Montblanc Eco 60 is ideal for glazing standard and business class objects. Montblanc Termo 60 is a popular profile with excellent technical characteristics that allows you to create any window designs of the most complex shapes. Montblanc Grand 80 meets the weather conditions of northern regions, which are more demanding in terms of heat conservation. Montblanc City 120 is designed for non-standard architectural designs. In particular, it is suitable for replacing wide wooden frames in “Stalinist” houses.

Montblanc Logic is designed for glazing loggias and balconies. The mounting depth of Montblanc Nord 70 - 70 mm allows the air chambers to be optimally positioned in the frame and sash, which increases heat and sound insulation.

The profiles are completed with a window sill, plastic slopes and two types of removable platbands produced by the company taking into account full structural compatibility. This allows you to quickly and efficiently close the window opening during installation.

The company collaborates with world-renowned raw material manufacturers to ensure high quality Montblanc brand window systems. At each stage of production, careful control is carried out, which includes:

- incoming inspection of materials;

- acceptance control of finished window systems at the production site and in the laboratory;

- carrying out tests in specialized independent centers to ensure that the quality of produced profiles meets the requirements of GOST.

- Almost the entire process of producing profiles is automated, which eliminates by 99% the possibility of production errors and defects.

The company provides a wide range of colors for Montblanc windows that will satisfy even the most demanding consumer. The ability to paint window systems en masse allowed the Company to make them even more accessible to its customers. Montblanc colored plastic profiles are a great way to highlight the features of any interior.

Another option for Montblanc window systems is the wood finish on the window. This is achieved using a special laminate on one or both sides of the profile.

A little history

In June 2001, production of the first batch of MONTBLANC termo 60 profile was launched.

MONTBLANC termo 60 is the most popular profile that has proven itself in use in various climatic regions; it still occupies the highest place in the sales ranking among all MONTBLANC profile systems.

MONTBLANC termo 60 is a four-chamber profile with modern geometry, an installation width of 60 mm, and the ability to install double-glazed windows up to 32 mm.

An important feature is the unique profile design, which ensures a more uniform temperature distribution on the inside of the windows, due to which its heat-insulating property has sharply increased.

This innovative geometric shape of the MONTBLANC termo 60 PVC profile was patented by the Russian Patent and Trademark Agency (invention patent No. 2171347 with priority dated 08/04/2000). After successful testing of thermophysical and acoustic measurements in a testing laboratory, the excellent technical properties of MONTBLANC termo 60 were confirmed. The reduced heat transfer resistance with installed steel liners is 0.7 m2 H°C/W. This is one of the most important indicators that characterizes the MONTBLANC termo 60 product as a universal profile suitable for glazing objects for any purpose in various climatic regions. The MONTBLANC termo 60 profile is distinguished by exemplary quality and stylish design, which opens up a wide range of application possibilities.

Then the production of two systems MONTBLANC grand 80 and MONTBLANC city 120 was launched.

MONTBLANC grand 80 is a high-quality profile designed to meet the requirements of the northernmost regions, which are the most demanding in terms of heat conservation. MONTBLANC grand 80 is a 6-chamber profile with an installation width of 80 mm and the ability to install double-glazed windows up to 52 mm.

The MONTBLANC grand 80 system meets international standards for all criteria and requirements for PVC window systems, therefore it is the ideal choice for the most demanding client.

Thanks to six chambers and a unique patented design feature that ensures a more uniform temperature distribution on the inner surface of the windows, the highest quality of thermal and sound insulation is achieved. Tests carried out in a testing laboratory for thermophysical and acoustic measurements confirmed that the MONTBLANC grand 80 PVC profile belongs to the highest level of thermal protection - the first class of products. The reduced heat transfer resistance of MONTBLANC grand 80 PVC profiles with installation reinforcement liners is 0.82 m2 x ° C/W, which fully satisfies the requirements of GOST (30673-99).

In June 2004, the five-chamber profile MONTBLANC city-120 was launched into production.

