With the onset of cold weather, a thrifty owner strives to escape the cold without causing significant damage to the family budget. Let's look at how to seal old wooden windows for the winter. All methods are aimed at doing it yourself at home using improvised means and inexpensive insulation materials.

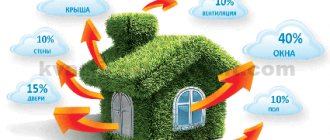

According to thermal photographs of houses, a significant part of the heat leaves the room through walls, windows, doors, and roof. Insulating these units allows you to increase the heat-saving properties of the house. However, complete insulation is an expensive task, plus it is not always possible to do it yourself.

But sealing the windows for the winter is a relatively simple and easy-to-implement measure that anyone can do, and the effect is confirmed by an increase in the room temperature by 2-4 °C, depending on the chosen method of insulation.

Materials for insulating windows for the winter

10 ways to seal your windows for the winter

Summarizing the experience of previous generations, you can write an entire encyclopedia on the topic: how to seal the windows to prevent the draft.

Let's consider proven and affordable methods of insulation, for ease of comparison, arranging them in the form of a rating, in ascending order of the cost of performing the work:

Window paper

More precisely, paper putty. This is the cheapest method, since all you need to seal the windows is a selection of old newspapers and water. To increase the effectiveness of the putty, you can add 2 parts of crushed chalk or 1 part of clay to it. The resulting mass is highly plastic, which makes it easy to seal even the smallest cracks. The window can be easily washed off the putty during operation (as long as it remains wet). Insulating windows with paper is an effective way, but only for one season; in addition, a covered window does not make it possible to open the sashes in winter. As the weather gets warmer, the putty is removed from the cracks and the window is washed.

Cost : 0 rub.

Pros : free and simple.

Disadvantages : the need to repeat the work annually, there is no way to open a sealed window, it is not aesthetically pleasing and the presence of additional decor in the form of gluing paper or fabric strips.

Description

A special place in the Klebhemi production program is occupied by high-quality adhesives for the production of building structures, including window blocks and doors.

Wood is a raw material traditionally used in construction. It is environmentally friendly, provides a high degree of thermal insulation, comfortable air temperature, and coziness. That is why it is the most common material for the production of windows and doors. The European quality of manufactured windows and doors is ensured by many factors, among which one of the first places is occupied by the glue used. According to European standards for products exposed to weathering, only adhesives of load group D4 with high water and heat-resistant properties are applicable. For products used indoors, the use of adhesives of load group D3 is allowed. Testing of adhesives according to the degree of load is carried out based on the requirements of European standards EN 205. The most used adhesives for the production of wooden windows and doors are the following adhesives of the KLEIBERIT brand:

| Name | Recycling | Application area | Recommendations for use | Note |

| LIGNUM 301 | from 15 оС | Gluing hard and exotic wood, plywood, laminate. | Wood moisture content is 8-14%. Application using glue-applying devices. | D3 |

| KLEIBERIT 303, LIGNUM 303 | Gluing hard and exotic wood, plywood, laminate. With hardener KLEIBERIT 303.5, bonding quality D4 is achieved. | D3/D4 | ||

| KLEIBERIT 304 | Gluing window beams and tenon joints. High frequency bonding. | Long viability up to 5 days. Elastic, tool-friendly adhesive seam. | D4 | |

| KLEIBERIT 501 | Waterproof and heat-resistant adhesive joint with D4 bonding quality. Bonding of synthetic, wooden and mineral materials | Application by brush, spatula and hand roller. The free space is filled due to the foaming of the glue. Devices are cleaned with solvent. | D4 |

Paper tape or fabric strip

The fastest way to eliminate a draft. You can’t count on significant insulation, but the work can be done quickly and at minimal cost.

Approximate price : 100-130 rubles/roll, strips of fabric (used material).

Advantages : cheap, high speed;

Disadvantages : minimal efficiency, tape peeling off in a draft.

How to seal windows with soap and paper (toilet) - video

Why is it important to choose the right product?

