Balcony structures are a continuation of the attic, interfloor slab, and can be arranged as attics and additional space above stairs and columns, or formed independently, according to the construction project.

Balcony ceilings have a number of characteristic qualities that are used by specialists strictly in accordance with the technical rules regulated by GOSTs. What types of floor slabs for balconies are there, how to choose and strengthen them correctly, what equipment to use, as well as other nuances, read more in this article.

The difference between a balcony and a loggia

Modern construction technologies and layout options have erased some of the signs between a balcony and a loggia - essentially different types of structures. It is important to see the difference between them when calculating the usable area - during registration of housing transactions, carrying out repairs, redevelopment, and finishing work.

A balcony is a room that is attached to the wall of a building in various ways and protrudes beyond the boundaries of its facade. The outer perimeter has fences.

A loggia is an extension that is part of a building, with one, two or three open sides, based on a supporting structural element. The facade can be decorated with a parapet, arcade, colonnade.

On a note. Visually distinguishing a balcony from a loggia is not difficult. The balcony extends beyond the perimeter of the house, and the loggia is buried in it.

These two designs also differ in shape. Since the loggia exactly follows the contour of the building, it can have only two shapes - corner or rectangular.

Standard types are mostly rectangular in shape. Houses built according to individual projects may have the following types of balcony structures:

- Rounded;

- Arrow-shaped;

- Triangular;

- Beveled;

- Elongated.

Other distinctive features of these two designs include the following:

- The balcony structure protrudes beyond the facade, the loggia does not.

- The balcony has one common wall with the building, while the loggia has three. The corner and semicircular loggias have two common walls.

- Loggias, unlike balconies, have ceilings.

- Legal heating is only possible on loggias. But in this case, the space will become part of the total area of the housing.

- When arranging areas on balconies, it is necessary to take into account the level of permissible load.

Features of balconies

Mounted

Hanging balconies differ from permanent balconies in that they can be installed on any floor, regardless of whether there are balconies below or not. They can be installed anywhere, since they are mounted on a special frame, which, in turn, is fixed to beams.

You can also hang clotheslines there, install a drying rack, a window sill, or put a flower pot there. The differences, in general, are exclusively in design terms. But there is one very important “but”: such buildings need additional strengthening.

Scheme of strengthening the slab of a small balcony using guy wires

Moreover, the brackets and the metal frame itself rust over time; the structure will have to be strengthened at least once every 5 years. This rule should not be neglected, because you need to understand that we are talking about the safety of human life.

Before talking about the features of permanent balconies, it is worth adding that most often plastic material such as PVC or siding is used for finishing hanging balconies. A window sill, clotheslines, a flower pot and a dryer can be installed there, we must repeat, the same way as on a permanent one.

Capital

As it is not at all difficult to guess, a capital balcony is a structure that extends from the load-bearing wall of an apartment building. In new buildings, all such structures are exclusively capital.

Basic methods of fastening balcony slabs

On the one hand, such a design can withstand a very heavy load. On the other hand, it is extremely difficult to repair it; it will require a lot of time and a lot of money.

To drain water, even in capital balconies, the slab is laid at a certain slope.

The main thing that needs to be done when strengthening such a structure is to strengthen the load-bearing balcony slab, fences, parapet and everything else - this is also important, but secondary.

You can also install clotheslines on the loggia, put a flower pot, install a window sill in front of the parapet, organize a dryer, do glazing by installing any window, whether plastic, wooden or aluminum.

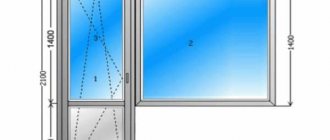

Standard sizes

In standard houses, which became symbols of the 50-80s of the last century, balconies and loggias were “serialized”. In those days, design institutes developed sketches of future buildings according to standards. That’s when the concept of “standard balcony width” appeared.

In most cases, the balcony slab has the following parameters:

- Width equal to 3275 mm;

- The protrusion from the wall is 800 mm.

The slabs under the loggias mainly have:

- Width 5800 mm;

- Overhang - 1200 mm.

But the main fundamental difference between these two designs is that in the second type the slab is divided into two parts (2900 mm each) and separates two different apartments.

Note! The only exception is the corner type, in which the size changes due to the joining of two plates.

The table shows the standard dimensions of structures depending on the building series:

Another regulatory act regulates the size of balconies and loggias based on geography. This is chapter 2.08.01-89 SNiP clause 3.2. The more severe the weather conditions in the climate zone, the shallower the depth of the structure.