The emergence of this system is associated with the growing consumer interest in glazing non-standard architectural structures. The installation depth of the profile of 120 mm prevents the formation of a “cold bridge” along the perimeter of the window in the area of the construction quarter and opens up new possibilities in finishing slopes. This profile is perfect for installing glazed partitions indoors, as it is the most stable due to its large installation width.

In the manufacture of the MONTBLANC city-120 profile, as in all MONTBLANC profiles, a unique patented design feature is used, which ensures a more uniform temperature distribution on the inner surface of the windows and increases the thermal insulation property. The use of this technological innovation in the MONTBLANC city-120 system with a five-chamber profile section creates maximum thermal insulation. The reduced heat transfer resistance with installed steel liners is 0.72 m2 x °C/W. This indicator characterizes the MONTBLANC city-120 product as a profile that is perfectly suitable for use in climatic regions that are especially demanding in terms of heat conservation.

High sound insulation undoubtedly makes this profile suitable for use in buildings located along the streets of large cities and near various noise sources.

In the manufacture of the MONTBLANC city-120 structure, traditionally impeccable quality is observed, due to the highest level of production.

In January 2005, production of another MONTBLANC eco 60 profile began

, whose popularity is due to its excellent performance, elegant design and competitive price.

In March 2006, the MONTBLANC termo 60 profile was radically improved.

Now this is a five-chamber MONTBLANC termo NEW profile, with a modified modern design. At the same time, the cost of products from the new profile remained the same.

Also in 2006, the production of a new economy class profile – LOGIC – was launched.

This is a three-chamber system that meets all the heat and sound insulation requirements for modern window systems, while the finished products from this profile are very affordable.

The most common problems with Montblanc windows and how to fix them

Poor quality installation

If the installation was carried out quickly and without using a measuring level, this could lead to unpleasant consequences. The structure quickly deforms, there will be no tight pressure and it will begin to blow at the joints. Often these problems appear immediately, so you can take advantage of the current warranty. After the warranty period expires, you need to contact trusted specialists.

Solution: Sealing seams, adjusting windows, eliminating blowing.

Errors or dealer savings in production

During installation or production, original German fittings and seals can be replaced with cheap analogues. This will lead to rapid wear and replacement of components. You can often find counterfeits of well-known brands of window designs. You will notice an uneven surface, roughness, areas of subsidence, bursting or yellowed profile when using low-quality raw materials. In this case, only reinstalling windows from trusted manufacturers will help.

Solution: repair or replacement of fittings, replacement of the seal.

Problems during operation

Problems with installed double glazed windows often occur. This may be due to glass damage and depressurization, which could occur due to physical damage or shrinkage of the new building. Many people simply want to improve the quality of their double-glazed windows.

Solution: Replacement of double-glazed windows.

PVC profile Montblanc Eco 60

Plastic windows Montblanc

Eco 60 appeared on the window market relatively recently. This is a new product in the MONTBLANC series of impeccable quality profiles - MONTBLANC eco 60-three-chamber profile with modern geometry, installation width of 60 mm and the ability to install double-glazed windows up to 32 mm.

The three-chamber system MONTBLANC eco 60 is ideal for glazing objects of any purpose, “standard” and “business” class. The attractive appearance of MONTBLANC eco 60 profiles, thanks to the glossy surface and rounded edges, combined with high technical characteristics, meets the modern requirements of the discerning buyer.

Tests of a window unit with a standard glazing unit 4-10-4-10-4 and a frame element MONTBLANC eco 60, carried out in a testing laboratory for thermophysical and acoustic measurements, have the following characteristics:

- The reduced heat transfer resistance is 0.58 m2 x°C/W (0.55 m2 x°C/W with a ratio of the glazing area to the filling area of the light opening of 0.7);

- Air permeability - when pressure changes on the outer and inner surfaces of 10 Pa - 0.90 kg/m2 h h and 100 Pa - 3.83 m3/m2 h h;

- Sound insulation is 30.0 dBA, which reduces the external noise of urban transport by 32 hours 35 dB.

Eco 60 has 3 air chambers, mounting area – 60 mm, double-glazed windows – up to 32 mm.

This is a very light and elegant design. The design of the system features a glossy surface and rounded corners, which makes the profile very attractive. All this, combined with the high quality standard of these windows, makes them popular among consumers.

