For decorative finishing, especially in the private sector, material from the group of thin-sheet metal products is increasingly in demand. Let's look at the features of the process of cutting corrugated sheets. Let's get acquainted with controversial issues regarding the use of an angle grinder and a hand-held circular saw. We will also learn about tools with which you can perform straight and curved cuts with minimal harm to the workpiece.

An example of corrugated sheeting for cladding a fence Source domstyle.by

Features of cutting sheets

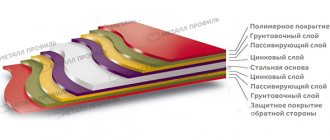

The corrugated sheet is based on thin sheet steel with a thickness of 0.3-1.2 mm. To prevent the material from rusting and serve for a long time, it is coated on both sides with a thin layer of an alloy containing zinc. For the decorative component, there are layers of special primer and powder paint, which also extend the service life of the canvases.

During installation work, the corrugated sheet is cut. As a result, the protective layers are destroyed. Therefore, the most gentle tool is selected for cutting, and the edges are treated with anti-corrosion agents.

Edge protection against corrosion

There are special paints in cans that are applied by spraying onto the work surface. They are supplied for sale in the same colors as corrugated sheets. Another option is anti-corrosion mastic. In any case, you need to read the instructions to find out whether and what kind of primer should be applied to the damaged edge before finishing.

An example of special paints for protecting rolled metal products Source armadius.com.ua

Edge protection against corrosion

Even the use of special tools for cutting corrugated sheets does not guarantee complete protection against damage to the corrugated sheet coating. Only in profiled sheets of galvanized steel of the 1st class of zinc coating thickness, the presence of molecules at the cut site creates a barrier that prevents oxidation of the metal.

Therefore, in order to avoid shortening the service life of the corrugated sheet, it is necessary to apply a special anti-corrosion mastic to the edges of the cut. In addition, you can also paint these places with paint in the color of the protective coating of the profiled sheet. Fulfilling these simple requirements will reliably protect the edges of corrugated sheets in the fitting areas, ensuring the reliability of the profiled sheet throughout its entire service life.

Useful article? Save it on social networks so you don’t lose the link!

Top ↑

Team oprofnastile.info

Read on topic:

How to join corrugated sheets?

What are the rules for joining profiled sheets? Is it necessary to seal the joints of corrugated sheets? How much overlap is needed for a small roof slope? The answers to these questions are in the article.

Screws for fastening corrugated sheets

Do you want to know how many screws are needed for a sheet of corrugated sheeting? How do screws for corrugated sheets differ from other types of self-tapping screws? How to choose them? Read the article!

Selecting a cutting tool

The main three criteria for choosing the optimal tool for cutting corrugated sheets are the permissibility of working with thin sheet metal, gentle and accurate cutting, and ease of performing the task. These parameters correspond to scissors, hacksaws, their electric analogues and equipment with replaceable discs. Let's take a closer look at the features of working with each option.

Scissors

Hand-held metal shears for cutting corrugated sheets are more convenient to use when cutting a small number of workpieces and forming curved edges. Craftsmen recommend choosing spline samples from this category. Here, the cutting part of the tool is represented by a rectangular plate (also known as the supporting part) and a movable sharpened head that fits into the groove of the plate. The thickness of sheet metal for cutting can reach 2.5 mm.

Using conventional metal scissors Source yandex.net

Another solution is nibblers or notching shears for corrugated sheets in the form of an attachment for a drill or screwdriver. There is a mechanism here that converts the rotation of the cartridge into reciprocating movements of the cutting elements of the device. They can cut both steel blanks and plastic with polycarbonate. The edges are equally neat regardless of the curvature of the intended line.

Example of using a screwdriver attachment Source leguidedelamaison.com

See also: Catalog of companies that specialize in finishing materials and related work

The third option for scissors for cutting corrugated sheets is a power tool. Externally, the technique is similar to an angle grinder. The working part is designed in a similar way to the drill attachment described above. There is also a static part and a moving part. Only there are models that, during cutting, act on the metal from one or both sides (like nibblers or hand scissors, respectively). In the case of the former, there is one drawback - the edges of the prepared sheet are slightly bent.