Application

Balcony slabs are installed in brick and panel houses. These structures are used in the construction of public and private institutions and public buildings. Products made from high-strength concrete are used as a base for a balcony. The thickness, width and length of the products correspond to the architectural plan. These parameters are calculated taking into account the applied load and the dead weight of the slabs. Typical products are intended for certain types of buildings. The higher the expected load, the greater the safety margin the slab should have.

This video shows the construction of a balcony in a private house:

Beam and balcony slabs

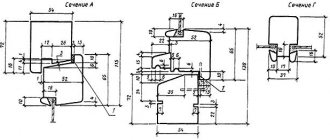

Balcony slabs, which you can buy from us, are classified according to different criteria. There are several types of slabs depending on the type of internal and external structure. They can be flat multi-hollow, or flat solid, as well as ribbed. Depending on the method of support on all load-bearing structures, there are cantilever and beam ones.

The cantilever slab is used for buildings built of brick, ceramics, and shell rock. The edge of the slab opposite to the one protruding beyond the walls can be fixed using an I-beam. Also, the building in which cantilever slabs series 1.137.1-9 will be used must have floors made of reinforced concrete structures. Balcony beam slabs of the 1.137-3 series, which are mounted on cantilever beams or brackets, are suitable for houses with heavy brick walls and wooden buildings.

Average prices in Russia

Purchasing balcony floor slabs is an important process that depends on the recommended type of product for a given building and its compliance with the project. Average prices for different types of balcony slabs may also vary depending on the region. In the northern regions, Moscow Region and St. Petersburg, prices for ceilings for balconies are the highest.

In general, in the Russian Federation the approximate cost for 1 standard product is from 5,500 rubles to 30,000 . For example, in the Leningrad region, a PBK balcony slab will cost from 3,210 to 6,600 rubles, and in Krasnoyarsk this price will be from 2,000. It is most profitable to purchase consumables on the official websites of manufacturers, as well as from companies that cooperate with them directly.

Reinforced concrete slabs will always cost more than conventional monolithic slabs. For private wooden balconies in their homes, beams will cost from 230 to 9,500 rubles per m3, and boards will cost from 86-320 rubles per piece.

Marking of balcony slabs

Balcony slabs, which are made according to GOST 25697-83, have a special marking. A plate of a certain brand consists of letters and numbers. The first letters indicate the type of plate. The following numbers indicate the length and width of the slab in decimeters. Moreover, the values must be rounded to the nearest whole number. Very often, the marking indicates the class of reinforcement for prestressed slabs and also determines the type of concrete for slabs made from a light mixture. If necessary, during design work, the mark indicates the types of finishes on the top surface of each slab. G means glossy, W means polished. Also, in some cases, the level of resistance of the slab to earthquakes is indicated.

Preface

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established in GOST 1.0-2015 “Interstate standardization system. Basic provisions" and GOST 1.2-2015 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Rules for development, acceptance, updating and cancellation"

Standard information

1 DEVELOPED by the Joint Stock Company "TSNIIEP Dwellings - Institute for Integrated Design of Residential and Public Buildings" (JSC "TSNIIEP Dwellings")

2 INTRODUCED by the Technical Committee for Standardization TC 465 “Construction”

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (protocol dated June 27, 2022 No. 53)

| The following voted for adoption: |

| 4 By Order of the Federal Agency for Technical Regulation and Metrology dated October 2, 2022 No. 693-st, the interstate standard GOST 25697-2018 was put into effect as a national standard of the Russian Federation from May 1, 2022. 5 INSTEAD GOST 25697-83 Information about changes to this standard is published in the annual information index “National Standards”, and the text of changes and amendments is published in the monthly information index “National Standards”. In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the monthly information index “National Standards”. Relevant information, notices and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet (www.gost.ru) © Standardinform, design, 2018 In the Russian Federation, this standard cannot be fully or partially reproduced, replicated and distributed as an official publication without permission from the Federal Agency for Technical Regulation and Metrology UDC 691.328.1.022-413:006.354 MKS 91.080.40 Key words: balcony slab, loggia slab, beam slab, length and width, brand, concrete, class, technical requirements, reinforcement 9 BZ 3—2018/40Editor L.S. Zimilova Technical editor I.E. Cherepkova Proofreader L.S. Lysenko Computer layout I.A. Naleykina Delivered for recruitment on 10/05/2018. Signed for publication on October 15, 2018. Format 60><841/8. Arial typeface. Uel. oven l. 1.40. Academic ed. l. 1.26. Prepared based on the electronic version provided by the developer of the standard Created as a single unit by FSUE "STANDARTINFORM" for the acquisition of the Federal Information Fund of Standards, 117418 Moscow, Nakhimovsky Prospekt, 31, building 2. www.gostinfo.ru [email protected] INTERSTATE STANDARDREINFORCED CONCRETE PLATES FOR BALCONIES AND LOGGIAS General technical conditionsReinforced concrete slabs for balconies and loggias. General specifications Date of introduction: 2019—05—01 |