Plastic windows montblanc eco 60

- an ideal offer for a customer interested in a favorable price-quality ratio and demanding design.

Characteristics of Montblanc Eco 60 windows:

- Three-chamber profile with modern geometry

- Installation width 60 mm

- Possibility of installing glass units up to 32 mm

- Reduced heat transfer resistance - 0.58 m2 x ° C/W

- Air permeability - when pressure changes on the outer and inner surfaces of 10 Pa - 0.90 kg/m2 and 100 Pa - 3.83 kg/m2

- Sound insulation - 30.0 dBA

- MONTBLANC eco 60 is ideal for glazing objects of any purpose, “standard” and “business” class

- When manufacturing the MONTBLANC eco 60 profile, the impeccable quality characteristic of all MONTBLANC products was observed. This is due to the highest level of production and technological control, which ensures guaranteed unchanged properties of the MONTBLANC profile for 60 years.

Window sills and window slopes

Often, window installation is not limited to just installing the product. Installation of additional types of finishing, both external and internal, is also required.

Internal types of finishing include installing window sills and finishing the opening with slopes. External finishing consists of installing ebb and decorative corners, or even full slopes.

Window sills

The most popular are economy class window sills from the BFC company. Such window sills are installed everywhere, have a white color and a slightly rough surface.

This type of window sill is quite durable, but is susceptible to contamination due to its color and texture. Also, such window sills do not fit well with laminated colored windows, which are often installed in country houses.

PVC profile Montblanc Termo 60

Plastic windows Montblanc Termo 60

were developed by STL-Extrusion together with its Austrian partners. Careful work was carried out to update the previous system, its technical performance was improved several times. Today this is one of the most competitive and best-selling Montblanc profile systems. Combines high consumer qualities and low price.

This system has 5 air chambers, which significantly increases its heat-saving functions compared to analogues. At the same time, maintaining the average window width of 60 cm is achieved.

To enhance the heat-saving functions of the window, the updated MONTBLANC termo 60 profile has five air chambers while maintaining the basic width of 60 mm and allows for the installation of glass units up to 32 mm.

Such a double-glazed window will satisfy the requirements for heat conservation in almost all climatic zones. This allows the MONTBLANC termo 60 system to be widely used. The updated MONTBLANC termo 60 system is fully compatible with all additional profiles. The dimensions of the chambers for the reinforcing profile, both in frames and sashes, are unified.

To create the attractive appearance of Termo 60, the designers made the profile edges rounded and the surface glossy. This modern “soft” design perfectly complements the system’s high thermal and sound insulation performance.

Main advantages of Termo 60:

- High quality (GOST 30674-99);

- Affordable price;

- Excellent heat and sound insulation;

- Modern design;

- Installation of 32 mm double-glazed windows.

The Termo 60 system is suitable for almost any region of Russia. It is suitable for those who want high quality for reasonable money.

Characteristics of Montblanc Termo 60 windows:

- The MONTBLANC termo 60 system is designed not only to replace its predecessor, but, reflecting new design requirements and increased technical requirements, to become the most popular and competitive in the line of MONTBLANC profile systems

- To increase the heat-saving functions of the window, the updated MONTBLANC termo 60 profile has five air chambers while maintaining the basic width of 60 mm and allows for the installation of glass units up to 32 mm

- Such a double-glazed window will satisfy the requirements for heat conservation in almost all climatic zones. Which allows the MONTBLANC termo 60 system to be widely used

- The updated MONTBLANC termo 60 system is fully compatible with all additional profiles. The dimensions of the chambers for the reinforcing profile, both in frames and sashes, are unified

- The MONTBLANC termo 60 system has rounded edges and a glossy surface, thanks to which it looks modern and attractive.

- The design is complemented by a 14.5 mm wide bead developed for this system, and 24 mm wide for the most popular glass unit.

Adjusting plastic windows "Mont Blanc"

Window installation is completed by hanging the sashes and checking the operation of the fittings. Adjustment is carried out by manipulating the hinges. The bottom loop is responsible for eliminating the vertical gap.

