Designers do not always consider it justified to hang curtains and curtains from ordinary wall curtain rods. Modern interior design styles offer us new solutions. The original design of the ceiling cornice is able to confidently withstand the weight of draperies and at the same time not be conspicuous. At the same time, attaching it will not be difficult if you read the proposed article.

Ceiling cornice in the interior - Photo 1

Design elements

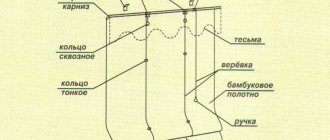

The design of a ceiling cornice with through fastening is extremely simple and consists of several elements. Some of them are included in the standard kit, and some are additional and can be purchased as needed.

- Tire. This is a plastic or metal profile with runners for moving fixing hooks for curtains. It can have different sizes - the width of the ceiling cornice depends on the number of runners (working tracks), and the length is standard (2; 2.5; 3 m, etc.).

Three-row profile tire

Advice. The number of working tracks must correspond to the number of layers of curtains. But lambrequins can also be attached to the front plane of the cornice using special Velcro.

- Hooks are holders for curtains with a leg and a base that prevents them from falling out of the runners. Once connected to the fabric, they snap tightly into place, allowing them to remain in place even when washed.

Photo of plastic hooks

- Caps and stoppers serve to limit the movement of the hooks and prevent them from falling out at the ends of the bar.

Screw stoppers can be installed anywhere on the track

Additional elements include connectors, turns, decorative hoods and brackets.

- Connectors are needed to increase the length. For example, you can assemble a 4-meter ceiling cornice from two two-meter tires.

- Turns allow you to change the configuration of the profile - make it with rounded ends or a broken plan.

- Blends are colored plastic strips that snap onto the front surface of the cornice. Needed for decorating an open structure.

The cornice behind the ceiling plinth is not visible, so it does not need decoration

- Brackets. If the bus cannot be attached to the ceiling due to the low strength of the base, the instructions allow installation of the ceiling cornice on wall brackets fixed flush to the ceiling.

Types of fastening curtains to the cornice

There are holes left on the wall from the old cornice, can you install a new cornice using the old holes?

Yes, you can, the brackets on the eaves are installed at an arbitrary distance. Please note that if the distance between the holes is 2.0 meters, then a cornice 2.5 meters long is needed. The length of the cornice and the distance between the attachment points are different things; the distance between the attachment points is at least 10 cm less than the size of the cornice.

Will the heating pipe in the apartment interfere with the installation of the cornice?

For a ceiling cornice, not a radiator, not a window sill, not a pipe, not in the way; you can step back from the wall at least a meter. Aluminum curtain rods - the distance from the wall to the curtain is 11 cm. (Aluminum cornice is easy to attach to the ceiling.) Round and “forged” - the distance from the wall to the curtain is 13 cm. Before buying a curtain rod, measure the distance by which the pipe extends from the wall.

Installation technology

A set of additional accessories for the ceiling rail gives freedom of choice when shaping its length, configuration, and method of fastening. Their price is low, so even buying extra parts “in reserve” will not make a hole in your budget.

Let's follow the entire installation process from purchasing the cornice to hanging the curtains.

Assembly

First of all, decide on the required length and shape. If you want the curtains to reach the walls at the edges, purchase rotating elements, and if the standard length of the rail is too short, buy another one of the same width and a connector.

Assembling the ceiling cornice begins with measurements. If it is from wall to wall, reduce this distance by 1-2 cm for ease of installation. If with curves, do not forget to subtract the size of the turning elements from the total length.

If you are satisfied with the standard dimensions of the ceiling cornice, then assembly will be simple:

- Decide on the number of hooks for each row and install them in the runners , inserting them into the groove at the end of the tire;

- Install stoppers and/or plugs;

Advice. The plugs can be placed on glue for reliability.

- If there are turns, instead of plugs, put these elements on the ends of the tire . They are fixed using special locking connections.

The turn and the tire must be the same width and profile design

If you need to increase the length, use connectors with the same locks as in the picture above. And you can reduce it by simply sawing off the excess with a hacksaw in a direction strictly perpendicular to the longitudinal axis.

Let us tell you, as an example, how to shorten a ceiling cornice with a turn.

- Measure the length of the assembled cornice with turns;

- Subtract the desired length from it;

- Disassemble the structure and cut off a section from the tire equal to the resulting difference;

- Reassemble and test again;

- If a hood is provided, it is pulled along the profile until the ends align, and the excess at the other end is sawed off with a hacksaw.

Ceiling mount

For installation in a concrete ceiling you will need a hammer drill, a hammer, a screwdriver and dowel nails; for a wooden ceiling - only a screwdriver and self-tapping screws.

Ceiling rails usually already have mounting holes. If not, then drill them with your own hands, making the distance between them about 60 cm. A step of greater length can lead to the following consequences:

The curtain rod sags under the weight of thick curtains

Note! Mounting holes in a three- and four-lane bus are made in two rows in a checkerboard pattern.

Your further actions are described in the table.

| Installation stages | Your actions |

| Line marking | Mark the fastening line. It should be parallel to the wall and spaced at such a distance from it that the first row of curtains does not touch the window sill, radiators and window handles. |

| Fitting | Try on the cornice to make sure the markings are correct. Install it symmetrically to the window opening or in accordance with how it should be secured in the end. |

| Marking fasteners | While holding the tire in a stationary position, make marks on the ceiling with a pencil through the mounting holes in it. |

| Installation | Drill holes at the designated points according to the diameter and length of the dowels, and hammer them into place. Raise the ceiling cornice, aligning the holes in it with the dowels, and screw it in place. |

In the case of a wooden ceiling, there is no need to drill anything - the cornice is simply fixed with self-tapping screws.

Creative Step-Down Ceiling Feature in 12 Steps

Tools and materials for installing cornices

Methods for fixing cornice elements using gypsum to decorate the ceiling are shown. Often a cornice is called a coving or a molding (mouldings, in the UK).