Characteristics of balcony slabs, loggia slabs

| Brand | Weight 1 piece, t | Pieces per 1 car | Length, mm | Width, mm | Height 1, mm | Height 2, mm | volume, m3 |

| 14. Balcony slabs - PB; PBC; PBP | |||||||

| PB 32-6a | 1,10 | 10 | 3190 | 1340 | 150 | 80 | 0,44 |

| PB 32-5a | 1,16 | 10 | 3190 | 1240 | 150 | 80 | 0,47 |

| PB 33-5a | 1,19 | 10 | 3290 | 1240 | 150 | 80 | 0,48 |

| PB 36-5a | 1,30 | 9 | 3590 | 1240 | 150 | 80 | 0,52 |

| PB 39-5a | 1,41 | 8 | 3890 | 1240 | 150 | 80 | 0,57 |

| PBC 27-11-4 | 0,88 | 12 | 2690 | 1140 | 150 | 80 | 0,36 |

| PBK 18-12-5a | 0,66 | 18 | 1790 | 1240 | 150 | 80 | 0,27 |

| PBK 24-12-5a | 0,88 | 14 | 2390 | 1240 | 150 | 80 | 0,36 |

| PBC 27-12-5 | 0,98 | 12 | 2690 | 1240 | 150 | 80 | 0,40 |

| PBK 27-12-5a | 0,98 | 12 | 2690 | 1240 | 150 | 80 | 0,40 |

| PBK 33-12-5 | 1,20 | 10 | 3290 | 1240 | 150 | 80 | 0,48 |

| PBK 33-12-5a | 1,20 | 10 | 3290 | 1240 | 150 | 80 | 0,48 |

| PBK 36-12-5a | 1,30 | 10 | 3590 | 1240 | 150 | 80 | 0,52 |

| PBK 39-12-5a | 1,41 | 9 | 3890 | 1240 | 150 | 80 | 0,57 |

| PBK 42-12-5a | 1,58 | 8 | 4190 | 1240 | 150 | 80 | 0,64 |

| PBC 24-13-6 | 0,78 | 15 | 2390 | 1340 | 150 | 80 | 0,32 |

| PBK 24-13-6a | 0,78 | 15 | 2390 | 1340 | 150 | 80 | 0,32 |

| PBC 27-13-6 | 1,08 | 11 | 2690 | 1340 | 150 | 80 | 0,44 |

| PBK 27-13-6a | 1,08 | 11 | 2690 | 1340 | 150 | 80 | 0,44 |

| PBK 33-13-6 | 1,33 | 9 | 3290 | 1340 | 150 | 80 | 0,54 |

| PBK 33-13-6a | 1,33 | 9 | 3290 | 1340 | 150 | 80 | 0,54 |

| PBK 36-13-6 | 1,43 | 8 | 3590 | 1340 | 150 | 80 | 0,58 |

| PBK 36-13-6a | 1,43 | 8 | 3590 | 1340 | 150 | 80 | 0,58 |

| PBK 39-13-6a | 1,55 | 8 | 3890 | 1340 | 150 | 80 | 0,62 |

| PB-1i | 1,53 | 8 | 3000 | 1930 | 160 | 100 | 0,62 |

| PBKU-3 | 1,80 | 10 | 3700 | 1440 | 160 | 140 | 0,72 |

| PBK-2d (right; lv) | 2,06 | 9 | 4040 | 1440 | 160 | 140 | 0,83 |

| PBK-2 | 2,15 | 9 | 3700 | 1545 | 180 | 160 | 0,86 |

| PBK-3 | 2,92 | 6 | 6000 | 1545 | 180 | 160 | 1,17 |

| PBP 66-12a | 2,80 | 7 | 6580 | 1180 | 220 | 190 | 1,12 |

| PBP 70-12a | 2,89 | 7 | 6960 | 1180 | 220 | 190 | 1,16 |

Options for fastening balcony slabs, their characteristics and possible restoration methods

To ensure the effectiveness of reconstruction work on balconies, it is necessary to study their characteristics and methods of attachment to the building. Often, a balcony and a loggia are the same concepts for the average person. But in fact, these are two structures of different design. Balcony with (Old German balko - beam) - a slab with a railing protruding beyond the facade of an architectural building. Loggia (from Italian loggia - covered gallery) is an unheated niche in a building, with an open side (sides) and supporting elements such as columns, arches, slabs, etc. Since the design of the platforms discussed above differs significantly from each other, in The article does not cover loggia repairs.

Options for attaching balcony slabs.