By turning the hex key in the adjusting groove clockwise, you can raise the sashes. Similar actions counterclockwise will lower the sash.

Adjustment to the left or right is carried out using the same hex key rotated at the bottom of the hinge. Turning clockwise tilts the sash to the right, counterclockwise tilts it to the left.

If necessary, you can adjust the valves yourself

The adjustment is similar at the top of the sash. All work is carried out with the window open. Only adjustment to the pressure of the upper half of the sash requires opening in the “ventilation” and “open” positions.

Then you can see the scissors holding the sash. The desired adjustment groove is located on them. After the manipulations, the window is closed.

Adjustment is an important skill. It is useful to master it in order to independently cope with sagging sashes and regulate air circulation at different times of the year.

PVC profile Montblanc Logic

Plastic windows Montblanc Logic

were developed in 2006 and are intended specifically for glazing facades. The installation width of these windows is 58 mm, which allows for elegance and lightness of the entire structure. At the same time, the company has developed a special chamber for the reinforcing profile made of galvanized steel, which ensures very high strength of the entire system.

The idea of creating a new MONTBLANC logic profile system arose from the growing market need for a PVC profile designed specifically for facade glazing. MONTBLANC logic is a lightweight, elegant three-chamber system with an installation width of 58 mm. To ensure maximum structural strength, a chamber is provided for a reinforcing profile made of galvanized steel. Rounded edges and a glossy surface give this profile system a special elegance.

Another feature of Logic Montblanc is the ability to combine it with additional profiles. This allows you to create a translucent structure of any size and type depending on the client’s preferences. In addition, this also allows us to produce both tilt and turn windows, as well as tilt-and-turn or hinged windows.

To increase energy savings, glass units up to 32 mm can be installed in the Logic profile system.

Like other Montblanc Logic systems, it meets all GOST requirements and has all the relevant quality certificates. This new product is equipped with several additional mechanical connections for the impost. The use of these connections will significantly expand the possibilities of using MONTBLANC logic.

Features of Montblanc Logic windows:

- MONTBLANC logic is a lightweight, elegant three-chamber system with an installation width of 58 mm.

- To ensure maximum structural strength, a galvanized steel reinforcing profile chamber is provided

- Rounded edges and a glossy surface give this profile system a special elegance.

- The new profile system can accommodate glass units up to 32 mm, which will significantly increase thermal and noise insulation

- This new product, whose production began in 2006, is equipped with several additional mechanical connections for the impost. The use of these connections will significantly expand the possibilities of using MONTBLANC logic

- Number of cameras: 3

- System class: C

- Fitting groove, mm: 16

- Installation width, mm: 58

- Seam distance, mm: 0

- Seal material: EPDM

- Range of glass units used, mm: from 4 to 32

- Availability of international certificates: GOST

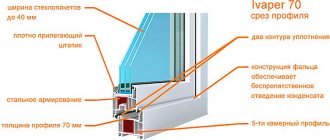

PVC profile Montblanc Nord 70

Plastic windows Montblanc Nord 70

have been produced since 2007 and have already established themselves among consumers as a very reliable and high-tech window system. In Russia, with its wide geography of climatic zones, the constant improvement and development of window profile systems is not only justified, but also necessary. Significant differences in winter temperatures, even in central Russia, have shown the need to use window structures with increased energy-saving properties. The profile system MONTBLANC nord 70 perfectly matches this task.

This system combines 5 air chambers and an installation depth of 70 mm. Such characteristics make it in demand in conditions of harsh winters and temperature changes, as they allow one to achieve high levels of heat and sound insulation. In terms of the level of thermal protection, such indicators, according to GOST 30 673-99, classify the MONTBLANC nord 70 profile system to the highest - first class. It also follows from the test conclusion that these profiles are recommended for use in window and door blocks of residential and industrial buildings in any climatic zones of Russia. This opens up wide possibilities for application.

The Nord 70 energy saving system is considered one of the best in Russia and belongs to class A (GOST 30 673-99). In addition, the Nord 70 system has a high-class, modern design. The high technical characteristics and modern appearance of the MONTBLANC nord 70 profile system are due not only to perfect design developments, but also to constant quality control.