When performing such tasks, it would be advisable to have the help of another person, since each length of curtain rod is quite long. Four hands will make the job easier than two hands.

No special tools are required to make internal and external cuts.

An instructional video is included at the bottom of this article, showing the entire process from start to finish.

Necessary materials:

- A cornice around the entire perimeter of the room is enough.

- A type of PVA-based sealant/primer that reduces porosity before installing the cornice.

- Texture compound package.

Required tools:

- An ordinary hacksaw for wood.

- Pencil for marking.

- Fine sandpaper.

- A wide scraper and caulking tool (such as a flat putty knife, while caulk is made from wood and plastic and is used to apply material such as filler or texture and is used to smooth and blend the material into the surface.)

- A bucket for mixing the fixing/filling compound and a mixing device for mixing from the powder form.

- Means to reach the ceiling/wall.

- Brush and soft sponges for cleaning and blending.

- Dustsheets.

3 stages of cornice marking

1: Using a regular hacksaw, cut a small piece of cornice, about six inches long, stand on a ladder or jump and hold the piece straight to the ceiling/edge of the wall at the correct angle and straight to the wall. (Put it at the very corner.)

The correct angle of inclination of the cornice is 50% from the wall and 50% from the ceiling.

2: Draw a pencil along the top of the cornice to create a mark on the ceiling straight from the corner of the room and about 6 inches long. Also mark a six-inch line on the wall directly below the cornice.

3: Take the same piece and take it to the adjacent wall directly next to the wall you just marked and draw a pencil line on the wall and ceiling.

You should have made 4 pencil marks where the two marks on the ceiling intersected. You will also draw a line on each wall.

The two pencil lines on each wall can be about 4-5 inches long, of which they will act as guides, ensuring that each length of curtain rod will be at the same level throughout the room when completed.

Stages of marking internal corners before cutting

4: Hold the curtain rod all the way to the wall/ceiling and close to the corner. Align this detail with the marks you made on the ceiling and walls. The pencil cross on the ceiling is a place on the cornice.

5: Take another new length and do the same to the adjacent wall, marking the cornice.

The marks are ready for cutting the internal miters at the correct angle.

Steps for trimming interior corner jambs

6: Cutting the cornice to length: Place the piece back on a flat surface with the finished edge facing you. Holding the saw at the very end of the cornice, move the saw so that it lines up with the pencil mark on the cornice. This corresponds to an angle of 45%. Angle the saw to create another 45% angle.

When you cut the end, 45% of the cornice corner will be removed. Do the same with the next piece of cornice. These two curtain rods fit together perfectly.

Principles of adhesion: ensuring that the curtain rod does not fall

Because the texture compound is mixed with water, a vital step before bonding is to ensure that the ceiling and wall surfaces are not porous. If the adhesive compound is applied to a porous surface, the adhesive will dry too quickly and lose its ability to adhere adequately.

7: Mix a suitable PVA SEALER (primer) with water according to the instructions for porous surfaces. Apply this solution to the top of the wall and the edge of the ceiling where the pieces are to be installed and allow it to dry completely before installing.

External and internal cuts at an angle. Angles. Butt connection

To ensure that one part of the cornice is in direct contact with another part, it is not recommended to join one end directly to the other end, as this will look untidy. In this case, the finished joint may be visible, so you will need to cut the 2 parts at a slight angle.

How to solve this problem:

Set the saw at an angle to the end of the piece you want to join. Tilt the saw slightly before cutting the end. Before placing another piece next to this one, you can also cut a new piece in the same way.

Marking and trimming external bevels

External or external bevels are necessary when cornice is installed around protruding obstructions such as chest walls or similar obstructions.

As with inside corners, use the piece as a guide for proper measurement before cutting and fixing.

8: Place the piece against the ceiling/wall, making sure it is at the right angle.

It should extend beyond the edge of the obstacle by about 5 to 6 inches. Take a pencil and make a mark along the ceiling, following the top of the cornice.

9: Press the piece against the adjacent part of the obstacle. Again, draw a mark on the ceiling with a pencil.

Two pencil marks will make a cross on the ceiling at the corner of the protruding obstacle.

10: Use the entire length 5-6 inches more than the actual area intended for the cornice. Hold the corner of the wall/ceiling at the correct angle and mark with a pencil on the part where the cross is located. Take a new piece for the other edge of the wall/ceiling and mark it the same way, using the same angles and lettering techniques to cut off the outer miters.

Mounting cornice: glue

The textured composition with the addition of PVA SEALER makes an ideal adhesive for lightweight gypsum-based cornices.

11: Apply a generous amount of PVA to clean water before adding the texture powder, making sure the PVA is thoroughly mixed with the water before adding the texture.

12: Place a piece of curtain rod on the front. Using a scraper, apply a generous amount of the mixture to the back of the curtain rod. Attach the first piece to the ceiling/wall.

Basic tips for successful cornice repair

These steps are important for smooth operation and a professional quality finish.

Secure the first piece of cornice there.

Even if you have already cut the second piece ready for mounting, sometimes the next piece may not line up perfectly. In other words, an angled cut may go a little overboard.

Once the first piece is glued to the ceiling, it becomes possible to hold the next piece in place. You may find that more needs to be cut off the new piece to fit neatly into the first one.

Do this test before installing any of the following parts. Apply to the area before applying the compound and you will see if any light cuts may be required to get the part to fit neatly to the next part.

The glue must be mixed thick enough so that the wall can support the weight of the cornice.

Another aspect of the thick mixed texture material is used to fill joints, seams and corners where needed.

Remove each piece as you go. Don't let the glue dry or you may need to sand it down later.

Please note that the texture mixed with water will shrink slightly after drying. Therefore, corners and joints may need to be re-filled afterwards.

.

Instructions for assembling a cornice with your own hands (16 photos)

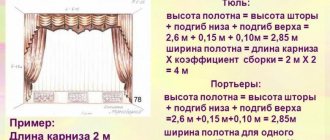

The most common arrangement of curtains is two parallel rows of curtains - made of light, usually translucent, fabric and a denser material. This explains the higher demand for double-row cornices - devices for placing such a combination of fabrics.

