Set: window ventilation valve and acoustic visor.

The valve height of 31 mm allows it to be mounted on all types of windows.

The Aereko ventilation valve can be installed on the frame, while other valves may not fit into the space between the sash overlap and the slope.

Oblique air flow, which can be changed to horizontal using an additional device - the O-EMM² spacer. Generally, horizontal flow is required in close proximity to windows or ceilings. The operating mode switch allows, if necessary, to manually close or open the damper of the air supply device. Three modes:

- minimal ventilation

- automatic (hygroregulation)

- maximum air flow

The Aereco inlet valve features a modern, stylish design, embodied in a slim body, ensuring ideal installation on most windows and roller shutters. The use of highly effective sound-absorbing materials, together with a special spacer and external visor, provides sound insulation of up to 42 dB. A special switch allows, if necessary, to manually close or open the damper of the supply unit, which functionally complements the hygroregulation system equipped with

The principle of operation of the supply unit is based on changing the flow area depending on the level of relative humidity in the room. The air flow is modulated depending on the relative humidity level in the room. Performing the functions of a sensor-drive of a hygro-controlled system, the V8 converter obeys the principle of a well-known physical law: as humidity increases, matter lengthens, and as humidity decreases, it narrows. In accordance with this law, 8 polyamide strips operate the damper, regulating the air flow depending on the level of relative humidity in the room. The higher the humidity level inside the room, the more the damper opens.

The V8 transducer is isolated from the air flow direction and only measures the humidity level in the room. In addition, thanks to the thermal adjustment system, the process of opening the damper occurs regardless of external climatic conditions. The lower the outside temperature, the lower the relative humidity the hygro-controlled air supply device opens.

Condensation as a result of ventilation

Frequently airing rooms will not solve the problem of condensation on windows, since the benefits of replacing regular windows with plastic ones are lost.

The result is heat loss, low sound insulation, penetration of unpleasant street odors, and a layer of dust on the window sills and floor. Some manufacturers offer to install a slot microventilator as an additional accessory to the window. It is installed on the tilt-and-turn sashes of a plastic window. By turning the handle 45 degrees, the sash opens 3-5 mm. Passive air exchange is created in the room, and a draft occurs. The problem with heat conservation and tightness remains. The effective supply of the required fresh air occurs provided that the internal ventilation is working well and there must be access to the ventilation ducts.

Solution

If you turn the handle to an angle of 45°, the sash opens a few millimeters, this allows you to create passive air exchange and a draft. However, the problem with tightness and heat conservation remains. Fresh air will be effectively brought into the room if the internal ventilation works well and the rooms have access to ventilation ducts. The solution to this problem is moisture-sensitive ventilation systems, which are called automatic valves, which will be discussed below.

Operating principle of the Aereco valve

In 1983, in Paris, Aereco created a unique moisture-sensitive ventilation system - an automatic valve designed to regulate the flow of outside air depending on the degree of humidity inside the room.

Thanks to the Aereko window supply valve, there is no need to constantly ventilate the room using micro-ventilation, while maintaining heat and noise-proof properties. In addition, when there is a large crowd of people, the sensor actively works, and if no one is in the room, the valves close. Thus, these valves provide as much cold and dry air as needed.

Aereco window valve operation diagram

When preparing food, the carbon dioxide we exhale increases the humidity in the room, which is an excellent condition for pathogenic microflora.

A constant supply of fresh air creates comfortable living conditions in the room and prevents respiratory diseases and oxygen starvation.

Also, effective regulation of air humidity prevents the formation of mold on window slopes and walls and protects against condensation.

The Aereko window valve itself is a small lining. It has a beautiful appearance, does not take up much space and fits perfectly into any interior. Depending on the type, the Aereko ventilation valve has several colors: white, grey, beech and teak.

Color solutions for the EMM humidity-controlled air supply device

The inlet valve is easy to maintain. It is enough to remove dust several times a year using a vacuum cleaner with a soft attachment.

The Aereko valve is quite easy to install. Installation takes 45-60 minutes. A supply air curtain is mounted in the window sash above the glass or in the wall, and a canopy is placed outside to control the air flow with a grille that protects from dust and insects.

Installation of the Aereko flow valve occurs immediately at the factory during the manufacture of windows, as well as on already installed windows without dismantling them and replacing double-glazed windows.

The operation of the ventilation valve sensor is based on the principle of the physical law of thermal expansion of solid materials: expansion when humidity increases, contraction when humidity decreases.

The valve consists of 8 or 16 polyamide moisture-sensitive plates. They, reacting to a given degree of humidity, influence the mechanism for opening and closing the damper without the use of power.

As the amount of humid air in the room increases, the moisture-sensitive tape in the Aereco supply valve lengthens. The damper opens, letting in dry air from the street and displacing carbon dioxide through the kitchen or bathroom exhaust vent, which should not be blocked. The higher the humidity level inside the room, the more the dampers open.

The Aereko ventilation valve is not exposed to air flow from the street, so it accurately shows the degree of humidity in the room.

When the air humidity decreases, the valve closes automatically. During strong winds or bad weather, you can manually switch valve modes.

An exhaust ventilation system equipped with a similar barrier creates a mode for automatically maintaining high-quality air in the apartment.

Aereco air supply devices are produced in several versions.

