Since they are made from a man-made polymer, these profiles are resistant to most weather conditions and pests.

Let's look at the types of PVC windows, their features and external differences, the requirements for such profiles, and how they are produced.

What it is?

A PVC window is a plastic profile with voids inside , the body of which is reinforced with a metal frame. To assemble all parts, steel reinforcement is welded together at the corners of the window at a temperature of 250 °C.

The decoding of the name PVC window means that the blocks are made of polyvinyl chloride.

A feature of PVC windows is durability. Since polyvinyl chloride is made from refined petroleum products, it, like other polymers, has a long service life.

This profile withstands moisture and sunlight well. Due to the fact that plastic does not conduct heat well, cold bridges do not form on plastic windows. Also, polyvinyl chloride is highly resistant to microorganisms (fungi, bacteria) and insects.

Due to the addition of special modifiers, the polymer on plastic windows is more rigid and durable than usual, which makes it possible to make windows resistant to mechanical damage. This material is more durable than wood and can withstand temperature conditions from -60 to +60 °C.

Since PVC windows are made from a polymer profile with voids, they have good sound insulation . Despite the fact that most of the structure is made of artificial material, metal-plastic windows are not toxic in themselves and are environmentally friendly. Caustic fumes may be generated when the material melts (for example, in a fire).

The difference between plastic windows and wooden ones is that the latter are heavier and more expensive, but have a more attractive appearance, and from aluminum ones - in thermal conductivity and strength. A metal profile is more durable and resistant to mechanical damage, but has higher thermal conductivity than plastic.

Where can PVC structures be placed?

Depending on the selected double-glazed window and fittings, metal-plastic windows can be installed in any room .

Most often they are installed in external walls to protect the room from the cold, while allowing natural light. PVC windows are also used to equip balconies and partitions between the room and the loggia.

For interior door or window structures, metal-plastic windows are used less frequently, since they do not have high fire resistance, which is why their installation can be dangerous. For residential premises, a profile with a 2- or 3-chamber double-glazed window is required, because a single one does not retain heat well, which is why it is more suitable for outbuildings.

TOP 10 window manufacturers

To make it easier for you to decide on the choice of glazing, we present a rating of companies installing plastic windows in Moscow 2020-2021. The most popular and high-quality products are the following brands:

| Place in the ranking | Name | Models |

| 1 | REHAU window profile |

|

| 2 | VEKA |

|

| 3 | KBE |

|

| 4 | SALAMANDER |

|

| 5 | MONTBLANC |

|

| 6 | KALEVA |

|

| 7 | PROPLEX |

|

| 8 | DECEUNINCK |

|

| 9 | TROCAL |

|

| 10 | ALUPLAST |

|

What plastic windows are best to install in an apartment? The decision is up to you. In addition to the performance characteristics of glazing, consider your taste preferences, budget, and location of the facility. In any case, the best windows are high-quality ones. You can order high quality windows from our company. We produce them from the original REHAU profile. We install in openings of various shapes and sizes. To call a surveyor for free, call us on the website or leave a request in the online form.

Requirements based on GOST, SP, SNIP

Most regulatory requirements are outlined in:

- GOST R 56926-2016;

- GOST 23166-99;

- GOST 30674-99;

- GOST 30971 2016.

They contain references to various SPs and SNiPs, as well as some other GOSTs.

For example, in accordance with SP 52-54.13330, window units are designed to provide the room with a natural source of lighting and direct sunlight into the living space.

Double-glazed windows must be able to transmit the visible spectrum of solar radiation in the range from 770 to 380 nm, and ultraviolet rays from 200 to 380 nm. Such conditions must be maintained throughout the entire life of the window, taking into account its safe repair and maintenance.

In accordance with GOST 23166-99, which provides general technical conditions for window blocks and profiles, the permitted substances for manufacturing the frame, filling the space between double-glazed windows and standard shapes or sizes of the profile, as well as the entire window, are indicated.

Example: the maximum size of one window unit should not exceed 6 m2, and the area of the moving part (sash) should not exceed 2.5 m2. The opening part can have a maximum weight of up to 80 kg. The deflection of the frame structure from the wind should not exceed 1/300 of the span length (but not more than 6 mm), and from the glass - 2 mm.

Part 5 transparent – double glazing

Double-glazed glass is such an important component of a window that buyers often confuse it with a window. No wonder - thanks to the double-glazed window, light enters the room.

A double-glazed unit can have two, three or four glasses, hermetically connected to each other by spacers and sealant.

