Which double-glazed window should you choose – plastic, aluminum or wood?

A double-glazed window is a transparent element of a window. This is a sealed structure of two or more glasses connected by spacers. The tightness of the double-glazed window is ensured by 2 layers of sealant, which reliably glue the entire structure.

Photo: double-glazed windows are only about 50 years old, but they have become the main building material. The prototype of the modern double-glazed window was invented in the USA in 1938. A lead spacer was inserted between the two glasses and soldered together. The invention was unsuccessful at first - the first double-glazed windows could not withstand temperature loads and constantly burst.

Hollow aluminum profiles began to be used as spacers in 1950. In 1970, double-glazed windows of a modern design with two layers of sealant and a frame filled with an air dryer appeared in Germany. The invention of double-glazed windows was an important milestone on the path to the invention of energy-saving windows.

The role of double glazing in a window

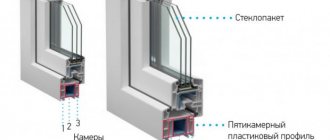

A double-glazed window is often associated with a window (plastic, aluminum, wood) and there is some truth in this. A modern window consists of a double-glazed window, profile, and fittings. The double-glazed window is an important element of the window structure, occupying the predominant area - 70% -90%.

Sunlight penetrates into the house through a double-glazed window, through which you can see the world around you - this is why primitive people began to make holes in the walls.

Modern double-glazed windows are radically different from their predecessors - pieces of mica or bull's bladder. Technological progress has taught glass to selectively transmit radiation and retain heat in the house. The glass has become durable, beautiful, super transparent.

Photo: the possibilities of modern double-glazed windows are multifaceted

Installation rules

When installing a package into a PVC frame, you must be especially careful and use personal protective equipment: shoes, gloves, goggles and overalls. This is due both to the fragility of the structure and the possibility of damage to the skin of the hands or eyes from glass fragments.

The main stages of installing a double-glazed window in a PVC window:

- Thoroughly wash the PVC profile from dust, dirt and traces of sealant, with the obligatory degreasing of all surfaces.

- Straightening PVC plates are placed on the bottom of the frame at intervals of 100-200 mm; it is important that they are the same in height and larger in size than the protruding elements of the profiled material, fasteners and corners.

- The glass unit is carefully inserted, leaving free cavities of up to 5 mm to install the fastening profile.

- Make sure that the plates are firmly fixed during installation, do not move and do not interfere with the installation of window beads in the prepared grooves.

- The glass unit is installed in such a way that it fits evenly behind the rubber bands, adjusting its position left and right with a specialized plastic spatula.

- The fastening process begins with the installation of short beads into the grooves.

- After installing them in the groove, they are lightly struck several times with a rubber mallet or a wooden handle from a regular hammer, making sure that the metal part does not touch the glass.

- Before inserting long glazing beads, they are first bent, inserted into the hole and similar. using the above method, hit several times with a rubber mallet.

A full article about installation is here.

How are double-glazed windows produced?

The most important characteristic of a double-glazed window is its tightness. If the tightness is broken, or the glass unit is initially made with defects, it will not perform its function.

The production of double-glazed windows consists of several stages:

⇨ Glass cutting and its dimensions.

Glass in modern enterprises is cut on automatic lines. First, scratches with a depth of 1-1.5 mm are applied to the glass with a diamond roller, then it is broken along these marks. Standard glass sheets have dimensions of 3210x2250mm or 6100x3210mm. There are special programs for cutting glass; they allow you to minimize cuttings, which reduces the cost of the final product

Important! The cost of all glass trims is included in the price of the double glazed window. Try to choose sizes of double-glazed windows so that waste is minimal (very important for façade and panoramic glazing).

Photo: modern glass cutting lines practically eliminate human intervention. Sheet cutting is generated automatically

⇨ Preparing the spacer frame.

The spacer frame is a hollow inside profile made of aluminum, steel or plastic. The frames come in different widths from 6 to 24mm; they create an air chamber in the double-glazed window.

An air dehumidifier is poured inside the frame. There are small holes on one surface of the frame and the desiccant granules through them absorb water molecules contained in the air. If the dehumidifier does not cope with the task, then condensation will form on the inner surfaces of the glass - such a double-glazed window is considered defective.

