PVC windows are available in a wide variety. All models are equipped with a locking device. Many people choose a tilting mechanism for plastic windows. It is simple in design and setup. You need to understand what it is and how it differs from other locking options. Having an idea and basic knowledge regarding the operating principle and internal structure of a plastic window will make it easier to choose the appropriate option, and also easier to carry out adjustments and repairs yourself.

Closing mechanism for plastic windows

Opening and locking of the plastic window is provided by fittings. It consists of a handle, a locking plate, a corner element, scissors, a counter plate, a trunnion, etc. Additionally, there may be a child lock. It prevents the child from opening the sash and protects it from falling out.

Scissors are installed along the top edge. The main lock is mounted on the side of the handle, and the middle one is mounted below. The upper elements are connected by an angular transmission using a tire. The middle lock is equipped with a direct angular gear. The operating principle is simple. When the handle is turned, the steel rail is set in motion and the sash is pulled to the frame. When the handle is turned up vertically to the window sill, the sash is switched to ventilation mode. And when it is located diagonally, micro-ventilation is installed. Scissors take part in changing modes. The levers are blocked by a microlift. This protects the system from errors.

Content

- 1 ACCESSORIES

- 2 TURNING CLOCK

- 3 ROTARY LOCK

- 4 PIN LOCK

- 5 ANGLE SWITCH

- 6 SCISSORS

- 7 MEDIUM CONSTIPATION

- 8 LOOP

- 9 KEEPER

- 10 TURN-OUT KEEPER

- 11 DECORATIVE OVERLAY

- 12 UPPER HINGE PIN

- 13 LOWER TURN-OUT ESCAP

- 14 UPPER ESCAP (UPPER LOCK CONNECTOR)

- 15 SLIT VENTILATION

- 16 STAGE VENTILATION

- 17 BALCONY LATCH

- 18 LEAF ROTARY BLOCKER (CHILD LOCK)

- 19 SIMPLE EQUIPMENT OF A TURNING WINDOW

- 20 IMPROVED TURNING WINDOW EQUIPMENT

- 21 Contribution of participants

ACCESSORIES

is a system of mechanical window devices designed to provide a perimeter (along the entire perimeter) fit (pressure) of the sash to the frame, as well as drive the sash to the required position.

Composition of accessories

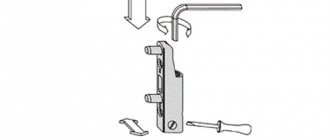

TURN AND TILT CLOCK

- this is a fitting part designed to convert the control rotation of the window handle into translational movement of the moving part of the lock and its transmission to the moving parts of the mating parts of the fittings (corner switch, middle lock, etc.). Installed in the fitting groove of the sash of a plastic or wooden window. Structurally, it is made in the form of a steel plate and consists of fixed and moving parts. The moving part of the tilt-and-turn lock with a middle position of the handle at the top and bottom is made in the form of a “comb”, with the help of which the movement of the moving part is transmitted to the mating parts of the fittings. The moving part of the lock includes a locking pin that interacts with the striker to ensure that the sash is pressed against the frame. The fixed part of the lock with a fixed (permanent) handle position at the bottom has a protrusion (trunnion), with the help of which the weight of the sash is transferred to the swing-out strike plate during the process of moving the sash to the folding position

ROTARY LOCK

is a piece of fittings designed to convert the control rotation of the window handle into translational movement of the movable part of the lock. Unlike a tilt-and-turn lock, it does not have a “comb” and does not transmit the translational movement of the moving part to the mating parts of the fittings. Thus, the rotary lock allows the sash to be pressed against the frame only from the lock side

PIN CONSTRUCTION

- this is a fitting part designed to convert the control rotation of the handle into translational movement of the moving part of the lock and its transmission to the moving parts of the mating parts of the fittings (corner switch, middle lock, etc.) of the hinged sash of a plastic or wooden window. Structurally, it is made in the form of a steel plate and consists of fixed and moving parts. The moving part of the pin lock is made in the form of a “comb”, with the help of which the movement of the moving part is transmitted to the mating parts of the fittings. The fixed part of the lock includes strike plates for the locking pins

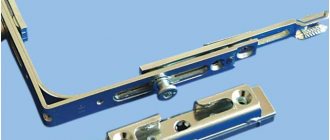

ANGLE SWITCH

- this is a hardware part designed to transmit translational movement of the movable part of the hardware at an angle of 90 degrees. – for rectangular windows, more than 90 degrees to 135 degrees. – for trapezoidal windows, less than 90 degrees from 35 degrees to 45 degrees – for triangular windows from the bottom of the sash. Installed in the fitting groove of the sash of a plastic or wooden window. Structurally, it is made in the form of a corner and consists of fixed and moving parts. The moving part consists of four steel plates, with the help of which the movement is transmitted at the required angle. The moving part of the corner switch includes a locking trunnion that interacts with the strike plate to ensure that the sash is pressed against the frame and toothed receiving parts for connection with the “combs” of the scissors and the main lock