By design, balconies are divided into:

- Cantilever (a) - a reinforced concrete slab with a thickness of 90 - 120 mm, placed outside the facade of the building and attached between the load-bearing walls. The method of installing such a structure is called pinching.

Balconies of beam and cantilever type.

The plate is installed at an angle of 10 degrees to the ground. In the absence of protection from precipitation, improper care, or improper installation, the slab quickly collapses. Often cantilever platforms can be seen in houses built by Khrushchev. In the part “Strengthening the balcony slab in Khrushchev” the option of a major restoration of all elements of the balcony will be considered in detail.

- Beam (b) – beams made of different materials (reinforced concrete, metal, wood) are used as supports for the site.

During the construction of a house, supporting elements are laid in the load-bearing wall to a depth of at least 400 mm, or a niche is made in the installed wall, followed by the installation of beams. In older houses, the outer platforms are held in place by reinforced concrete modillions (decorative brackets). But since corrosive wear of the reinforcing layer occurs in the brackets, reducing its load-bearing capacity, balconies of this design quickly become unusable.

Photo of the restored beam-type balcony slab.

After reconstruction and protection of reinforced concrete supports from destruction, the slab was expanded and strengthened with channel No. 10, the entire balcony was additionally fixed with hangers from a profile pipe, combined with elements of the railing and roof supports.

- Overhead (c) - a metal platform with a railing, connected to the facade of the building with anchor fasteners.

The load-bearing capacity of such elements is not large, therefore, it is advisable to install the floor from wood and fill the free space with light things. Since the entire structure is held in place by anchors, they must be periodically inspected for cracks, changes in design position, and corrosive wear. To extend the service life of the structure, balcony elements must be periodically protected with an anti-corrosion coating. In cases of damage to the fastening, it is necessary to install a new anchor nearby, at a distance of 80 - 100 mm. In case of minor frame defects, worn elements are restored with additional stiffeners.

When the wear of the metal structure exceeds 50%, the balcony is considered emergency. The area where pedestrians can move underneath is fenced off until a new structure is erected or an emergency one is dismantled.

- Suspended (d) - the balcony slab is held by overhead brackets, most often in the form of a right triangle, attached to the wall with anchor fasteners.

The support can be placed under the slab, in which case the hypotenuse will act as a support, or above the slab, with the hypotenuse acting as a suspension. In the first case, the structure will work in compression, in the second, in tension. More often, the strengthening of the balcony slab is carried out using hangers, since the neighbors of the lower floors do not allow supporting brackets to be installed in their space, which would disturb the interior of the balcony.

Maintenance and measures in case of wear are similar to those listed for overhead balconies.

- Attached (e) - the platform rests on columns and walls placed on the foundation.

Structural elements are made of wood, iron, etc. The main load falls on the vertical supports and foundation; these elements are designed to hold the design load capacity, taking into account the safety factor. It is not advisable to attach the slab to the facade of the building, since when the supports shrink, overturning forces may occur in the load-bearing slab. With proper care, the structure is reliable and durable.

In the process of major repairs, supports and railings are replaced, the foundation and platform are strengthened.

Let's look in detail at how to strengthen a cantilever-type balcony slab using an example.

Balcony slabs: calculation and standard sizes

Balconies with loggias in modern houses are reinforced concrete slabs, fixed in various ways to the wall structure of the building. The shape of balconies can be very different. Many people are interested in how to calculate a balcony slab. This may be necessary when expanding balconies. This kind of work is done by designers and you need to order a project from them.

How to calculate balcony slabs

This work is carried out by design organizations that have design licenses. When calculating, the following factors are taken into account:

- - recommended slab elevation;

- — weight calculation of elements;

- - required slab thickness.

Using special programs, the designer has the opportunity to calculate the most optimal design of the balcony connection, taking into account the load.

Dimensions of slabs for balconies

The standard dimensions of balcony slabs are 3275 in width and they protrude 800 mm above the plane of the facade. For the construction of loggias, hollow floor slabs with standard dimensions of 1200x5800 mm are usually used. With all this, the slab at the loggia in the middle parts of industrial houses is divided in half and therefore the loggia in one apartment is no more than 2900 mm in length. In corner apartments of multi-storey buildings, the size of loggias with balconies can be larger due to the pairing of slabs. Such a balcony will simultaneously overlook two planes of the facade. In older houses, the sizes of slabs for balconies can vary significantly. Attached balconies come in all sizes and configurations. In typical buildings, standard slabs with a width of one meter and twenty centimeters and a length of six meters were used for balconies. Usually there are two balconies on one slab, separated by a partition. In modern new buildings, balconies come in unusual shapes and their dimensions are also non-standard. The thickness of the balcony slab must be at least 100 mm.