Option for electric metal shears Source amazon.com

Hacksaw blade

Despite the labor intensity, craftsmen often prefer a hand hacksaw for metal to other tools than can be used to cut profiled sheets. This is justified by accurate and accurate results, the absence of restrictions on the thickness of the blade, and safety compared to electrical analogues. Disadvantages include the difficulty of forming curved edges.

An example of a hand hacksaw for metal Source artem-tools.ru

Alternative powered or battery powered tools for cutting corrugated sheets include a jigsaw or reciprocating saw. Only in the case of the former, the height of the wave on the workpieces should be limited to 20-25 mm in order to prevent the formation of a torn edge. The latter are equipped with a comparatively smaller base plate, so there is no dependence on the topography of the sheet. But in each case, the speed of the saw must be adjusted downward so that the paint along the cut line does not burn.

Electric jigsaw Source ozone.ru

Is it possible to cut corrugated sheets with a grinder?

An electric grinder is often used in construction because it can process or cut any metal as quickly as possible. The device is also quite easy to use, and the speed of surface processing is its main advantage.

But it is worth noting that when cutting a profile with a grinder, experts highlight many disadvantages from using the tool. The grinder is an abrasive construction device that can quickly damage the sheet.

This happens for several reasons:

- Metal particles heated during operation spoil the coating by burning through it. If the material is not treated with a protective coating after cutting, corrosion will form in these places.

- After processing the corrugated sheeting, uneven edges remain, so you will have to additionally remove burrs from the surface.

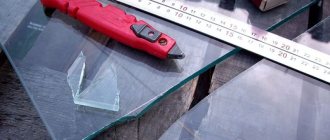

To avoid such difficulties, you need to select special discs for cutting corrugated sheets and promptly coat the sheet adjusted to size with protective paints.

Recommendations from the experts

When working with thin sheet metal, you need to use construction gloves. They can significantly reduce the likelihood of injury from a sharp edge on the cutting line, from burrs and other defects on it. Another important point concerns tools with replaceable disks. They must be equipped with protective covers to prevent sparks from getting into the eyes and face in general. They also reduce the area of distribution of hot metal chips.

As a rule, cutting of corrugated sheets is carried out in a straight line. To make the process of creating a straight edge easier, you can use another sheet as a guide. Simply place it on top of the workpiece. It can also be used at the same time to protect the bottom sheet from damage from sparks.

Another point concerns the flexibility of rolled metal. If you use ordinary metal scissors to cut corrugated sheets, then reliable fixation of the workpiece is not required. In other cases, this must be done.

An example of a working platform using wooden blocks Source stroitelstvo.expert

Otherwise, vibrations and mobility of the blade will contribute to the performance of work in uncomfortable conditions. As a result, the quality of the formed edge will suffer.

Features of cutting corrugated sheets

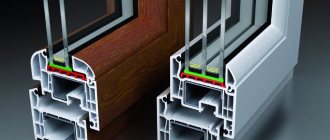

Profiled material is a thin sheet of laminated metal that can be damaged if cut incorrectly. Since the material is coated on top with a special polymer and galvanized, the use of conventional methods for processing tin sheets should not be allowed (cutting corrugated sheets with a knife or hitting with a chisel is a bad idea).

It is also prohibited to use high-temperature cutting methods (gas), since the sheet coating will immediately deteriorate, despite the initial factory protection methods. As a result of improper processing, the sheet itself will be damaged, and not just the outer protective shell.

To cut polymer-coated corrugated sheets correctly, you cannot use a grinder with an abrasive wheel, since there will be a risk of severely damaging the outer layer of the material, which will inevitably lead to the formation of rust. The service life of such corrugated sheeting will be reduced several times.

The structural features of the profiled sheet do not allow the use of any rough construction tools for cutting. Therefore, it is necessary to know exactly how to process the material.

How to protect the cut?

