Waterproofing of an open balcony is done from the inside. Its purpose is to prevent the base plate and insulation material from getting wet. Closed structures can be additionally protected from the outside, this allows you to extend the service life of the fences and avoid precipitation from entering the premises.

Open balconies of private houses require high-quality waterproofing Source klub-masterov.ru

About the features of waterproofing

Balcony waterproofing scheme

A water-repellent and waterproof additional layer on the floor, ceiling and balcony partitions creates reliable protection against the destructive ingress of moisture.

Waterproofing is necessary regardless of the location of the balcony. For example, moisture gets onto the first floor balcony not only from the environment, but also from the basement. But the balcony on the middle floor of the house is threatened by leaks from neighbors on the top floor.

Properly performed waterproofing increases the service life of the balcony without major repairs, and also increases its comfort.

Balcony waterproofing technology depends on the following factors:

- type of balcony: open or glazed;

- location relative to neighboring balconies: next to or separately;

- balcony construction material.

On the open balcony of the top floor, the roof and ceiling must be waterproofed. If the balcony configuration is complex, liquid waterproofing is laid on the floor.

Before waterproofing a wooden balcony, all structural elements are treated with protective material, and natural ventilation is provided. Under the wooden floor there is a slope and a drain to the street.

Let's sum it up

For all types of insulation, it is correct to insulate the balcony ceiling by overlapping the wall by at least 10-15 cm. Such an overlap is required in order for the waterproofing to smoothly move from the wall to the sheer surface. This will give a 100% guarantee that water will not get into the joints of the plates. Any waterproofing requires protection from mechanical damage - you should not drop hard objects onto such a surface. The best option for protection would be to use flooring on the balcony: tiles, linoleum, carpet or simple wooden floors.

Basic waterproofing options

When choosing an option for waterproofing a balcony, not only the condition of its surface is taken into account, but also the material from which it is made.

Simultaneous use of different options on the same balcony is allowed. The main waterproofing options are:

- Coating method. Bitumen-based paint is applied in layers. The coating protects well from moisture. The method is successfully used on wooden and brick balconies.

- Plastering method. The prepared solution is laid in several layers. Good adhesion to the reinforced concrete base is noted.

- Pasting method. Moisture-resistant material is glued to the surface. It can even be used on surfaces with a polyethylene base.

- Cast method. Heated or cold mastic is poured into the formwork. It is considered the most reliable way to protect a balcony concrete slab from moisture.

- Penetrating method. Used for concrete base. Elements of a special solution penetrate the pores of concrete and create a protective layer.

Balcony waterproofing work is carried out in three stages:

- Preparation;

- selection of materials;

- laying waterproofing.

Sealing seams and cracks inside the balcony

Unlike external roof and window insulation, which requires climbing skills, internal balcony waterproofing can be done with your own hands. Structural seams and resulting cracks require mandatory sealing before further repairs. Delaying or neglecting this process will lead to the formation of “wet” spots and subsequent aggravation of the problem.

Types of balcony seams

More than 90% of the moisture entering the balcony passes through unprotected joints of the slabs, which in their normal state are not a serious obstacle to rain or melt water. Construction seams are divided into two types:

- fixed (cold) – formed between two stationary structures (slabs, walls, ceilings, etc.);

- moving (deformation) - made to prevent deformation of the object, which may arise as a result of soil movements and temperature fluctuations.

Open seams are the main reason for the spread of fungus and mold on the balcony

Methods for sealing seams

Each joint has individual characteristics (width, depth, geometry), and therefore requires an appropriate approach. Sealing seams and cracks on the balcony is carried out using several methods:

- Sealing with cement mortar. The simplest and cheapest, but not the most reliable option. The hardened mortar does not have even minimal elasticity, so if it is used to seal an expansion joint, there is a high probability of cracks appearing.

Sealing the seam with concrete

- Sealing the joint with an elastic band. One of the most common methods of sealing joints of concrete slabs. A sealing band made of foamed polyethylene or butyl rubber is pressed into the groove, after which the seam is sealed with a sealing compound.