Balcony slab

Rules No. 1: general provisions

Despite the fact that the dimensions of the balcony slab may be different, they often have the same problems, this is a weakening of the structural strength, since it extends beyond the facade and is subject to atmospheric influences.

Console plate PBK 24.12-5a

GOST for balcony slabs 2569783 divides them into:

- multi-hollow (only for loggias);

- solid flat;

- ribbed;

- the entire load in a monolithic or brick house is transferred to two or one side, pinched in the wall at two edges.

Balcony installation method

Fastening in a brick house and in a panel house is essentially the same and the same problems also arise, especially in old houses. For example:

- in the well-known “Khrushchev” buildings, the design permissible load per linear meter along the wall was 100 kg, but under the influence of moisture it decreases over time;

- It is noteworthy that in some houses of this type, over 40 or more years of operation, the cross-section of the reinforcement in the slab has decreased four (!) times, therefore, at the moment the permissible load is 50 kg;

- the situation in “Stalin” buildings is much worse, since they are older and reconstruction has long been needed there, because the service life of the slabs has already come to an end - they are more than 50-60 years old;

- therefore, it is not recommended to allow any additional loads - in some cities, slab collapses were observed and people were injured;

Balcony collapse in Ryazan: photo from 2013

- so those who are looking for how to properly fill a slab should take into account that this is not a restoration, but an extra weight. In addition, the pouring does not strengthen the reinforced concrete structure in any way, but simply lays an additional layer on top;

- Naturally, the question may arise here: at whose expense will the repair of the rotten slab be paid? But this already depends on the service agreement that you drew up when purchasing your apartment. Although any organization will resist such a replacement in every possible way (I know from my own experience);

- If you need to replace the slab, then it is better for you to contact a private company, since they will dismantle and install it using special equipment and specialists.

Rule No. 2: strengthen the slab

If the top layer collapses, remove it

But how can you make major repairs and calculate loads if you notice that the slab has begun to collapse? First of all, if the top layer is full of cracks and potholes, then you better remove it, getting to the mortgages and reinforcement.

But don’t rush to re-fill anything. If you have the skills of a welder, turner, mechanic, or have a technical education, then you can independently determine whether the reinforcement scheme will withstand further loads. However, if you do not understand this, then it is better to take the help of a specialist.

The arrows indicate the places of sticking to the embedded parts.

You can knock down the collapsing top layer later if you are sure that the mortgages are “living” - this is the same as the reinforcement of the vault - the entire structure is supported by the frame. Therefore, you will need to cut the fence flush with the slab.

And weld the 50th corner to the vacated mortgages around the perimeter - this will strengthen and replace the old edging. But I want to repeat once again that this is only possible if the reinforcement is in good condition, and this can be determined by the condition of the mortgages.

If you do not expand the balcony, then in place of the knocked down top layer, after the perimeter has been fastened and the fence has been installed, you can pour a light screed, no more than 2 cm thick.

This photo shows how to strengthen the slab on both sides

But what to do and how to restore mortgages if they are rotten? To do this, screw a steel strip 40 mm wide along the length of the slab to the wall with anchor dowels and weld the same strips to it across the slab (towards the offset) after 60-70 cm.

Dimensions of balcony slabs

The type, main characteristics and thickness of the balcony slab are controlled by GOST 25697 - 83 “Reinforced concrete slabs for balconies and loggias”. It was approved on January 1, 1984 by the State. Committee of Civil Engineering and Architecture of the Soviet Union. After which it was republished three times with the addition of changes.

Varieties

The balcony slab is classified according to the method of support on the supporting structure, which in turn are divided into several types:

- Cantilever, fixed to one or two adjacent sides.

- Beam, supported on two or three sides.

And according to design solutions, divided into the following categories:

- Solid.

- Hollow, used directly for the loggia.

general characteristics

The product is divided into several categories, depending directly on its design and place of application.

The geometric shape of the slabs is not specifically specified and depends on the designed and architectural features of the structure.

Diagram of the balcony slab

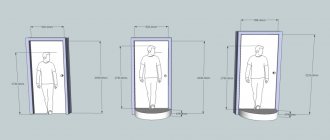

The overall dimensions of slabs for balconies and loggias are allowed in the following values:

- Length – from 120 to 72 cm inclusive.

- Width - for a balcony from 120 to 180 cm, for a loggia - from 90 to 300 cm inclusive.

- Thickness from 16 to 22 cm, depending on other sizes. The number must be a multiple of 2.

Based on the type of finishing of the upper front surface, it is customary to distinguish 3 main categories, indicated by an additional letter:

- G – smooth or glossy finish.

- Ш – polished mosaic.

- K – finished with ceramic or natural stone tiles.

