European technologies for manufacturing wooden windows have been successfully taking root in the Russian Federation for decades thanks to the development of GOST standards.

Wooden GOST windows are structures manufactured in accordance with a package of documents compiled by various research institutes, employees of the State Construction Committee, representatives of domestic and foreign window companies.

According to GOST, the service life of wooden windows is much longer, since all standards established by the state were observed during the production of translucent products. GOST also controls installation rules. But not all window buyers know what to consider when purchasing and what to demand from installers. Our advice will help you buy timber products with double-glazed windows and control the installation process in accordance with GOST.

CLASSIFICATION

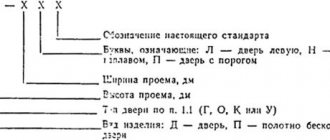

1.1. Windows and balcony doors are classified according to the main characteristics: purpose; designs; number of sashes in one row; directions for opening the doors; method of opening the doors; devices for ventilation of premises; materials for filling the light opening of the sashes; sash vestibule structures; moisture resistance; type of finish.

1.1.1. According to their purpose, windows and balcony doors are divided into: for residential buildings; for public buildings; for industrial buildings and structures of industrial enterprises; for livestock and poultry buildings.

1.1.2. According to their design, windows and balcony doors are divided into windows and balcony doors: single design with one row of glazing; the same, with two rows of glazing; twin design with two rows of glazing; the same, with three rows of glazing; separate design with two rows of glazing; split-pair design with three and four rows of glazing.

1.1.3. Based on the number of sashes in one row, windows and balcony doors are divided into: single-leaf; double-leaf; multi-leaf.

1.1.4. Based on the direction of opening of the sashes, windows and balcony doors are divided into: opening into the room; opening outwards; opening in different directions; non-opening (deaf).

1.1.5. According to the methods of opening the sashes, windows are divided into: hinged - with rotation around the vertical extreme axis; suspended with rotation around the upper extreme axis; folding - with rotation around the lower extreme axis; tilt and turn - with rotation around the vertical and lower extreme axis; rotating - with rotation around a horizontal or vertical middle axis; sliding - with the sash moving in a horizontal plane; lifting - with movement of the sash in a vertical plane.

1.1.6. Based on devices for ventilation of rooms, windows are divided into windows: with vents; with window leaves; with valves; with blinds; with transoms; with opening doors.

1.1.7. Based on the materials used to fill the light opening of the sashes, windows and balcony doors are divided into windows and balcony doors: with glass; with double glazed windows; mixed type (glazed window and glass).

1.1.8. Based on the design of the sash narthex, windows are divided into: pierless - with an average quarter narthex; with imposts - with a porch to the impost.

1.1.9. Based on moisture resistance, windows and balcony doors are divided into windows and balcony doors: increased moisture resistance, installed in the external walls of buildings and indoors with a relative air humidity of more than 60%; moisture resistance standard, installed in rooms with a relative air humidity of no more than 60%.

1.1.10. Based on the type of finishing, windows and balcony doors are divided into: with an opaque finishing coating, finished with enamels, paints; with a transparent finishing coating, finished with transparent varnishes.

1.2. The surfaces of assembly units and parts of windows and balcony doors are divided into front and non-face.

Non-facial surfaces include: surfaces of boxes adjacent to the walls; upper and lower edges of balcony door leaves; mating surfaces of composite frames and paired sashes of windows and balcony doors; folds for glass; surfaces of layouts, flashings, ebbs, casings, etc., connected to other parts.

The remaining surfaces of assembly units and parts are classified as facial.

1.3. The types, sizes and designs of windows and balcony doors, as well as their areas of application, are established in standards and specifications for specific types and sizes of these products.

(Changed edition, Amendment No. 1).

TECHNICAL REQUIREMENTS

2.1. Windows and balcony doors (products) are manufactured in accordance with the requirements of this standard according to standards, specifications for specific types, sizes and designs of these products and working drawings approved in the prescribed manner.

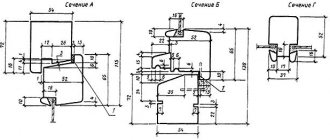

2.2. Prev. off from nominal The dimensions of products and their assembly units, the dimensions of tenon joints and the free dimensions of parts should not exceed those established in Appendix 1. At the same time, off. from nominal The dimensions of the gaps in the vestibules should not exceed those indicated in the table. 1 .