Nord 70 undergoes annual inspections, which allows developers to constantly improve the quality of their products.

Characteristics of Montblanc Nord 70 windows:

- Installation depth – 70 mm. This installation depth will allow for optimal design and placement of air chambers in the frame and sash, which is of great importance for heat and sound insulation

- To increase energy saving, the MONTBLANC nord 70 profile system provides for the installation of double-glazed windows up to 42 mm

- The reduced heat transfer resistance of MONTBLANC nord 70 profiles in the assembly is: with galvanized steel reinforcing liner - 0.77 m2 x °C/W, without reinforcement liner 0.82 m2 x °C/W

- In terms of thermal protection level, such indicators, according to GOST 30 673-99, classify the MONTBLANC nord 70 profile system to the highest - first class

- The high technical characteristics and modern appearance of the MONTBLANC nord 70 profile system are due not only to perfect design developments, but also to constant quality control

Installation of plastic windows

Installing PVC structures with your own hands is a common practice. It is also relevant for Mont Blanc windows. Before installation begins, the plastic window must be delivered to the site.

Even at the stage of measuring the opening, professional installers recommend measuring all bottlenecks in the room (entrance, interior groups). This will let you know if the structure will need to be disassembled for transportation.

Dirt and dust are natural companions of glazing. Curtains and other textiles must be removed, furniture covered or taken out.

- Dismantling the old structure is the first stage when installing windows.

- Drilling holes and fastening additional elements, if necessary, are carried out before the new structure is put into place.

- The sashes are removed from their hinges, and the double-glazed windows from the blind parts must also be removed.

- To secure the frame into the opening, hardware is used: anchor bolts and plates, dowels and construction screws. Installation of profile systems takes place with fastening installation increments of 700 mm, the distance from the corner to the first fastening element is 120 or 150 mm. The dimensions of the holes for bolts and screws are made 1-2 mm larger. The reserve will allow you to compensate for changes in the linear dimensions of the product during temperature fluctuations.

- Self-expanding tapes when installing Mont Blanc window systems help prevent blowing. Silicone sealants solve the same problem.

- Before installation, the protective coating must be removed. As time passes, the film will become more difficult to remove from the plastic. You should immediately check the cleanliness of the drain holes and install decorative plugs.

- Installation of the starting, connecting or expansion profile is carried out before installing the frame in the opening. External vapor barrier is performed with a special PSUL tape (vapor-permeable self-expanding sealing tape). For a tight fit, it is cut off with a margin of 1-1.5 mm.

- Installation of the structure in the opening is impossible without the use of supporting blocks. They are made from polymer materials or solid wood and help transfer the weight of the window to the wall.

- Control over the even position of the structure is carried out using a level in three planes. After this, it is temporarily fixed with wedges. Holes are drilled in the wall where the hardware is attached to the profile. Now you can continue installation, securing the window with bolts.

Now you can install the flashings, glue the insulating material on the inside and foam the existing gaps. While the foam has not expanded, the vapor barrier is finally attached to the opening. The window sill is installed on the support blocks.

Mont Blanc windows are of excellent quality

Installation of slopes begins with the side panels. After their installation, the platbands are attached. Fixed double-glazed windows are installed first; installation of opening sashes involves their adjustment.

PVC profile Montblanc Grand 80

The Montblanc Grand 80 window system is characterized by the highest possible heat and sound insulation and is extremely in demand in the northern latitudes of our country. Thanks to six chambers and a unique patented design feature that ensures a more uniform temperature distribution on the inner surface of the windows, the highest quality of thermal and sound insulation is achieved. Tests carried out in a testing laboratory for thermophysical and acoustic measurements confirmed that the MONTBLANC grand 80 PVC profile belongs to the highest level of thermal protection - the first class of products.

The Grand 80 profile has 6 air chambers and an installation width of 80 mm. Within this system, double-glazed windows up to 52 mm are installed. The technology for creating Grand 80 profiles is unique, as it allows you to evenly distribute the temperature over the inner surface of the window and thereby increase energy savings.