Laying the harness and applying a layer of sealant

- Sealing of small seams and cracks. Small-width joints and structural defects are sealed using the injection method, in which the sealant is injected into the joint cavity with a construction syringe.

Isolation of small seams by injection

Preparatory work

The quality of waterproofing work and durability depend on preparation. Preparatory work is carried out in a certain sequence:

- the base of the balcony is inspected and the old flooring is dismantled. Many people believe that moisture does not seep through the tiles, however, this is a mistaken opinion. Through the pores of the ceramic tiles, water gets onto the concrete. A slight frost is enough for the frozen water to begin to destroy the foundation. For this reason, the tile must be removed;

- The base for the waterproofing layer is being prepared. It should not have loose layers or protruding reinforcement. All irregularities are cut off with a grinder;

- Using an iron brush, the base is cleaned of all contaminants;

- Concrete is removed around protruding reinforcement. The fittings are cleaned of traces of corrosion and covered with a protective layer;

- The concrete base is being restored. A slight slope is created along which the collected moisture will flow;

- the ceiling is inspected and the scope of sealing work is determined;

- Balcony partitions are inspected and the scope of sealing work is determined.

It has long been established that waterproofing a glazed balcony is more reliable than an open one. That is why double-glazed windows are installed on the balcony before waterproofing work. Their tightness depends on the presence of an external cornice and on the high-quality filling of the seams with polyurethane foam.

Processing joints as one of the important stages

After any installation work: be it glazing or installing a roof, many visible joints and cracks remain on the balcony. They need to be properly treated, as it is possible that the roof on the balcony will leak because of this.

The easiest and most cost-effective way to hide all the cracks is to fill them with foam. It will swell as it dries and close all the holes as much as possible. After this, the protruding remains must be cut off with a construction knife and plastered.

If you do not finish the polyurethane foam, then under the influence of sunlight the foam will acquire a dark brown tint and begin to crumble, allowing moisture to pass through it.

Sealing joints on a balcony using polyurethane foam Source strport.ru

Selection of materials

The result of waterproofing equally depends on compliance with the work technology and on the correctly selected material. Conventionally, materials are combined into several types:

- coating materials - include mixtures of cement, bitumen, rubber and polymers. They create a covering on which the screed is then laid;

- penetrating materials - intended for concrete. The solution, penetrating into the pores of concrete, creates crystals with cement that displace water and clog microcracks. Concrete must be moistened before use;

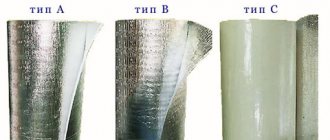

- pasting materials ― are manufactured in the form of rolls and sheets based on polymers (polyethylene, vinyl plastic) or bitumen (roofing felt). It is convenient to use self-adhesive roll materials for the balcony.

When choosing, some features of waterproofing materials are taken into account.

- Rolled pasting materials from Folgoizolon and TechnoNIKOL are supplied in two versions for creating various types of coatings:

- built-up coatings - before laying, the material is heated with a burner. The molten base of the material adheres well to the surface;

- self-adhesive coatings - strong adhesion to the surface occurs due to the sticky bitumen layer. Aluminum foil gives the material strength. Laying such materials is a labor-intensive but inexpensive process.

- Coating materials in the form of various mastics are easier to use. Their peculiarity is that a screed is required on top.

Mastics with bitumen are sold in finished form, so they are immediately ready for use.

Mastics with cement are purchased dry and then diluted with water according to the instructions. The resulting mixture retains its quality for no more than two hours, so it is prepared in small portions and immediately applied to the surface.

So. What and how should be done so that repairs do not turn out to be a dubious waste of money?

