MagolFORUMHOUSE user

I installed ready-made plastic windows. Very pleased, they keep warm well, don’t feel stuffy

This article will tell you how to properly install a plastic window in a wooden house, taking into account all the features and risks.

Why do you need a casing? Types of frames How to install a casing How to install windows Rules for a plastic window in a wooden house

Why is casing needed?

Plastic windows will completely suit the owners of a wooden house if two important rules are followed when installing them:

- Allow the house to stand after assembly for a year, or better yet two, until the wood dries to equilibrium moisture content. If there is no time to wait, then it is necessary to leave a shrinkage gap in height of 6-8% of the height of the area being settled.

- Install a PVC window only in a thick frame, a rough frame - builders call it casing, frame, carriage, deck.

Rexther FORUMHOUSE user

The casing secures logs or beams around the window opening. And it has one more function: wood is a “living” material, it changes its size depending on air humidity, so even in an old house the openings will move a little. The casing is made in such a way that it can slip at the point of contact with the wall, thereby compensating for seasonal changes in the dimensions of the opening.

If you are installing plastic windows not in the enemy’s house, but in your own house, then the use of casing is not a desirable measure, but a mandatory one.

Of all materials, logs and timber with natural moisture are most susceptible to shrinkage. And when the wood dries out, the linear dimensions of the building change, sometimes dramatically - so the most responsible builders cut window openings a year or even two after the walls are erected.

Wooden houses made of laminated veneer lumber give the least shrinkage, a little more from timber and chamber-dried rounded logs.

The problem is not that the wood dries out, the problem is that the linear dimensions of the structure change unevenly as a result: longitudinal dimensions - slightly, and across the grain - greatly. It is not the width that decreases, but the height of the walls, and with it the height of the window opening. The casing holds the window opening within its original boundaries and prevents the movable sashes from jamming.

technologistSPKUser FORUMHOUSE

The casing forms a window opening, strengthens it, holds the wall so that the logs do not crawl, and most importantly, it minimizes seasonal temperature and humidity changes in the tree.

The casing is attached to the wall in the window opening using a sliding method, and the gap between the upper rim of the opening (in practice it is 30-80 mm, and sometimes more, depending on the wall material) is filled with fiber insulation and covered with platbands on both sides.

For log houses that have stood for less than a year, a gap the width of a palm is quite normal.

All this helps to reduce the impact of shrinkage to a minimum. Also: the joint is made only from dry bars.

To summarize: the casing is made to prevent the window from moving relative to the wall made of logs or timber. The wall will shrink, and the window in the casing will not be subject to loads and move relative to the internal opening.

FORUMHOUSE experts say that it is possible not to make a frame in a wooden house that has already undergone shrinkage after standing for more than five years, but even here opinions differ. And the casing is not needed for a light small wooden building.

Olegos33 FORUMHOUSE user

There is no need to frame a window in a “toilet” type toilet from a log.

Types of pigtails

The casing in the opening is always fastened according to the same principle: it is a “tenon-to-groove” connection, but the very methods by which the sliding fastening is created can be different.

Zack75FORUMHOUSE user

The existing frames seem to be inserted into another frame between them and the timber. Is this a pigtail? With an internal “tooth” in the timber?

A handbook for all self-builders, “How to Build a Rural House” by A.M. Shepelev, tells in detail about the main methods of constructing sedge frames.

The pigtail is made from durable, dry material. This can be an edged board with a thickness of 50-60 mm (but not 15-20 mm). The width should correspond to the width of the opening.

The most common type of okosyachka, the classic okosyachka has a U-shaped appearance from the end (side posts and a crossbar on top), carpenters have been making it in huts and towers for centuries, and called it “deck” or “frame”. On the side of the window in the casing, choose a quarter for the window profile (not always).

As FORUMHOUSE experts say, a casing frame is not a standard product, what is needed, this can be done - with a quarter, with a reverse quarter, without a quarter.

On the casing with a reverse quarter, the plastic frame is simply fixed in the resulting wooden opening; the frame is pressed against this back quarter, and everything is closed from the outside with platbands. This is the easiest way to install plastic windows in a wooden house with your own hands. The design does not prevent the walls from shrinking, but ensures the stability of the wall at the opening.

In houses made of timber with walls 100-150 mm thick, casing is made in the shape of the letter T. This type of casing became popular due to house kits made of profiled timber: the supplied structures already had selected grooves in the window openings. In a high-quality T-pipe, the tenon is glued into the body, or it is integral with the base, and therefore the rigidity of the product increases several times. The window is attached to such a casing with screws. The groove in the opening is selected in the center of the cross-section of the log, but it can be shifted slightly to the outer edge, but so as not to affect the strength, no closer than 50 mm from the edge.

According to the second classification, there are rough and finishing sockets.

IPaltusUser FORUMHOUSE

Finish – when all elements are planed/sanded and remain visible, that is, not covered by finishing. This type of window frame is installed in houses made of polished timber/round timber.

Roughing - when the entire opening is then covered with finishing. There is no need to plan/sand the casing material.