Examples of cornice devices

Let's look at the assembly and installation of double-row baguettes for curtains using the most common designs as an example.

Sewing double-sided curtains

When it comes to double-sided curtains without lining, their cuts are processed using a regular seam with a hem. If the fabric is not dense (silk, brocade or satin), the side sections and bottom can be edged using bias tape or decorative braid. In this case, both the back and front sides of the panel will be equally beautiful and neat.

Before hemming the curtain, it must be cut to the desired length. It is more correct to shorten the panel from the bottom side, cutting off the factory edge. If you leave it, the fabric on the window will wrinkle.

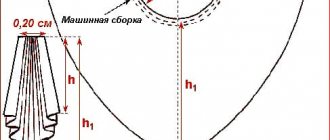

You need to leave 10, 14 or 20 cm for the hem of the bottom cut. The edge is folded twice at the same distance from the edge (5+5, 7+7 or 10+10 cm). The side sections are folded twice by 1.5 or 2 cm. How much fabric to leave for processing the upper edge depends on the width of the mounting tape. Before it is sewn, the panel must also be hemmed, making a hem the same width as the braid that will be used.

First of all, the side sections of the panel are processed. Then you need to hem the bottom of the curtain and finish the top by making a hem and stitching curtain braid on the back side.

Types of double-row cornices, their assembly and installation

Any room is characterized by a number of parameters, both general for a certain group and individual. Based on this, several types of curtain rod devices designed to accommodate two rows of curtains are produced, taking into account the dimensions of the rooms, the material of the enclosing structures, the size of window and door openings, as well as consumer preferences.

Options for the design of cornice devices: on the left - metal with wood, on the right - painted steel.

Without going into a detailed classification of these accessories, we list their main types:

- rod - a round crossbar on two or more brackets mounted on a wall or ceiling;

- bus and profile - a flat baguette with slots, installed on the ceiling or, using brackets, on the wall;

- strings - two brackets with steel wire stretched between them.

Curtain rod devices for two curtains: on the left - made of plastic tires; on the right – from a metal profile

The design of any type of this accessory is not complicated, so you can assemble and install a store-bought two-row curtain rod either with the help of a professional or on your own.

Curtain rod devices of string construction

The installation of tire and string accessories practically comes down to their installation on a supporting base, since the assembly process of these products is minimized or absent altogether. But rod-type curtain rods consist of a larger number of components, the assembly and fitting of which often raise questions. Therefore, we will consider equipping the window opening with an accessory of exactly this design - a double-row industrially manufactured rod cornice.

Installing curtain rods on the ceiling or wall

Anyone can install curtain rods! To do this, you must strictly follow the instructions and take into account what material the walls or ceiling are made of.

An important part of the design of the room is the decor of the window opening. It is impossible to produce it without cornices! At the same time, their choice should be approached with all seriousness. After all, even a couple of centimeters of poorly placed curtains or curtains will ruin the overall impression in one fell swoop. So, let's look at what a cornice is and what should be taken into account during installation.

What kind of cornices can there be?

- round;

- strings;

- profile;

- roll;

- flexible;

- baguette.

Based on the type of fastener, they are divided into:

How to choose a fastening method? The ceiling cornice includes guides and a profile. In this case, the movement of the curtains occurs on the hooks and along the entire plane of the guide. The profile is made of aluminum or plastic. Installing curtain rods is the same as for the ceiling.

The design can be rail, rod or string. For string products, the suspension thread is a strong string. For rod products, a round rod is installed on the mounting bracket. Rail devices “move” the curtains “on rails”.

Wall cornices: “cozy” rod

Don't know how to install and choose curtain rods?

Installation of rod-type curtain rod devices

Installation of cornices of most designs is not complicated, does not require expensive tools and is quite possible to do it yourself. However, during the installation process, a number of rules regarding the layout and drilling of holes must be observed.

Requirements for the location of the cornice

When choosing a cornice, first of all you need to decide on its width - whether the curtains will cover only the window opening, or whether you plan to place them over the entire width of the wall.

In the first case, the length of the device should exceed the width of the window opening by 0.4-1.0 m, that is, the end tips of the accessory should extend beyond the lines of the side slopes by 0.2-0.5 m - the wider the window, the greater this value , and more voluminous than the folds of parted curtains.

When placing curtains on the entire wall from the ends of the cornice to the vertical corners of the room, it is optimal to leave a gap of 5 cm.

The height of the cornice depends on the artistic design of the room, as well as the correctness of the angle between the ceiling and the wall. If the line of the ceiling corner is not straight, then a straight baguette installed below will emphasize this defect with contrast in the geometry of the elements.

If the cornice device is mounted higher, under the ceiling, then the baguette will hide the curvature of the line of interface between the structures.

Conventional diagram of the location of the cornice on the wall above the window opening

If the length of the cornice is more than 2.5 m, it is mounted on 3 brackets - two at the edges and 1 in the middle of the span. Drilling holes for attaching the middle bracket should be done no closer than 5 cm from the upper slope of the window opening to prevent peeling of the plaster layer.

Important! If the lintel above the window openings is made of reinforced concrete, then drilling holes for the brackets must begin from the middle element - if the drill rests on the reinforcement, you can make a hole a little higher, then mount this support, and install the outer nodes already at its level.

Assembling the cornice fixture

The device is unpacked and the contents are checked for compliance with those stated in the passport or installation instructions. Sometimes, when the structure of the load-bearing base is loose, it is necessary to replace standard self-tapping screws with screws of greater length or diameter.

If necessary, the accessory can be shortened to the required length using a hacksaw for accurate cutting, but you should know the rule - all shortened elements must be cut to the same amount.

As a rule, most industrially manufactured products have assembly and installation instructions that describe the installation procedure in sufficient detail. In case of its absence, we will briefly describe this operation in order to avoid wasting time due to errors in the sequence of work.

For models with three brackets, find the middle on the main rod and fix the middle support on it.