First of all, it is necessary to abandon the principle of saving on matches: If you decide to purchase materials for repairs yourself, then this should be done without asking the seller who is interested in selling the stale goods. It is important to purchase material accompanied by a repair specialist who has already examined the front of the upcoming work and knows exactly the degree of compatibility of certain materials, their weak and strong qualities. An important role will also be played by the volume of purchases required, since a specialist is able to visually assess the degree of wear or destruction of previous materials, determining what is required and what you yourself might miss by dooming yourself to travel to purchase this or that. material or tool.

Step-by-step instructions for the floor

Depending on the materials used and the method of performing the work, various technologies for waterproofing the balcony floor are used. The most common technologies are:

- Cast method.

A reliable, but expensive technology that permanently solves the problem of waterproofing the floor on the balcony. The moisture-repellent layer is created in two ways. If you follow the instructions, it is not difficult to complete the work yourself.

"Hot" option:

- Dust and debris are removed from the base of the floor. To do this we use a vacuum cleaner;

- all cracks are covered;

- The concrete slab dries well. We use a hair dryer;

- The base of the floor is primed with a liquid solution of bitumen;

- along the perimeter of the balcony slab, formwork made of plywood or thick cardboard with a height of up to 400 mm is placed;

- to create strength, a metal mesh is laid;

- According to the instructions, the mastic is heated and poured;

- Using scrapers, the mastic is evenly distributed over the entire balcony slab.

- After drying, two more layers of mastic are laid.

"Cold" option.

It differs from the “Hot version” in that the mastic does not heat up. The sequence of work remains the same:

- the surface is cleaned and all cracks are removed;

- the concrete slab is dried and coated with a primer;

- formwork is installed around the perimeter of the balcony;

- metal mesh creates strength for the laid mixture;

- the cold mixture is poured in and then leveled with a rule or scraper.

- Coating method.

Simple technology has made this method popular among balcony owners.

Its advantages include, firstly, no special knowledge is required to apply the composition, secondly, a service life of up to 6 years, and thirdly, an affordable price. There is a drawback: bitumen quickly breaks down at subzero temperatures. This limits the use of materials on open balconies without special additives.

Coating materials are applied hot or cold using the following technology:

- Dirt, dust, and smudges are removed from the surface;

- degreasing of the coating area is carried out;

- 2 layers of primer are applied;

- The waterproofing compound is spread on top of the soil with a brush.

- Pasting method.

The technology associated with gluing several layers of sheet or roll material is familiar to many. It is equally suitable for balconies made of concrete and wood. However, this technology has recently been rarely used due to the following disadvantages:

- painstaking preparation of the surface is required before installation;

- it is difficult to lay material with large dimensions on a small balcony area;

- after installation, a specific odor from the material remains on the balcony for some time;

- seams form between fragments of glued material, which often leak;

- temperature fluctuations negatively affect the quality of waterproofing using this technology;

- The waterproofing layer must be protected with a concrete screed. If it is not possible to make a screed, then another waterproofing technology is selected.

Getting rid of dust

Before applying all putty layers (filling cracks and potholes), you need to prime these areas using penetrating compounds. This will help bind any dust that is not swept away. Otherwise, everything that is applied to a dry surface will lie like a cake, and over time it will simply come off and compromise the integrity of the waterproofing. This will help those solutions that will seal all the cavities to firmly connect to the slab.

A flat and smooth surface allows you to apply the primer with a brush or spatula without gaps, gaps or pores. When waterproofing an open balcony in a private house, you need to pay attention to the material it is made of. Remember - a wooden covering does not require a primer, and its sealing will only be done with sheet materials with foil reflectors.

Step-by-step instructions for the ceiling

The ceiling must be protected from precipitation. This is especially important when the balcony is located on the top floor, or the upper neighbors did not take care of sealing their balcony.

Typically, the top balcony slab is insulated with penetrating compounds. In this case, the following sequence is selected for arranging waterproofing:

- The ceiling is first inspected to identify leaks. Such places are treated with a polyurethane-based composition. Large cracks are filled with polyurethane foam or polyethylene sealant;

- the entire surface of the ceiling is thoroughly cleaned of whitewash and paint with a metal brush;

- the prepared surface is wetted with water;

- a layer of penetrating protective material is applied to the wet surface with a brush;

- Polystyrene foam boards are laid on the dried penetrating waterproofing using plastic fungi.