Problems due to poor quality or incorrectly selected double-glazed windows:

- The house is cold in winter and hot in summer;

- High heating and air conditioning bills;

- Burnout of furniture from the sun;

- The room is not protected from prying eyes;

- Fogging of windows;

- Cracks in double-glazed windows;

- Condensation inside the glass unit;

- Need to be replaced after 2-3 years.

Photo: the use of low-quality sealant can lead to such an unsightly picture - drips inside double-glazed windows. Depending on the types of glass used in a double-glazed window and the number of glasses in it, its properties can be significantly improved.

Double-glazed windows are:

- Single-chamber double-glazed window - one air chamber between two glasses. Double-glazed windows are used in non-residential, unheated premises or in residential ones in the south.

- Two-chamber - three glasses and two air layers between them. Double-glazed windows are suitable for glazing residential buildings in any region of the country where heat conservation is important.

- Three-chamber double-glazed windows made of 4 glasses are a premium and rare product. Double-glazed windows are installed only in wide profile systems from 80mm. They have the highest rates of heat and sound insulation.

Photo: double-glazed windows vary in the number of chambers. The glass in a double-glazed window can be:

- Plain float glass is an older version of modern glass, without a coating. In terms of heat conservation and sun protection, they are significantly inferior to coated glass;

- Low-e glass to retain heat. Due to special spraying, it reduces heat loss through windows by up to 70%. There may be 1-2 such glasses in a double-glazed window. The more of them, the warmer the double-glazed window.

- Multifunctional – glass to reduce heating and air conditioning costs. Protects against heat from the sun 60% more effectively than regular glass, while heat loss is also reduced by 50-100%.

- Multilayer – triplex for high sound insulation and burglary resistance. Triplex increases sound insulation by 5-15 dBa, and the window becomes quieter by up to 30% compared to a regular one.

Photo: private glass – during the daytime it allows you not to use curtains. Mirror coating allows light to pass inside, but protects from prying eyes from the street. Modern glass with coatings significantly improves the quality of life. Installing double-glazed windows made of simple float glass without special functions is an unacceptable waste in a difficult economic situation.

How many years of warranty?

The warranty for windows made of polyvinyl chloride profiles is established in accordance with GOST 23166 and standards for specific types of products. Most often, the warranty period is based on the intensity of use, conditions of use (for example, weather), and also on the basis of customer service provided by the manufacturer or seller.

The warranty period for windows and balconies (profiles, fittings, assembly units) is at least 3 years, taking into account compliance with all regulatory documents , as well as intended use. For special blocks (stairwells, technical floors), the warranty period must be at least 2 years. The service life of a double-glazed window must be at least 5 years from the date of installation.

But Federal Law of the Russian Federation N 2300-1 “On the Protection of Consumer Rights” in Article 19 states that the buyer can return the goods within 2 years from the date of purchase if relevant manufacturing defects are identified. Given the service life of up to 40 years, such measures are based on the fact that an error was made in the production of the window or fittings (a part was defective), as a result of which it does not perform its functions.

Production according to GOST

Factory-produced plastic windows undergo strict quality control and have certificates confirming their fire and environmental safety. Compliance with GOST also confirms their high-quality performance characteristics.

We offer products from the German VEKA profile with Austrian MACO fittings and STIS double-glazed windows. The quality of these components is recognized by European standard leaders, and production and installation in accordance with GOST by our corporation will ensure long-term and reliable operation.

259 Reviews | 5 current promotions | 9 advantages of the manufacturer

How to find a good deal?

Really inexpensive windows can be purchased ONLY from manufacturers or their large official dealers. As a rule, they all provide installation services and provide significant discounts on order volume.

We offer all our clients plastic double-glazed windows at 45% cheaper, installation according to GOST and finishing of slopes.

What does a window block look like?

For the most part, a plastic window looks the same as wood or aluminum. It has a frame, glass unit and fittings. Most often the profile is made white , but depending on preferences at the time of production, the outer part can be covered with a special laminating film.

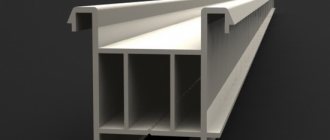

The shape of the profile is more similar to its aluminum counterpart, since in the section you can see the presence of empty air chambers (sometimes filled with insulation), as well as connection elements or grooves for the glass unit, sealant and glazing bead.

Unlike aluminum profiles, you can see metal inserts inside the profile that serve as a frame to increase the rigidity of the structure. The voids in the steel frame can also be filled with insulation in order to avoid the formation of cold bridges or shifts in the dew point.