Photo: not the entire frame is filled with desiccant; it is enough to fill it in two directions, i.e. 50% of the frame ⇨ The cut frame is assembled into plastic corners or simply bent at the corners. The second option is used more and more often, as it allows you to minimize frame trimming.

Important! The spacer frame can be joined along its entire length. The number of joints on one frame is not limited. Frame joints are not considered defective, but companies that value their reputation do not make more than one joint.

A thin strip of non-hardening sealant is applied to the end of the frame; it allows it to stick to the glass and creates the first barrier to the entry of outside air and moisture inside.

The prepared frame is glued to the cut and washed glass, assembling the glass unit like a sandwich. In a single-chamber double-glazed window there are two glasses and one frame between them, in a double-glazed unit there are three glasses and two frames.

The assembled glass unit is driven through a press, in which the glass is pressed tightly against the frames.

Glass is washed in automatic washing machines with warm water and a special product.

Important: the glass must be clean on internal surfaces that cannot be washed on the assembled glass unit. Fingerprints, debris, stains inside - all this is defective and the double-glazed window should be replaced free of charge!

Photo: the size of the glass unit that can be manufactured is limited by the size of the washing chamber and press

⇨ A second layer of sealant is applied to the end of the assembled glass unit and left to dry. The sealant dries in about 1-1.5 hours, after which the double-glazed window can be installed in the window. It is better if the sealant of the second layer is applied in a vertical position of the glass unit - this way the glass does not sag initially and the risk of its deflection and destruction in the finished window is much less.

Important: the second layer of sealant should not have gaps or voids. Even the smallest gap will lead to gradual depressurization of the double-glazed window!

The highest quality double-glazed windows are manufactured on fully automatic lines.

Double-glazed windows formulas

The glass unit formula is a short record of all its components.

| For example: 4M1 - 16 Ar - 4i or 4EL - 12 - 4M1 - 14 - 4M1 |

The formula states:

- Glass - thickness in millimeters and short name. For example: 4M1 – transparent glass grade M1, 4 mm thick; 4i – low-emissivity glass 4mm thick; 6 EL – multifunctional Energy Light glass 6mm thick.

- Distance frame and gas in the inter-glass space. For example: 12 or 14 – spacer frame 12 or 14 mm wide, the space is filled with air; 16 Ar – spacer frame 16mm wide, the space between the glass is filled with argon.

The thickness of the glass unit depends on the width of the window profile. It consists of the sum of the thicknesses of the glass and frames.

For example: glass thickness 4M1 - 16 Ar - 4i = 4 + 16 +4 = 24mm

Or 4EL - 12 - 4M1 - 14 - 4M1 = 4 +12 +4 +14 + 4 = 36mm

Important: according to GOST 24866-2014, the glass unit formula is written starting with the street glass (the one located first on the street side). Many window manufacturers write the formula starting with the internal glass (the one on the room side). Check the spelling in the documents when concluding the contract.

Types of double-glazed windows

Double-glazed windows according to the number of chambers are:

- Single-chamber - two glasses and one air gap (one spacer frame) between them. The scope of application is limited to premises without high requirements for heat conservation (summer cottages, unheated balconies).

- Two-chamber - three glasses and two air layers (two spacers) between them. This is an option for residential premises.

Photo: three-chamber or more chambers are rare; these are very thick and heavy structures

Depending on their functions, double-glazed windows are:

- Heat -saving (energy-saving) – designed to preserve heat in the room.

A heat-saving glass unit must include low-emission I-glass (for example, Planibel LOW-E from AGC) or multifunctional glass * (for example, Energy Light from AGC). A good addition would be a plastic spacer frame and filling with inert gas.

Example formula: 6 EL – 14Ar – 4М1 – 14 Ar – 4 i

- Sun protection – to protect the room from overheating by sunlight and save on air conditioning.

On the street side they are equipped with solar control glass (Sunergy, Stopsol, Stopray) or multifunctional glass.

Example formula: 4S – 12 – 4M1 – 12 – 4M1

- Noise-proof – for protection from street noise.

Such double-glazed windows use laminated glass (Stratobel) or special acoustic triplex (Stratophone). An added bonus to silence is that laminated glass is shatter-proof and burglary-resistant.