Permissible deviations in dimensions

In any type of manufacturing, the dimensions of balcony slabs may differ slightly from the specified ones. This is allowed by the requirements, and the indicators should not be more than the following:

The limit of permissible deviation in dimensions is allowed both up and down.

A balcony slab whose size does not correspond to the above values will not be certified according to GOST and is considered defective. The use of such products in the construction of houses is not permitted.

Requirements for the manufacturer

The strength of the concrete from which the product is made must comply with GOST 18105. The compressive strength must be at least B 15 (M 200). The concrete itself used for production is in accordance with GOST 25820, 13015-0 or 26633.

Watch the video, all sizes are perfectly illustrated there:

The requirements for metal structures are indicated by GOST 13015-0. In all cases, only reinforcing steel is used for the production of slabs. Moreover, reinforced thermomechanical as well as thermal methods are used for prestressing elements. For non-prestressed parts, it is permissible to use conventional reinforcement bars or steel wire.

For all categories of products, a ratio is taken to certain requirements related not only to strength, rigidity, and frost resistance, but also in accordance with the attached documentation.

Basic requirements of GOSTs

The most important requirement that applies to balcony floor slabs is compliance with GOST 18105, which specifies the standards for the use of concrete, its grade and pouring method.

Also in the document, much attention is paid to compressive strength , which should correspond to indicator B15.

GOST 13015.0-83 fully establishes the requirements for the manufacture and use of reinforcing steel in slabs, and the quality of the structure itself. Of great importance for installed floor slabs on balconies is the maximum load and the ability to distribute it over the entire surface of the product.

The values of the indicators can be found in SNiP 2.01.07-85 , which is especially important for panel and brick houses.

Depending on the age and condition of the balcony, it should normally withstand a load during operation of 200 kg/m2. Thanks to this indicator, as well as taking into account the dimensions of the balcony slab (width, length), these values are multiplied among themselves, and the result is the permissible load for a particular balcony.

For example, with a slab length of 3 (m) and a width of 120 (cm), its total load will be 720 (kg). This indicator does not take into account windows, ice, precipitation, floor pie, and interior design. So in practice, the load, taking into account the deduction of the weight of all materials, is 150 kg/m2. Knowing the permissible load allows the homeowner to correctly distribute the weight of objects that he wants to install on the balcony.

Also, the following regulatory requirements are used for balcony slabs:

- GOST R 56926-2016;

- GOST 25772-83;

- GOST 25697-83;

- GOST 30777-2012;

- SNiP 01/31/2003.

All the above documents are basic. In their first sections, they provide references to lower regulations and GOSTs relating to manufacturing, installation, quality of the material used, requirements for reinforcement and welding, etc.

But the most important thing that every technical standard draws attention to is that the balcony slab must be durable, strong, non-flammable , resistant to atmospheric, mechanical and seismic influences, and made of high-quality composition, high grade concrete, and capable of withstanding heavy loads.

Balcony slabs can be equipped: insulated with insulation, waterproofing and vapor barrier, similar to the formation of a pie on the attic and interfloor floors.

GOST dimensions: balcony slabs

Parameters, sizes, types of balcony slabs are regulated according to GOST 25697-83. The slabs themselves are divided into several types: PB - solid flat beams, PBK - solid cantilever flat, PBR - cantilever ribbed. The length of balcony slabs is from 1200 mm to 7200 mm, the width of balcony slabs is 1200-1800 mm.

The thickness of typical balcony slabs in a brick house or panel house is in the range from 150 mm to 220 mm. It all depends on the type of slab, the dimensions of the slab and the weight of the slab.

It is possible to expand the balcony structure along the base of the slab. This concept involves providing additional usable space. But first, the loads of the balcony structure on the same slab are calculated to prevent its collapse. Typically, metal or steel brackets are used to expand the balcony.

What types of slabs are there, how are they classified?

Slabs of this type are usually classified according to the method of support on the supporting structure. According to this parameter, products can be:

- Console. Such models are attached to one or two adjacent sides. Traditionally they are used in buildings that are made of brick. Fixation is carried out using an I-beam. Please note: such slabs can be used on objects in which the floors are made of reinforced concrete structures.

- Beam. They rest on two or three sides. They are mainly used in buildings with heavy brick walls or in wooden houses. Fastening is carried out using brackets or cantilever beams.

According to the design of the product, it can be:

- solid;

- hollow, such modifications are used directly for loggias.

Protection of reinforced concrete balcony slabs

To protect balcony slabs, special compositions made of polymer materials are used, which make it possible to isolate the surface of the slab from the negative effects of the external environment: chemicals and mechanical influences.

The reinforced concrete base is protected by various methods that reduce dust separation, increase the wear resistance of the structure, improve resistance to chemical influences, and give the product decorative properties.

