Window profile - width matters

The most common window profile widths are 60 mm and 70 mm systems. The 60 series includes systems from 58 to 62 mm, the 70 series includes systems from 70 to 76 mm.

In Russia, 60 mm systems are more popular due to their lower cost. In Europe, the most common width is 70 mm. Why do Europeans prefer to buy larger systems when living in warmer climates?

A wider window profile has improved heat saving and sound insulation properties, but that’s not all. A wide 70 mm profile creates more opportunities for a safe and comfortable life for the future owner.

Photo: the wider the window profile, the “warmer” it is (on the left - a three-chamber profile 58 mm, on the right - a five-chamber profile 70 mm) A plastic profile 70 mm wide is “warmer” than 60 mm by approximately 20%. The main indicator that determines the level of heat conservation is the reduced resistance to heat transfer (Ro, m²∙o C/W). For a 60 mm profile with 3-4 chambers (with steel reinforcement) it can be in the range of 0.68-0.70 m²∙o C/W, and for a 70 mm profile with 5-6 chambers (with steel reinforcement) – 0. 79-0.82 m²∙ o C/W.

More air chambers

In addition to classification by width, there are differences in the number of air chambers formed by vertical or inclined internal partitions of the systems. For example, a three-chamber profile, a five-chamber profile, etc. The more such chambers, the higher the thermal characteristics. The number of chambers must correspond to the width of the profile: 60 mm should have 3-4 chambers, and 70 mm should have 4-6 chambers. This is the optimal ratio for effective thermal insulation.

A window profile 60 mm wide with 5 chambers does not provide additional benefit to the window, but in terms of heat saving it corresponds to 3-4 chambers.

Double-glazed windows - warmer and quieter

In a 60 mm profile, you can usually install a double-glazed window with a maximum width of 32 mm, and in a 70 mm profile - with a maximum width of 40 mm. The leading Russian manufacturer of PVC profiles, ExProf, produces profile systems that allow the installation of a larger glass unit in a 58 mm profile - up to 36 mm, and in a 70 mm profile - up to 44 mm.

Photo: EXPROF Experta allows you to install a double-glazed window with a thickness of 44 mm* The wider the double-glazed window (subject to the same window configuration), the “warmer” the window. In a wider plastic profile, you can install a double-glazed window with better sound insulation properties

Window profile for residential premises

For residential premises with a moderate continental and extreme continental climate, it is advisable to use 70 mm systems, which, together with a “correctly” selected double-glazed window, allow obtaining high thermal characteristics of the window.

Plastic profile for non-residential premises

In rooms that do not require high levels of heat saving (utility rooms, garden buildings, etc.) you can get by with 60 mm wide systems in any climate. For residential premises in the southern regions, it is also sufficient to use 60 mm, if there is no need for additional safety or sound insulation functions.

When choosing between a 70 mm and 60 mm profile with the same number of chambers, preference should be given to systems with a larger width.

Quality matters when choosing a profile

An important point when choosing a plastic profile, in addition to the stated characteristics, is the quality of the product itself. Profile production is a complex technological process that requires constant monitoring of production and inspection of the finished product. The ExProf* company is the largest Russian manufacturer of profile systems for windows, producing a whole range of type A profile systems with different installation widths. Type A is the highest in profile wall thickness according to GOST.

Photo: class “A” profile is stronger than class “B” profile. Wall thickness affects the strength of the profile and welding in the corners of the window structure. All exprof profiles for climatic operating conditions are produced in class I (universal), that is, suitable for use in any climate from the subtropics to the Arctic.

How to choose the right window profile

When purchasing windows, clients most often know almost nothing about the profile and other components used for assembly. To simplify the formulation as much as possible, window profiles are the elements from which the framework of frames and sashes is made. Their choice is influenced by many factors that are recommended to be taken into account. Profiles are responsible for the stability of window structures, energy saving, sound insulation, appearance and tightness, and the durability of windows also depends on them.

Customers usually receive information about the characteristics of PVC systems from the manager in a highly compressed form and may make a mistake in their choice. After all, they do not have basic knowledge and time to think through different options. As a result of such actions, buyers do not get what they wanted. To avoid falling into such situations, you need to fundamentally change your approach to the ordering procedure. Our article will tell you how to choose a profile for plastic windows and what else you need to pay close attention to.