The EMM valve is a classic device. It is ideal for small spaces. Has a thin body. Air from the street enters the room vertically or obliquely, depending on the position of the window.

The ENA2 valve has a stylish design and has a higher degree of protection from external noise. The air flow of this valve is directed to the ceiling, thanks to which the incoming air is heated, which gives maximum comfort to the residents of the apartment. In the photo below, the device is equipped with an acoustic spacer on top.

Sometimes, for some reason, it is not possible to install an Aereko supply valve in a window, so an alternative device has been created - the EHT system, which is attached to the wall. It has a beautiful appearance and is easily installed in the wall using a special cutter. The valve provides effective protection against external noise.

Aereko valve.

All Aereco supply window valves are installed in the center of the upper horizontal part of the sash, in the sash. To install them, it is necessary to mill ventilation ducts in the overlap of the sash and frame. The principle of self-regulation is based on a physical law - when humidity increases, matter lengthens, and when humidity decreases, it contracts. In accordance with this law, eight polyamide strips operate the damper, regulating the air flow depending on the level of relative humidity in the room. The higher the humidity level inside the room, the more the damper opens and the larger volume of air enters the room.

Attention!

Any supply ventilation valve at a temperature of -150C can be covered with ice to a greater or lesser extent (due to the physical processes described above).

Aereco valves have a lower probability of icing

than

Air-Box

, since the air passing through it is not directed vertically upward, to the junction of the frame and the slope, where a zone with low air temperature is formed, but at an angle to the window, to the ceiling, where it collects warm air (although if you have slopes wider than 35cm, the air stream will still be directed into the slope, but in this case the likelihood of icing is lower).

The disadvantages

Aereco

valves include: - the need to mill the window, - the lack of manual adjustment of the flow of incoming air, - the impossibility of installation when the window frame is deeply recessed in a quarter of the wall, - the full opening of the sash may be limited. Since the thickness of the valve is 3-4 cm, when the valve is opened in full swing mode, it rests on the slope and can damage it or damage itself - cost.

Design features

On sale you can find windows in which the valves described are built into them at the factory, so the consumer does not have to deal with these manipulations on his own. The operation of the sensor is based on the principle of the physical law of expansion of materials.

When humidity increases, solid structures expand, while when humidity decreases, they contract. The composition contains moisture-sensitive polyamide plates, the number of which in the system can vary from 8 to 16. They react to a given humidity temperature, influencing the mechanism for closing or opening the damper, and no power supply is required.

What else you need to know about the operating principle

“Aereko” is a valve that has a moisture-sensitive tape inside the room. When the level of humid air in the room increases, the tape lengthens, the damper opens, and dry air from the street enters, displacing carbon dioxide, it exits through the kitchen exhaust vent, which should not be blocked during operation. As the level of humidity inside the room increases, the dampers open more and more.

“Aereko” is a valve that has a unique design; it is not exposed to air flow from the outside, so the humidity level in the room is determined as accurately as possible. When air humidity decreases, the valve closes automatically, and during bad weather or strong wind, the modes can be switched independently.

Advantages

- Hygro-controlled system: controls air flow depending on the relative humidity level indoors

- Reduces acoustics: up to 42 dB with accessories

- Operating mode switch

- Angled airflow for occupant comfort

- Slim body for easy installation into window profiles

- Easy installation

- Easy maintenance: no need for adjustment, just clean the dust once a year.

Classification of Aereco valves

The device described above is classified into two types, including:

- EMM;

- ENA2.

The first option is a classic design that is perfect for small spaces. It has a thin body, and the air from outside enters inside obliquely or vertically, which will depend on the position of the window. The second type of valve has a stylish design and a fairly high degree of protection from outside noise. This air supply valve "Aereko" is directed to the ceiling, thanks to this the incoming air is heated, as a result it is possible to achieve maximum comfort in the apartment.

Reliability and simplicity

With all the variety of air supply devices, EMM is the basis of the AERECO humidity-controlled technology. EMM has two ways of air supply (with vertical or inclined flow direction) and three basic colors. Thanks to its simple and reliable design, the EMM supply valve is widely popular in all countries where the company operates. Supplemented with an acoustic visor, the device reduces the noise level to 37 dB.

Hygro-controlled system: controls air flow depending on the level of relative humidity inside the room.

Operating mode switch: allows you to reduce the air flow to a minimum in case of strong wind or cold weather.

Reduces acoustics: up to 37 dB with accessories.

Directional airflow: The base directs the airflow vertically or obliquely.

Easy maintenance: no need for adjustment, just clean the dust once a year.

Adapts to any position

The EMM supply unit features a controlled base, which allows it to direct the air flow depending on the position of the window in relation to the slope for maximum comfort for residents.

Installation recommendations

Installation of Aereko valves is carried out using a certain technology. There is no need to dismantle the windows for this. To begin with, the master will have to mark the place where the device will be located. It is important to pay attention to the presence of other window fittings that may interfere with installation. The inlet valve strip is secured with self-tapping screws.

On the frame narthex it is necessary to mark grooves, which may also be on the sashes. When installing the Aereko ventilation valve, the next step is to remove the strip and cut the holes, for this you should use an electric jigsaw or drill. First, holes are made in the sashes, and at the next stage - in the frame. Next, you can reinstall the strip and secure the window valve with the latches.