Wooden window blocks maintain the best microclimate in the house, while recreating a harmonious and rich interior. However, prolonged use of such windows leads to cracking of the wood and the appearance of cracks, which contribute to the loss of the heat-saving ability of the window.

In order to retain heat in the apartment and not spoil the appearance of the window, you will need to choose the right material for insulating wooden blocks. Experts recommend carrying out such work immediately after identifying defects.

An owner who chooses high-quality multi-seasonal insulation will protect not only the house from drafts, but also the tree itself; such a window will last a long time, without requiring expensive frame restoration work.

Cotton wool or foam rubber for windows

Technical wool is cheaper, but it is sold in large quantities.

Using cotton wool or foam rubber, you can seal large gaps, for example, between window sashes or a sash and a wall or window sill. The cotton wool/foam rubber must be sealed on top with paper tape or special tape, because It is difficult to seal small cracks with cotton wool. In this case, the paper tape will serve not only a decorative function, but also increase the efficiency of insulation.

Average cost : cotton wool (50 rubles/200 g), foam rubber (30-35 rubles/skein).

Advantage : simplicity and lack of wet work.

Disadvantages : the cost of insulation increases (+ the price of cotton wool or foam rubber), additional finishing of the insulated seam is required. In addition: cotton wool and foam rubber absorb moisture, the work must be repeated annually, and a sealed window cannot be opened for ventilation.

How to cover windows with newspaper for the winter - video

Tips for choosing

Before the start of the heating season, all wooden windows must be inspected for the technical condition of their frames and glazing.

The choice of material for insulation will depend on the result obtained: seasonal or multi-season option, external or internal.

Outside

If multi-season seals are already installed on the windows, you only need to seal the windows under the glazing beads, then ordinary external putty or sealant will do for this. These materials are also used if you need to temporarily protect windows for one season, for example, before major repairs to frames and installation of multi-season seals.

You need to choose seals by color and profile:

- for large cracks - D, 11 mm;

- medium backlash - P, from 3 to 7 mm;

- small cracks - E, V up to 3 mm;

- minimum gaps - C, I up to 1 mm.

From the inside

Internal frame protection is almost always seasonal; the choice of material depends more on cost, application, functionality and appearance.

The most functional and multi-seasonal are seals; such windows can be opened, but they are also more expensive. Next in the rating is acrylic sealant; it is applied at the joints of the glass and the frame.

If you need to protect large gaps in the wooden base of the frame, it is better to use a special wood putty that can be painted and can protect the window for more than one season.

Self-adhesive foam for windows

A more technologically advanced way to seal windows and combat drafts. This method is good because it allows you to do without sealing the cracks with paper or fabric strips. Due to the presence of adhesive (adhesive) tape on the foam rubber insulation, it can be glued to the inside of the window sashes.

Approximate cost : 60-75 rub./roll.

Pros : the window can be used as usual.

Cons : after gluing, the insulation can prevent the window from closing; foam insulation is non-hygroscopic and is not protected in any way. If the sashes fit tightly to the frame, you need to either saw down (cut, adjust) part of the wood, or choose other methods of insulation. If the gaps are large, you will have to decide what can be used to seal wooden windows besides this material.

Foam rubber for windows with an adhesive layer (foam rubber seal)

Material requirements

Despite all the advantages of wooden windows, they do not meet modern requirements for energy efficiency and heat conservation, so they need to be additionally protected from heat loss.

This does not frighten their owners, since over a long period of operation of such blocks, dozens of options for their insulation have been developed, which make it possible to qualitatively seal all the cracks that could potentially become “cold bridges.”

Materials for sealing and thermal protection of wooden frames can be solid, liquid or paste. According to SNiP requirements, all heat-protective materials must have the following characteristics :

have the necessary plasticity to fill even the smallest gaps;- environmentally friendly;

- harmless to human health;

- have a fairly rapid polymerization and hardening process;

- climate resistant;

- be moisture and frost resistant;

- work in the temperature range from -40 °C to +60 °C;

- be heat resistant;

- be resistant to ultraviolet radiation;

- Compatible with paint and varnish coating on the wooden surface of the window.