The reduced heat transfer resistance of MONTBLANC grand 80 PVC profiles with installation reinforcement liners is 0.82 m2 x °C/W, which fully satisfies the requirements of GOST (30673-99).

Standing out for its technical features, the MONTBLANC grand 80 profile has an elegant design and demonstrates a successful combination of functionality and aesthetics. The traditionally impeccable quality of MONTBLANC system products is achieved by a high level of modern production and careful control of all its stages, which is a fundamental condition for durability. For more than 60 conventional years of operation in a temperate climate zone, the MONTBLANC profile will retain its properties guaranteed to remain unchanged.

This Montblanc line is considered the highest quality and most reliable. The Grand 80 system has passed many Russian and European tests, which confirmed its high technical characteristics.

In addition, the Grand 80 has a very elegant and modern design.

Characteristics of Montblanc Grand 80 windows:

- MONTBLANC grand 80 - 6-chamber profile with an installation width of 80 mm and the ability to install double-glazed windows up to 52 mm

- The MONTBLANC grand 80 system meets international standards for all criteria and requirements for PVC window systems, therefore it is the ideal choice for the most demanding client

- Thanks to six chambers and a unique patented design feature that ensures a more uniform temperature distribution on the inner surface of the windows, the highest quality of thermal and sound insulation is achieved. Tests carried out in a testing laboratory for thermophysical and acoustic measurements confirmed that the MONTBLANC grand 80 PVC profile belongs to the highest level of thermal protection - the first class of products. The reduced heat transfer resistance of MONTBLANC grand 80 PVC profiles with installation reinforcement liners is 0.82 m2 x ° C/W, which fully satisfies the requirements of GOST (30673-99)

Standing out for its technical features, the MONTBLANC grand 80 profile has an elegant design and demonstrates a successful combination of functionality and aesthetics. The traditionally impeccable quality of MONTBLANC system products is achieved by a high level of modern production and careful control of all its stages, which is a fundamental condition for durability. For more than 60 conventional years of operation in a temperate climate zone, the MONTBLANC profile will retain its properties guaranteed to remain unchanged.

Types of double-glazed windows

- Single chamber (2 glasses)

- Double chamber (3 glasses)

- With energy-saving glass (low-emissivity coating, k- or i-glass)

- With triplex glass (impact-resistant)

- With increased sound insulation

- Double-glazed windows with layout (white or gold layout)

A single-chamber double-glazed window consists of two glasses, between which there is an air gap (chamber). The usual shape of a single-chamber double-glazed window is 4x16x4, where 4 is the width of the glass (4 mm), and 16 is the distance between the glasses (16 mm). The width of the single-chamber double-glazed window installed in our company is 24 mm and is usually installed in windows made of a profile with a system width of 60 mm. We recommend installing single-chamber double-glazed windows only in unheated rooms or summer houses; installation of ordinary single-chamber double-glazed windows in apartments or other residential premises is prohibited by GOST. Double-glazed windows do not provide the level of heat protection and sound insulation required for comfortable living.

Double-glazed windows consist of three glasses with two air chambers between them. The thickness of double-chamber double-glazed windows manufactured in our company is 32 mm and 40 mm (for windows made of profiles with a thickness of 70 mm) and such double-glazed windows are recommended for installation in windows intended for residential premises. Double-glazed windows are our choice!

Energy-saving double-glazed windows are so called because of the special reflective coating (in most cases this is a thin layer of silver), which is applied to the inner surface of one of the glasses. Externally, this glass is no different from others, but has unique properties. In winter, when it is frosty and cold outside, it prevents heat from leaving the room outside, and in summer, during hot weather, thanks to the infrared coating, it rejects the sun's rays, making the temperature in the room lower and more comfortable. A single-chamber double-glazed window with energy-saving glass is equal in heat transfer resistance to a regular double-chamber one, although it loses to it in noise insulation. And a double-chamber double-glazed window with energy-saving glass (i-glass) has the most maximum heat-saving properties. It is more expensive than usual, but over several years of operation of windows with energy-saving double-glazed windows, you will not only save this money on heating, but over time you will make a profit by reducing your monthly energy bills.

