protects the home from the penetration of external moisture.

Installation procedure for the combined threshold strip:

- Cutting the strip and brush to the size of the threshold. It is important to ensure that the overhanging edge penetrates into the opening. You can use a hacksaw as a tool.

- Brush installation. In the correct position, it should exert some pressure on the bar.

- Screwing the brush onto the lower edge of the canvas (away from the home). For this, a screwdriver and self-tapping screws are used.

How and with what you can decorate the slopes of the main door of your home

If you are faced with the task of how to finish the slopes of the front door, you can find step-by-step instructions in this material and in the video in this article, and we will try to analyze to the smallest detail all the pros and cons, which are often forgotten to be mentioned in advertising brochures.

Option number 1. Good old plaster

Finishing doorways with cement plaster is deservedly considered the patriarch of the trend. This decoration of door slopes appeared along with the doors themselves.

A well-plastered and finished slope will last for decades; it is not afraid of temperature changes, humidity, or cold. The plaster will fill all voids and uneven areas. To ruin such a slope, you need to hit it with a hammer. If you are not going to influence your doors so radically, then you can rest assured about the rest. To refresh the surroundings, the plastered slope can be repainted, wallpapered, or covered with the now fashionable reflective film with a 3D effect: a smooth and durable surface will withstand everything.

But plaster also has a downside. Of all the finishing methods, plastering slopes is the most labor-intensive and dirty process.

Of course, if you install the beacons correctly, buy good plaster mixtures and quality tools, then things will go much faster. Although believe me, if you have never plastered doorways with your own hands, this kind of design is not for you. In addition, plaster is, in fact, stone, only artificial, and you should not expect any serious insulation from such a finish.

There is one more professional nuance. Even on a well-leveled slope, you can only glue wallpaper, and then after two layers of primer. For high-quality painting, plaster alone is not enough: the surface will still have to be additionally puttyed and sanded, and puttying and sanding will take no less time, effort and money than plaster.

By the way, if you plan to finish the slope with natural or artificial stone, then plaster will be the best and most reliable base; you do not need to putty it.

Option No. 2. Drywall slopes

The next most reliable option is finishing the doorway of the front door with sheets of plasterboard. This type of cladding is also called dry plaster.

Drywall attracts with its speed and relative ease of installation, plus, if necessary, door jambs can be closed almost completely. If we roughly break down all the work, then briefly finishing the front door opening with sheets of moisture-resistant plasterboard consists of 5 stages:

- According to the rules, before finishing the front door opening, the surface must be cleared of debris and covered with soil. But if the base is strong, for example, a brick wall, then just wipe off the dust and go over it with a solution of copper sulfate to prevent fungus from forming.

- Next we install the frame from metal profiles. There are wall and ceiling profiles, but for slopes it is better to take ceiling ones (UD/CD). If a large space is covered, then a solid frame is mounted, and when there is little space, only the outer vertical guides are installed.

- It is better to take wall gypsum board (12.5 mm), and the sheets must be moisture resistant. If an arch is formed, then there is arched plasterboard for it (7.5 mm). The sheets are attached to the frame with self-tapping screws, and glued to the wall with tile adhesive or a similar building mixture.

- When the structure is assembled, it needs to be puttied. Remember - nothing is glued, painted or attached to “bare” sheets.

- The last stage is decorating the doorway. It all depends on taste, dexterity and financial capabilities. The easiest way is to cover the slopes with wallpaper. They do not require extensive sanding. Next comes painting, but before that you will have to sand the slope well. Tiles or stone are more expensive, but they are installed quickly and easily.

A hollow plasterboard slope has another undeniable advantage: it can be filled with insulation, thereby increasing heat and sound insulation. In this case, it is better to use foam plastic as insulation. There is an option to blow foam inside, but you need to act carefully: it can squeeze out the sheet when it expands. It is advisable not to use mineral wool or any other type of wool to insulate entrance door passages: condensation will cause it to become damp and useless.

Many people blame drywall for allegedly breaking easily, but believe me, if you install a good frame with a gap between the profiles of no more than 200 mm, and when installing it with glue, you don’t have to worry about the strength of the slope.

Option number 3. MDF

Finishing entrance door jambs with MDF boards is currently considered perhaps the most common. This is a fairly tough and at the same time beautiful material; such panels behave well under temperature changes and in conditions of high humidity.