The finishing casing is made from very high quality wood and forced drying. For it they take solid cedar, larch, Karelian pine. It itself is a decorative element. Euro casing is a variant of finishing casing, but is made not from solid wood, but using the glue-type method from dry bars.

Tree selection

The selection of the type of wood from which the windows will be made primarily depends on the taste and preference of the homeowner. The quality of a particular wood plays a special role. To do this, you need to know all the characteristics of a particular material.

Larch

A decent wood with a high level of hardness. It surpasses pine by several tens of percent in these parameters. It is slightly inferior to oak, but the strength indicators are much higher. It owes its popularity to its aesthetic, naturally reddish tint.

By installing larch windows, you can easily do without additional painting. What is important is that larch is highly fire resistant and has decent resistance to rotting. By choosing larch windows, the buyer will pay 40% less than for an oak product. Compared to pine, the price will be more expensive.

Pine

In the construction market, the most common and inexpensive window material is pine. It amazes with its thermophysical characteristics. If you compare a product made of pine and high-quality plastic based on these properties, you can put an equal sign between them.

One of the advantages is that it can be easily painted in any color. Due to the presence of a large amount of resins in pine, this wood has excellent moisture resistance.

Oak

The very name of the tree already exudes hardness, extraordinary strength and durability. Oak wood is considered an elite material. Also attractive are the aesthetic qualities and biological resistance to various fungal plants.

Of all the listed materials, oak is a fairly expensive material for making windows. In the photos presented in our photo gallery, you can easily choose windows for a wooden house to suit every taste and budget.

Do not discount the important advice of experts: do not forget about the correct installation of the window. After all, the service life of the product will depend on its quality. And if the window arrangement is done poorly, the performance of wood or plastic will be reduced to zero.

How to install casing

This is what the casing installation technology looks like:

- You need to cut a window opening in the wall; this is the most critical stage, requiring accuracy, compliance with dimensions (especially if the windows have already been ordered), checking the horizontal and vertical. The opening must be soaked with an antiseptic.

- Insulate the opening with jute tape. Why use jute tape - it is an excellent wind barrier in itself, and this material will also improve the sliding of a log or beam in the casing during shrinkage of the house. The jute is secured in the opening with a construction stapler.

Trojan1User FORUMHOUSE

The tow is stuffed only from the top; jute is laid from the sides under the casing.

Olegos33FORUMHOUSE user

Between the casing and the wall - tow/jute. Between the window and the casing - professional mounting foam.

- Select a groove on the sides of the opening, or, conversely, form a tenon.

The groove is selected for a T-shaped casing; its width should be 1 cm larger than the width of the casing tenon. The tenon is made for a U-shaped casing, and it should be a centimeter narrower than the casing groove (in both cases, you need to leave space for laying two layers of jute tape).

Master FORUMHOUSE user

I did this: a groove is cut out in the wall, a block is driven into it, wrapped in jutolene for tightness. A box is placed on the bars, and a foam window is already inserted into it.

- Mount a wind block on the bottom of the opening; it also needs to be insulated with jute fabric or an analogue. How to do this: lay a layer of jute, mount a wind block on it, and another layer of jute on it.

- Mount the window sill;

- Install risers;

- Mount the top;

- Seal the gap between the top and the opening with soft insulation. The size of the gap is determined depending on the material from which the walls are made. If they are from an array of natural moisture, the gap should be large, even 60-70 mm per linear meter of wall. If the situation is not so dangerous, then:

Serg89 Moderator FORUMHOUSE

You can increase it to 80 mm, and that’s enough.

The foam has very good adhesion to wood, so the gap is sealed with it when the house has definitely undergone shrinkage, and by this time the enlarged fence may disappear naturally.

You can also close the gap like this:

Olegos33 Member of FOUMHOUSE

You need tow and a pipe for thermal insulation of water pipes (approximately 100mm). You wrap the tow around the pipe (in a dense layer), push it into the gap (so that the pipe insert is compressed by a third) and stuff a little more tow (without tamping) into the upper part of the junction of the pipe to the wall and to the casing.

To fill the gap, you can take any materials common on the market: mineral wool, tow, flax wool.

The side gaps also need to be filled with soft insulation, and not foam - it will simply tear when the wall moves relative to the frame during shrinkage.

The house will shrink and press against the insulation for about 3-5 years, so during this period it is better not to install platbands on the side of the room in order to control the process, or to install them so that they can be quickly removed.

In frame houses they do not make staking.

When buying windows, you need to start from the size of the opening. The height of the opening is 120 cm - which means the frame is 116, so that there is somewhere to insert the sweet clover, a supporting plastic profile. It is necessary to check that the sweet clover is included in the package; it is needed to correctly install the window sill; You need to check the entire package and its quality so that there are no minor damages. Pins almost always have to be purchased separately.

How to install windows

Each house has its own characteristics, and even in the same house, windows can behave differently. Professionals recommend strictly adhering to GOST recommendations.