Example formula: 6 Sb – 14 – 4M1 – 14 – 4 i, where 6 Sb is Stratobel laminated glass 6mm thick

- Safe – to protect health, life, property

Glass is a fragile object, and its fragments pose a serious risk of injury. Heat-strengthened (tempered) or laminated glass - care about your safety; if such glass breaks, the risk of damage is minimal.

The safety category also includes fire-resistant glass that is impenetrable to flames and combustion products, such as Pyrobel and Pyrobelite from AGC.

Formula examples: 3.3.1 – 14 – 4М1 – 14 – 4 i, 6 – 14 – 4М1 – 14 – 3.3.1 (3.3.1 – triplex designation)

6zak – 14 – 4М1 – 14 – 4 i (with tempered glass)

- Vacuum - the best heat and sound insulation

Vacuum double-glazed windows are both fiction and reality. It is a fiction that all double-glazed windows are vacuum - the bulk of the packages produced are filled with dried air or inert gas; there is no vacuum in them. Vacuum bags are very expensive and are produced in very limited quantities. There are no such production facilities in our country yet. However, advanced glass factories are already producing vacuum insulating glass units, such as Fineo from AGC.

| You can use different types of glass in one double-glazed unit, giving it a whole range of properties. For example: 6 EL – 14 – 4M1 – 14 – 3.3.1 – energy-saving, sun-protective and safety double-glazed window with multifunctional glass and triplex for installation in a children’s room 6 SPH -16 – 4M1 – 12 – 4i – heat-insulating, noise-proof double-glazed window with acoustic triplex Stratophone and low emissivity glass |

Types of window profile designs

For the manufacture of window frames, various types of profiles are used - wooden, aluminum and plastic.

Wooden windows

Wooden windows are considered the most environmentally friendly and at the same time they are quite expensive to manufacture. The wood must be thoroughly dried and treated with antiseptics and protective and decorative compounds. When humidity changes, it can warp, so the profile is glued together from several wooden parts - the directions of the fibers in them differ, due to which warping becomes less. The protective coating also protects the wood from fluctuations in air humidity.

To further protect the surface of wooden frames from negative atmospheric influences and the sun, on the street side the profile is covered with metal overlays, which also increases the price of the windows.

Aluminum profile

Aluminum is a strong and durable material. Thanks to these properties, it is excellent for large-area translucent structures, for example, for greenhouses, winter gardens, pavilions, etc., where metal-plastic structures, for example, are too heavy.

Aluminum has a very high thermal conductivity - this is not at all necessary for window frames. But it is widely used for glazing unheated rooms, for example, for cold glazing of balconies, loggias, and terraces.

In order for an aluminum profile to be used for windows, heat-insulating plastic spacers are added to the profile design, which reduce the total thermal conductivity of the frames to the value required by regulations.

PVC profile systems

The plastic profile is distinguished by a balanced combination of consumer properties: it is durable, looks good, has good thermal insulation properties, is affordable, and is widely represented on the market. In addition, PVC profiles are produced in various designs, which gives the buyer freedom in choosing the color of the window frames.

Each PVC profile manufacturer's product range includes several models of profile systems - the buyer has the opportunity to choose a window with the necessary characteristics. It is important to note that different profile systems are designed for different double-glazed windows.

Gas in double glazing

A conventional double-glazed window is filled with simple air, the moisture from which is removed by a dehumidifier in a spacer frame.

Heat and noise insulation can be enhanced by pumping inert gases into the air chambers. For these purposes, argon, krypton, and sulfur hexafluoride are used.

Contrary to popular belief, the gas does not evaporate after 1-2 years, but serves properly for the entire life of the glass unit, provided that high-quality sealants are used.

The fear of gas poisoning due to the destruction of a double-glazed window is also groundless. The volume of gas is too small to cause significant harm to a person’s well-being.

Defects of double-glazed windows

Defects in double-glazed windows can be divided into two categories: mechanical damage and assembly defects.

Mechanical damage:

- Cracks in glass;

- Scratches on glass longer than 1 cm;

- Chips on the ends of the glass or corners. If a glass unit is delivered with such defects, it is always a defect and must be replaced. Even the smallest chip can lead to complete destruction of the entire glass.