The photo shows a sample of a plastic window:

Window profile in section:

True German VEKA quality

Premium German brand on the Russian market since 1995. With VEKA you get true German quality from a company with a 48-year history around the world.

- ALL profile systems of the highest class “A”

- ALL are made frost-resistant and marked with the letter “M”

- ALL have maximum 4-sided steel reinforcement

- Uniform quality standard regardless of country of production

The more air chambers, the less air exchange and, accordingly, the higher the thermal insulation.

The wider the profile and the greater the installation depth, the higher the thermal insulation.

Frame characteristics

The characteristics of plastic windows depend on their size and profile thickness, as well as the materials used for insulation or sound insulation. The frame width can be from 58 to 84 mm , but in some cases these parameters may differ.

So, for example, for a window with a profile width of 70 mm, the thermal transfer resistance coefficient can average from 72 to 78, the maximum width of a double-glazed window is 32-40 mm, and the number of chambers inside the profile is 4-6 (most often 5).

The thickness of PVC walls in a metal-plastic window is from 2.5 mm, and noise insulation without additional materials is up to 42 dB. These windows can withstand temperatures from -60 to +60 °C. Removing the fitting groove, which affects the degree of burglary protection, also differs from the width and shape of the profile. Most often in standard windows this distance for a frame with a thickness of 70 mm is 13 mm.

For metal-plastic windows, another important parameter is the installation of steel reinforcement. Usually it has a U-shape. This part can be regular or closed. The thickness of the metal in the reinforcement is 1.5 mm.

Areas of application

Having studied the main characteristics, as well as the strengths and weaknesses of plastic and metal-plastic windows, you can begin to choose the most suitable option for your room. Each case is individual, but there are a number of general recommendations from experts that are worth listening to:

- For rooms on the upper floors of high-rise buildings, as well as for installation in houses located in open space (with the maximum likelihood of regular exposure to strong winds), it is worth choosing metal-plastic windows.

- Apartments in standard multi-storey buildings in large cities located in central Russia (and other regions with a temperate climate) can be equipped with simple plastic windows.

- Ordinary plastic windows are a decent option for buyers on a limited budget.

- For installation in buildings with large window openings or panoramic glazing, it is recommended to use exclusively metal-plastic windows.

- Windows designed according to individual projects, structures of non-standard shape, original models for designer interiors are made mainly from PVC profiles with reinforcement.

- Glazing of structures that cannot withstand a significant load, for example, balconies with a fragile fence, should be done with products made of plastic profiles without a steel liner - they have less weight and minimize the likelihood of damage or destruction.

What does a plastic window consist of?

The plastic window consists of :

- reinforcing inserts inside the profile;

- plastic frame;

- seal;

- plastic beads;

- glass;

- drain;

- window sill;

- insect nets (not always included);

- desiccant;

- sealant;

- dividing frame for double glazed windows;

- air or special gas, which fills the voids between the glasses;

- a locking mechanism with pins, locks and a knob for turning the latch position;

- loops

The window itself consists of:

- frames;

- double glazed windows;

- accessories.

It can have different forms of a turning and locking mechanism, and can also be with or without a sash. In some windows, the glass and sash can occupy the entire area of the window opening, which is why there is no pronounced impost in this design, and the locking mechanism (if there is one) is built into the part of the frame that is adjacent to the wall/

Read more about the elements here.

We don't skimp on quality

Guardian Industries is one of the world's largest manufacturers of flat glass and specialty glass products for a variety of industries.

The company's activities began in 1932; to date, enterprises and branches of the corporation operate on five continents and in 22 countries. To date, more than 10,000 architectural projects in the world have been implemented using GAURDIAN glass.

About 700 people represent Guardian in the Russian Federation. Guardian's turnover in Russia exceeds 8 billion rubles per year.

GUARDIAN

Climate control

Description of the production process

The production process of PVC windows can be divided into several points :

- Cutting reinforcing material for the profile at an angle of 90°. For this, special circular saws are used, and then the burrs are removed using an emery wheel.

- Using single- or double-head miter saws, the PVC profile is cut: imposts at an angle of 90 °, and the side parts of the sashes and frames - 45 °.

- After cutting, drainage voids are ground out in the lower parts of the window profile. This is done using a milling machine with a tip diameter of up to 5 mm.

- The PVC profile is reinforced with metal reinforcement. To do this, steel parts are cut to the required length and inserted into the grooves inside the plastic using a special machine.