The use of the mentioned tools will allow minimizing the area with damaged polymer. However, the integrity of the protective coating of the corrugated sheet will be damaged if cut or cut by any of the listed methods.

Under the influence of humidity, an unprotected cut can oxidize and begin to rust. Treating the edges with a special anti-corrosion compound will prevent destruction from negative environmental influences and extend the service life of the material.

After applying the moisture-resistant preparation and curing according to the instructions, the cut areas must be coated with high-quality factory paint of the appropriate tone and texture, which can be included with the packaging of the profiled sheets.

If the dye is not available, you can purchase a spray can with a coating of the desired color. You will have to tinker a little, but the damaged material will again acquire an aesthetic appearance.

When arranging the roof, you can disguise the painted cut areas by using additional elements in the form of ridges and end strips.

Working with an angle grinder

The biggest danger when working with corrugated sheets is the heating of its surface, which usually accompanies cutting. It is for this reason that when choosing an option on how to cut a profiled sheet, it is better not to use gas cutters. The same applies to the grinder: like all other high-speed tools with abrasive wheels, it provokes combustion of the metal along the cut line. As for the protective coating, it is damaged on both sides of the cut line. The thickness of the damage strip can reach 3-5 mm, which is why edge corrosion appears on the surface.

Sparks that occur when cutting corrugated sheets with a grinder also pose a certain danger. The high temperature allows them to damage the protective coating of the profiled sheet even at some distance from the processing site. The grinder can be used only if the abrasive wheel is replaced with a special disk for cutting corrugated sheets, which has fine teeth. It is important to understand that even this tool cannot guarantee the complete absence of damage. If you are not completely sure how to cut corrugated sheets with a grinder, it is best to exclude this option.

Specifics of using a jigsaw - how to cut correctly

When choosing a suitable tool for cutting profiled sheets, it is recommended to pay attention to an electric jigsaw. It is especially good in cases of independent implementation of roofing work at your dacha. The same applies to the construction of a fence made of corrugated sheets. Preference should be given to a tool with a laser guide. A jigsaw allows you to cut profiled sheets without any experience in such operations. Serious efforts are also not required. In addition, this device will be useful in carpentry work or for cutting branches in the garden.

Maintaining an electric jigsaw is quite simple. The same applies to handling it - in this case, cutting a profiled sheet does not require any special skills. The tool has a high operating speed, with a very minimal likelihood of injury. If the saw breaks, installing a new attachment is very quick. Thanks to these qualities, a jigsaw is very popular when choosing the appropriate option for working with corrugated sheets.

How to use an electric jigsaw:

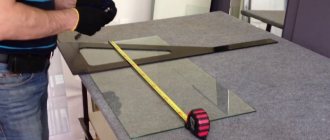

- Before cutting a profiled sheet, you need to carefully mark the surface to be cut. It is convenient to mark the lines of future cuts with a regular marker.

- When securing the sheet, it is important to raise it to a height of at least 100 mm from the desktop, achieving its secure fixation. Any displacements during operation should be excluded. In this case, it is convenient to work on ordinary construction trestles.

- Once the material has been marked and fixed, you can begin cutting it. It is better to replace visual control with a laser pointer: this will allow you to achieve even cutting, without deviating to the right or left from the intended direction.

- When working, it is advisable to press the jigsaw against the fabric being cut as tightly as possible. This will not work in every area, but where possible, it is advisable to do it. In this case, the load on the saw will noticeably decrease, and it will not break down as often.

- This tool is one of the safest options for working with profiled sheets - the risk of injury or damage in this case is reduced to almost zero. For this purpose, the jigsaw has special safety and protective mechanisms, such as guards and saw movement limiters. However, despite this, additional caution will not be superfluous. When cutting, it is not recommended to use your hand as a support on the sheet. It is better to hold it by the edge or edge. The hand should not be located along the cutting line at all - not a single safety mechanism can save you from such stupidity. It does not matter at what distance the cutting tool is located. As for protective clothing, thick mittens or gloves, a thick jacket and goggles to protect against flying chips will not go amiss.

We recommend reading: Second full floor or attic: difference, tips