PVC profile Montblanc City 120

Plastic windows Montblanc City 120

They are a five-chamber profile with an installation depth of 120 mm. This profile was created for glazing partitions created indoors. It is considered the most stable structure due to its significant installation depth.

In the manufacture of the MONTBLANC city 120 profile, as in all MONTBLANC profiles, a unique patented design feature is used, which ensures a more uniform temperature distribution on the inner surface of the windows and increases the thermal insulation property.

The unique design of the City 120 profile allows the temperature to be evenly distributed over the inner surface, which improves its energy-saving properties. According to the manufacturer, the reduced heat transfer resistance with installed steel liners is 0.72 m2 x °C/W. Such indicators indicate the possibility of using City 120 structures in areas with the most severe weather conditions. The profile will perfectly provide heat and sound insulation.

High sound insulation undoubtedly makes this profile suitable for use in buildings located along the streets of large cities and near various noise sources. The exemplary quality and excellent technical performance of the MONTBLANC city 120 profile are perfectly complemented by its elegant design. It should be noted here that for the consumer looking for a variety of colors, it is possible to produce all profiles of the MONTBLANC system painted in the mass in any colors.

In the manufacture of the MONTBLANC city 120 structure, traditionally impeccable quality is observed, due to the highest level of production. The durability of the MONTBLANC city 120 system is more than 60 conventional years of operation in a temperate climate zone.

Characteristics of Montblanc City 120 windows:

- The installation depth of the profile of 120 mm prevents the formation of a “cold bridge” along the perimeter of the window in the area of the construction quarter and opens up new possibilities in finishing slopes

- This profile is perfect for installing glazed partitions indoors, as it is the most stable due to its large installation width

- In the manufacture of the MONTBLANC city 120 profile, as in all MONTBLANC profiles, a unique patented design feature is used, which ensures a more uniform temperature distribution on the inner surface of the windows and increases the thermal insulation property. The use of this technological innovation in the MONTBLANC city 120 system with a five-chamber profile section creates maximum thermal insulation

- The reduced heat transfer resistance with installed steel liners is 0.72 m2 x °C/W

- High sound insulation undoubtedly makes this profile suitable for use in buildings located along the streets of large cities and near various noise sources

The durability of the MONTBLANC city 120 system is more than 60 conventional years of operation in a temperate climate zone.

The big picture

Caring for Mont Blanc windows is simple and, as practice shows, allows you to remove all the so-called shortcomings.

- A yellowing profile is the result of incorrectly selected detergents with aggressive additives.

- Possible unpleasant odor from rubber seals and mosquito nets disappears after washing with a simple soap solution.

- Disadvantages of fittings - handles falling out or doors closing tightly - can be solved by adjustment. You should not skimp on fittings.

Windows do not require special care and do not cause trouble to consumers

There are no other secrets to caring for Mont Blanc windows; all you have to do is follow the above recommendations and enjoy the warmth in your home.

PVC profile Montblanc Quadro 70

Production of the MONTBLANC QUADRO 70 profile began in 2011.

To increase energy saving, the MONTBLANC QUADRO 70 profile system provides for the installation of double-glazed windows up to 42 mm. An important distinguishing feature of this five-chamber system is its installation depth of 70 mm. This installation depth will allow for optimal design and placement of air chambers in the frame and sash, which is of great importance for heat and sound insulation.

In Russia, with its wide geography of climatic zones, the constant improvement and development of window profile systems is not only justified, but also necessary. Significant differences in winter temperatures, even in central Russia, have shown the need to use window structures with increased energy-saving properties. The profile system MONTBLANC QUADRO 70 is perfectly suited to this task.

Based on studies carried out in the testing laboratory of thermophysical and acoustic measurements at the Research Institute of Building Physics, the reduced heat transfer resistance of MONTBLANC QUADRO 70 profiles in the assembly is:

- with galvanized steel reinforcing liner – 0.76 m²Cº/W

- without reinforcing liner - 0.80 m²Cº/W

- In terms of the level of thermal protection, such indicators, according to GOST 30 673-99, classify the MONTBLANC QUADRO 70 profile system to the highest - first class. It also follows from the test conclusion that these profiles are recommended for use in window and door blocks of residential and industrial buildings in any climatic zones of Russia. This opens up wide possibilities for application.