- Next, holes and grooves for the fittings are made on a copy-milling machine.

- After this, the ends of the mullions are milled using shaped cutters so that they can be assembled together with fittings.

- On a special welding machine, the temperature of the connecting knife is 250 ° C, the profile parts are fastened together.

- Using a screwdriver or electric drill, an impost and a stand profile (a strip for attaching an external and internal window sill) are attached to the frame.

- Next, a seal is installed (P-shaped is most often used). It is installed in special grooves, starting from the middle of the upper profile and frame. The ends of the seal are connected with cyano-acrylate glue (“Seconda”).

- All fittings (hinges, locking mechanism and corner switches) are mounted.

- After this, a glazing bead is cut, inside which the sealant is installed.

- A double-glazed window is installed with a separator inside, which is fixed with glazing beads. They are carefully installed in place using a rubber mallet.

- The fittings are pre-adjusted on the stand. To do this, all the parts are installed in their place, tightened using hex keys, after which the window is disassembled into its components (frame and sashes).

Additional information about the production of plastic windows is here.

The first part of the window is a PVC profile

A PVC profile is the basis of a window, a durable frame for a double-glazed window, which should serve for many years, not let heat out, emphasize the beauty of the facade and decorate the interior.

Photo: an incorrectly selected window profile will cause many problems for future owners. Problems due to an incorrectly selected profile:

- Large heating bills in the house;

- Cold in winter;

- Poor sound insulation.

Photo: when choosing a profile, you should pay attention to the width and number of cameras Profile width

The wider the system, the warmer and quieter it is.

- 60mm systems (economy class) these include systems with a width of 58-64 mm. This profile is called narrow, economical. The systems are intended for installation in non-residential premises or southern regions of Russia.

- 70mm systems (standard) - for residential premises, apartments, where heating bills are formed based on generally accepted standards, but comfort is required. The system is wider, and therefore warmer - 10% warmer than 60s systems, while being quieter and more reliable in operation.

- 80mm systems and more (premium class) - for private houses, where heat saving is especially important, and heating costs are 100% borne by the owner. It is recommended to install the premium profile in properties with panoramic windows. The systems are 20% warmer than 60s systems, while being more durable and durable. The profile in combination with a special double-glazed window allows you to achieve high sound insulation.

Number of air chambers in the profile

A less significant parameter, but important. Air chambers add heat conservation and sound insulation to the profile.

Photo: the number of cameras varies from 3 to 8. The number of cameras should only be considered in combination with the width. The most common width/number of chamber ratios are: 60/3, 70/5, 80/6.

| Attention! When choosing between profile width and number of chambers, preference should be given to width. |

Profile quality

In addition to the width and number of cameras, you need to pay attention to the quality of the profile. Quality directly affects durability. Experiments with reducing the cost of the formulation, saving on expensive additives (titanium dioxide, impact resistance modifier) will lead to the need to replace the window again after 5-7 years.

Problems with the window due to poor quality profile:

- Cracks in the profiles and welds of windows (window replacement will be required);

- Deformation of the profile under the influence of temperature changes (problems with opening and closing the valves, blowing);

Photo: the most common problem is loss of whiteness and gloss (yellowing, permanent stains) The durability of the profile is confirmed by test results in research centers. You can get acquainted with them in the test reports - responsible manufacturers do not hide this information and provide it to their customers.

Profile color and design

In addition to choosing a high-quality and suitable type of profile, it is necessary to take into account that the profile is responsible for the color and design of the window.

The color of the profile can be:

- Colored (wood, aluminum, colored);

- White.

Photo: profile lamination can be on one or both sides. The profile can be colored using:

- Film lamination (on 1 or 2 sides);

- Coloring;

- Aluminum linings.

The form may be:

- Rounded and ergonomic;

- Direct and brutal;

- Elegant with figured glazing bead;

- Low – gives more light.

Using designer profile models, you can create an exclusive window that will become a real decoration of the interior or facade of the house. Change the color of the window when it is installed more expensive and not.

Varieties

Plastic windows differ from each other due to a large number of factors.

For example, according to the form:

rectangular;- triangular;

- polygonal (most often 6 or 8 sides);

- arched;

- round;

- trapezoidal;

- oval;

- semicircular.

According to the shape of the swing mechanism:

- blind (without doors);

- rotary;

- folding;

- tilt and turn;

- transom;

- guillotine;

- rotating along the axis;

- swing;

- accordion (folding);

- sliding

Also, windows may differ in the number of sashes (from 1 to 3). In some designs the following may be installed :

- windows;

- shtulpa;

- sprouts;

- additional fittings that increase burglary protection.