What kind of plasterboard profiles can there be?

In 1980, a paper mill owner named Ostug Sackett had the idea of creating a new building material from gypsum. At first, plasterboard sheets replaced plywood and chipboard in small houses. It was then that the interesting properties of this material were discovered. The joints of smooth and even cardboard are very easy to seal so that when painting or other types of finishing, they will be completely invisible. Breaking a marked sheet instead of sawing it is much easier. Constancy of dimensions eliminates cracks in joints... Drywall has proven itself in the construction market for a long time and has remained an integral part of repairs to this day.

This or that plasterboard structure must be supported by a frame made of strong and stable parts. These are guides and profiles of various shapes, which are connected to each other using special fasteners. They differ in purpose and application, as well as in size and quality. It is very important to make the right choice when purchasing, the result of the work will depend on it. After all, if you take a bad or simply unsuitable profile for a certain type of work, the design will eventually have to be redone. For example, a sheet on a partition will bend or “move” to the side, gaps at the joints will become visible, or a noticeable “wave” will appear on the wall itself. In order to avoid mistakes during repair and construction, you need to thoroughly study the types and sizes of drywall profiles. Find out exactly what material is needed to build a particular structure.

What to consider when choosing a PVC profile

Profile class

The durability of class A products ranges from 40 to 60 years, and class B is only 20 years. Class C profiles will last only 5 years, but they are not commercially available.

Profile width and number of air chambers

The width (installation depth) and the number of chambers affect both the stability of the windows and their heat-saving properties. The greater these parameters, the warmer and stiffer the structures assembled from such a profile. Today, the market offers systems that have from 3 to 8 cameras and installation depths from 58 to 127 mm.

Thickness of external and external walls

These parameters affect the strength, durability and level of load resistance. For profiles of different classes, these indicators differ as follows:

A-class

– the outer walls must exceed 2.8 mm, and the internal jumpers must be at least 2.5 mm;

B-class

- the minimum allowed by the standard for external walls is 2.5 mm, and for internal walls - 2 mm.

The thickness of the profile walls also determines the level of noise absorption of window structures and their energy efficiency.

With the same number of chambers and the same installation depth, class A windows are warmer and quieter than class B models.

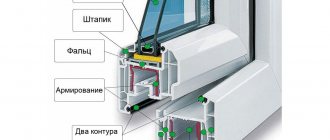

Reinforcement

Plastic windows without reinforcement can become deformed due to the load from large sashes that are heavy. This process entails depressurization of the structure. To prevent this, special metal inserts are inserted into the internal chambers. They differ from each other in cross-section and wall thickness, which should not be less than 1.2 mm. Their optimal thickness is 1.5 mm.

Today, leading European manufacturers of premium systems are actively replacing metal liners with elements made of durable fiberglass. Without sacrificing strength, they reduce the weight of windows and increase their energy efficiency.

Environmental friendliness of PVC

When producing profiles, various stabilizers and modifiers are added to pure PVC to improve the strength, color and heat resistance of the products. Previously, many manufacturers used additives that contained harmful lead. Although studies conducted in Europe partially dispelled buyers' fears and proved that PVC is harmless to health, fear of this metal remains. In addition, lead is undesirable in plastic recycling. As a result, manufacturers replaced the harmful additive with a new, completely safe stabilizer, CaZn.

How to choose a suitable plastic profile if you need warm windows

To figure out which profile to choose for PVC windows with high energy efficiency, you first need to understand how heat is retained indoors. Fittings, double-glazed windows and, of course, the profile system are responsible for this process. Most heat is lost through the translucent filling, so you need to take care of this part of the window structure first. However, without taking into account the characteristics of the profiles, it is impossible to complete this task, since there are 2 ways to increase the energy efficiency of windows:

- Install thick double-glazed windows

- such integration is only possible in structures assembled from profiles with an installation depth of 70 mm. The number of internal cameras in such windows is usually 5-6 pieces. - Install single-chamber double-glazed windows with selective coating

- such installation does not require a powerful profile. However, the use of 3-chamber systems with an installation depth of 58-60 mm will lead to heat leakage in the area of the sashes and frame, so a 5-chamber profile would be the best option.