To increase anti-corrosion properties, the reinforcement used for the manufacture of reinforced concrete balcony slabs is coated with zinc phosphate, which reacts slowly to the corrosive chemical, thereby forming a stable apatite coating.

Balcony slabs: dimensions and characteristics

The state standard does not specify the strictly geometric shape of the slabs; accordingly, it directly depends on the designed or architectural features of a particular object. The most popular are rectangular, triangular, and oval slabs.

Concept

The balcony floor slab is a structure of increased strength, which is attached in a special way to the load-bearing (main) wall , taking into account some protrusion beyond its limits.

Most often, this type of slab has metal loops on the surface, with which they can be welded and attached to the base of the floor.

Floor slabs have different standard subtypes, the production and operation of which are regulated by GOST 25697-83.

Externally, balcony floor slabs have a rectangular shape, gray color and a porous concrete surface , as they are made on the basis of a cement mixture of strong grades M500 and higher, with reinforced rods. The slabs are manufactured only in factory conditions, and are transported, loaded and stacked only with the help of special lifting equipment.

Each type of slab must be marked. The markings applied to the piece product include letters and numbers that indicate:

- type of concrete and reinforcement class;

- surface finishing (polished, glossy, natural stone, etc.);

- seismic resistance level.

Slab products that are not marked are not used in construction , as they are considered counterfeit and defective. Most construction companies purchase slabs only from trusted manufacturers who provide quality certificates for products, instructions, guarantees and other accompanying documents.

The quality of load-bearing floor slabs is an important requirement for effective construction, which is the safety of further human life.

All products for balcony ceilings have their own dimensions and weight.

The standard panel has the following dimensions :

- 760-1 425 (kg) – weight of one piece;

- 1 200-7 200 (mm) – length;

- 150-220 (mm) – thickness;

- 1 200-1 800 (mm) – width.

Non-standard slabs for buildings are formed on the basis of customer orders, but are carried out in strict accordance with technical standards regarding the production of the product, its composition, weight and dimensions.

Balcony slabs are divided by type into: PB (beam), PBK (solid cantilever), PBR (ribbed). The support unit for the slab on the wall is calculated according to the permissible loads specified in GOST 956-91.

The fastening of the balcony slab depends on the material from which the structure is built. For brick houses, fastenings are located in the masonry walls . In panel ones, the slabs are clamped between blocks. In all other cases, they are secured with anchors or welded into the fastenings and fixtures of the structural wall.

You can use one or more floor slabs. Expanding balconies through the use of several products on the bases is permissible only if it complies with technical standards and will not contribute to the collapse of the structure.

Standard balcony width and repair of balcony slabs

The width of the balcony in Khrushchev is 0.65-0.8 m, and the width of the balcony in Brezhnevka will be the same, but the length is shorter. In panel houses, the width is 0.7 m. And a three-meter or six-meter loggia will be 1.2 m wide. All these points, as well as other dimensions, are included in a document called a technological map. And all your reconstructions, taking the same example, expansion along the base of the slab, are entered into this map.

What does repairing a balcony slab mean:

- It refers to major repairs that involve a large amount of work;

- Such repairs are carried out if the destruction of the slab has not yet reached the base, and the reinforcement has not been damaged by corrosion by more than 10%;

- The restoration process includes some transitional blocks - this includes cleaning the slab, updating the reinforcement frame, installing formwork, screeding concrete, and, of course, strengthening the parapet.

If the slabs have more significant damage, these are already emergency slabs. They need to be replaced. If you yourself discover that the slab is collapsing, contact the management company, write a standard statement, so that the company can create a commission and draw up a report on the condition of the balcony. If it is recognized as an emergency, this is already the work of the management company. That is, for example, you repair what is in the apartment – the doors, the floor – yourself. Any decor (if you want a stained glass window for your balcony) - do it yourself. But the balcony slab is already the responsibility of the managing party.

How to repair balconies

The main cause of damage to balcony slabs is moisture. Penetrating inside the slab, water can activate corrosion of the reinforcement. In old houses, the protection of concrete from moisture is reduced; water easily penetrates to the reinforcement. Corroded reinforcement loses its load-bearing capacity, expands and destroys concrete.

Restoring a balcony slab involves several working stages:

Remember that the thickness of the concrete screed must exceed the thickness of the reinforcing mesh by two or even more times.

If the reinforcement frame is severely corroded, the balcony slab will need to be strengthened - this is a more extensive job:

- Rolled steel beams are installed on the sides of the balcony slab and cantilevered to the wall.

- The reinforcing mesh is welded to the beams.

- Then the work of pouring concrete described above begins.