Also, differences in windows can be based on the type of double-glazed window (number of chambers, glass thickness, impact resistance) or its transparency (tinting, insulating film, stained glass).

More about the types of PVC windows here.

How to choose?

When choosing a plastic window, you should consider many factors that will affect thermal efficiency, sound insulation or the appearance of the structure:

The degree of protection against burglary, as well as its durability, depends on the choice of fittings. Parts made from cheap materials can quickly break or become deformed.- You should carefully calculate the size of the window and its weight, since excessive weight can damage the supporting base, and a large glass area leads to an increase in windage.

- A double-glazed window can consist of sandwich glass, which is sandwiched and covered with a special impact-resistant film. It can withstand large mechanical damage, and can also improve heat or sound insulation.

- The number of cameras inside it depends on the width of the profile. The more there are, the lower the thermal conductivity and the better the sound insulation.

- When purchasing a window, you should immediately check it for mechanical damage, distortions, unevenness or other defects. All fittings must move smoothly without hesitation or sudden jumps. You should also check the tightness of the valves.

More information about choosing windows can be found here.

Evolutionary double-glazed windows SmartGlass 2.0

Our multifunctional double-glazed windows work for you both in winter and summer. In winter, the spraying of silver particles retains up to 90% of the thermal energy of heating devices, and in the summer, a double-glazed window reflects 25% more solar heat than conventional plastic windows.

- 42% more HEAT in winter (energy saving properties)

- 25% less HEAT in summer (sun protection properties)

All our double-glazed windows contain special energy-efficient glass. We DO NOT use regular glass even in the most basic configurations.

2 cameras up to 32 mm

2 cameras up to 32 mm

2 cameras up to 40 mm

2 cameras up to 40 mm

2 cameras up to 52 mm

Glass manufacturer

Assembly and disassembly

When disassembling a plastic window you need :

- lower the rotary mechanism handle completely down (to the closed position);

- use a screwdriver to pry off the plastic casing on the lower and upper hinges;

- Use a flat screwdriver to remove the pin on the top hinge;

- Unscrew the lock on the bottom hinge with a hexagon;

- lift the handle up halfway (open position, not ventilation) and pull the sash towards you.

To install the sash back, you need to do all the steps in reverse order.

In order to remove the glass unit you need:

- remove all unnecessary parts from the window sill and remove the sash;

- insert the knife into the gap between the profile and the bead, with the sharp end and gently knocking on the handle, drive the nose to a depth of 10-15 mm;

- carefully turn the knife towards the glazing;

- during rotation, the gap will begin to widen, so the previous action must be repeated along the entire length of the bead until it is completely disconnected;

- you need to press on the glass on one side so that it begins to come out of the grooves. It is recommended to do this in pairs: one holds the frame and presses, and the second accepts the double-glazed window.

Reinstalling the glass occurs in the reverse order. It is recommended to replace the seal on the beads, then install the top one first, then the side ones, and the bottom one last.

About disassembling windows in detail here.

Installation process

To install PVC windows you need :

dismantle the old window;- check the window opening for damage;

- remove all protruding pieces of concrete;

- clean the surface of debris;

- level the opening using concrete mixture.

two ways to install a window :

- Disassemble it (remove the doors) and drill holes in the frame. Using anchors, secure the entire structure to the wall. This type of fastening is more reliable, but takes more time.

- The window is installed without disassembly using metal plates, which are attached from the outside to the frame and then to the wall. This method is faster, but will not withstand high wind loads.

After installing the frame, the cracks are filled with foam and covered with sandwich panels. Also, during installation, the sashes must be removed to make installation more convenient. After the window is completely installed, the sill, flashing and waterproofing should be attached.

Read more about installation here.

How to connect?

To connect two plastic windows together you need:

- 2 people, since one person will spend 3-4 times more time and can also damage the window;

- assemble the connector and attach it to the frame, which has a smaller height;

- drill a hole in the metal profile for fastening into which you need to insert a screw;

- insert the frame with the connector into the window opening;

- install the second frame and secure both together using clamps;

- drill through both frames and the connector to secure them with a screw.

More information here.

Is it possible to drill?

In some cases, drilling of the profile may be required to route the cable. The standard diameter of coaxial wire is 6 mm. Such a hole will not damage the structure if everything is done carefully. When drilling, it is recommended to use a sharp metal drill and a mode without perforation , so as not to damage the glass or frame, and also to make a hole in the PVC window reinforcement without difficulty.