To produce warm windows with any type of double-glazed windows, it is necessary to use profiles with increased installation depth for assembly. Otherwise, the energy efficiency of the structures will be insufficient to maintain a comfortable temperature in the interior.

Additional accessories for fixing drywall.

In order to assemble the sheathing, you will need auxiliary parts:

- Two-level connector for CD profile. This part is sold in an unfolded, flat form and before starting work it needs to be bent in the shape of the letter P. It is used to connect rack-mount parts perpendicular to each other.

- Single-level connector for CD profile or “Crab”. They connect perpendicular CD profiles in exactly the same way. If the load is more than 20 kilograms, then you will need two self-tapping screws for fastening. Otherwise, the seals are simply bent.

- Direct suspension for a rack (supporting) profile. This is a bracket, the standard length of which is 12.5 cm. It looks like a strip of aluminum or galvanized steel with holes. Withstands loads up to 40 kilograms. It is attached to the wall with two dowel nails, then the edges are bent and the frame parts are already attached to them.

- Anchor suspension for ceiling carriers. Often called suspension with traction. Replaces the part described above if it is not long enough. Used on horizontal surfaces, for ceilings, for example.

- Extension. Needed to connect two carriers to each other. It has tubercles on the sides, this indicates where the profile joins. There are also two holes for screwing in self-tapping screws.

- Corner connector. It connects elements that do not form a cross. You can do without a connector. Cut the flanges of the profile that needs to be connected so that a tongue is formed, and screw it in place with self-tapping screws.

How to choose the right profile at a good price

Systems that meet all the most stringent requirements belong to the premium class. But this does not mean that buying high-quality windows excludes savings. With the right approach, you can reduce your costs a little.

Firstly, you will need to first find out, when ordering inexpensive plastic windows, which profile to choose for your climate. Not all regions require maximum thermal insulation values. Secondly, take into account the location of your window openings. If the windows face the courtyard, then there is no point in overpaying for increased sound insulation characteristics.

If you absolutely require structures that retain heat well, do not allow noise to pass through and make it difficult to break into, use our tips on how to purchase windows at a good price without sacrificing quality.

Selecting a profile is the first priority from which you should begin the window purchasing procedure. This process requires prior knowledge of the basic information necessary for a successful search. You can find all the latest information about components for assembling window and door units on the OknaTrade website in the “Useful Articles” section.

Which plastic window profile is better to choose? Selection tips and manufacturer ratings

The profile is the main element of any window; the durability and reliability of the entire structure depends on it. At first glance, the profile for PVC windows from different manufacturers looks almost the same. The difference in quality becomes obvious after a few months (or even years!) of use, when cheap windows begin to warp and cracks form in them. How to choose a good plastic profile for windows? How are the products of different brands different from each other? And does it make sense to save on glazing by choosing an economy class profile?

Selecting a metal profile for a gypsum plasterboard frame

What is it Types Manufacturers How to choose

Rare renovations inside an apartment are completed without drywall. With its help, you can bring to life various design ideas from interior partitions and arches to multi-level ceilings. All these structures are mounted on a lightweight, durable metal frame made of profiles. It is difficult for someone who is faced with this task for the first time to immediately understand the variety of their types. We will tell you what sizes and types of profiles there are for drywall, and for what purposes it can be used.

Profile for PVC windows: characteristics and types

The profile is the basis of the entire structure from which window sashes and frames are made. They determine not only the appearance of the window, but also its strength. Common materials for window profiles are wood (cedar and larch) and aluminum. But most often the profile for windows is made of PVC, or polyvinyl chloride. This profile is reinforced with metal inserts and has air cavities inside that increase the thermal insulation of the structure.

According to the European standard EN 12608 SR “Unplasticized polyvinyl chloride (PVC-U) for the manufacture of windows and doors” and the similar Russian GOST 30673-99 “Polyvinyl chloride profiles for window and door units. Technical specifications" profiles are classified according to a number of characteristics. In particular, according to the thickness of the external and internal walls, the following are distinguished:

- class A profiles - have outer walls with a thickness of 2.8 mm and inner walls with a thickness of 2.5 mm; they provide the best thermal insulation and are considered the optimal choice;

- class B profiles - have outer walls with a thickness of 2.5 mm, internal walls - from 2.0 mm; such windows are not only “cooler”, but also 15% less resistant to deformation;

- class C profiles - all others that do not meet standards A and B; no strict requirements are imposed on them.