Photo: a leaky double-glazed window may well turn into an aquarium. Assembly defects include:

- Dirt on the inner surfaces of the glass

- Displacement of spacer frames relative to each other by more than 3mm

- Dirt on the spacer frame

- The glass is not installed according to the formula or with the coating facing outwards. Modern coatings are very sensitive to environmental influences and the glass will begin to rust.

- Gaps in the sealant layer, especially if the spacer frame is visible.

- The sticking of glasses together is not always an assembly defect. More often this is an error in choosing a formula, so for double-glazed windows larger than 1200x1200mm you need to carefully select the thickness of the outer glass

Production

Currently, packages for PVC windows are produced by manual assembly in workshops with low productivity up to 40 windows per day, on semi-automatic lines up to 100 windows per shift and automatic lines up to 400 packages per shift.

Features of the production of double-glazed windows for PVC windows:

- Cutting window sheets to size.

- To create a perfectly clean surface, before assembly they are washed with a washing solution and wiped dry.

- Cutting the spacer frame.

- Filling the remote rack cavity with a desiccant.

- Assembling a glass unit along the contour.

- Primary and secondary sealing with installation of sealants.

- Installation of window sheets in a package.

- Crimping

Which double glazed unit is the same as the window?

| Buy plastic windows with the correct double glazing |

A double-glazed window occupies from 70 to 90% of the window area, and it is this that dictates what the window should be like. It’s easy to change it and breathe new life into the window if it was installed a long time ago and does not meet the consumer’s requirements. Innovations in glass production have increased the thermal insulation of glass by 50%, sun protection by 60%, and sound insulation by 3 times. A double-glazed window with innovative energy-saving glass can make even a modest window ultra-modern.

*The article contains contextual and visual advertising

| The WINDOWS MEDIA portal recommends: How to inexpensively update a window and give it a second life? |

Manufacturers

The PVC window market today occupies the largest niche in residential, public and industrial urban planning. The resource for using such window systems in the country goes back several decades, so it is natural that not only assembled PVC windows, but also individual double-glazed windows have become in demand on the market.

They are used for the production of PVC windows by small assembly companies and service centers for the repair and replacement of already installed window systems.

On the double-glazed window market there are both well-known representatives of window brands, as well as companies that are engaged only in the production of packages for sale as a complete set.

The most rated companies producing double-glazed windows are:

"VEKA Rus" , Russian branch of the company.

Advantage: six types of profiles, from three to 7 chambers, respectively with a width of 58-90 mm, full compliance with Russian and EU standards, stable quality, high heat, moisture and noise protection characteristics. The disadvantages include high cost and a certain shortage in the market; replacement of packages is mainly carried out for VEKA window systems for service.- REHAU , German quality. Advantages: large selection of models with different characteristics, manufacturer guarantees, high protective characteristics. Disadvantage: price and installation are only possible with service maintenance of PVC windows with a REHAU profile.

- KBE is also produced by a German manufacturer; in the Russian Federation there are branches of factories in Voskresensk and Khabarovsk. Advantages: reasonable price, high quality, wide range of models from 3 to 6 chambers, maximum package thickness of 88 mm, optimal price-quality ratio. No deficiencies found.

- SALAMANDER is a German company. Advantages: a wide range of packages from 3 to 5 chambers, maximum thickness 76 mm, high protective characteristics, especially on the outer surface and design. Most users consider the high price to be a disadvantage.

- KALEVA is a Russian company. Advantages: optimal cost, range of package modifications from 4 to 6 chambers, maximum width 70 mm, high energy-efficient and sound-proof characteristics. No deficiencies found.

- Profine - production of profiles only, mainly for KBE models. Advantages: high quality meets European standards, 4-5 chamber options with a maximum thickness of 72 mm, high energy efficiency and protective characteristics. Disadvantages: high cost and small selection of models.

- Priorglass , a Russian company produces a variety of high-quality bags from the simplest single-chamber ones at a price of 1100 rubles. m2 to the highest quality structural double-glazed windows at a price of RUB 3,800. per m2. Advantages: wide range of products, well represented on the domestic market, can be suitable as a replacement for almost any standard PVC windows, favorable price. No deficiencies found.

- Russian Glass Company - a wide range of models, both in terms of package width and glass processing: decorative, sun-protective, multifunctional and curved. Advantages: high-quality assembly, high protective performance and emission factor. No deficiencies found.