If the cable is no longer needed, but the hole remains, it can be sealed using plastic plugs or tape. In some cases, the void between the rivets can be filled with rigid polystyrene foam to avoid the formation of a cold bridge.

More information about drilling in the article at the link.

Installation

Installing windows with a metal frame is an art that should be entrusted to experienced craftsmen. We install structures quickly and at a time convenient for the client. We provide a long-term guarantee on all work and products.

A few installation features:

- Vertical and horizontal must be strictly observed. Constantly check the levelness during installation. The deviation should not be more than 3 mm in width and length.

- When making a construction seam, remember that there is a summer and winter size of foam.

- Double-glazed windows can be installed in the frame only after the foam has hardened, preferably the next day.

- Instead of foam, it is better to use other filling materials. Experienced craftsmen understand them, so it is better to consult with them or completely entrust the work to them.

- The window sill can be installed some time after installing the window, but the ebb should be done immediately so that water does not flood under the frame.

Painting process

For painting plastic windows it is recommended to use :

- acrylic lacquer;

- auto enamel;

- nitro paint.

PVC windows are usually white, so sometimes it becomes necessary to paint them.

This procedure can also be used to update the appearance of the frame. It is recommended to use paint that is resistant to external weather conditions and does not emit harmful substances.

More information about painting here.

Material homogeneity

The plastic itself should be smooth, without gluing. The surface of low-quality material may be grainy, streaky, or uneven in color. In this case, there is a high probability that a fake was purchased and such frames will perform poorly in operation.

To distinguish an unscrupulous manufacturer, you need to look at the printed inscription inside. On quality materials, the name of the manufacturer and a series of numbers indicating the number of the machine that stamped the profile and the date of production are indicated.

Insulation

To insulate a plastic window, you can use a special glass film that reduces heat loss. Also, to remove cold bridges on the walls around the profile, you can insulate the outer part of the walls, slopes and window sills.

This is done using polystyrene foam, special glue, fiberglass mounting mesh, and plaster. In some cases, slopes can be insulated using mineral or basalt wool, as well as fiberglass.

All information about insulation is here.

Evolutionary double-glazed windows SmartGlass 2.0

Our multifunctional double-glazed windows work for you both in winter and summer. In winter, the spraying of silver particles retains up to 90% of the thermal energy of heating devices, and in the summer, a double-glazed window reflects 25% more solar heat than conventional plastic windows.

- 42% more HEAT in winter (energy saving properties)

- 25% less HEAT in summer (sun protection properties)

All our double-glazed windows contain special energy-efficient glass. We DO NOT use regular glass even in the most basic configurations.

Prevention and care

Prevention and care of metal-plastic windows consists of constantly cleaning moving parts and connecting parts from debris and dust. This can be done with a soft brush or vacuum cleaner. It is also necessary to lubricate the hinges and locking mechanism 1-2 times a year. Silicone oil is most often used for this.

When the sashes sag, they need to be tightened. To change the horizontal position using a hex wrench of the required size, you need to turn a special screw on the top hinge: clockwise - the sash will be drawn to the frame, counterclockwise - it will move away. To change the vertical position, you need to use the corresponding screw on the bottom hinge.

To prepare the window for winter, it is recommended to increase the tightness of the sash. This is necessary to reduce the air passing through it. To do this, you can use one of three methods :

- using eccentrics that are located around the entire perimeter of the frame;

- using plates on the doors;

- adjusting the clamping mechanism.

Read this article to learn more about structural maintenance.

Which fittings for plastic windows are better?

Fasteners are:

- Rotary . Allows the doors to rotate around a vertical axis.

- Sliding . Popular in balcony glazing. Provides for shifting the profile in the opening along its plane.

- Folding . Allows the sashes to rotate at an angle of up to 180 degrees, and the transoms to recline.

- Universal . With it, the doors rotate around their axes vertically and recline horizontally. Their lower edge is fixed. To select an option, move the handle.

Fastening elements

- Strikers . Mounted inside the frame in a quantity of at least 4 pieces in a profile system, they make it possible for the sash to fit tightly to the frame.

- Blocker for incorrect rotation of the handle. Helps protect fittings from damage due to improper use of the glazing. If the blocker is not installed, when the sash is tilted, the transom is held only by the lower hinges.

- Loops. There are hidden hinges (opening the profile by less than 100 degrees), screw-in hinges (fixed with pins), collapsible or non-removable linings. There are also tilt-and-turn linings, reinforced burglar-resistant ones, and rotary ones. There are upper and lower fastening loops.