Installation of the Aereco EMM valve.

To install the Aereco EMM

It is necessary to mill holes in the flaps of the sash and frame and secure the valve on the sash (indoors) with self-tapping screws, and the canopy on the frame (from the street).

Holes in the frame overlay for the EMM valve visor. Acoustic visor of the EMM valve (without mesh). Hole in the flap overlay for the EMM valve. Valve control self-regulating valve minimum open

Price. * Visit of a master - 300 rubles. * Aereco EMM

with an external standard canopy (sound insulation -32 dB) - 3200 rub.

* Aereko EMM

with external acoustic visor (sound insulation - 37 dB) - 3400 rub.

* During installation, the sash is removed. Although the opening closes, the room cools down a little. * The minimum possible sash width is 40cm (EMM). * The window frame (top) must extend beyond the quarter by at least 2.5 cm (EMM). * It should be taken into account that the thickness of the valve (EMM) is 4 cm and it can rest against the slope, which will reduce the angle of possible opening of the window. Aereco

valves are not sold without installation.

* Installation of one Aereco

takes approximately 2 hours. * Possible colors - white (for EMM oak, teak, check availability).

Specifications

The Aereko valve, the characteristics of which you should consider before purchasing the product, is offered for sale in several models, among them:

- EMM 5-35;

- EMM 11-35;

- EMF 35.

In the first two cases there is a hygroregulation function; as for the presence of an operating mode switch option, it is available in the first and last options. It is also important to pay attention to the air flow at a pressure of 10 Pa. In the first case, this parameter can vary from 5 to 35 m3/h, in the second - from 11 to 35, and in the third it is 35 m3/h. The maximum opening area in all three cases is 4000 mm2.

Models and specifications

At the moment, the Aereco range of air handling units includes two models: EMM and EHA2. These are window valves, and in addition to them, the range includes another option - wall valves. A model called Aereco EHT can be used either in addition to windows or separately.

Each series (EHA2 and EMM) includes 3 variations, which differ in characteristics and the presence/absence of some options. In addition to the air inlets themselves as standard, Aereco also produces several types of additional accessories that are purchased separately.

Aereco EHA2

Aereco EHA2 is a model that replaced the outdated EHA series, which is now discontinued. It does not have any design delights: an oblong body with upward-pointing holes, made of plastic. Available in the following colours: white, grey, oak or teak.

Aereco on a wooden window

The Aereco EHA2 valve series includes 3 models:

- EHA2 5-35. Marked by the manufacturer: EAR201, 283, 286 or 308.

- EHA2 11-35. Marked by the manufacturer: EAR202, 290, 292 or 327.

- EHA2 17-35. Marked by the manufacturer: EAR203, 295, 297 or 328.

The numbers at the end indicate the minimum and maximum productivity (in m³/h) with a difference in air pressure outdoors and indoors of 10 Pa.

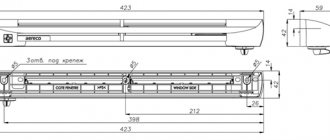

Here are the overall dimensions common to all 3 models:

| Case dimensions (WxHxD), mm | 423 x 41.5 (54 – with regulator) x 59 |

| Weight, g | 271 |

| Size of 1 hole on frame, mm | 172 x 12 (total 2 holes) |

Performance characteristics:

| Open valve opening area, mm² | 3600 |

| Noise insulation with valve open, dB | 37 |

| Hygroregulation system | + |

The differences between the models lie in their performance limits.

Also, ENA2 5-35 has an operating mode switch (the other two models do not have it). It is a small round part that is installed in the lower right part of the case, and can take 3 positions (modes):

Aereco EHA2 mode switch

- Minimum productivity (5 m³/h). On the body it is designated as “0”.

- Automatic performance adjustment (using hygroregulation technology). On the body it is designated as “*”.

- Maximum productivity (35 m³/h). On the body it is designated as “1”.

The price for this series starts from 2500-2600 rubles (without installation).

Aereco EMM

Externally, the Aereco EMM series is similar to the EHA2. The main difference is that in these models the valve base (the part that is located outside on the frame) is movable. By tilting it, you can change the direction (angle) of the air flow.

The body colors of this series are white, teak or oak.

The EMM series also includes 3 variations:

- EMM 5-35. Marked by the manufacturer: EMM716, 717, or 830.

- EMM 11-35. Marked by the manufacturer: EMM751, 974 or 975.

- EMF Manufacturer's mark: EMF963.

The principle of the model name is the same as for EHA2: the number at the end indicates the capacity in m³/h. The latest variation stands out - Aereco EMF 35: the cross-section of this valve is not adjustable, and can be either completely open (and let through 35 “cubes”) or completely closed. For this reason, the model does not have a hygroregulation system, but is equipped with a mode switch.

Aereco EMM mode control - black “tab”

Model EMM 5-35 also has a manual regulator. It is made in the form of an oblong rod with a curved flat end. The protruding end is located on the left edge of the body and is used to adjust the operating modes of the valve. There are two of them - minimum inflow (the regulator is in the upper position) and automatic operation (in the lower position, respectively).

Model EMM 11-13 does not have a regulator and can only operate in automatic mode.