SCISSORS

is a piece of fittings designed to ensure installation and fixation of the tilt-and-turn window sash in the “reclined” position, as well as transmitting the movement of the moving parts of the fittings to the mating parts. Structurally, they are made in the form of one element (article). Consist of fixed and moving parts. The moving part of the scissors for wide sashes includes a locking pin that interacts with the striker to ensure that the sash is pressed against the frame

Scissors on the sash Scissors on the frame

MODERATE CONSTIPATION

- this is a piece of fittings designed to ensure that the sash is pressed against the frame. Installed in the fitting groove of the sash of a plastic or wooden window. Pairs with scissors, tilt-and-turn lock, upper or lower latch, and pin lock. Structurally, it is made in the form of a steel plate and consists of fixed and moving parts. The movable part of the lock includes a locking pin that interacts with the strike plate to ensure that the sash is pressed against the frame

A LOOP

- this is a piece of fittings designed to hang the sash on the frame and ensure their required relative position. There are hinges on the frame (upper and lower) and on the sash (corner, lower, middle, transom).

Hinges ensure the installation of sashes with a maximum weight of up to 130 kg Bottom hinge on the sash Bottom hinge on the frame

Middle loop

RETURN PLAN

- this is a piece of fittings designed to ensure that the sash is pressed against the frame (together with the locking pin of the movable part of the fittings elements). Installed on the frame and depends on the profile. Structurally made non-adjustable. To ensure increased anti-burglary properties of the window unit, anti-burglary strikers are used that prevent unauthorized pressing of the sash from the frame in the closed position of the fittings

Striker

standard anti-burglary

TURN-OUT KEEPER

- this is a piece of fittings that, in addition to the function of pressing the sash to the frame, provides a support point for the sash during its tilting. It is installed on tilt-and-turn windows on the frame and depends on the profile. To ensure increased anti-burglary properties of the window unit (the so-called basic security), anti-burglary tilt-and-turn strikes (folding supports with a microlift) are used.

DECORATIVE OVERLAY

- This is a fitting part designed to give the necessary color design to the fittings. They are made of plastic of various colors and are installed on hinges.

UPPER HINGE PIN

- this is a piece of fittings designed for a movable connection between the upper (corner) hinge on the sash and the hinge on the frame

IN

- top hinge pin

LOWER TURN-OUT ESCAP

- this is a piece of fittings designed to ensure that the sash is pressed in the closed position and the sash is tilted into the tilt-and-turn position, as well as to ensure that the movement of the movable part of the tilt-and-turn lock is transferred to the middle lock. It is connected at the bottom to a tilt-and-turn lock with a middle (variable) handle position. It can also be used with fixed turn-and-tilt locks of the A0089 series. Structurally, it is made in the form of a steel plate and consists of fixed and moving parts. The moving part of the lower latch “receives” the movement from the swing-out lock with the help of the mating part of the “comb”. In addition, the movable part includes a locking pin that interacts with the swing-out strike plate to ensure that the sash is pressed against the frame. The fixed part of the lower latch has a protrusion (trunnion), with the help of which the weight of the sash is transferred to the swing-out strike plate during the process of moving the sash to the folding position. The connection of the tilt-and-turn lock to the lower latch is carried out using the comb mating part of the latter

UPPER CLOTCH (UPPER LOCK CONNECTOR)

- this is a piece of fittings designed to ensure the transfer of movement of the moving part of the tilt and turn lock to the middle lock, as well as to press the sash to the frame. Connects at the top with a tilt and turn lock. Structurally, it is made in the form of a steel plate and consists of fixed and moving parts. The moving part of the upper latch “receives” the movement from the swing-out lock with the help of the mating part of the “comb”. In addition, the movable part includes a locking pin that interacts with the striker to ensure that the sash is pressed against the frame. The middle lock is structurally attached to the upper latch

CRACK VENTILATION

- limited single-mode ventilation of the room through a fixed gap in the vestibule slightly with the sash tilted (ajar) (opening area no more than 0.02 sq. m.).

STEP VENTILATION

– one-, three-, four- or five-mode limited ventilation of the room through fixed gaps in the narthex of a slightly tilted (ajar) sash

BALCONY LATCH

Balcony latches are designed to fix the balcony door in the closed position without closing it with a handle or locking it with a key. • installed on main tilt-and-turn and rotary locks; • the latch pin (E) is metal, screwed to the main lock; • the frame part of the balcony latch (D) depends on the profile (KBE, VEKA, REHAU, WOOD Eurofold, Eurogroove 7/8, etc.) • allows vertical adjustment in the range of ±2.0 mm due to the oval holes of the fastenings for screws

LEAF ROTATOR BLOCKER (CHILDREN'S LOCK)

• designed to block the opening of the sash - the “open” mode, but at the same time the “reclined” mode remains operational, the so-called “child lock”; • consists of sash and frame parts (one article); • color: white, brown; • options: with key and hexagon lock;

