Why is proper storage important?

Polyurethane foam consists of a prepolymer, which is a mixture of substances that form polyurethane foam upon contact with air. The contents are under the pressure of a propellant pumped inside - a mixture of gases based on propane or other components that provide two main functions. Firstly, it accelerates the release of material out during operation, promotes foaming of the contents and uniform expansion of the mass. Secondly, it maintains the necessary conditions for conservation and storage for a specified period, reduces the intensity of degradation processes. All types of polyurethane foams have a limited and rather short shelf life, even the most expensive and professional varieties. To extend the storage process, it is necessary to follow a number of recommendations, including temperature conditions, correct location of the cylinder and a number of other requirements, which will be discussed below. If they are not followed, the material can quickly become unusable.

Mechanism of formation of polyurethane foam

It will be easier to choose if you understand the issue

Polyurethane is a compound of methylene diphenyl diisocyanate (MDI) and polyhydric alcohols (polyols). The polymer compound is formed in two phases:

- Formation of prepolymer macromolecules. It is a viscous liquid substance obtained by mixing excess MDI with polyols. It is the prepolymer that is contained in aerosol cans of single-component foam. To slow down polymerization, stabilizers (benzoyl chloride, acetyl chloride) are added to the prepolymer.

- Polymerization of a prepolymer by reaction with water, which forms cross-links between molecules, displacing carbon dioxide from them. In addition to water, other nucleophiles, such as acids, are also used as reagents. They are used in the production of two-component mounting compounds.

In construction, polyurethane foam is used to perform the following actions:

- Sealing and sealing cracks and joints of structures;

- Insulation and sound insulation;

- Sealing of pipe passage holes in building elements;

- Installation of building parts (window sills).

- The main area of application is the installation of door and window blocks, where it is used to fill the gaps between the frame and the wall.

Proper storage in different situations

When working with polyurethane foam at home or at a professional level, two main situations arise when proper storage is required:

- before the first use, while the cylinder is not yet open;

- after the first use, when it is necessary to preserve the remaining material.

In both cases, it is necessary to follow the manufacturer’s recommendations and the methods used by professionals who regularly work with foam during installation and other work.

The advantages of MP include:

- High coefficient of expansion of the material, allowing you to perform a large amount of work with one can of foam.

- Sealing the seam with foam simultaneously increases its sound and heat insulation characteristics.

- MP does not conduct electricity and is not afraid of moisture.

- There are several types of foam on sale, which can be divided according to the degree of fire resistance (B3 - flammable material, B2 - self-extinguishing material, B1 - fire-resistant). Therefore, it is possible to choose a material depending on the operating mode of the sealed structures.

Storage until first use

Storage of polyurethane foam before first use should be carried out in accordance with the recommendations indicated on the packaging. As a rule, they boil down to the following:

- the cylinders are positioned vertically, bottom down;

- Avoid exposure to direct sunlight on the surface, which can provide heating to a high temperature;

- Cylinders should not be placed near heating or heating devices, left on a heated floor or next to a heating radiator;

- The temperature regime of the environment should be +5...+25 °C without sudden changes. If you are not sure at what temperature to store a particular brand of polyurethane foam, you can find information on the packaging;

- vibration loads must be eliminated;

- cylinder valves must be protected from accidental damage and external mechanical influence.

Thus, the list of requirements is quite simple and includes easily fulfilled items. The best place for storage would be a heated garage, warehouse or storage room in the house, where exposure to UV radiation and temperature changes are excluded. Long-term outdoor storage is not recommended, as changes in temperature and humidity can lead to depressurization. It is also worth avoiding long-term storage in vehicles. Regular shaking will sooner or later lead to rupture of the walls or valve failure. After such an incident, you will have to spend a lot of time eliminating the consequences and traces of dried foam in the trunk or interior. The listed conditions are most relevant for construction and installation companies and organizations that have significant reserves of working materials.