Now let's move on to the general characteristics of the products:

| Case dimensions (WxHxD), mm | 402 x 39.5 x 40 |

| Weight, g | 170 |

| Size of 1 hole on frame, mm | 140 x 12 (total 2 holes) |

Performance characteristics:

| Open valve opening area, mm² | 4000 |

| Noise insulation with valve open, dB | 34 |

Prices for Aereco EMM models are about 2800-3000 (without installation).

Additional accessories for valves

The manufacturer produces the following additional accessories:

- External visors with various functions.

- External AC visor protects against strong gusts of wind.

- Telescopic ventilation duct E-TFR.

The general purpose of external visors is protection from moisture and insects. Products are available in 4 variations:

- AS: standard visor.

- AP: Flat (10 mm) canopy that can be used in conjunction with protective external blinds.

- A-EMM: device that improves the acoustic protection of EMM series valves (up to 37 dB).

- A-EHA: device that improves the acoustic protection of the EHA2 series valves (up to 42 dB).

The AC type visor deserves special attention. Its installation is relevant at high altitudes, or for buildings that are located in open areas (and subject to strong wind loads).

Valve with visor - outside view

The AC visor body has a silicone flap that restricts the air flow when gusts of wind are too strong, preventing excessive ventilation.

You can also separately purchase a telescopic ventilation duct called E-TFR. It replaces a standard strip where the thickness of the window profile is too large to allow its use.

E-TFR consists of two strips instead of one: one for attaching the visor, the second for mounting the valve body. Between them there can be an additional section - an extension, thanks to which you can use the product on windows with a profile thickness of up to 130 mm.

Hygroregulation - the operating principle of Aereco

In 1984, the Aereco company developed devices that provide hygroregulated air flow (hygro..., from the Greek hygros - wet). The operating principle of these devices is that the air flow is modulated depending on the level of relative humidity in the room. Aereco supply and exhaust devices have one or more dampers that regulate the air flow, which close, limiting the air flow, or open, increasing the air flow. These dampers are controlled by polyamide strips depending on the humidity level, which act as a humidity sensor and drive a hygro-controlled system.

The Aereco air supply unit has a V8 converter (polyamide strips) installed, which controls the flow of supply air.

As humidity increases, the polyamide fabric strips lengthen, causing the dampers to open, and when humidity decreases, they narrow, closing the dampers. The higher the humidity level inside the room, the more the dampers open. This mechanism, called a V8 transducer, is isolated from the airflow direction and only measures the humidity level in the room. In addition, thanks to the thermal adjustment system, the process of opening the dampers occurs regardless of external climatic conditions.

Advantages of the Aereco valve

- Hygro-controlled system: controls air flow depending on the relative humidity level indoors

- Reduces acoustics: up to 42 dB with accessories

- Operating mode switch

- Angled airflow for occupant comfort

- Slim body for easy installation into window profiles

- Easy installation

- Easy maintenance: no need for adjustment, just clean the dust once a year.

Ventilation through sealed windows without noise

As you understand, such a ventilation system is simply necessary in modern apartments equipped with airtight windows, sealing residents in damp and stuffy rooms. Aereco air supply devices allow you to constantly ventilate rooms without opening windows and avoiding noise.

The hygro-regulated air supply device is mounted on a specially cut slot in the window profile in the upper part of the window. An external canopy is installed on the outside of the window to protect against rain and insects entering the room, as well as to protect the internal structure of the window. The supply unit can be equipped with effective acoustic visors that reduce street noise from 37 to 52 dB.

Aereko supply ventilation cross-section

You can buy a ventilation valve EMM 5-35 with the following Technical characteristics:

| Indicator name | Unit change | Meaning |

| Hygro-regulated | Yes | |

| Minimum air flow at 10 Pa | m3/h | 5 |

| Maximum air flow at 10 Pa | m3/h | 35 |

| Maximum opening area | mm2 | 4000 |

| Sound insulation at maximum opening (according to air flow) with visor A SAM, AC, AP | dB | 33 |

| Sound insulation at maximum opening (according to air flow) with acoustic visor A-EMM | dB | 37 |

| Weight | G | 170 |

Aereco fits perfectly into the design of the premises

The design of Aereko supply units goes well with plastic frames, and the exhaust units fit perfectly into the interior of a modern apartment or country house.

This is what the Aereko supply ventilation device looks like on a plastic window frame and the Aereko exhaust ventilation device in the interior of the room.

In cases where installation of supply ventilation devices in a window is not possible, installation of a wall-mounted, humidity-controlled supply device may be proposed as an alternative solution. The device is mounted on a hole specially cut in the wall at the top of the room. An external canopy is installed on the outside to protect against rain penetration. Additionally, an anti-insect filter grid is installed in the channel of the device, which is easy to clean.

The illustration shows the appearance of the Aereko wall-mounted air supply unit in the interior and its structure.

care and maintenance of the air supply ventilation valve aereko

The inlet valve does not require special maintenance. Caring for the aereco ventilation valve involves periodic cleaning (1-2 times a year) and depends mainly on the level of pollution in the outside air. Dust deposits on the grille of the external visor of the fresh air ventilation valve can be removed using a vacuum cleaner or other means. The surface of the damper and the supply valve body are wiped with a damp cloth. The use of abrasive and chemically aggressive detergents is not allowed.