Even windows in the same house can have their own characteristics. Therefore, in your work it is necessary to adhere to the recommendations of GOSTs, namely:

- GOST R 52749-2007 Window installation joints with vapor-permeable self-expanding tapes;

- GOST 30971-2002 Assembly seams of junctions of window blocks to wall openings. General technical conditions;

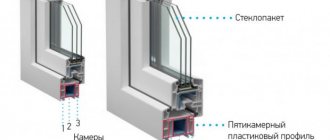

- GOST 30674-99. Window blocks made of polyvinyl chloride profiles

The window installation algorithm is as follows:

It is necessary to place the window frame in the opening, previously prepared and with a mounted frame, and wedge the structure with corners strictly according to the level. The corners are needed to form a gap for foaming; you can leave 35 mm at the bottom and 20 mm on the other sides.

Then secure the window. Most of those who do it themselves attach a PVC window in a wooden house with self-tapping screws.

The self-tapping screw must not pass through the casing and get into the end of the log, otherwise it will simply be torn out when the opening is deformed!

There is another scheme in which we insert the frame using steel corners: they are screwed to the profile with screws and a drill and attached to the casing quarter with self-tapping screws. The method where such fasteners are used is shown in detail in the video at the end of the article.

The number of attachment points depends on the size of the window: the larger they are, the more attachment points are needed; make from 30 to 70, departing from the corners of the frame by 12-15 cm.

Next, you need to treat all the gaps with an antiseptic and let it dry, and you can start foaming, but there is one more feature: wooden houses shrink, and the polyurethane foam can be destroyed during this process. You need very good professional polyurethane foam - it is quite expensive, and very good, deformation-resistant tape and coating materials are also used to protect assembly seams.

The self-tapping screw must not pass through the casing and get into the end of the log, otherwise it will simply be torn out when the opening is deformed!

The next stage is the assembly of the window block, installation of movable and fixed sashes. Until the polyurethane foam dries, keep the shutters closed so that when it dries, it does not bend the window.

After this, the ebb and window sill are installed, so that the window sill has a slight slope towards the room.

The last stage is the installation of slopes (from the inside) and platbands (from the outside).

Required Tools

Before starting installation work, you should take care of purchasing a set of necessary tools.

The set includes:

- hammer;

- screwdriver;

- drill;

- perforator;

- level;

- hexagon;

- pliers;

- level;

- spray;

- chisel;

- anchor plates;

- polyurethane foam.

Care should be taken when handling tools. Some of them may be interchangeable, but there may be significant differences in their use. You need to perform every action carefully to avoid mistakes.

Rules for a plastic window in a wooden house

A plastic window in a wooden house has a right to exist, and not necessarily with a “wood” profile: sometimes you can insert white windows and it will look appropriate and stylish.

But for normal operation of such windows, the following requirements must be met:

- It is advisable for a wooden house with a finished roof to stand for at least a year so that the house can shrink. If this is not possible, you must leave a large gap (about 10 cm, depending on the wall material) between the casing and the upper part of the window opening;

- Windows can only be installed in frames made of timber or thick boards;

- When installing windows, choose foam, coating and tape materials with high deformation properties.

Read our article on how to choose attic windows, as well as a large article about wooden houses. On our forum, to help people with skillful hands, there is an excellent topic “Such a difficult joint.” And watch the video, which tells in detail how to install a PVC window in a wooden house.

Installing windows in a log house: choosing materials

The natural movement of logs leads to a reduction in the window opening. In a few years, this figure can reach a value of 10 cm. Geometric deformation can be avoided by using a special design - casing (casing). It takes on the load of the structure and allows the wooden box to move freely in the vertical direction.

Immediately after the construction and processing of a wooden house, it is recommended to install wooden window installations that have a more dynamic design. After shrinkage is completed, they can be replaced with metal-plastic, laminated ones. They are more familiar to many people and have good thermal and waterproofing properties.

If the house will not be lived in for the first few years, you can install simple wooden frames covered with transparent film. They prevent moisture from getting inside and promote free shrinkage. Installation of the frame is mandatory; it ensures that the correct proportions of the opening are maintained.

Features of installing windows in a log house

It is recommended to place the opening at a height of 80-90 cm (slightly higher than the height of the tabletop). Installation of the socket involves the use of one of three main technologies: tenon, groove, block. Installing windows in a log house has the following features:

- To install wooden structures, a “groove” casing is used, while for metal-plastic structures, a “tenon” casing is used.

- It is recommended to install window frames with anchor plates, since through drilling breaks their tightness.

- The opening should have the following dimensions: window width: +3-4 cm, height: +6-8 cm. These gaps are filled with polyurethane foam, allowing the frame to lower freely.

- The technology for installing plastic windows does not differ from the generally accepted one. It involves fixing the frame, filling the holes with foam, installing sills, window sills, and adjusting the mechanisms.

Wood-look laminated metal-plastic window openings have high performance characteristics and represent an interesting design solution.

Installing windows in a log house: the cost of a mistake

Only professionals with experience in performing such work can take into account all the features of installation and preparatory stages. The cost of error is quite high:

- violation of the tightness of the structure - holes are formed that allow moisture, drafts, and cold to pass through at low temperatures outside;

- violation of the geometry of the opening - the window stops closing normally, the mechanisms are deformed, and cracks may appear in the frames;

- the need to replace the window due to premature physical wear.