On the balconies of the top floor of the house, additional work is being done to seal the roof.

The following sequence of work is selected:

- roofing material is laid overlapping on the roof;

- a protective layer of mastic is applied on top of the roofing material;

- sometimes an additional protective structure made of roofing materials is installed;

- joints are isolated;

- outlets are installed for runoff collected after rain.

Usually, after waterproofing the ceiling, the condition of the balcony glazing is checked. Frames installed in violation of technology are a common cause of moisture getting onto the balcony.

Elimination of blowing and freezing of window openings

Insufficient sealing of window units on balconies often leads to the formation of mold and mildew on adjacent slopes and walls. This problem occurs when using old wooden windows or as a result of improper installation of metal-plastic structures.

Why is it blowing from the window?

Blowing through a window is a consequence of insufficient tightness between the frame and the wall or the sash to the frame. There may be several reasons:

- Incorrect window frame installation technology. Most companies selling plastic windows hire outsiders (often without relevant experience) for installation work. It is not surprising that when using window units, unpleasant consequences of “professional” installation appear.

- Wrong choice of sealant for sealing the seams between the frame and the wall. Some installers mistakenly believe that construction foam is a sealant and therefore does not require additional finishing. In fact, under the influence of sunlight and temperature changes, the foam begins to deform and peel off from the surface, breaking the tightness of the seam.

- Misaligned sashes. The sash pressure of a plastic window is an adjustable value. To do this, eccentrics are located around the perimeter of the window, the position of which determines the level of pressure - weak, medium or strong.

The presence of a foam seam alone is not a sufficient condition for sealing a window seam on a balcony

Rules for sealing window seams

You cannot do without polyurethane foam when installing plastic windows. In this case, in no case should you skimp on the foam seam, especially since excess remains of dried material can be easily cut off. After drying, the foam on the inside and outside should be covered with a moisture-resistant sealant, which will serve as a reliable barrier to ultraviolet radiation and water.

Before applying the sealing material, the seam must be cleaned of dust and degreased.

It is allowed to seal the balcony from the inside with putty, dry putty mixture, or paint. It is recommended to cover the outside of the foam seam exclusively with a sealant that is highly elastic and will not crack as a result of temperature exposure.

Sealing the junction of the window and the wall

When glazing a balcony, be sure to install ebb sills for high-quality drainage.

Step-by-step instructions for balcony partitions

Waterproofing of balcony partitions is carried out using a technology that is no different from treating the floor and ceiling. Insulation using foil-clad polystyrene foam boards is considered optimal. The slab is glued to the partition using a building mixture with high moisture resistance. Reinforcing mesh is used for tile joints.

The following sequence of work is selected:

- the coating waterproofing layer is applied with a brush to the moistened surface of the slabs;

- no earlier than five hours later, another protective layer is applied perpendicular to the first layer;

- The external cladding of the layers is done by painting or plaster.

So, if waterproofing work is carried out carefully without violating technology, then the safety of the balcony slab and a comfortable environment on the balcony are guaranteed. In addition, any owner with little construction skills can waterproof a balcony.

Various coatings

When waterproofing a balcony, in addition to rolled bitumen, all kinds of putties are used. They are distinguished by their versatility, reasonable cost and simple method of application.

The list of the most common products includes:

- Various sealants;

- Polymer, cement mastics;

- Modern fillers (plasticizers, latexes, rubber granulates).

The listed and other products increase the waterproof properties and ensure the durability of concrete structures. Materials are applied with a brush, spatula or roller.

The beginning of waterproofing a balcony begins with the preparation stage. First of all, old decorative textures are removed. The surface is well cleaned from dirt and dust. Exfoliated cement mortar in certain places should also be removed. After completing the preliminary work, all seams, cracks and cracks are sealed with a special primer. Hard-to-reach areas are treated using a brush.