The dust stain that sometimes forms on the window slope above the supply valve is also removed with a damp cloth. DO NOT WASH THE SUPPLY VALVE under running water or soak it completely.

Aereco ventilation is also controlled manually and via sensors

In addition to hygroregulation, Aereko ventilation devices implement functions for controlling air flow manually, as well as through presence and motion sensors.

Aereko ventilation can be turned on forcibly with a button, or using presence and motion sensors.

In Aereko supply ventilation devices, you can manually limit the flow of air from the street, i.e. If desired, for example, in cold weather the damper can be closed. This functionality will be very useful in areas with low temperatures during the winter months.

The lever can be used to limit the flow of air into the Aereco air supply device.

Silent fans Aereco

In addition to passive ventilation means, such as supply and exhaust valves, our company offers silent Aereco exhaust fans for installation to increase draft in standard ventilation pipes of apartments and houses.

The low pressure mechanical fan is switched on automatically via a temperature sensor or pressure switch.

The illustration shows three models of Aereco fans, which provide different maximum air flow rates in rooms.

These fans have low noise characteristics (from 29 to 34 dB) and low power consumption.

Advantages of the EMM vent valve:

— opens depending on the level of humidity inside the room; — protects rooms from mold on walls and furniture, prevents moisture condensation; - reduces heat loss; — ensures consistently good air quality; — the direction of the air stream provides comfortable conditions for residents; — automatically regulates air flow in each room 24 hours a day, depending on ventilation needs; — works at any temperature, without using electricity; — easy to maintain: there is no need for adjustment, it is enough to clean it from dust once a year.

Aereco vent valve

The French company Aereko is a developer of comprehensive solutions for providing natural ventilation using window and wall valves for the supply of fresh air and automatic fans and exhaust grilles for removing exhaust air.

The principle of operation of the supply valves is based on changing the flow area depending on the level of relative humidity in the room. The movement of air through the valve is carried out under the condition that natural or mechanical exhaust is functioning and there is a flow between the rooms (undercutting the door leaf from below by 1.5 cm, or cross-flow grilles in the door leaf or wall). Air supply devices "AEREKO" are designed for a constant dosed flow of outside air into the room, based on the minimum amount required by hygienic requirements per person (approximately 30 m3/h). The devices allow you to constantly ventilate the room without opening windows.

Aereco supply valves, EMM series (hygro-regulated)

The most common model of a supply ventilation device, the operating principle of which is based on the use of Aereco hygroregulation technology (moisture sensitivity) - changing the flow area of the valve depending on the level of relative humidity of the internal air.

The EMM valve has two mounting methods, which are characterized by air supply options (with vertical or inclined jet direction). Three basic colors (white, teak, oak) are focused on the most common colors of window profiles, and its compactness and elegant design allow it to fit into any window without compromising the integrity of the interior perception.

There are 2 positions: “automatic” and “minimum ventilation mode”. Air consumption: 5 - 35 m3/hour at 10 Pa.

Control

— the “automatic” mode is activated using the black lever – down position. This mode involves automatic regulation of the supply of outside air depending on the level of humidity in the indoor air.

— the “minimum ventilation” mode is activated using the black lever – position up. This mode of operation of the supply valve is designed to reduce the air flow in the event of severe frost and wind, or “underflow” due to a temporary decrease in the power of the heating system.

What does installation/installation of an Aereko window supply valve in St. Petersburg provide?

The French company Aereco has been developing and producing energy-saving ventilation systems for apartments and individual houses for more than 30 years, but let's start with some background. In Russia, when designing apartment buildings, a natural ventilation system is used by default. It involves natural inflow and outflow. There are exhaust vents in non-residential premises - the kitchen and sanitary room. Through them, due to the difference in pressure in the apartment and the exhaust duct, in theory, air is constantly removed. The flow of air into the apartment occurs through discontinuities in window carpentry or through supply window/wall valves (in the case of installing sealed plastic windows).

This is what poor ventilation in a house looks like

Proper operation of the natural ventilation system

Disadvantages of a natural ventilation system:

On the lower floors, the draft of the hood is strong. As the floor goes up, the draft weakens noticeably. Lack of air flow, automatically blocks the hood and vice versa - blocking the hood stops the flow of air from the street

In this case, the air in the room is not renewed, the humidity rises, and a feeling of stuffiness appears. Also, high humidity is a favorable environment for the development of pathogenic bacteria, fungus and mold. Constant inhalation of their spores leads to a decrease in immunity and provokes diseases of the pulmonary respiratory tract. It is especially harmful for young children to be in a poorly ventilated area. Very often, in rooms where there are small children, ventilation is neglected. Because You need to take the children out so they don’t catch a cold. It is in such situations that it is advisable to install an Aereco window supply valve, which allows you to ventilate the room in real time and not create drafts.