- Handles. Brass, aluminum with PVC coating are stronger than those made only from plastic. Burglar-resistant models with a locking mechanism prevent the doors from opening from the outside. There are flat and curly. Roto and Maco handles are the most durable.

- Corner switches. Allows you to move the lock in the corners when tilting the sash. Formed by several plates.

- Locking pins. Increases burglary protection. Mounted with strips without special settings, they make the locking system move smoothly.

- Locking fastener. Makes it possible to close, open, tilt the window profile, that is, move the sash to different positions. There is a main one (depending on the type of fastener), an auxiliary one (responsible for the tight vestibule, located next to the hinges), and an intermediate one. If the locking becomes loose or difficult, the locking mechanism must be adjusted.

Reliable window systems with expensive German alloy steel fittings - these are the plastic windows that are considered the best. There is no need to skimp on fasteners. This can lead to additional costs for window repairs soon after installation. Low-quality, cheap fasteners wear out quickly and can lead to damage to the window system and injuries. Fasteners from the Siegenia, Maco, and Roto brands are known for their excellent performance characteristics.

User manual

To prevent windows from fogging up, you need to:

Regulate room humidity. To do this, you can ventilate it in a special window mode 3-4 times a day for 10-15 minutes or install a special device to regulate humidity.- Check the performance of ventilation systems.

- Place heating appliances under the window.

The window sill should not be large so that warm air can easily reach the window. All these measures are necessary in order to avoid the formation of an ice crust on the outside, as well as the appearance of fungi or mold.

Also, to ensure the performance of PVC windows for a long time, you should adhere to the following rules :

- in strong winds, do not leave the doors open;

- do not insert anything into the space between the frame and the sash;

- do not load the sashes with additional weight;

- carefully close the window so that it does not hit during connection;

- regularly clean the fittings and insulation from debris or dirt;

- do not place anything hot on the windowsill;

- do not wash windows with abrasive products;

- do not leave the sash open for a long time, so that the fittings do not begin to sag;

- Do not carry out work near the window on the windowsill using equipment that can damage glass or plastic (for example, welding or hammering something in).

Convenient glazing additions

For greater comfort, the window system can be supplemented with window accessories and additional mechanisms. Let's look at the most popular of them.

Mosquito net

PVC frame filled with polyester mesh with different weave frequencies. When the windows are open for ventilation, the mesh retains dust, insects, specks, fluff, and serves as a protective screen. The frame is fixed in the opening using mounting angles or using metal brackets.

The nets come in roll form, with adhesive tape and magnets. The first ones do not need to be removed from the window. They go up like curtains. But roll-up screens are more expensive and more difficult to keep clean. The “mosquitoes” on the frame are easy to remove from the opening, clean, and can be stored in the pantry for the winter.

For homeowners with pets, windows with reinforced canvas. They are stronger and remain intact even after being hit or scratched by cats.

Ventilation valve

It is installed at the top of the window system to ensure air exchange when the windows are closed. You can adjust the air exchange rate. The ventilation valve is easy to clean with a vacuum cleaner, it is silent, and does not require power from the mains. Some recuperator-type ventilation valves are designed in such a way that they provide heating of the supply air due to the heat of the exhaust air.

Comb

With a comb that limits the interval of 1-7 cm between the sash and the frame, it is convenient to regulate air exchange. It serves as a clamp for the profile's stepwise retraction. Allows you to ventilate a room with the door slightly open and securely fixed in the opening. The comb does not allow small children or pets to open the sash wider than 7 cm from the frame.

Turn limiter

Fixes the profile 6-8 cm from the frame. The interval is sufficient for air flow from the street. A similar element is a clamp for a stepped profile retraction.

Ventilation clamp

The option is also known as “winter ventilation”. Allows you to ventilate the room in winter without significant heat loss and drafts.

Slot ventilation

Provides an influx of air mass through the gap (the sash is 4-5 mm away from the frame) at the top of the opening. The gap is formed when the handle of the window system is turned upward 45 degrees.

Child lock

To make children safer, child locks are installed on windows. They prevent small children from opening the door more than adults did. More often, mechanisms are installed that block the rotation of transoms. Handles of a removable type or with a locking mechanism or key are also installed.

Window sills

Window sills are not just decorative glazing elements. This is a practical and functional window detail. A home garden, a playground for a child, a cat house, storage for household appliances, and an auxiliary countertop are arranged on the windowsill.