It is important!

There is a so-called “object” profile, which is intended for installation in non-residential industrial premises. It cannot be used in houses and apartments: due to its thin walls, it does not retain heat and is not resistant to deformation. At first glance, such a profile is no different from a regular one - except that you can see the object marking on the protective film. Often, unscrupulous companies offering very low prices for their products sell windows made from exactly this profile.

Choosing the best profile for plastic windows

It is not easy to determine by eye which profile of plastic windows is better, but there are some features that can say a lot about its quality.

Profile uniformity

The plastic must be uniform and absolutely smooth. The grainy surface indicates that the windows were most likely made at home and are fake. The coating should also be uniform, without streaks or gradients.

By the way

To avoid buying a fake at the price of branded windows, pay attention to the factory markings on the inside of the window frame. It should have a stamp with the name of the manufacturer and a series of numbers: shift number, device for producing PVC profiles and date of manufacture.

Profile width

Most often, companies offer a plastic profile for windows with a width of 58 mm - this is a classic option, preferable for residential premises. There is also a profile with a width of 70 mm; this is often installed in high-rise buildings or where the climate is particularly harsh. The 90 mm wide profile is a premium offering and features excellent heat and sound insulation properties. However, not all companies work with such products.

How to choose a profile for plastic windows?

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Everyone knows that the design of a plastic window consists of a profile frame, sashes, double-glazed windows installed in them and fittings. The profiles for making frames and sashes are, at first glance, absolutely identical. They are made of polyvinyl chloride (PVC), have the same external shape and similar internal structure.

Manufacturing materials

The main materials for making profiles for drywall are steel and aluminum. As a rule, there are steel profiles, galvanized, as well as ordinary ones, although they are quite rare. As for aluminum profiles, they are quite expensive, although they have very good characteristics.

These are the main types of profiles for gypsum boards

Steel profiles can be not only galvanized, but also ordinary ones, which are used in rooms with normal operating conditions. As for rooms with high humidity, it is better to use galvanized profiles in them, although they are somewhat more expensive than conventional steel profiles.

Existing profile classification

Technical requirements for the manufacture of plastic window profiles and classification parameters are given in GOST 30673-99 and European EN 12608 SR. According to these regulatory documents, the classification of profile products is determined by several different indicators. Let's try to use them to determine which profile to choose for PVC windows.

Wall thickness

The cross-section of a plastic window profile is a hollow structure built in the form of a system of external and internal partitions. External surfaces include all surfaces that are visible after the final installation of the window.

This means that the walls resting on the wall and located under the glass unit are internal. The strength, durability and cost of the profile depend on the thickness, size, number and location of the walls.

Depending on the wall thickness, accepted standards define 3 classes of window profiles:

- “A” with a thickness of external walls of more than 3.0 mm (according to the European standard at least 2.8 mm) and internal walls of more than 2.5 mm. Structures with such parameters have the highest strength and excellent thermal insulation properties.

- “B” with outer walls 2.5-3.0 mm and inner walls 2.0-2.5 mm. This profile is less resistant to mechanical deformation by an average of 15% and has a thermal conductivity coefficient that is 10-15% higher.

- “C” are materials for which certain requirements are not imposed. These economy class profiles are usually used to make plastic windows for industrial and unheated facilities.

Please note that the classification of the profile by wall thickness is made according to the lowest indicator. If the outer thickness is 3.2 mm and the internal partitions are 2.1 mm, then this section is classified as class “B”, despite the thick outer walls. You can find out the exact dimensions and make a choice of profile for plastic windows only by taking measurements using measuring tools.

Depending on climate zones

Manufacturers of plastic profiled products produce products with different technical characteristics for countries with hot, temperate and cold climates. Therefore, depending on the average outside temperature in January, window profiles are distinguished:

- light – for regions where the average January temperature does not fall below -5°C;

- normal version – for areas with outside temperatures from -5°C to -20°C;

- frost-resistant - for harsh northern conditions, where below -20°C.

Russian manufacturers produce only the last two types of profiles. The lightweight version can only be purchased on order from foreign companies and Russian companies from Krasnodar.