Storing leftovers after first use

Often, after finishing work, half or more of the initial volume remains in the cylinder. What to do in such a situation, because it would be a pity to simply throw away expensive building materials? Even if the cylinder has been opened, it is still possible to extend its life by a couple of months. If we are talking about semi-professional materials supplied with a plastic tube for foaming gaps, the following recommendations should be followed:

- Without removing the tube, place the container vertically and wait 10–20 minutes so that the foam inside the glass goes down;

- Remove the plastic tube from the spout and wipe it with a cloth soaked in solvent to prevent the material from hardening. Screw the cap on tightly;

- put the cylinder in a dark place with the appropriate storage conditions described above;

- for subsequent use, you need to attach the tube to the valve and cut off the part of the spout with dried foam.

These recommendations are given by most product manufacturers. However, experienced users have their own technology that allows them to extend the life of polyurethane foam residues after use.

Two-component polyurethane foam

Above we mainly discussed one-component foams. However, there are also two-component ones that must be mixed in a strictly defined proportion immediately before use. To do this, you must have a special mixing gun, or a special installation with a gun.

The difference between two-component foam is faster hardening, as well as good polymerization, regardless of air humidity. For example, excess foam produced by Makroflex Rapido (Henkel), lSoudafoam 2K (Soudal) or llbruck 2K (Tremco lllbruck) can be cut off within 10 minutes after application. The undoubted advantage of two-component foam is its greater yield. However, given the complexity of use and higher price, it is advisable for professionals to work with them.

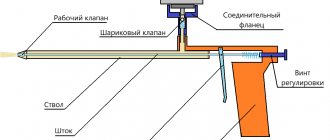

Pistol storage: features and benefits

Many installers recommend storing cylinders with residues without removing them from the gun. The advantage of this method is that the attached tool seals the cylinder. Simply tighten the adjusting screw on the gun all the way. If the gun is not tightly screwed to the cylinder or is not sealed, the foam will harden in the cylinder valve and will be unsuitable for further use. Storage is carried out vertically with the valve facing up. It would be a good idea to place the gun in a regular plastic bag to further limit the possibility of air getting inside. This method actually allows you to keep the material in working condition for up to 1 month or more. Its disadvantage is that during long-term storage the composition can dry out in the nose of the gun, rendering it unusable. But usually the situation can be corrected by disassembling the tool, carrying out mechanical cleaning and treatment with a washing compound. If the gun has a non-separable design, then it will not be possible to restore it by cleaning, which should also be taken into account.

The material also has disadvantages:

- The main disadvantage of MP is its instability to ultraviolet radiation - when exposed to it, the polymer begins to deteriorate, for this reason the treated seams must be protected from light by puttying or painting.

- Cylinders must be stored in a cool room, since when exposed to high temperatures, the pressure in them increases, which can lead to the explosion of the can and damage to all nearby materials.

- Once on the skin, the foam is very difficult to remove. It can only be washed off with a special solvent. Therefore, you need to work with gloves. If the foam still hardens on the skin, you will have to steam the area and then clean it off with a pumice stone.

All foam offered at points of sale is divided according to several criteria. Depending on the method of use, it can be semi-professional or professional.

Semi-professional is used without any additional devices. To apply it, use a plastic tube with a lever included with the cylinder, which is placed on the cylinder valve. Professional foam requires the use of a special gun, which allows dosing of the supplied jet, and is also convenient for working in hard-to-reach places.

Based on temperature of use, foam is divided into three types:

- summer The container with summer foam indicates that the surface temperature of the structure being treated can be from +5 to +35 degrees. But at the same time, the hardened foam has temperature resistance from -50 to +90 degrees. That is, the limitation concerns only the immediate moment of application of the material;

- winter Winter foam is used when carrying out work in winter. The temperature range allowing the use of this foam is from -10 (-18) to +35 degrees. When using winter foam, you need to take into account that its volume after leaving the cylinder strongly depends on the ambient temperature - the lower its temperature, the lower the foam yield. Thus, foam consumption may increase;

- all-season. All-season foam combines the properties of the two previous materials. It has a special formula that allows you to get a large volume of foam even at low temperatures. In this case, the material quickly polymerizes even in the cold. This is still a fairly new material, which is not produced by all MP manufacturers.