Installing brackets and end stops on rods

Of the total number of rings for fastening curtains, set aside 2 pieces, and the rest are distributed equally on the rod - on both sides of the middle bracket.

The outer brackets are put on the bar and fixed - in the standard places or, in their absence, at equal distances from the ends. The two rings that have been set aside are strung one at a time after the brackets - they will prevent the outer edges of the curtains from moving towards the middle of the window.

Leftmost retaining ring on the rod

Stopper tips are installed at the ends of the main rod.

Proceed identically with the second rod or profile guide - fasteners with clamps are attached in its middle and along the edges, placing rings with tulle clips between them according to the same principle. The end stops are installed, and the profile is fixed to the brackets with clamps.

Attaching the profile rod to the brackets

Important! The total number of rings installed on each rod must correspond to the number of attachment points for the curtain intended for it.

Base marking and installation

Having measured the width of the window opening, mark it in the middle and set aside a section corresponding to the planned height of the baguette.

Through the upper point of the segment, under the control of a bubble or laser level, draw a horizontal line on which all the brackets will be located.

The assembled cornice is applied with the bases of all three brackets to the line on the wall, and drilling points are marked along the holes of the supports.

Installation of cornice on the wall

Using a hammer drill with a concrete drill, holes are drilled for the middle support, they are sealed with nylon holes, and the cornice bracket is secured with self-tapping screws to the wall. If the reinforcement in the path of the drill prevented the hole from being made in the lintel, the base is drilled again - stepping back above 2-3 cm.

After checking that the molding is horizontal with a bubble level and that the marks on the wall for the side brackets have not moved, the cornice is removed to drill for the rest of the fasteners. Once all mounting holes are ready, the curtain rod device is installed at the design location.

To get a clearer idea of installing a double-row cornice, watch this video:

How to connect a cornice from two parts

PFCHEFSHCH ABOUT YUBUFSHCHPRTPUSH:

lBL UPEDYOSFSH "LPCHBOSHCHE" Y RPFPMPYUOSCH LBTOYSCH NETSDH UPVPK.

VHI "LPCHBOSHCHI" Y RPFPMPYUOSHI LBTOYIPCH EUFSH UREGYBMSHOSCHE UPEDYOOYE. "LPCBOSHCHK" LBTOY UPEDYOSAF NEFBMMYUEULIN LTERMEOYEN, LPFPTPPE CHUFBCHMSAF PE CHOKHFTSH FTHVSHCH. oP RTY LFPN CHYDEO UFSHL UPEDOEOYS, UFSHL RTYLTSHCHBAF LTPOUYFEKOPN . lTPNE PVSHHLOPCHEOOPZP UPEDOEOYS EUFSH YBTOYTOPE, DMS ЪBLTERMEOYS DCHHI LBTOYЪPCH RPD KHZMPN. dMS RTPZHYMS RPFPMPYUOPZP LBTOYB RTYNEOSAF r - PVTBOPE UPEDYOOYE. dMS un - RTPZHYMS, RTY PFUHFUFCHYE UPEDYOEOYK NPTsOP RTYNEOIFSH VPLPCHSHE ЪBZMKHYLY. bLLHLHTBFOP PFTETSFE r - PVTBОХА YUBUFSH PF FPTGB. y RTYNEOSKFE EE LBL UPEDYOOYE.

pYUEOSH YUBUFP RPLHRBFEMY OE RPOINBAF LBL YN LHRIFSH LBTOY, OBRTYNET 2.7 NEFTB, LPZDB UFBODBTFOSCH TBNETSH 3.0 YMY 2.5 NEFTB?

LBTOYSH RTPYCHPDSF UFBODBTFOPZP TBNETB, OP YI LPOUFTHLGYS RPJCHPMSEF KHNEOSHYFSH MAVPK TBNET DP OHTsOPK DMYOSCH. YuFP MEZLP UDEMBFSH CH DPNBOYI HUMPCHYSI, PFRYMYCH LBTOY OPTSPCHLPK RP NEFBMMKH. rTPNETSKHFPYUOSHI TBNETPCH OE VSHCHBEF. fPYuOSche TBNETSH LBTOYPCH UNPFTYFE ABOUT UFTBOYGBI U PRYUBOYEN: RPFPMPYUOSCH LBTOYSH LTHZMSCH LBTOYSH BMANYOECHSHCH LBTOYSH "LPCHBOSHCH LBTOYSH"

lBLYE UBNSHCHYE TBNETSH GEMSHOSCHI LBTOYPCH?

"LPCHOSH LBTOYSHCH" - GEMSHOBS FTHVB 3.0 NEFTB; RPFPMPYUOSCH LBTOYSCH UN — 4.0 NEFTB; BMANYOECHSHCHE LBTOYSHCH - 4.0 NEFTB; LTHZMSCHE LBTOYSHCH - 3.5 NEFTB; LTLETOSH LBTOYSH - 6.0 OIL.

OHTSEO LBTOY 5.0 (YMY VPMSHYE) NEFTPCH?

UPEDYOSAF DCHB LBTOYB, DMS RSFY NEFTPC DCHB LBTOYB RP DHB U RPMPCHYOPK NEFTB. uFSHL LBTOYPCH OE CHYDOP FPMSHLP CH UMHYUBE LPZDB KHUFBOBCHMYCHBAF RPFPMPYUOSCH LBTOYSHCH, DELPTBFYCHOBS OBLMBDLB NPTSEF VSHFSH RTBLFYUEULY MAVPZP TBNETB.

PUFBMYUSH PFCHETUFYS ABOUT UFEOE PF UFBTPZP LBTOYB, NPTsOP KHUFBOPCHYFSH OPCHSHCHK LBTOYYURPMSHJHS UFBTSHCHE PFCHETUFYS?

dB NPTsOP, LTPOYFEKOSCH ABOUT LBTOYBI HUFBOBCHMYCHBAFUS ABOUT RTPYCHPMSHOPN TBUUFPSOYY. rTY LFPN KHYUFYFE, YuFP EUMY TBUUFPSOYE NETSDH PFCHETUFYSNY 2.0 NEFTB, FP OHTSEO LBTOY DMYOOPK 2.5 NEFTB. dMYOB LBTOYB Y TBUUFPSOYS NETSDH FPYULBNY LTERMEOYS TBOSCH CHEY, TBUUFPSOYE NETSDH FPYULBNY LTERMEOYS NYOINHN ABOUT 10 UN. UNOSHYE TBNETB LBTOEB.