Installation

This factor is often not given due attention, as a result of which they encounter problems during the operation of windows. A lot of troubles can happen due to an incorrect installation:

- the profile becomes deformed;

- the integrity of the double-glazed windows is compromised;

- depressurization of windows occurs.

Only installation in accordance with GOST can guarantee the correct operation of window structures, which will not cause problems for their owners. Neglecting this recommendation in some cases leads to the need to completely replace the windows.

Factors affecting the durability of wood window structures

One of the most important points that affect the service life of wooden windows is the type of wood. On average, the durability of such products ranges from 25-30 years, but with careful and regular care:

- the service life of oak structures is about 90 years;

- pine windows will last at least 60 years;

- larch will retain its properties for up to 50 years.

The processing of the material used to make windows is of no small importance. The profile, which is made from blanks processed according to all the rules, will last much longer. If insufficient attention has been paid to this point, during use the wood will be more prone to cracking, rotting and fungus formation, and may also dry out.

Double-glazed windows remain airtight for 20-25 years, and the service life of the fittings is within 25 years.

How can you extend the life of wood windows?

To increase the service life of wooden windows, it is necessary to properly care for them. On the modern building materials market there is a wide range of various antiseptic impregnations that give wood increased resistance to such negative influences as:

- excessive humidity;

- ultraviolet radiation;

- temperature changes;

- damage by mold and various insects.

Also, such compositions retain the original appearance of wood profiles and their surface structure for a long time.

The humidity in the room should be within 60%. Higher rates, and especially the “weeping windows” effect, must be addressed urgently. This is done by normalizing the operation of ventilation and heating systems. Changes in the humidity conditions in the room are no less destructive - this leads to cracking on wooden windows.

Particular attention is paid to painting or varnishing, which not only gives the windows an attractive appearance, but also protects them from almost any environmental influences. The frequency of coating renewal should be at least once every 1-3 years. Before applying new layers, the surface must be cleaned of old paints and varnishes, primed and any possible defects filled. This method allows you to increase the service life of windows made of coniferous and deciduous wood up to 70 years.

Service

Proper care of both types of windows involves several basic procedures, each of which requires attention:

- Inspection and renewal of paintwork. Wooden and PVC profiles painted with enamel should be inspected once a season for the appearance of microcracks, paint fading, and separation of the coating. Under the influence of temperature changes, humidity, precipitation, chemical and wind erosion, and UV radiation, the coating layer becomes thinner. The paint layer is formed at a rate of 10-15 microns per year with an initial thickness of 80-120 microns. It is easy to calculate that the layer will lose half its thickness in 4-6 years. If you find any integrity issues with a layer, update it.

- Cleaning the surface from contamination. It is not recommended to clean any profile using substances with abrasive particles (they damage the paint layer), or to use solvents or acids. Wooden double-glazed windows must be washed with the same products that are used to care for furniture in the apartment, or you can purchase a specialized cleaning composition. The soap solution is suitable for both wood and plastic. Additionally, PVC does not require treatment after washing, and wood should be treated with a polishing agent. This can create a protective layer on the profile surface that prevents dampness and drying out.

- Preventing the condition of seals. A high-quality seal has a high level of sound insulation and does not allow the formation of condensation. It is important to maintain it in good condition, control elasticity and integrity. The seal is cleaned of dirt once a season, for example in spring and autumn. Use a soapy solution and a mild detergent. It is contraindicated to wash the seal with concentrates, acids, and solvents. They destroy rubber. The clean seal is wiped dry and treated with oil containing silicone and a glycerin-based mixture. Seals should be replaced every 5-7 years; during this time, even with proper care, they lose their elasticity, often shortening the life of plastic windows. Do not replace it yourself, contact your service company.

- Hardware maintenance. It is important that the hinges, latches, and window handles do not creak, and that the frame opens and closes easily. To do this, in parallel with inspecting the seal twice a year, lubricate the moving metal elements of the fittings. Sewing oil, machine oil, or silicone grease will do. Do not lubricate the bottom hinge. This may cause the frame to become distorted, requiring professional repairs. If you notice other malfunctions, the window becomes difficult to close, also contact a specialist. A preventive visit every two years is necessary.