Self-adhesive window seal

Most owners of old wooden windows prefer this type because of the optimal price/effect combination. The rubber seal is glued to the inside of the window sash. Due to the fact that the seal is hollow, it does not create problems when closing the sash. It adheres well to the frame due to the adhesive strip, which opens when glued. The seal lasts 1-2 years.

Average price : 84-100 rub./roll.

Advantage : longer service life, window operation mode is not affected, aesthetics.

Disadvantages : cost, labor intensity, you can install a low-quality seal (many fakes), the likelihood of the seal coming off the frame.

Features of insulation of plastic windows

There is no point in sealing new plastic frames - they have sufficient tightness. However, over time, the mechanisms become loose and the seal becomes unusable. What methods will help you determine where the cold air is coming from:

- raise your hand and feel the cold currents;

- candle - the flame will be visible;

- paper - the sheet, due to its light weight, will move if it is brought to a draft.

There are not many reasons, most often - poor-quality installation, shrinkage of the house or wear of the sealing rubber bands. An important condition is insulation from the outside. This is done with plaster, polyurethane foam or polystyrene foam. Blowing around the entire perimeter indicates that it is time to change the entire seal.

Attention! It is advisable to entrust the insulation or replacement of the seal to professionals, since poor quality work will again lead to heat loss. Carrying out sealing yourself may impair the functionality of the structure.

Construction putty for windows

Allows you to seal the glass seat. First you need to remove the old putty or glazing bead, apply a new compound, level and paint or cover with glazing bead and paint. In this case, the putty is applied in a thinner layer, which reduces its effectiveness.

Approximate cost : 30 rubles/pack.

Advantage : relatively cheap putty, hygroscopic.

Disadvantages : labor-intensive work, the need to periodically renew the putty. Does not allow protection against blowing between the frame and the sash.

Classification of adhesives

Adhesive connections must comply with the DIN EN 204 standards described below:

| Load group | Examples of climate conditions and applications |

| D1 | Indoors, the temperature can exceed 50 ° C only for a short time, wood humidity is up to 15% |

| D2 | Indoors with short-term exposure to running or condensed water and/or increased air humidity for a short time |

| D3 | Indoors with frequent short-term exposure to running or condensed water and/or increased air humidity for a short time. For outdoor use with protection from prolonged exposure to weather conditions. |

| D4 | Indoors with strong exposure to running or condensed water and prolonged exposure to high air humidity. Outdoor bonding is subject to all weather conditions, however, if possible, with an appropriate protective surface. |

Certification of adhesives for load groups D1, D2, 03, D4 is carried out based on the results of special testing of glued parts

Requirements for adhesive strength and test:

To assign an adhesive to the appropriate load group, see the table above, all requirements for the strength of the adhesive joint (N/mm2) defined below must be met:

| Item no. | Storage conditions and duration | D1 | D2 | D3 | D4 |

| 1 | 7 days1) in normal climate2) | ≥ 10 | ≥ 10 | ≥ 10 | ≥ 10 |

| 2 | 7 days in normal climate, 3 hours in cold water3), 7 days in normal climate | ≥ 8 | |||

| 3 | 7 days in normal climate, 4 days in cold water | ≥ 2 | ≥ 4 | ||

| 4 | 7 days in normal climate, 4 days in cold water, 7 days in normal climate | ≥ 8 | |||

| 5 | 7 days in normal climate, 6 hours in boiling water, 2 hours in cold water | ≥ 4 | |||

| 6 | 7 days in normal climate, 6 hours in boiling water, 2 hours in cold water, 7 days in normal climate | ≥ 8 |

1) - 1 day = 24 hours 2) - (23±2) °C - temperature, 65±5% - relative humidity 3) - water must have the same temperature, 20±2 °C

Adhesive testing is carried out based on the requirements of DIN EN 205 and compliance with the following conditions:

• Testing is carried out on samples with a thin adhesive line. • At least 20 samples are tested. • Each result is taken into account separately, as well as the average result.

Window sealant

This method involves applying sealant to the junction of the glass and the seat. Before starting work, the window must be washed and degreased. When applying, try to squeeze out the sealant with equal pressure to ensure a beautiful sealed seam.