The high technical characteristics and modern appearance of the MONTBLANC QUADRO 70 profile system are due not only to perfect design developments, but also to constant quality control.

Our own technical control laboratory tests all raw materials and checks finished products according to all the main indicators regulated by GOST.

Thus, the company is committed to producing only high-quality profiles with consistently high characteristics.

How are Montblanc profiles made?

The history of PVC profile production goes back more than one decade. Window systems from Germany and Austria were the first to conquer Russian spaces, then Turkish products filled the market.

The obvious promise of a new product for Russia—windows made of PVC profiles—quickly gave birth to a domestic manufacturer of profile systems, and competition with the masters of European extrusion demanded high quality. Quality is the most important issue at all stages of production processes.

The STL-Extrusion company, which appeared on the domestic PVC profile market in 2001, has set itself the task of producing profiles of the highest European level. Unlike a number of companies that produce PVC profiles in Russia using equipment that has already been sufficiently used at European enterprises, the STL-Extrusion company works only on new, ultra-modern equipment, both for extrusion and for other production processes.

Suppliers of raw materials and components for extrusion are reputable and world-famous manufacturers, such as Chemson Polymer - Additive AG (Austria), Vinnolit Gmbh & Co.KG (Germany), Renolit AG (Germany), Klebchemie MG Becker Gmbh & Co.KG ( Germany) and others, cooperation with whom is the key to the quality of the finished product.

However, all raw materials are tested in the enterprise’s own laboratory, equipped with equipment that is not only modern, but also allows for unique computer diagnostics for color, gloss and accuracy of geometric parameters. Samples from each batch of finished products are subject to laboratory control (in accordance with GOST 30673-99).

The mixture preparation section is equipped with the best equipment in the world from Henshel (Germany) and Plasmec (Italy), which eliminates defects at this technological stage. The entire complex operates in automatic mode, is equipped with a quality control and assurance system, as well as automatic software control of recipe management. The mixture preparation section has a large power reserve and is capable of producing up to 6 tons of mixture per hour. This allows us not only to regularly commission new lines, but also to quickly respond to market needs.

One of the most important features of STL-Extrusion is a detailed approach to quality at all stages of the production cycle. High-tech processes required highly purified water, and drinking water began to be purchased from a food plant. This water is additionally softened and constantly filtered to prevent the ingress of abrasives, and to prevent the development of bacteria, it undergoes biopurification using ultraviolet light.

The technical and technological innovation of production allowed the STL-Extrusion company to quickly launch the production of PVC profiles that meet the highest world standards. Together with the Austrian company A+G Extrusion Technology GmbH, a leader in the global extrusion equipment market, PVC profile systems with the MONTBLANC trademark were designed and developed. During their development, special attention was paid to the peculiarities of the Russian climate, in which operational properties are of great importance.

Mont Blanc, sir!

A plant for the production of PVC structures under the Montblanc TM opened in the Moscow region in 1999. A year later, the production of Montblanc windows was launched, meeting all generally accepted international standards for systems made of polyvinyl chloride and subsequently receiving many positive reviews from consumers.

The production was organized jointly with the English one. Currently, 30 automated lines are operating to meet the needs of consumers.

Mont Blanc windows are 7 lines of systems that have already been developed and tested in our climate. A dozen more PVC structures are at the design stage. Each of the seven offers - Logic, Termo 60, Grand 80, Eco 60, City 120, Nord 70, Quadro 70 - is available to consumers today.

The manufacturer took care of the variety of PVC windows, giving each profile specific technical characteristics. In order not to make a bad choice, you will have to get acquainted with each modification separately.

You need to choose a PVC window profile in accordance with the climate and consumer needs

Benefits of Montblanc window systems

- proven modern technologies for the production of window profiles

- careful quality control of products at every stage of production

- modern European equipment

- own scientific and technical developments with the aim of constantly improving product quality and improving its design

- carefully thought-out design that combines convenience and beauty

- wide range of products from economy to premium class

- high reputation and reliability of the Company, operating for more than 13 years on the market