The result of high humidity is mold on door openings

In recent years, developers have been required to provide for natural flow when using plastic windows. You may have seen all kinds of supply window valves on the windows of new apartments. Builders have actually begun to actively install them. But here too there are pitfalls. 90% of these valves are installed just for show. Like, look, we made an influx. This means the room complies with sanitary standards. The problem is that most of these valves have a limited capacity, usually up to 30% of that prescribed in SNiP. When renting out an apartment, no one takes measurements of the actual air exchange in the room. The fact is that it is not profitable for the developer to install full-fledged supply valves. To install them, it is necessary to mill the window sash or diamond drilling of the wall. Do the math yourself. If you have a room of 10 square meters. with a ceiling height of 2.5 meters, the volume of the room will be 25 cubic meters. SNiP requires at least one renewal of the entire volume of air in a residential area every hour. This is provided that they do not cook food in the apartment, do not water or grow flowers, do not wash clothes, and do not exercise, because all these actions cause an increase in humidity. Window valves, which are installed with the seal trimmed, have a throughput capacity of up to 10 cubic meters per hour. The numbers speak for themselves.

Control of the air supply ventilation valve aereko emm:

1. “Automatic” mode: aereco ventilation is turned on using the black lever - down position. This mode involves automatic regulation of the supply of outside air depending on the level of humidity in the indoor air. 2. “Minimum ventilation” mode: activated using the black lever – up position. This mode of operation of the supply valve is designed to reduce the air flow in the event of severe frost and wind, or “underflow” due to a temporary decrease in the power of the heating system.

| The AEREKO EMM valve has a movable damper inside that regulates the amount of air supplied. The movement of the damper is controlled by a sensor-drive. Buy plastic PVC windows with a supply ventilation valve for plastic PVC windows AEREKO EMM 5-35 in the design: 1 – body; 2 — mounting plate; 3 — spring cover; 4 — cover of the adjusting mechanism; 5 — housing cover; 6 – sensor-drive; 7 – damper. | |

| Buy a supply ventilation valve for plastic PVC windows AEREKO EMM with a mounting strip (installation from the room side). Price: 2650 rub./piece Installation: within the Moscow Ring Road 1500 rub/piece , up to 40 km from the Moscow Ring Road 1500 rub/piece, 41-100 km from the Moscow Ring Road 2000 rub/piece, more than 100 km from the Moscow Ring Road 2500 rub/piece. | |

| Buy the installation of a supply valve for PVC windows with a standard external canopy with an anti-insect grille type A SAM. Price: 350 rub./piece | |

| Buy an acoustic external canopy with an anti-insect grille for the aereco valve (buying the installation of such a canopy is necessary for increased sound insulation). Price: 1350 rub./piece | |

| Ventilation valve for PVC plastic windows with an external canopy with a flow limiter with an AC type insect screen (it is necessary to purchase the installation of such a canopy for high floors, etc. rooms with high wind load). Price: 1200 rub./piece | |

| Ventilation on windows with a “flat” external visor with an anti-insect grill under AR “blinds” (you need to buy the installation for PVC windows, in which the sash structure is flush with the frame on the outside). Price: 700 rub./piece | |

| Installation of valves on windows with a telescopic channel (you must purchase the installation when installing a ventilation valve in a blind “non-tearing” part of a PVC window and when installing a ventilation valve in aluminum windows). Price: 700 rub./piece | |

| The standard color scheme for AEREKO ventilation supply valves is: white RAL9003, oak RAL8001 and teak RAL 8017. You can buy aereko emm valves in any other color scheme when ordering from 500 pcs with painting at the factory in France by the Aereko company. O-KNA company is ready to paint the supply ventilation valve in any color according to the RAL catalog for the best combination of ventilation on the windows with the interior and exterior of your house and/or apartment. Price per set (valve + standard visor): RUB 2,750/piece Installation price within the Moscow Ring Road 1500 rub/piece |

Instructions for installing the Aereko supply valve

As noted above, installation of the Aereko valve is possible on already installed plastic windows without dismantling them.

1. mark the installation location of the ventilation valve, paying attention to the installation locations of other window fittings, which should not interfere with installation;

2. screw the supply valve strip onto the self-tapping screws for plastic windows;

3. mark technological grooves on the frame/sash rebate of the sizes shown in the figure below;

4. remove the strip and cut holes using a drill and jigsaw, first in the sash and then in the frame;

5. re-installation of the strip;

6. Attach the aereco window valve to the latches.

Operating principle of the hygroregulation system

The opening and closing of the inlet is carried out automatically, using hygroregulation technology, which was developed by the manufacturer (French brand Aereco) in 1984. For its operation, the valve is equipped with a V8 sensor, which consists of 8 thin strips of polyamide fabric.

The strips subtly respond to the level of air humidity in the room: when it increases, they lengthen and activate the drive, which opens the valve. When the humidity decreases, the length of the polyamide strips decreases, weakening the impact on the actuator - which causes the valve to close.

Polyamide strips inside the housing

The sensor itself is located away from the passing air flow, so it shows an accurate value. This operating principle is mechanical and does not require power supply.

Why use it?

The use of Aereko window ventilation is relevant for two reasons:

- Providing fresh air to breathe.

- Preventing the appearance of condensation (and, as a result, mold) on slopes, frames and glass.

The above-mentioned problems arise everywhere: modern windows are almost completely airtight. As a result, stuffiness reigns in the room, since fresh air cannot flow inside.

In addition, due to the lack of fresh air, the humidity inside the room also increases - which is harmful for the body, for indoor plants, and for the window itself.

In old wooden windows, the frames had quite large gaps (due to which people often sealed them up for the winter). Through them, air from the street could pass into the room, and then be removed through ventilation shafts. After installing sealed mass structures, this ventilation “system” is disrupted.