Window sills are made of plastic, wood, chipboard, stone, MDF. They come in various colors, textures, sizes. Stone models are more environmentally friendly and durable. But they are expensive and weigh a lot. Wooden window sills are also environmentally friendly, they have a pleasant texture and beautiful colors. But wooden models wear out quickly, are expensive and vulnerable to moisture.

Products made from MDF and chipboard are moisture resistant and are not afraid of temperature changes or ultraviolet rays. They are inexpensive. But such window sills are not very durable; they contain chemical components (adhesive, with resins).

Plastic options are the most practical. They are not afraid of moisture. They withstand ultraviolet rays and temperature changes. At the same time, the PVC profile is durable and inexpensive. It insulates heat well and is easy to clean from dirt. The resistance of a PVC window sill to load depends on the number of stiffeners in it. The more there are, the stronger the window sill board.

Problems and repairs

The main problems of PVC windows are:

- Condensation that appears due to improper air exchange or high humidity.

- Mold and mildew. Most often, the cause is condensation, as well as improper finishing of the slopes.

- A seal failure that occurs when the seal is damaged, clogged, or when the position of the valves changes.

- Damage to the fittings can occur due to improper handling of the window or debris getting into the mechanism itself.

- The appearance of ice and heat loss is most often a consequence of improper window installation.

It is recommended to trust the repair of fittings to professionals, since without experience you can damage the frame, locking mechanisms or hinges. In some cases, minor repairs can be done independently :

- tighten the doors using a hex wrench;

- replace the seal.

Reinstalling double glazing can be a challenge as it requires skill, but if necessary you can use the assembly/disassembly advice described above.

Read more about troubleshooting here.

Dismantling rules

To dismantle a plastic window, most often you will have to remove the double-glazed window, since the anchor fastenings are located behind it. To do this, first remove the sashes, and only then take out the glazing beads and glass.

If the slopes were treated with plaster, then it can be knocked down using a chisel and hammer. To dismantle the window sills and ebbs, you need to unscrew the screws and pull them out of the grooves with a sharp jerk.

More information here.

Advantages and disadvantages

The positive qualities of plastic windows include:

high energy efficiency;- good value for money;

- no need to spend a lot of time and money on window care;

- strength;

- good sound insulation;

- ease of use;

- environmental friendliness.

Disadvantages include:

- Tightness. This point can be considered a plus if a private country house or apartment has a good ventilation system. Plastic, unlike wood, does not breathe, so condensation and stale air can form in the room.

- Difficulty in repair. If the frame breaks, you cannot replace a separate part.

- Increased dust formation on the surface of the window.

- When heated, the plastic expands and contracts, which can lead to problems with opening or deformation of the frame.

- For greater insulation, you will have to use a profile, the voids in which are filled with special materials. Because of this, the frame thickness and cost increase.

Analysis of the pros and cons in the article at the link.

ONLY frost-resistant profiles

According to GOST 30673-99 “PVC profiles for window and door units” for resistance to climatic influences, ALL of our profiles are “frost-resistant” - for areas with an AVERAGE monthly air temperature in January BELOW minus 20°C.

GOST standards for different classes:

- normal version “N”: the average temperature in January is minus 20°C and above

- frost-resistant version “M”: the average temperature in January is lower than minus 20°C

Our assortment includes ONLY frost-resistant profile systems marked with the letter “M”.

Heat transfer resistance (thermal thermal resistance) is the main thermal insulation coefficient. It is determined by the ratio of the temperature difference between the outside and inside the room to the heat flow passing through the window. The higher this number, the better the insulation performance.

What does the price depend on?

The main factors that determine the price of PVC windows are:

- frame size and shape;

- fittings (burglary-resistant or high-strength ones cost more);

- shape and width of the profile (number of chambers, as well as their filling);

- number of doors;

- window shape;

- the glass unit used (shockproof or with insulating film), as well as the number of cameras in it;

- presence of gas in double-glazed windows;

- window automation;

- window sills and ebbs;

- the presence of blinds;

- number of sealing circuits;

- decoration and availability of sprats.

More details about pricing here.

Double-glazed window installation

The glass that we are used to seeing consists of several transparent plates connected to each other. A small space remains between them, which is either left untouched or filled with inert gas to maintain thermal insulation characteristics. The last method is used only in the premium class.

The packages are divided into chambers, for example, 2 glasses and the empty space between them - this is a single-chamber double-glazed window. If 3 glasses and 2 spaces are installed - two-chamber and so on.