In addition, the State Standard defines 5 classes of plastic window profiles according to the coefficient of heat transfer resistance. Digital readings range from 0.4 m°C/W to 0.4 m°C/W, with a step between classes of 0.1 m°C/W.

By mechanical strength

Based on their ability to resist mechanical loads, PVC profiles are divided into classes I and II. Class 1 materials must withstand without damage the impact of a special test impactor when dropped with a mass of 1 kg when dropped from a height of 1 meter. For class II, it is tested at a fall height of 1.5 meters. The temperature of the plastic during testing should not exceed -10°C.

Mechanical tests make it possible to determine how well the internal partitions are located, and which profile to choose for plastic windows, depending on the resistance to mechanical shocks at subzero temperatures.

Typical sizes and types

Before purchasing a profile, you need to understand its types and their purpose.

Frame

Types of drywall profiles from this group are divided into several categories:

- guiding;

- rack-mounted;

- ceiling;

- arched

Let’s take a closer look at what each type is intended for and its scope of application:

Guide – abbreviation “PN” or “UD”. It has a cross-section in the shape of the letter “P” and is used as the basis of frames. Jumpers and racks are also made from it. It is attached to the edges of the structure, with subsequent installation of additional elements into it.

Guide profile Source peregorodkainfo.ru

- Rackmount – abbreviation “PS” or “CD”. Mounted in “PN” with subsequent fastening of sheet material. The cross-section is similar to the first type and is reinforced with additional stiffening ribs.

- Ceiling – abbreviation “PP” for guide and “PPN” for load-bearing. The cross-section is standard, characterized by a reduced form factor relative to the wall profile.

- Arched – no abbreviation. This profile is characterized by additional cuts on the side ribs to increase flexibility. As the name suggests, its main purpose is to create various arches.

What types of galvanized profiles are there? The sizes and types are given in the table of standard sizes of various elements:

| Purpose of the profile | ||||

| Typical sizes | Support profile | Rack profile | Ceiling profile | Ceiling support profile |

| 28x27 mm | 50x50 mm | 60x27 mm | 28x27 mm | |

| 50x40 mm | 65x50 mm | |||

| 65x40 mm | 75x50 mm | |||

| 75x40 mm | 100x50 mm | |||

| 100x40 mm | ||||

Selected types and accessories

In addition to those listed above, there are certain types of profiles used to solve non-standard problems, and accessories that are used to install the entire structure. The main additional profile is the corner segment. It is used for installation of corner elements made of plasterboard sheets. In cross-section it has a right angle.

Arched profile Source izgipsokartona.com

See also: Catalog of frame house projects

There are several main types of this profile:

- without perforation – the profile flanges are solid;

- perforated - with large holes on shelves designed for mounting on plaster;

- mesh – a special mesh is attached to the shelves for better adhesion to the surface;

- with a paper base - these are two metal strips fixed to thick paper with glue and used to level unloaded areas.

Key accessories include:

- Perforated pendants. They are used in the construction of suspended ceilings and consist of a plate measuring 125 by 60 millimeters. The plate has marks dividing it into dash parts, the outermost of which are perforated. The middle is attached to the plane, and the outer elements, bending 90 degrees, hold the supporting profile.

- Suspensions with anchor fastening. Designed for installation of suspended ceilings and have convenient height adjustment, which greatly simplifies leveling the plane.

- Connectors are two-level or single-level. When installing suspended ceilings, they allow intersecting profiles to be connected to each other. Builders often call this accessory a “crab.”

- Extension. A bracket with dimensions of 110 by 58 millimeters, designed for merging profiles having the same form factor.

Two-level connector Source otdelkasten.com

It is worth noting that in practice many of these devices are not used and are replaced with homemade parts. For example, for splicing, “NP” of the required size is used. To do this, it is inserted inside the connecting segments, crimped and fixed using self-tapping screws. The frame part is more rigid and reliable than when using standard accessories.

The same situation applies to the construction of a frame, where hangers with perforations are rarely used; a “boot” is preferred - a section of profile bent with the letter “G”. This is done not to save fittings, but to obtain more reliable fasteners. Initially, these suspensions were created for the installation of suspended ceilings. Plasterboard on the walls, often laid in two layers, is difficult for them to withstand.

Features to Pay Attention to

In addition to the technical characteristics of the plastic window profile discussed above, there are several consumer indicators that must also be considered. This is, first of all:

- number of chambers in cross section;

- width of the system for installing double-glazed windows;

- manufacturer of window materials.