SIMPLE EQUIPMENT OF A TURNING WINDOW

- this is a set of fittings for a pivot window, which includes: a rotary lock, rotary scissors, a middle clamp and a hinge group. This set of fittings is used for sash rebate widths of less than 700...800 mm (depending on the profile)

IMPROVED TURNING WINDOW EQUIPMENT

- this is a set of fittings for a turning window, which includes, among other things, a tilt-and-turn lock, a corner switch (2 pcs.), an extension (2 pcs.), a middle clamp and a hinge group; or a tilt-and-turn lock, an upper latch with a handle rotation limit of 90 degrees, a lower latch (middle/variable handle), a middle latch (2 pcs.), a middle clamp and a loop group. This set of fittings is used when the width and height of the sash along the rebate exceed 700...800 mm (depending on the profile) in order to ensure the necessary pressing of the sash to the frame to prevent blowing

The device of the turning mechanism of a plastic window

The rotary mechanism is traditional. Provides opening of the sash into the room. The system is thought out to the smallest detail. It is based on canopies that are installed vertically in the fitting groove. This mechanism is basic. Present in almost all plastic windows. Its advantage is the ability to connect automation.

The angle of rotation of the sash depends on the comb and the design features of the handle. Doors with this operating mechanism are available in different shapes: square, arched, trapezoidal, rectangular.

The main disadvantage of this version of a plastic window block is that when open, the sash takes up space. This does not make it possible to place plants and necessary decorative items on the windowsill.

How to choose the right main lock?

If the installation takes place without employees of the window company, first you need to decide on the following data:

- The sash height is required.

- The height of the sash, measured from the bottom of the glass unit to the center of the handle.

- Type of profile system.

Measurements must be taken from the side of the window facing the street, that is, take measurements beyond the rebate. Also for the future, you need to know that when replacing one component of the fittings, it is necessary to replace all other parts, because in most cases, the locks are not interchangeable parts of the window. When replacing an old-style lock with a new one, there is a possibility that the sash mechanism will not work as originally intended. For example, the closing lever will not be able to reach the end position in either direction.

Regardless of the type of constipation that is suitable specifically for your type of double-glazed windows, it is recommended to purchase high-quality parts in specialized stores or on trusted sites to avoid problems with rapid replacement in the future.

Tilt-and-turn mechanism for plastic windows

The tilt-and-turn mechanism for plastic windows is an optimal and reliable solution. Combines the advantages of tilting and rotating systems. Allows you to fully open the sash and set it to ventilation mode.

Modern tilt-and-turn fittings make it possible to adjust the degree of opening and the pressing force of the sash when closing. To open the window, you need to move the handle to the horizontal position. To activate the ventilation or micro-ventilation mode, you need to turn it up vertically or install it at an angle of 10-35 degrees. To perform such operations you only need one handle. Its design is complex. Window units with this locking method are more expensive.

Accessories

Fittings are of no small importance for long-term operation and comfortable use:

opening-closing mechanisms;

The share of the cost of accessories in the total price of the product emphasizes its importance. The cost of door hardware is up to a quarter of the cost of the product.

Depending on the purpose, door fittings are assigned various tasks.

The device of the folding mechanism of plastic windows

This mechanism works on the rotary principle. Accordingly, it consists of the same parts. The only difference is that the canopies are not located vertically, but in a horizontal plane. This system provides only ventilation. It will not be possible to open the door completely. The advantage of the folding option for opening a plastic window is to protect the room from penetration from the street. It also allows you to save space, place the necessary decorative elements on the windowsill, and hang roller blinds. Such devices are safer for animals and small children. But caring for double-glazed windows will be more difficult. However, this option is often chosen. And often this is due to its reasonable cost. There are plastic windows with transoms. These are standard designs with a folding window located on top. They are rare. As a rule, large window openings are equipped with transoms.

Gate bolts

Another type of deadbolt design is sliding. For its production, wooden or steel strips are used. To make it yourself, you need to have metalworking skills and a set of tools.

The metal thickness of the valve should be thick enough to prevent bending

Algorithm.

- Prepare the steel strip. Its length must be at least 40 centimeters and its width – 5 centimeters.

- Since the strip will move along the guides, they must be secured to the gate by welding. The bolt is attached to the sash using self-tapping screws or welding.

- After installation, a groove is also installed on the second leaf to fix the second half of the steel strip.

Sometimes, in order to make a deadbolt with the ability to lock with a lock , additional holes are drilled or special arms are mounted.

Decorative latch looks impressive

Make it yourself or buy a valve

Gate valves are often purchased, but for gates they prefer to make them themselves. And there is an explanation for this.

- The gate is used much more often, therefore, the mechanism must be durable, work flawlessly and look aesthetically pleasing.

- The design and dimensions of gates are more standard, and choosing a locking mechanism is much easier.

- Gates have more individuality: design, materials, sizes. In this case, the lock for swing gates is usually of a hidden type. As a result, beauty is in the background, safety and reliability come to the fore.

It is for all these reasons that the manufacture of gate locking devices is more demanding and is made independently, as they say, to be sure. But what type of constipation to choose is up to you to decide.