Average cost : 200 rub./pack.

Advantage : speed of the method.

Disadvantages : insulation costs increase due to the cost of the sealant and the gun for it, does not eliminate blowing through the frame.

Review of the best products for wooden frames

There are many ways to protect against cold weather: using simple paper and soap, fabric, cotton wool, foam rubber, sealant and special seals. It all depends on desires and capabilities, but even expensive products do not guarantee 100% results. It is better to resort to proven and accessible methods.

Paper and soap

The most popular “grandmother’s” method, which everyone is familiar with. Simply cut long strips of paper and then stick them onto the frames using soap. Previously, it was replaced with a paste made from flour or starch, since there was no desire to spend money on a soap solution. How to glue paper to windows:

- put laundry soap in hot water and leave until softened;

- generously lubricate the strips with the soaked part;

- Cover the wooden frames with paper in the area of the joints.

After drying, the paper becomes dense and almost impervious to cold air. The main advantage is that the strips come off easily in the spring; after washing with warm water, no traces remain on the paint. However, in winter, the paper can also come off, especially if condensation forms on the glass.

You can replace paper with strips of cotton fabric. It is advisable to grate the soap and dissolve it in a small amount of water to obtain a good solution. You need to dip the cut pieces into it and glue them. Make sure that the material is well moistened with the product.

Masking tape

Those who are not satisfied with the option with paper and soap can be advised to pay attention to masking tape. An adhesive composition is applied to one side, which significantly facilitates the task of insulation. There is no need to cook the paste or lubricate the strips with soap - the tape can be immediately glued to the frame, after first cleaning the surface of dirt.

The disadvantage of pasting is the difficulty of removing the adhesive tape, because the adhesive tape firmly adheres to the paint during the winter period and then breaks off in pieces. If the “grandmother’s” method of protecting against drafts does not require money, then you will have to spend money on masking tape.

Note! Do not try to rip off the tape abruptly - it will come off along with the paint. You need to heat the tape with a hairdryer and pull it, and sticky stains from it can be easily removed with gasoline and white spirit.

Sealing with cotton wool and foam rubber

It is useless to seal large cracks with paper or cloth; cold will still flow through them. You can use technical or pharmaceutical cotton wool, following the instructions:

- tear off small pieces of cotton wool and use them to seal the cracks between the sashes, under the window sill, between the wall and the window frame;

- lay the cotton wool as tightly as possible using a knife or spatula;

- Be sure to seal the sealed cracks on top with paper, cloth or masking tape.

The tape pasted on top not only performs a decorative function (hides the cotton wool), but also creates additional protection. The disadvantages of this method are the time spent on work and money on materials. In addition, the sealed sash cannot be opened for ventilation, so it is better to leave the window without insulation.

Self-adhesive seal

An effective and cheap method that protects against drafts for at least one year. With careful use, the service life can be extended to two years. The rubber seal is glued with the sticky side to the inside of the sashes. It does not interfere with closing due to the fact that it is hollow. There are several disadvantages:

- labor-intensive and the need to properly prepare the frame (degrease);

- cost (from 100 rubles per roll);

- high risk of peeling off if technology is violated.

A high-quality seal does not spoil the aesthetic appearance of the window, lasts a long time, and allows the room to be ventilated. It is necessary to study the instructions before use so that the material does not come off.

Sealant

There are modern methods and one of them is sealant. It is necessary if cracks have formed at the junction of the glass and the wood. Before starting work, be sure to wash the windows, dry them well and degrease them. The tube is inserted into the gun and the spout is cut along the line. You must coat it carefully, controlling the pressure, otherwise the sealed seam will be unsightly. Thanks to the thin spout, the putty is easy to apply even in hard-to-reach places. Despite the relatively high cost of 200-300 rubles (when compared with other methods), the sealant has many advantages, the main one being that the material is quickly applied and hardens.

Additionally, you need to invest in a sealant gun. The material does not eliminate drafts in the frame area, so you should remember how to seal the windows in this area.

Note! The sealant hardens “tight”; you need to work slowly. It is recommended to immediately wash off any material that gets onto the windowsill using a cloth soaked in gasoline. It is better not to rub the stained glass with a cloth, but to remove the sealant with a knife after it has hardened.