Regulatory documentation for the production of wooden windows

The basis for any design and subsequent production of anything, including wooden windows, can be the following documents: - TK - technical specifications;

— TU – technical conditions; — GOST – state standard. If we talk about wooden windows, the installation is also regulated by such a state document as SNiP - building codes and regulations, but since this regulatory document does not apply to the production of wooden windows, we will omit it in this article. The Technical Specification is a customer document and is developed if for some reason the end user cannot or does not want to use standard wooden windows manufactured in accordance with technical specifications or GOST. In other words, technical specifications are developed for the production of individual, non-serial products.

The Technical Conditions are a manufacturer's document; in terms of design structure and regulatory requirements, they are similar to GOSTs, but are less stringent in terms of requirements. Specifications are developed directly by the manufacturer, coordinated and approved by the relevant government bodies (fire service, sanitary and epidemiological station, ministry, etc.).

Tables with popular dimensions

Typical characteristics of wooden blocks are similar to plastic ones, as well as products for different types of wood. According to regulatory requirements, manufacturers manufacture products according to the following limit parameters :

- 1 casement, height limits from 400 to 1470 mm, and width up to 870 mm;

- 2-leaf doors, height limits from 570 to 1470 mm, and width up to 1470 mm;

- 3-leaf, height limits from 1170 to 1470 mm, and width up to 2070 mm;

- balcony blocks, height limits up to 2200 mm, and width up to 900 mm.

Since most of the existing housing stock was built in the last century, during the renovation and major renovation of such houses, wooden windows are required that will be compatible with the existing window openings.

Dimensions for different pine options for stone houses:

| Window option | Height, cm | Width, cm | Window price, rub. | Window sill price, rub. | Cost of installation with slopes, rub. | Total, rub. |

| Single leaf | 470 | 470 | 1330 | 639 | 1833 | 3802 |

| 570 | 870 | 2986 | 775 | 3003 | 6764 | |

| 1170 | 870 | 6127 | 775 | 3723 | 10625 | |

| 1470 | 870 | 7770 | 1980 | 4173 | 13923 | |

| Double-leaf | 1170 | 870 | 7873 | 1980 | 4670 | 14523 |

| 1470 | 870 | 9899 | 1980 | 4954 | 16833 | |

| 1470 | 1170 | 13312 | 2180 | 5343 | 20835 | |

| 1470 | 1470 | 16725 | 2800 | 5733 | 25528 | |

| Tricuspid | 1170 | 1170 | 9623 | 2180 | 4563 | 16366 |

| 2070 | 1170 | 17023 | 2180 | 6090 | 25293 | |

| 1320 | 1170 | 10775 | 2180 | 4927 | 17882 | |

| 2070 | 1320 | 19209 | 2560 | 7098 | 28867 | |

| 2070 | 1470 | 21392 | 2800 | 7293 | 31485 |

Standard

This concept is quite relative; the usual dimensions may vary depending on the series of the house, depending on the illumination of the rooms. Its indicator is also influenced by the size of the window sill; if it is wide, the window size will be larger, if narrow, it will be smaller. Standard lighting is considered to be the presence of one balcony and two/three casement window units.

Dimensions of standard wooden blocks for different series of houses :

- “Brezhnevka”, two- and three-leaf windows were installed with dimensions respectively: 1300 X 1400 and 2100 X 1400 mm;

- “Stalin” windows, as a rule, have T-shaped windows in three standard sizes: 1500 X 1900, 1250 X 1800 and 1080 X 1800 mm;

- “Khrushchev”, two- and three-leaf windows were installed with dimensions respectively: 1208 X 1340 and 2040 X 1500 mm;

- “Czech”, two- and three-leaf windows with dimensions respectively: 1300 X 1400 and 1760 X 1400 mm were installed.

High

This category of wooden windows according to GOST is installed for rooms that are small in width and significant in length in order to provide a sufficient level of lighting. They come in double-leaf, single-leaf and balcony types.

According to the tables of GOST No. 11214, published in 1986,

high frames correspond to the following indicators :

- single-leaf: 870 X 1760 mm;

- double doors: 1320 X 1760 mm;

- balcony: 720 X 2375 mm.

Large

This category of wooden blocks according to GOST is applicable for large rooms, both in width and length. They are produced in double-leaf, three-leaf and separate balcony blocks. According to the tables of GOST No. 11214, published in 1986, large-sized wooden products must have the following characteristics :

- tricuspid: 1470 X 2070 mm;

- double doors: 1470 X 1470 mm;

- balcony: 870 X 2375 mm.