When choosing MDF panels, there is a small nuance: to decorate the inside of the front door, you can take any sheets, but for external slopes, especially if the doors go directly to the street, you should buy only moisture-resistant ones (the back of them has a greenish tint), otherwise within a year all the beauty will bubble up.

In this case, we are only interested in laminated panels; there is no point in taking regular ones and then painting them separately. The line also includes panels covered with natural wood veneer. The price for them is about half as high as for laminated ones, but such slopes are practically indistinguishable from expensive wood.

As for self-installation, it’s not a problem to buy and install extensions, trims, mounting angles and other things. Essentially, you are dealing with a constructor. First, a frame of wooden blocks is constructed around the perimeter of the opening, and panels are already attached to it.

A relatively expensive tool will require a miter saw or at least a jigsaw, as well as a drill and a screwdriver. A hammer, tape measure, etc. are usually in the arsenal of any home craftsman.

The only disadvantage of MDF slopes is the price of the material itself. The only thing more expensive than such cladding is natural wood of elite species; by the way, it is installed in the same way, but it is better not to undertake it yourself: the risk of spoiling it is too great.

Option No. 4. Lining

The price of a good wooden lining is approximately equal to the cost of MDF, but in this case you get slopes made of natural wood. This design of the doorway looks quite solid, but there are nuances.

Any lining is mounted on a wooden sheathing, which means you must have enough space for such sheathing. Accordingly, it is problematic to make small slopes from lining.

Natural wood is a good material, but rather capricious. In extreme conditions of entrance doors, wood must be covered with antiseptics, fire retardants and other protective compounds.

Previously, all linings were varnished, but now design experts do not recommend varnish. The fact is that most people associate varnished lining with balconies and garages, and the front door is still the face of the home. It is best to buy an oil-wax impregnation and apply it. The result is pleasing: fast, beautiful and inexpensive.

Option No. 5. PVC

Slopes made from finishing PVC panels can be installed within 1 day, plus the price of this material is affordable for almost everyone, but decorating a doorway with plastic has a number of negative aspects.

You can break through a hollow thin panel by simply leaning on it. As practice has shown, even the highest quality plastic panels on good sheathing in the area of entrance doors last no more than two to three years.

Under the plastic you need a wooden or metal sheathing. Theoretically, such a panel can be glued to a plastered slope with liquid nails, but if you have a good plastered slope, then why do you need plastic?

In addition, according to fire regulations, it is extremely undesirable to install plastic in the entrance area. In the event of a fire, it will actively melt and emit choking, acrid smoke, thereby blocking the exit.

Although, on the other hand, plastic is ideal as a temporary solution to the problem. And when you have enough funds, you can quickly dismantle it and install solid slopes made of high-quality MDF on the same sheathing.

Option No. 6. Decorative polyurethane linings

If you dream of seeing your doors decorated with luxurious stucco, we recommend paying attention to decorative polyurethane overlays. Visually, such a finish cannot be distinguished from good stucco, and the performance qualities of such slopes are an order of magnitude higher. The only problem is that the price for such jewelry is quite serious, plus you can’t glue an overlay to a crooked base. In other words, you will first need to level the slope with plaster or drywall, and then glue the polyurethane beauty onto it.

A few words about the decorative finishing of door slopes

The final decorative finish is applied only to a solid, prepared base; accordingly, we can only choose between plaster and drywall.

- Most often, people choose simple coloring. The quality of modern paints is such that they can retain their original appearance for quite a long time and in any weather conditions, plus, if you get really tired of the color, you can always repaint it.

- Next in the ranking of finishing door slopes is decorative tiles. Tile is not suitable for entrance doors, so it is better to give preference to clinker tiles. If funds allow, then you can line the slopes with artificial stone; by and large, these are the same tiles, only made from stone dust and polymers.

- Natural stone tops the top three. The pleasure is far from cheap, and besides, it’s better not to try it with your own hands and without preparation. Natural stone is a heavy and difficult material to process.

votes

Article rating

Laminate cladding

Such finishing usually does not raise questions even among inexperienced builders. This is due to the special flexibility of the laminate, its ability to take different shapes. The material looks good and does not harm the environment, but it does not tolerate high humidity, so you should not use it on the outside of the opening. The price of sheets is 300-3000 rubles.

Finishing a doorway with laminate differs little from lining it with MDF panels. But it is not necessary to mount the frame: another finishing method, suitable for smooth walls without flaws, involves gluing the material with foam directly to the surface.