Air supply through Aereco valve

The easiest way for many is regular ventilation: a person opens a window and fresh air freely enters the room. However, this is good if you live in a quiet area and it’s summer outside.

What if there is a construction site under the windows, or a busy street, or a place where there is a large gathering of people (for example, a shopping center or school)? Or is it simply winter and the temperature is below -20º? Or are you allergic to poplar fluff, which gets clogged into almost every crevice in the summer?

This should also include insects that fly through open windows and add to the inconvenience of a person. In addition, too frequent ventilation accelerates the breakdown of window fittings, which are designed for an average of 10 thousand movements .

The problems mentioned above are solved with the help of an Aereco supply valve, which ensures the flow of air when the windows are closed.

Benefits of use

Inlet valves from Aereko have a number of distinctive advantages that distinguish these models from other devices of this type.

External view of the Aereco EMM enclosure inside the room

These include:

- compact size and “invisibility” (the device is not conspicuous);

- the presence of an automatic valve opening and closing system depending on humidity;

- the ability to manually adjust operating modes (note: it is the modes that can be adjusted, not the amount of incoming air!);

- sufficient amount of passing air (more about the characteristics below);

- relative ease of installation;

- autonomy (valve operation does not require electricity);

- the ability to improve parameters by purchasing additional accessories.

After installing the valve, it should be taken into account that the opening angle of the window will become smaller: the inner casing will rest against the slope.

Description of design

Structurally, the ventilation valve consists of 3 parts:

- Mounting strip.

- External "visor".

- Valve body.

Externally, the device looks like a narrow oblong plastic lining, which is mounted in the upper part of the window frame and sash, in which a hole is cut.

The color of the body can be different - from white to beech. Both from the inside (from the room) and from the outside (from the street), the device on the window is practically invisible and does not catch the eye.

Aereco EMM valve disassembled

The air passing through the Aereco valve enters the room vertically, heading upward towards the ceiling. This ensures its mixing with the already heated air in the room - due to which the temperature in the room does not drop, and a person does not feel a cold flow even with the valve maximally open.

Full operation of the product is possible only with a normally functioning ventilation shaft or hood - “exhaust” air must be removed from the room, making room for fresh air.

Some models (more on this below) have an operating mode switch, which is located on the bottom of the housing and allows you to manually adjust the amount of air flowing through. This is especially true in regions where the temperature drops much lower than -10...-15º.

In severe frosts, it is recommended to close the valve, reducing the inflow to a minimum (or even completely blocking it), otherwise the room may become too cold - due to too large a difference in air temperatures outside and inside.

There is a cheaper and easier to install Russian equivalent: the Air Box window valve. This brand produces 3 series of products, with different parameters and capabilities.

Operating principle of the hygroregulation system

The opening and closing of the inlet is carried out automatically, using hygroregulation technology, which was developed by the manufacturer (French brand Aereco) in 1984. For its operation, the valve is equipped with a V8 sensor, which consists of 8 thin strips of polyamide fabric.

The strips subtly respond to the level of air humidity in the room: when it increases, they lengthen and activate the drive, which opens the valve. When the humidity decreases, the length of the polyamide strips decreases, weakening the impact on the actuator - which causes the valve to close.

Polyamide strips inside the housing

The sensor itself is located away from the passing air flow, so it shows an accurate value. This operating principle is mechanical and does not require power supply.

Why use it?

The use of Aereko window ventilation is relevant for two reasons:

- Providing fresh air to breathe.

- Preventing the appearance of condensation (and, as a result, mold) on slopes, frames and glass.

The above-mentioned problems arise everywhere: modern windows are almost completely airtight. As a result, stuffiness reigns in the room, since fresh air cannot flow inside.

In addition, due to the lack of fresh air, the humidity inside the room also increases - which is harmful for the body, for indoor plants, and for the window itself.

In old wooden windows, the frames had quite large gaps (due to which people often sealed them up for the winter). Through them, air from the street could pass into the room, and then be removed through ventilation shafts. After installing sealed mass structures, this ventilation “system” is disrupted.

Air supply through Aereco valve

The easiest way for many is regular ventilation: a person opens a window and fresh air freely enters the room. However, this is good if you live in a quiet area and it’s summer outside.

What if there is a construction site under the windows, or a busy street, or a place where there is a large gathering of people (for example, a shopping center or school)? Or is it simply winter and the temperature is below -20º? Or are you allergic to poplar fluff, which gets clogged into almost every crevice in the summer?

This should also include insects that fly through open windows and add to the inconvenience of a person. In addition, too frequent ventilation accelerates the breakdown of window fittings, which are designed for an average of 10 thousand movements .

The problems mentioned above are solved with the help of an Aereco supply valve, which ensures the flow of air when the windows are closed.

Benefits of use

Inlet valves from Aereko have a number of distinctive advantages that distinguish these models from other devices of this type.

External view of the Aereco EMM enclosure inside the room

These include:

- compact size and “invisibility” (the device is not conspicuous);

- the presence of an automatic valve opening and closing system depending on humidity;

- the ability to manually adjust operating modes (note: it is the modes that can be adjusted, not the amount of incoming air!);

- sufficient amount of passing air (more about the characteristics below);

- relative ease of installation;

- autonomy (valve operation does not require electricity);

- the ability to improve parameters by purchasing additional accessories.