Paraffin

A quick and inexpensive method that will save you from blowing. The cost of a kilogram of paraffin is about 140-180 rubles. It must be melted and applied to small cracks in the wooden frame to prevent drafts in winter. The process is quite labor-intensive, and it does not eliminate large crevices. If they are, then you can use the following instructions:

- press cotton wool, rubber band or cord tightly into the cracks;

- melt the paraffin and put it into a syringe;

- squeeze the contents of the syringe into large cracks, generously pouring the inserted cotton wool or cord.

The method is very effective, although it requires a lot of time to implement. In addition, you will have to allocate a container for melting the wax, and cleaning it later will be problematic.

Heat-saving film

Another product designed to eliminate gaps between glass and frame. A special film reflects heat, directing it back into the room. The only negative is the high cost of the material. The price starts from 300 rubles per square meter; heat-saving film is sold in rolls of 1.5x30 m.

As in the previous case, it can blow between the sashes and under the window if these places are not covered. However, this is no longer done with film, but with another material: paper, fabric, tape.

Seal "Eurostrip"

Little is said about how to seal plastic windows, because their main advantage is their tightness. For certain reasons, this often happens, but not everyone knows how to deal with it. Modern insulation techniques are suitable for PVC windows. The Swedish Eurostrip technology involves inserting the material into special grooves. The most durable is considered to be the herringbone holder, which reliably holds the seal together without letting air through.

Eurostrip technology is expensive, but it guarantees protection against drafts for 20 years. The cost starts from three thousand rubles, depending on the condition of the frame and design features, the size of the block. The process is labor-intensive; few people can do it on their own; it’s better to call in specialists.

Other insulation methods

In cases where the windows are heavily drafted, there are large cracks in the wood or cracks in the glass, it is recommended to restore them. To do this, the glass is removed, the old paint is removed, the frames are washed, dried and re-painted or coated with protective impregnations. You need to paint wooden sashes before installing glass, paying attention to all places. Cracked glass should be replaced with new ones, and the junctions with the frame should be sealed with sealant. It is important to choose correctly what you can use to coat your windows, since the product must contain rubber or alkyd resins.

The window frame can also let in cold air, which affects the temperature in the house. For this reason, the gaps between the frame and the wall should be eliminated. In old houses, as a rule, builders placed rags and other weaving waste under the windowsill, which harbor pests. They must be removed and the cracks filled with foam.

We recommend:

How to remove a handle from a leather sofa at home

Deteriorating insulation on the outside of the window is a common cause of drafts. There is no need to do everything thoroughly, since the risk of damage to the frame is high. It is better to fill the gaps with polyurethane foam with low expansion. The cracks are often located under the flashing, on the sides or on top. Slopes may be a way out of the situation. After the foam has hardened, you should cut off the excess and paint it to seal it. If everything is done correctly, insulated wooden windows will last for several more years.

The last method is to cover the outside of the windows with transparent film. Yes, it’s not very beautiful, but it’s warm. This is often done in houses where the windows face the courtyard. Dense polyethylene is stretched and secured from the street with strips. The resulting layer of air between the street and the glass will prevent cold air from entering the room.

Thermal film for windows

Energy-saving film allows you to cover the junction of the glass and the frame, and also reflects thermal radiation in the infrared range. Thanks to this, part of the heat remains indoors.

Average price : 270-550 rub./sq.m. mainly sold in rolls of 1.52 x 30 m. (45.6 sq.m.).

Advantage : efficiency.

Disadvantages : high price of the film, drafts remain between the sash and the frame.

How to cover a window with film - video

What is the best way to insulate?

Once the user has determined the method of insulating wooden window blocks, he will need to select a specific brand of heat-insulating material.

It is better to do this taking into account the current ratings, which are compiled by large construction trading platforms in the country based on user demand. It is important to consider the area of application of the materials - outside or inside.