OE VKhDEF NEYBFSH FTHVB PFPRMEOYS CH LCHBTFYTE RTY KHUFBOPCHLE LBTOYB ?

Tire cornice: types and installation features

Curtains are an important element of every room, but to hang them in the right place, you need to use a suitable curtain rod. Today on the product market it is easy to choose a cornice of the desired design for various types of curtains. Particularly popular at the present time is this type of cornices, such as the ceiling rail. This is a rail-type cornice in the form of a plate that is attached to the ceiling. The curtains are attached to the tire using special hooks that are threaded onto the runners of the tire. You can hang various types of curtains on such curtain rods, but Italian, Austrian, French, Roman and Japanese curtains are best combined with them.

Expert opinion

Galina Peremyshlnikova, sales manager for ceiling cornices at OLEXDECO.

Ceiling plastic cornices are the choice of those for whom the priority is the comfort and simplicity of window design, rather than its decorative qualities. If our clients voice such requirements, we primarily recommend ceiling “tires”.

The main advantage of a plastic tire curtain rod is its modest dimensions. Thanks to them, it is the best option when you need an inconspicuous cornice (with a low room height, for the effect of “curtains from the ceiling”). The slats are made of lightweight PVC, which has an optimal balance of flexibility and strength and can withstand the weight of even heavy curtains. Installation of the “bus” is available to everyone (“+” possibility of mounting to the wall).

And the most important circumstance for the buyer is that ceiling rail curtain rods have the most affordable price compared to other types of window decoration (forged metal and profile curtain rods, roller and Roman blinds).

Niche in a suspended ceiling under a cornice - Video

By carefully following the instructions, you will be able to make the draperies hanging in front of the window a true decoration of your interior.

Source postroiv.ru

Diana Smetanina, manager of the sales department for ceiling cornices at OLEKSDEKO her professional recommendations

on how to choose a ceiling cornice for windows .

Tip number 1 - figure out what kind of cornice it is

Tire type curtain rod

What is a tire-type plastic ceiling cornice? This is a flat profile made of plastic with internal cavities (curtain tracks) along its entire length. Special roller hooks are placed in the cavity, from which the curtain is hung. The roller part of the hooks will allow them to move smoothly along the curtain tracks, which makes moving the curtains easy and safe (primarily for the fabric). To prevent the hooks from falling out of the grooves and the curtain from “moving” off the “tire”, its end parts are closed with special plugs.

Tip No. 2 – find out what type of tire curtain rods you need

Ceiling “tires” differ according to two main criteria:

- number of available curtain rows

. You can find PVC profiles with up to 5 rows. However, the most common are single-row (for light curtains), two-row (classic composition “tulle + thick curtains”) and three-row (for complex curtain compositions); - the presence or absence of a special groove for the decorative strip

. If there is such a gutter, you can place a strip on the front of the plastic cornice that covers it.

Tip No. 3 – consider the advantages of ceiling tires

Pay attention to the advantages and decide how important it is for you to use these “bonuses”:

- adequate cost

- based on the “price per meter”, plastic cornices are the most affordable option (compared to forged cornices and aluminum profiles). Especially when we are talking about domestically produced goods. There is no special secret here - PVC is cheaper than metals; - excellent balance of strength and lightness

- plastic slats are designed to withstand the load of medium-weight curtains (it is better not to use heavy curtains - an extra risk). They can be used in traditional multi-row window design for the hall. And their own insignificant weight of the “tires” allows them to be attached to decorative coatings. The best option for a stretch ceiling. The result will be not only reliable and safe, but also beautiful: due to the “recessed” hidden cornice, you will get the effect of a “curtain from the ceiling itself”; - versatility

- thanks to the properties of plastic, bus systems can be installed in almost any room. These products are not afraid of high humidity, grease particles, strong odors - a good solution for decorating windows in the kitchen. “Tires” are not afraid of strong temperature changes, from low winter to high summer - they can be effectively used for placing curtains on balconies, verandas, and loggias.

Tip #4 – Don’t forget about the shortcomings

Plastic curtain rod

Let’s clarify – not “about shortcomings”, but about shortcomings. The plastic ceiling cornice has only one serious drawback - it cannot boast of a spectacular appearance. There's nothing you can do about it. The strengths of this curtain rod are practicality, accessibility, ease of installation and use. It will not work to use the “tire” as a decorative element of the decor; it is simply not created for this purpose. In a luxurious interior with an abundance of antique accessories, it will look, to put it mildly, strange.

Tip No. 5 – provide an installation option

Installation of plastic cornice to the wall

The main way to install the “bus” is, of course, ceiling-mounted. It is provided for by the design itself: the profile has holes through which it is attached to the ceiling using self-tapping screws and dowels. But, if for practical (uneven ceiling) or aesthetic (design features) reasons you need a wall mount, don’t hesitate to give up the plastic profile. It can also be wall mounted. To do this you will need a metal wall bracket and a mounting plate. The plate is screwed to the top of the “bus”, the bracket is mounted on the wall, they are connected - the cornice is ready for use.

Tip #6 – Use Additional Features

The main function of the ceiling cornice is the convenient placement of curtains and the comfortable movement of curtains along it. However, the “tire” has hidden potential - and if you use it, you can solve problems that cause a lot of difficulties when decorating the interior. For example:

- the ability to create a cornice of unlimited length

- for this it is enough to use connecting elements that will join individual plastic strips. A simple and practical way to decorate large windows with curtains; - installation in an extremely small gap between the window opening and the ceiling.