After installing the valve, it should be taken into account that the opening angle of the window will become smaller: the inner casing will rest against the slope.

Installation nuances

The Aereco window ventilation valve can be installed either on a removed sash or on an installed window - it is not necessary to dismantle the structure. However, if possible, it is better to remove the sash: it will be more convenient to work.

In this case, you should install the valve either in warm weather, or prepare some way to block the window opening.

The process itself consists of sawing holes in the frame and fusing the sash (the part that covers the frame) . You should work extremely carefully - the seal on the sash must remain intact when creating holes.

For convenience, you can remove the window fittings (corner gear and scissors) from the top of the sash.

List of tools

To work you will need:

- Drill with a drill bit with a diameter of 10 mm.

- Jigsaw.

- Narrow, fine-grained file (optional).

- Silicone sealant.

- Self-tapping screws (4 for the strip and 2 for the “visor”).

- Template for holes (not necessary, but working with it is both more convenient and more accurate).

For greater accuracy, you can use two drills: the first is 5 mm in diameter, with which a “test” guide hole will be drilled. The second is the main one, which will make a hole of the required diameter.

You can make a template for the grooves yourself from hardboard or plywood (in extreme cases, cardboard will do), according to the specified dimensions.

Stages of work

Installation is performed in the following sequence:

- The location where the valve will be installed is marked.

- Places for the grooves are marked (the dimensions of the holes are indicated in the characteristics, the distance between the grooves is 10 mm) on the sash and on the frame.

- A starting hole is drilled in the sash and frame at both edges of each groove.

- A jigsaw blade is inserted into one of the groove holes and cut to the desired size.

- If necessary, the edges of the grooves are processed with a file.

- The valve strip is installed on the sealant on the flap.

- The plank is additionally secured with self-tapping screws.

- The external “visor” is mounted on self-tapping screws.

- The holes for the self-tapping screws are covered with plugs on top (included with the valve).

- We install the fittings on the sash (if removed).

- We install the sash in the frame (if removed).

- We install the inner valve body onto the latches.

If the installation is carried out by a master, be prepared to spend about 1,500 rubles.

Stages of work (video)

Warranty obligations of the aereko supply ventilation valve:

The operation of the supply valve is guaranteed by AERECO for the entire period of operation, provided that the user observes the following rules: 1. Use the AERECO ventilation supply valve only for its intended purpose. 2. Do not disassemble the main body of the aereco supply ventilation valve. 3. Do not try to regulate the supply ventilation valve yourself. 4. When carrying out any construction and finishing work near the window opening, as well as in the opening itself, close the housing of the supply ventilation valve.

Installation + description of the Aereco inlet window valve

Installation of one supply valve takes about 30 minutes. Installation of the valve is only possible in an opening flap. The valve requires a normally functioning hood to operate. The valve cannot be closed completely. Minimum flow capacity prevents valve freezing

Installing one aereco window supply valve will solve the problem of air exchange in such a room with a reserve. Installation of an aereco supply window valve requires mandatory milling of the profile. This allows the ventilation valve to provide a throughput capacity of up to 35 cubic meters per hour. The installation time for one Aereko window valve is about 30 minutes.

aereco supply valves operate on the principle of hygroregulation. Those. The aereco automatic window valve opens and begins ventilation when the humidity level in the room rises above the permissible norm. Dried air comes from the street, thereby reducing the humidity in the room. The valve reacts to this decrease and closes. The aereco supply valve does not require any batteries to operate. The operating principle is based on changing the dimensions of a patented polyamide hygrosensitive tape, which regulates the opening and closing of the supply valve.

Air supply unit E-EMM² Aereco

New second generation EMM inlet valve from AERECO. Modern, stylish, compact and at the same time technologically advanced.

Housed in a thin body, EMM 2 is even easier to install and has a 3-position operating mode switch. The most important feature of the new model is the ability to increase air flow and change its direction.

Features of EMM 2 :

- Compact dimensions (height 31 mm)

- 3 colors (white, oak, teak)

- Humidity sensor

- Optionally, it is possible to order special spacers to increase air flow and change its direction

- Special visor reduces noise level to 37 dB (optional)

- Operating mode switch

Directional air flow

If the supply valve is located in close proximity to window slopes or ceilings, the inclined air flow of the basic model can be adjusted to horizontal using a special spacer O-EMM².

Additional air flow

An optional E-EMM² spacer can be used to increase airflow on various E-EMM² units to meet regulatory requirements or reduce the total number of vents in some rooms.

Operating mode switch

A special switch (available for version 5-35) allows you to select one of 3 operating modes: minimum flow, automatic mode (hygroregulation) or maximum air flow, which allows you to adjust the air exchange depending on the user's needs.

E H M 1276

Supply device EMM 2 (hygro-regulated air flow 5-35m3/h) for window structures, operating mode switch, white

E H M 1283

Supply device EMM 2 (hygro-regulated air flow 5-35m3/h) for window structures, operating mode switch, teak

E H M 1279

Supply device EMM 2 (hygro-regulated air flow 5-35m3/h) for window structures, operating mode switch, color - oak

Supply unit EMM², hygroscopic air flow 11-35 m³/h, for window structures, color according to RAL 9003 (white)