Outside

Rating of heat-insulating materials for outdoor wooden frames :

- self-adhesive rubber EPDM seal, D-profile, 12x10mm - 70 RUR/m.p.;

- self-adhesive rubber EPDM seal, P-profile, 9x5 mm - 35 RUR/m.p.;

- porous rubber seal, 10x15mm - 46 RUR/m.p.;

- self-adhesive thermal sealing tape, 2x10mm - 38 RUR/m.p.;

- self-adhesive thermal sealing tape, 8x30mm - 205 RUR/m.p.;

- fire-resistant rubber seal, self-adhesive E-profile, 15x8mm - 259 RUR/m.p.;

- self-adhesive PPE gasket, 48x48x10 mm - 3.50 rub./m.p.;

- colorless universal silicone sealant CMI, 260 ml - 145 RUR;

- colorless universal silicone sealant Soudal, 280 ml - 340 rub.;

- colorless universal silicone sealant Makroflex SX101, 290 ml - 500 rub.

From the inside

Rating of heat-insulating materials for internal wooden frames

:

self-adhesive PPE seal, 2×8mm - 3.90 RUR/m.p.;- self-adhesive PPE seal, 5×20mm - 10.20 rub./m.p.;

- self-adhesive paper tape, 50 mm x 20 m - 60 rub./pack;

- narrow foam rubber strips 14*14mm, 200 strips - 960 rub./pack;

- neutral transparent silicone sealant “Moment”, 280 ml - 400 rub.;

- putty COSMOFEN RM SP - 800 rub.;

- diffusion acrylic adhesive COSMOFEN PMMA 180 g - 600 rub.

- cyanoacrylate glue PENOSIL Premium 606, 20g - 86 rub.

Production of window beams

1. The following types of wood are most often used for the production of window frames:

- spruce

- pine

- fir

- oak

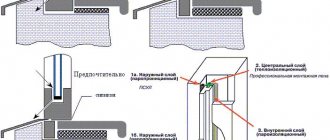

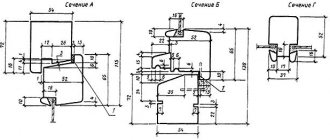

2. Wood moisture content in all types of wood should be from 8% to 10%. 3. Most often, 3 bars of 24 mm each with a total thickness of 72 mm are glued to produce a bar with dimensions of 72x88 mm (other sizes are possible). The bars located in the middle are often glued along their length using the tenon joint method. In order to save money, low-quality wood is usually used here. Only both external bars are always made of high-quality wood: without knots, cracks, etc. 4. Individual bars must be sorted according to growth rings. For the production of laminated veneer lumber, the location of the growth rings is of great importance: vertical or at an angle of 45°. Processing: cotter pin to cotter pin, or core to core. (The growth rings should be V-shaped after gluing.) If the growth rings are arranged chaotically, this may lead to a decrease in the quality of gluing. 5. Glued laminated window beams are checked according to 4 main methods: 5.1. Moisture resistance according to DIN/EN 204 Load group D4. To obtain this certification, the bond must pass the following test: 7 days in room temperature water, 6 hours in boiling water, 2 hours in cold water, 7 days drying). When testing for tensile strength, a minimum value of 8 N/mm2 must be achieved. 5.2. Heat resistance according to WATT 91. In this case, bonding is tested at various temperatures: +20°C, +40°C, +60°C, +80°C. In this case, the following requirement must be met: at a temperature of 80°C, the bonding strength must reach not less than 70% strength at 20°C. 5.3. Quality control of laminated window timber by the Rosenheim specialized institute. Samples 50 mm long are cut from glued timber and lowered into cold water (20°C). Then the same parts are placed in water heated to 60°C, and then in water at +20°C for 18 hours. After each placement in water, the adhesive joint is checked for any gaps or discrepancies. After 24 hours in water, the samples are dried at room temperature for 72 hours. When checking the adhesive joint, no cracks are allowed to occur. 5.4. Test of glued window timber STBA Samples of timber 50 mm long are placed in water with a temperature of 20°C for 72 hours. After this time, the sample is dried in an air circulation oven at 50°C. Here, only a maximum of 5% of open frontal wood joints is allowed.

6. Profiles used for window frames and sashes are milled from laminated window timber, manufactured in accordance with the above requirements.