The vertical size (thickness) of ceiling rails usually does not exceed 2 cm - this is the optimal way to place curtains in a limited space between the window and the ceiling; - creating curtain compositions for rectangular bay windows

is possible thanks to the use of special corner rotating elements. They not only connect two rails at an angle of 90 degrees, but also ensure free movement of the curtain fabric along the entire contour of the curved cornice.

Tip #7 – Consider the price of a specific product

As a manager working directly with clients, I have to deal with the following situation. The buyer saw a suitable model of ceiling cornice in our online store, remembered its price and contacted me to complete the purchase. After finding out all the parameters of the product needed by a specific client, I name the final cost - and it suddenly becomes “too expensive” for him.

It is only later that it turns out that the price stored in the buyer’s memory refers to a different tire model. To avoid such misunderstandings, it is useful to understand in advance what the cost of a ceiling cornice consists of:

- manufacturer

- so, a German-made PVC profile is of high quality. This “tire” will last longer and can be used with more massive curtains than Russian or Chinese ones. Accordingly, its “price tag” will be more expensive; - number of curtain rows

- I believe there is no need to explain for a long time that the cost of a three-row curtain rod will be higher than that of a two-row or single-row model; - length

- oddly enough, it is this moment that most often becomes the cause of misunderstanding. There is nothing complicated about how to choose the size of a ceiling cornice. But the buyer does not pay attention to the fact that the price is for a product of one size, but he needs a product of a different length. Obviously, a 4-meter long “bus” will cost more than a 1.5-meter “tire”.

I hope these tips will help you appreciate all the advantages of ceiling plastic curtain rods and choose the best option for your curtains and windows.

Ask questions in the comments below or by email. Subscribe to our newsletter. Good luck to you and good luck to your family!

Source chonemuzhik.ru

In this article we will tell you how to assemble a ceiling cornice, adjust it to size and install it in place. And also about how to choose and decorate it. With this information, you can easily solve this problem from start to finish.

Installing a cornice on the ceiling is one of the most preferred solutions

Features of choosing a ceiling tire

When purchasing ceiling cornices, you must take into account the following rules for decorating openings with curtains:

- You must immediately think about how many curtains or curtains this curtain rod is intended for in order to choose its correct width.

- If the room has low ceilings, you cannot use a wide curtain rod, but for rooms with high ceiling heights it is best suited.

- To visually expand a small window, it is necessary to use a tire with a length 50 cm greater than the width of the window; if the window is too wide, it should be the same in length as the width of the window.

- When determining the length of the cornice, you need to take into account the width of the caps at the edges.

- The color of the tire can be matched to the color of the curtains so that it is less noticeable, or you can buy a tire of a standard color, and then paint it in a suitable color or cover it with a special decorative tape - a hood.

How to connect a cornice from two parts

How to install curtain rods

1 Choosing a curtain rod

In glass telescopic cornice

| This small section cornice is attached to the window frame. It is threaded directly into the holes in the curtains. This cornice, made of metal or plastic, has a round shape and, as a rule, adjustable length. |

Main features of installing ceiling rails

- Before starting installation, it is necessary to check the evenness of the base, that is, the ceiling. If the ceiling is uneven in at least one place, the perfectly flat surface of the tire will not adhere tightly to it, and this defect will be very noticeable.

- Installation should always begin by marking the working surface for fastening the tire.

- The standard length of the cornice is 3 m. If necessary, you can cut the required piece with a special hacksaw or a stationery knife. The edge of the cut must be sanded so that the cut point is not visible. If you need a longer cornice, then use two pieces.

- The tire is fastened to the ceiling using holes made in it by the manufacturer, using a standard step of 0.5 m. This fastening will support almost all types of curtains, with the exception of heavy curtains. To increase strength, it is necessary to make additional holes in the tire and secure it more securely.

- Before fastening, you must first install the clamp and plug at one end of the bus, then attach the hooks to the runners and close the other end of the curtain rod with the same clamp and plug.

To install the ceiling rail, the following components are required:

- Cap - hides the internal parts of the cornice on the sides.

- Latch – limits the movement of the curtain in the plane of the cornice.

- Rotation - makes it possible to round the end of the cornice towards the wall.

- Hooks - curtains are hooked onto them.

- Decorative buttons – hide installation locations.

- Decorative tape – serves as a decorative element for the side parts of the cornice.

- Screws and dowels - hold the tire to the ceiling.

Accessories for curtain rails

Ceiling rails will be an excellent solution for any room. Simplicity of installation, strength, reliability and stylish appearance will conquer every person who uses this type of cornice in the interior of their home.

Fabric selection

It is better to choose the material of two-color curtains based on the following factors:

- the area of the room and its purpose;

- apartment design style;

- fabric pattern;

- texture of the canvas;

- presence/absence of light transmission.

Room style

In apartments decorated in a luxurious style, the best option would be to use curtain materials such as organza, satin and velvet. The main thing is that the fabric should not be see-through.

If the room is decorated with modern colors and fashionable prints, the canvas will look disharmonious among them.

Provence/country style goes well with cotton curtains. And the pattern is geometric or delicate and floral.

You can also use the following trick: if there are a lot of bright colors in the room, then curtains of a similar range, but in softer and more delicate shades, will most likely fit in. This creates contrast.

Purpose of the room

- For the bedroom it is better to choose natural and lightweight material. Silk and linen are good choices; products made from them are breathable and weightless.

- For a large room, it is more appropriate to use dense fabrics: acrylic, cotton, blackout and wool.

- For a small living room, thinner fabrics would be preferable: silk, viscose, linen.

- For the kitchen, it would be wiser to choose an easy-to-clean fabric. This includes linen, chintz and polyester. Another plus is that it takes very little time for the canvas to dry.

How to install a plastic ceiling cornice? Secrets of a cozy and comfortable interior

Practice proves that most problems arise in cases that initially seemed extremely simple. Installation of a ceiling curtain rod confirms this observation. Ease of assembly and fastening is one of the main motives when choosing a plastic curtain hanger https://olexdeco.ru/catalog/gotovye-karnizy-dlya-shtor/potolochnye-plastikovye-karnizy/. But if you don’t follow a few basic rules, decorating a window niche risks becoming a real headache.