Little ones

This category according to GOST is established for utility rooms that do not need to provide a sanitary level of lighting or have a limited area. They come in double-leaf and single-leaf types. According to the tables of GOST No. 11214, published in 1986, miniature blocks correspond to the following indicators :

- Single leaf: 470 X 470 mm;

- double doors: 570 X 1170 mm.

Existing State Standards (GOSTs)

State Standards apply to serial or mass-produced products. The Soviet Union left us a good information heritage, and today GOSTs can be found on the Internet for almost any product widely used both in everyday life and in production. GOST dictates the most stringent requirements, the implementation of which is mandatory. Many GOSTs begin with the phrase “failure to comply with the standard is punishable by law.” Even a slight deviation from GOST can lead to disastrous consequences, since production facilities producing products in accordance with State Standards are periodically inspected by representatives of the relevant authorities.

Lifespan of each element

The most expensive part of the entire structure is considered to be the plastic profile. The manufacturer claims that according to GOST, a plastic window will last up to 50 years or even more. But only with proper care. All manufacturers use polyvinyl chloride when creating double-glazed windows. But this does not mean that their quality is the same. Essentially, PVC is a pure powder that is highly resistant to solvents. But plasticity, resistance to temperature changes, and strength are provided by various additives. Thus, for everyone, and, alas, a low-grade product will not be immediately identified.

In order for the service life of plastic windows to reach the required 40 years or more, it is worth purchasing only products from trusted brands. For example, German brands are of high quality.

Similarities and differences

Basically, PVC and wooden windows have a similar design: profile, double-glazed window, fittings, seal. The difference lies in the details.

Plastic windows have a higher airtightness than wooden ones. It's not the seal, but the profile material. Plastic prevents the penetration of outside air if the window is closed. For factory and roadside areas this is a plus, for others it is a minus.

The wooden profile “breathes” all the time. Thus, the micro-ventilation mode is constantly active. If an apartment building is located near a forest or park, then a tree would be the right choice. On average, such windows allow up to 3-5 liters of air to pass through per hour. When the profile is coated with protective substances, the volume decreases.

Thermal insulation of both types depends on the tightness of the seal and other parts, the number of chambers inside the profile. The material does not directly affect this indicator.

Plastic double-glazed windows withstand seasonal climate changes worse than wooden ones. Under the influence of temperature, plastic expands and contracts unevenly. If improperly maintained, this leads to a reduction in the service life of the products. The seal breaks, the fittings jam, and the bags fog up from the inside.

In terms of design, both types of windows can be straight or arched. PVC can be laminated and different sides can be painted with two paints. Wood can be painted, but not primed. Without painting, plastic looks cheap, wood looks much more aesthetically pleasing.

To understand what period of operation you can count on, let’s read the GOST information.

Duration of service of double-glazed windows

According to the laws of physics, glass is an almost eternal material. Unless, of course, you break it. However, even glass has its own service life and is about 30 years. What is the reason for such a modest shelf life?

A double-glazed window itself does not consist of just one piece of glass. The design also includes sealant and spacers. During operation, the sealant loses its properties over time, and air gets inside, which leads to condensation. But this does not mean that you can no longer use such plastic windows. Simply, the heat and sound insulation properties will be reduced.

Recommendations

The choice between wooden and plastic double-glazed windows is not easy. Both one and the other can last a long time, or they can fail within the warranty period. The maintenance tips we reviewed will help extend the service life, but it must be remembered that even they are not a guarantee.

Regularly inspect the glass unit elements, wash and lubricate the parts. Use the services of installers both during installation and maintenance of double-glazed windows.

Did you like the article? Tell your friends:

Accessories

The shelf life of this part of the window depends on GOST and the loads to which the fittings are subjected. And the force of influence on it is considerable. During the constant opening and closing of the window, a person puts pressure on these elements, and over time they wear out.

To increase the operating period, proper operation and selection of reliable products are very important. The best results are demonstrated by such brands as Roto, Maco. Maintenance is also of great importance: the fittings should be periodically lubricated and cleaned of dirt.

Good products will last up to 20 years, but cheap fakes will last only 3-5 years.

Aluminum windows

Manufacturers promise that aluminum profile structures can last approximately 80-100 years. These are the most durable windows on the market today. For objective reasons, it is not possible to verify in practice the authenticity of manufacturers' promises, so we can only trust the results of bench tests. When choosing models, you need to take into account that the enamel on a painted profile may peel off over time, so anodized aluminum is more practical in this regard.