Glued laminated timber is always processed in such a way that the glue seam in the finished product is located in a vertical position. Only in this case the adhesive joint is not exposed to direct, intense exposure to climatic conditions (snow, rain, etc.)

Preparing the frame for pasting

Before you seal the windows, you need to prepare them for this procedure. So, first you need to wash them thoroughly. This will allow you to better seal the window frames for the winter and help secure the result for a long time.

To thoroughly clean window frames, use ammonia-based products. The fact is that they do an excellent job of removing grease stains and do not leave streaks on the surface of glass and wood. You need to wash not only the glass, but also the frame and window sill. It is on this that the putty will be applied and a special window seal will be glued. When gluing seals to a dirty surface, they will not last even half of the declared service life.

In addition, if wooden frames are glued, make sure that their surface is as smooth as possible. If there are knots, try to carefully go over the surface of the frame with sandpaper.

Why seal your windows every year?

Old wooden windows are made from solid timber, which does not hold its shape, dries out, swells and warps.

Photo: up to 25 m3 per hour easily passes through the gaps in the old window (highlighted in red). By the way, this amount of incoming air is taken into account when calculating the operation of the hood in old high-rise buildings. But in winter it is cold air and you want to reduce its intake. However, the problem of ventilation lies not only in the old woodwork. Some plastic windows are not inferior to them in this and blow out so much that the curtains move. I think the owners of apartments in new buildings understand what I'm talking about. Windows from the developer are in most cases an economical option, made from the simplest profile, thin reinforcement, cheap sealant, and any kind of fittings. Here we save on everything. The consequences are predictable - blowing.

Over time, high-quality plastic windows can also leak - this problem appears in windows installed 20-25 years ago. The seal begins to dry out, the fitting settings are lost, and the window begins to gradually leak.

How to deal with blowing depends on the reason for its occurrence. For old carpentry these are one event, and for plastic windows another.

Most common mistakes

When choosing a method for covering windows for the winter and actually performing the task, many sometimes make a number of common mistakes. Thus, under no circumstances should you use window sealing products on unprepared and dirty surfaces. No matter how much you would like to spend time on this, just keep in mind that any insulation will come off quickly from dirty surfaces and you will have to repeat the entire procedure again.

In addition, you need to first assess the complexity of the situation and decide on the optimal material for your case. So, if the main problem is cracks in the wood, it is best to use a special putty. Taping and sticking tape will do little to get rid of this type of draft. To seal the perimeter of windows, it is better to use specially designed seals.

We hope the article helped you find the optimal solution for insulating the window frames of your home. If you still have any questions, we suggest watching the video on how to seal windows with your own hands:

How to seal windows for the winter: insulate plastic windows

Plastic windows are more resistant to drafts than wooden ones. However, some windows of this type also require some insulation work. This especially applies to old plastic windows. If they are blown out, it’s time to decide what can be used to seal fiberglass windows. In particular, let's figure out how to seal a plastic window frame for the winter.

It is obvious that radical methods for insulating windows are unlikely to be suitable for plastic structures. So, you will definitely have to forget about all kinds of putties, because they are only suitable for eliminating cracks in a wooden window.

The optimal materials for insulating plastic windows are all kinds of adhesive tapes and specially designed rubber seals. The latter make it possible to improve the service life of the product, as well as eliminate blowing in areas of the vestibule.

It is important that each window model has its own individual types of seals. Be sure to pay attention to this factor when purchasing such products.

Do plastic windows need to be sealed?

Whatever one may say, if a window unit is leaking, it’s definitely worth gluing it. And if it does not allow flows of cold air to pass through, then there is no particular need for insulation.

This decision must be individual. However, some owners definitely advise at least light insulation, in order to thus extend the service life of the structure.

Where is it blowing from: how to find cracks?

To find out if it is blowing from a plastic window, just hold a wet palm to it. If you notice any blowing, it’s time to deal with it.

In addition, you can use the old-fashioned method: light a candle and carefully bring it to different joints on the window. If the flame is even, there are no problems. The light “dances” or goes out completely - consider that a draft has been detected.