You can avoid a threat to your interior, budget and peace of mind. It is enough to remember a simple procedure on how to hang a plastic ceiling cornice. And it’s best to start with an idea of the structure of this product:

- the basis is a plastic profile strip with an internal groove for curtain hooks;

- to limit the movement of hooks, blockades are used as necessary, as well as end caps along the edges of the “tire”;

- individual profiles can be fastened with connecting elements; decorative facade strip;

- rotating parts that serve as a corner intermediate link between two cornices.

Why plastic profile cornice is the right choice

We have already discussed the simplicity of the device and assembly. What other advantages of installing a ceiling cornice incline in favor of this option for window decoration?

- Possibility of hanging several curtains while saving space. The profile has several versions - with one, two, three runners for rollers. In this case, the width of the bar itself changes by only a few centimeters. While maintaining the usable area of the room, you can create various combinations of curtains. A single tulle curtain, a traditional composition of two curtains, or a complex ensemble of several curtains are a great option for all of these versions.

- The optimal combination of lightness and strength. The thin plastic “board” is almost weightless. Especially in comparison with other types of curtain holders, primarily metal ones. The low weight allows the profile to be used in combination with “capricious” surfaces - stretch ceilings, plasterboard walls. At the same time, the structural features of the profile allow it to withstand significant weight. If you want to use curtains made of massive dense materials, you don’t have to limit yourself.

- Universal fastening method. Sometimes the final decision on how to hang a ceiling curtain rod comes at the last moment. For some reason, wall mounting of the “bus” may seem preferable to ceiling mounting. Most often this is due to the reluctance to violate the integrity of suspended ceilings. Profile systems provide such freedom of maneuver; for the wall version, it is enough to use a bracket.

- Affordable price. This trump card completes our list, although for most buyers it comes first. Repairing and creating a harmonious interior is an expensive pleasure. If there is an opportunity to reduce costs without losing quality and reliability, you should definitely use it. The plastic profile system provides this opportunity.

Beauty and solidity require preparation

You need to think about how to hang a ceiling cornice on a ceiling or wall even before the “pick up a hammer drill” stage. The profile should fit snugly to the base plane. This ensures the attractive appearance of the window design and the reliability of its fastening. Therefore, the surface to which the “tire” is mounted must be strong and level. If the quality of the monolithic plane, brick or cement, is of normal quality, there should be no problems with these parameters.

Plasterboard walls and suspended ceilings are geometrically flawless. But the reliability of mounting additional structures on them is a big question. Over time, the added weight of the cornice can deform the base surface or even fall out. The best solution is to attach a mortgage, that is, a thick board, to a monolithic plane. It is better to do this in advance, before arranging the surface of the walls and ceiling. It is to the mortgages that the profile curtain hanger will be screwed. This is the only way to avoid increasing the load on decorative materials.

Accessories for curtain rods

Then you should pay attention to wall products. Such devices are a rod or pipe. The material from which the products are made: natural wood, metal or plastic.

The main advantage of the presented option is the ability to match the color of the curtain fabric to the color of the rod. How to choose a cornice? First of all, pay attention to the weight of the curtains. If you prefer long curtains, the plastic option should be excluded immediately. A good choice is a metal product.

Installation: instructions for use

Before installing the cornice, you need to familiarize yourself with the characteristics of the material from which the walls or ceiling are made. Installation of string, round, profile or rail products begins with marking the ceiling or walls. To carry out the work you will need dowels and screws. First, see if the cornice will interfere with the window.

Check to see if there are heating pipes near the window. Make markings using a level. The distance between the edge of the window and the bar should be equal. Next comes the installation itself:

- for a metal product - 3 self-tapping screws;

- for plastic or wood - for 1 dowel and 1 self-tapping screw.

You will need to drill a hole in the wall for the dowel and install the dowel itself into it. Next, the bracket is secured with a self-tapping screw. The second bracket is attached in the same way. The rod is fixed. Curtains are placed on the edge of the rod.

Don’t know how to install a ceiling curtain rod if the ceiling is made of plasterboard? Installation work is carried out in the same way as described above. In this case, special fastenings are used - “molly” dowels and “butterfly” dowels. The “spreading wings” feature of the presented dowels facilitates reliable fastening in plasterboard or plastic panels. For wall installation, the load can be up to 8 kg, and for ceiling installation – 5 kg.

Useful video

Useful tips

Before installing a ceiling cornice, you should familiarize yourself with some rules.

The device must be 40 cm larger than the width of the window. The distance between the product and the window is 5 cm. This is the only way the window will open without any problems.

How to connect two round metal cornices along the length?

In our private house we have a room 6.5x4m, in which there are two windows on the long side and we want to hang one full-length cornice, since curtains on each window separately do not look original. We are planning round metal cornices and need advice on the question: How to connect two round metal cornices along the length?

There are a lot of options, we need to know whether the curtains will “run” along the entire length of the cornice, that is, the place where the pipes connect should not become an obstacle, or are there options?

You can put a clamp like this in the area where the pipes connect

You can install a holder for a curtain rod in the area where the pipes connect.

And in my opinion, the best option is to connect the pipes using an ordinary round stick.

We find out the internal diameter of the pipe, select a stick (for reference, this is a shovel handle).

We drive it into one part of the pipes (tightly), but leave the same part of the “handling” on the “street” (the longer the stick, the stronger the entire cornice).

That's all, the wood is tightly packed inside the pipes, there is no seam, there are no obstacles to the movement of the curtains, the seam (joining point) is practically invisible.

I advise you to first attach the pipes with the ends; if necessary, adjust the ends with a grinder.

The answer suggests itself! If the cornices are metal and round, then they can be connected with a metal rod or a pipe of the appropriate diameter, which must be inserted tightly inside!

You can select it or make it yourself, for example, from an aluminum pipe of a suitable diameter or even a plastic one, or you can buy it in a store, if they have them, of course, since they are quite rare and sellers rarely order them for sale!