Best before date

What is the shelf life of polyurethane foam? This is one of the main issues when organizing storage. For professional teams it is usually 12 months. This period is relevant for closed cylinders placed in accordance with the manufacturer's recommendations. After this time, the foam loses most of its performance properties. For example, it may expand to a lesser extent, lose its adhesive properties, or become completely unusable, drying out inside on part of the exhaust valve. Due to the limited shelf life, the following recommendations should be followed:

- When purchasing, pay attention to the expiration date and take into account the period of time during which the cylinder is intended to be used. The best solution would be to buy foam that has recently left the factory - within 1-2 months. It will fully comply with the specified performance characteristics;

- when storing a used cylinder, you need to take into account the remaining shelf life recommended by the manufacturer and use the foam before it expires;

- if you are not sure that you will use the material before the end of the specified period, then the foam can be disposed of immediately, since it is likely to deteriorate.

It is better not to buy foam in advance, several months before use, for example, on a promotion due to discounts or other bargaining opportunities. Any building material has an expiration date, after which it loses its quality characteristics.

How to choose

Before choosing a material, you need to decide on the conditions in which the work will be performed.

As for structures, for example, any foam is suitable for plastic windows, but you will have to decide on the characteristics. It is best to apply the material with a gun, but for a one-time use you can also use a plastic tube. If you have to treat large spaces, you should choose professional compounds in massive cylinders.

6 Best Dog Breeds for Families with Young Children Many families decide to get a dog around the time they have their first child. But which dog breeds are best for families.

What is it like to be heir to the royal throne? 7 Surprising Facts Royal heirs are entitled to a range of benefits, but until recently these were also limited by ancient traditions formed over time.

How to tell your daughter or son that there will be another child in the family. Are you expecting another child? Congratulations! You might want to share this joy with your family and friends, but what about your older children? When

Top 10 Broke Stars It turns out that sometimes even the biggest fame ends in failure, as is the case with these celebrities.

10 mysterious photographs that will shock Long before the advent of the Internet and the masters of Photoshop, the vast majority of photos taken were genuine. Sometimes the pictures captured were truly incredible.

What does your nose shape say about your personality? Many experts believe that you can tell a lot about a person's personality by looking at their nose.

Do storage conditions depend on the type and brand of foam?

Is there a direct dependence of storage conditions on the brand and modification of the foam? Professional varieties of material are less sensitive to external factors. This is due to the fact that they contain various modifiers that slow down the polymerization processes inside the cylinder under the influence of temperature, humidity and due to poor valve tightness. In addition, cylinders with professional compounds are filled in accordance with the standard, while inexpensive amateur mixtures from not the most well-known manufacturers are only half filled, and sometimes less, without monitoring the quality of the pumped gas. As a result, degradation processes occur much faster and the material deteriorates even before the expiration date.

What you may encounter if the conditions are not met

Failure to comply with the requirements for storing polyurethane foam can result in various negative results:

- solidification of the contents inside the cylinder, reduction in quality and performance due to the fact that the material was not used within the designated expiration date;

- depressurization or rupture of the wall. Occurs due to overheating of the cylinder upon contact with UV radiation or non-compliance with the temperature regime. Also the cause may be mechanical influences, shaking, shock loads on the exhaust valve;

- If the foam is stored with the gun attached after use, then after a couple of months or after the expiration date it may harden in the valve or in the nozzle of the gun, thereby damaging the tool.

Failure to follow the manufacturer's recommendations is one of the main factors leading to material damage.

The Sika company offers customers a wide range of professional universal and winter mounting foams for use in various conditions and for a wide range of works. The products meet quality standards and are supplied at a competitive price. When you contact us, the company’s specialists will help you with your choice and provide recommendations regarding the storage of materials.

Heating a cylinder on a gas stove

The container must be heated to the desired temperature at room temperature or in warm water. Do not heat foam on a gas stove or other sources of open fire. Propelled gas is flammable and easily explodes; if the cylinder ruptures, all the foam will end up on furniture and clothes.

It is not recommended to burn old cylinders in a fire. You should not smoke or use other open flame sources near them. Read more about the composition of polyurethane foam in the article “What does polyurethane foam consist of”