It is also important to find a good installation supplier company that employs qualified craftsmen. Unless, of course, you are going to install the window yourself.

Number of profile cameras

There can be two types of prefabricated plastic elements in the window design. The first is a load-bearing window frame made from the main profile. The second type is an opening plastic sash for installing double-glazed windows. In both cases, the profile structure is hollow and in its cross-section consists of chambers separated by partitions, which can be from 3 to 7.

The greater the number of chambers, the higher the structural strength and the higher the performance characteristics. Each wall and partition performs a specific function and therefore the position and thickness of the profile elements are calculated mathematically based on experimental data. The most popular designs in central Russia have 5 chambers .

Profile width

The installation width of the frame determines which profile can be installed in this window and the number of cameras in the internal section. Both of these indicators greatly influence the thermal and sound insulation characteristics, the overall weight of the structure and the cost of the window.

Single-chamber double-glazed windows in the classic version of two glasses have a width of 58 mm and must be installed in a profile of the appropriate section. For two-chamber structures, the profile width must be at least 70 mm. Accordingly, 3-chamber – 90 mm and 4-chamber 110 mm. The last two types of windows belong to the “Premium” class and are installed only in the Far North.

Length value

For large areas of structures being built, they try to buy a profile for plasterboard, the dimensions of which in length make it possible to mount the frame without splicing the guides. This approach speeds up the assembly somewhat, but does not make much sense.

Extension cord Source ogipse.ru

With the help of improvised means, the profile is perfectly spliced. At the same time, the overall strength of the structure does not suffer. The only rule that must be followed is that the connection points must be “scattered.” If you do not make them on the same line, then the quality of the frame will meet all technological requirements.

The main gradation of profiles in length starts from 2.4 meters and ends at 6 meters. This allows you to solve almost any problem without splicing the guides.

Well-known manufacturers of PVC window profiles

The most popular brands in our country include the products of the following companies:

- KBE, Rehau and Veka from Germany;

- Montblanc from Austria;

- Salamander from Sweden;

- Kaleva, Proplex and Panorama from Russia.

All European companies, except Salamander, have established production of plastic window profiles in our country. Therefore, they are sold at quite affordable prices for most owners of apartments, private houses, office and other buildings.

Profile developed in Germany

The line of German profiles contains products with a number of chambers from 3 to 6 and a width of 58-90 mm. Each of these manufacturers offers not only a white profile, but also one with various factory-applied color coatings.

The most popular is finishing with polymer films that imitate various types of natural wood. The main advantages of products from European companies include:

- high rating and excellent workmanship;

- wide range of models offered;

- affordable democratic prices;

- plastic does not change color when exposed to solar ultraviolet radiation.

It should be noted that materials produced in Russia do not differ from analogues produced in European factories.

KBE profile.

Austrian windows

The Montblanc company produces the most budget-friendly, high-quality plastic windows. Production is located in the Moscow region, Elektrostal. Offers for sale 7 types of profiles with a width from 58 to 120 mm with a number of chambers from 3 to 5.

Types of profiles for drywall

- Guides or starting ones;

- Ceiling racks;

- Rack wall/partition;

- Reinforced;

- Arched;

- Beacons;

- Corner - protective and plastering;

- Guides.

- Creation of level ceilings;

- strengthening plasterboard edges;

- formation of the “skeleton of curvilinear structures, arches;

- installation of partitions;

- covering walls and ceilings with significant differences in the surface;

- internal wall or ceiling insulation, sound insulation

Starting ceiling guides for plasterboard - PPN or in the European marking UD. CD profiles for drywall are inserted into their grooves. They have smooth backs and a profiled shelf. May have factory-made holes for fasteners.

Ceiling - used for the manufacture of horizontal parts of ceiling frames. Each end shelf has 3 stiffening ribs. They are mounted on U-shaped hangers and fit into UD grooves, to which they are fixed, after which they are aligned using thread hangers. Beacon profiles - PM, types of profiles for drywall, used as a level guide when plastering surfaces.

They are made of galvanized metal - steel or plastic, and have high anti-corrosion properties. The length of the PM is 3 meters, their standard sections are 22×6, 23×10, and also 62×6.6.