The factory connector looks like this, you can make one in its likeness yourself!

I know a person who didn’t bother at all, but simply connected the cornices using a wooden mop holder, cut out the required diameter, tightly stuffed 15 cm into both cornices and everything is rigid and functional, and the main connection is flush and rings with clothespins.

Construction of cornice | JLC Online

Cape May, New Jersey has been a seaside resort since before the Victorian era, and the town has many homes in the architectural style of that period, as well as examples of many other styles. One feature that can be found in most of the older homes in the area is the cornice trim. We see this detail in elaborate Victorians, traditional colonials, Greek revivals and simple capes.

Cornice is simply a fancy word for the eaves detail at the edge of a building where the roof meets the walls, and in most homes it includes the soffit and fascia. When using cornice with eaves, a decorative layer of cornice is added to the fascia and the roof extends to the top corner crowns How to build such a facility can be a point of contention for many builders who incorporate historical details into the new buildings they construct.

Making a cornice rod begins with a life-size drawing of the details, including the height of the wall plate and the frieze board above the windows.

Our team is asked to add cornice moldings to almost every new home we build, and we have developed methods for creating them using modern building materials and efficient construction techniques. Last fall, clients asked us to build a modern farmhouse on a five-acre lot in a nearby town . My father designed a traditional style home that was in keeping with the architectural style of the area and had a large porch, tall windows, four steep gables, and traditional trim details including crown moldings.

Full scale layout

I've built quite a few houses with this detail, with different roof pitches and overhangs of different sizes, and I like to draw out the details before we start the roof framing. Before cutting the rafters, I make a full-size drawing of the eaves, including the roof pitch and all the details of the cornice, on a sheet blank (1). Using the blueprint, a piece of 1 x wide material representing the fascia, and a piece of crown molding, I can determine the rafter tail pattern, as well as the dimensions of the subfascia and crown lining.

I always indicate the height of the top plate and top rough window openings on the drawing. Many of the homes we build have a large fascia board that bridges the gap between the tops of the windows and the underside of the ceiling, and I

.

Connector for metal cornice.

Good afternoon! I bought a metal cornice in Leroy, like a tube with a diameter of 20. The tube is not round, but kind of twisted. I can't figure out how to install a connector between two tubes. The consultant says that inside. I can’t insert it either way – I’m afraid of deforming it. If you insert a smaller diameter - 16 - it fails. It may be suitable for a round tube, but not so for a twisted one (the diameter is uneven). I put it outside for now (maybe I’ll leave it like that), it’s ugly, of course, silver on gold, but it holds the structure rigidly. Either they haven’t made twisted connectors yet or I’m missing something.

The twisted pipe is probably only on the outside? But is it still round inside? their connectors fit quite tightly into the pipe, so take a 20mm connector and try to insert it into your curtain rod. First, you can measure the inner diameter of the hole, if you have something to do this with, of course.

In general, I am engaged in the construction of websites and online stores.

Not really. The pipe is twisted inside. the diameter changes. I'll measure it with a caliper this evening. In principle, you can leave it outside. It's purely aesthetics that suffer. In terms of rigidity, I think it's all the same.

numiz wrote: in terms of rigidity, I think it's all the same.

If the connectors are the same as for round cornices - made of hard steel sheet, then the rigidity will be different - it will work much worse on the outside!

In general, I am engaged in the construction of websites and online stores.

Pekkonen wrote: If the connectors are the same as for round cornices - made of rigid steel sheet, then the rigidity will be different - it will work much worse on the outside!

Cornice like this » > end -» > [smooth-twisted-pipes-on-cornice-buy]/ Connector like » > Measured it. the diameter varies from about 17 to 18 and the connector is made of a rigid steel sheet (by design, it should go inside. I just think maybe the twisted ones haven’t been delivered yet, although the consultant assures that they will go inside, he can’t explain how) two tubes of 1.4 m each on 3 holders " >

- one in the middle. Only tulle will hang. one at 3 m or two at 3 m. I think a 3rd bracket, which will be in the middle, is enough - a connector only of the type for fixing. I just don’t want the tubes to bend over time. You can, of course, crumple one 20 connector for testing.

Add length at the top of the curtains:

Fabric strip and eyelets

This method looks especially beautiful on tulle curtains. After all, to insert metal fittings on top, you need to “extend” the canvas with a denser fabric (matching or contrasting - the general style of the interior will tell you). And the combination of two such textures looks very impressive - it is a contrast in itself.

You can lengthen the curtains by adding a beautiful piece of fabric on top and adding eyelets

When inserting eyelets with your own hands, you should consider the following:

- this method of fastening involves raising the upper part of the curtain above the level of the cornice, so you need to correctly calculate its location above the window so that the fabric above it can be placed freely;

- In this case, the cornice should be round in cross-section, without additional hooks or clips;

- the fabric under the eyelets should not seem foreign. If the curtains have a pattern, it is desirable that one of its shades be repeated in the added fabric. Or a contrasting color was chosen to match the main curtain.

Sew on fabric loops

The same cornice will be needed to sew fabric loops along the top of the curtains instead of eyelets. They can be stitched into a ring or fastened with a button or Velcro tape. In this case, it is good to decorate the loops with additional decorative braid or bows, which are also quite easy to make with your own hands. Or simply sew ropes that tie onto the cornice. The length of the loops should just compensate for the missing length of the curtains.

Extending curtains in three ways - loops, inserting fabric from above, inserting from below

Add a lambrequin

Another option is how you can lengthen the curtains at the top of the canvas. It is believed that a lambrequin can only visually stretch the curtains. However, you can cheat here too. Fix the curtain rod directly above the window opening (if the curtains are long enough in this position), and hang the second curtain rod, for the lambrequin, 10 centimeters higher - it will cover the upper border of the curtains themselves, and the ensemble will form an overall elongated composition.

Curtains can be seriously transformed by setting the goal of lengthening them

Well, now - several ways on how you can lengthen short curtains or tulle at the bottom with your own hands.