Scheme for strengthening the balcony slab

When the reconstruction of the balcony slab is completed, its surface needs to be waterproofed , which is mandatory if the balcony is open. Various roll-type or coating-type waterproofing materials are suitable for this. In particular, penetrating waterproofing Penetron has proven itself well. It is applied to a pre-wetted surface in two layers, after which the surface must remain moistened for three days, and mechanical stress and temperatures below 0 degrees are not allowed.

Types of loggias and balconies

Additional rooms in the form of loggias are divided into several types depending on their location. They are straight, angular and lateral. The exception is loggias, which have a corner location, but lack forward visibility. It should also be noted that these premises have a varied architectural design. They mainly differ in the shape of their construction: angular, semicircular, rectangular, etc.

Balconies are also not far behind. They may differ not only in shape, but also in the material used to construct the fence. For example, metal forging.

Let's pay attention to the concept of a French balcony. A special feature of this design is the complete absence of floor. That is, we open the door to the balcony and immediately run into a metal fence.

Today, almost all loggias and balconies are being glazed and used as additional squares to expand the area of the apartment.

We recommend watching a video about increasing the balcony area:

What is a French balcony?

The classic French balcony has a purely decorative function. It is not a room and has practically no area; at most it is a small area equal in width to the length of a human leg. The fence is installed directly in front of the doorway. You can admire the beautiful view from the window, but it does not have space for walking or storing things.

In modern construction, the concept of “French balcony” has changed somewhat. Now this is an ordinary balcony, but instead of standard metal or reinforced concrete fences, double-glazed windows in aluminum or PVC structures are used.

Regardless of what type of balcony or loggia is in your home, this corner can be turned into a wonderful relaxing place. Thanks to modern materials and technologies, you can choose absolutely any type of exterior and interior decoration. It can be glazed or left open, at the same time make a beautiful fence, decorate it with flowers, then it will not only protect you from wind and precipitation during your vacation, but will also decorate the entire appearance of the building.

Types of balconies and features of installation of slabs

A balcony is usually called an open area that is adjacent to the wall on only one side, and is closed on the other sides by a fence.

According to SNiP, the height of the balcony railing must be at least a meter.

What types of balconies are there?

Example of an installed balcony slab

Depending on the design features, the following types are distinguished:

- The balcony is open.

- Balcony equipped with a wind screen.

- Built-in loggia.

- External loggia.

Balcony design

The balcony consists of the following elements:

- Horizontal reinforced concrete slab,

- Fencing.

- Waterproofing.

- Floor.

In some cases, the design includes fastening elements: racks, pendants, cantilever beams, etc.

For the construction of external structures (loggias, balconies), special parts are used - balcony slabs - GOST regulates the quality of the materials used. For the manufacture of slabs, concrete is used that meets the requirement of class B10 for compressive strength.

Requirements for concrete frost resistance may vary depending on the climate in the construction area, but not less than class F5. The section of the part must be solid, and the thickness of the balcony slab must be at least 100 mm.

Installation stages

Balcony slab installation diagram

As a rule, the installation of balcony slabs is carried out after the construction of the walls of the house has been completed and the ceiling has been laid above the floor below. Installation of slabs must be preceded by careful marking of their location .

The installation process takes place in several stages:

- First, the so-called lighthouse slabs are installed, placing them along the edges of the building.

- Between the lighthouse slabs along their upper edge, the mooring tension is carried out.

- The prepared balcony slab is lifted by crane to the installation site.

- The mortar bed for laying the slab is leveled using a trowel.

- The slab is laid in place by two installers, constantly monitoring the correctness of its lowering, focusing on the mooring cord.

- The slab is laid strictly horizontally or with a slight (1 - 1.5%) slope to the outside.

- The horizontality of the slab is checked by two levels laid perpendicular to each other.

- If a slope is detected in the longitudinal direction, you have to raise the slab and lower it again, replacing the mortar bed first. If a slope to the inside is detected, the situation can be corrected by installing temporary rods.

- As a rule, concrete slabs are strengthened by welding steel rods of floor slabs and balconies.

- The slings with which the balcony slab was lifted may be removed only after its position has been finally verified and the embedded parts have been welded to the anchors.

Technical requirements for the installation of balcony slabs

Example of a slab in need of repair

Control of installation work is carried out in accordance with SNiP series 3.03.01-87, namely:

- The difference between the floor level in the room and the plane of the balcony slab should not exceed 80-100 mm.

- The slope of the slab relative to the outer wall should not exceed two percent.

For the construction of balconies it is allowed to use the following materials:

- Reinforced concrete slabs complying with GOST 25697-83*.

- Reinforced concrete lintels (used in the construction of balconies in brick houses), corresponding to GOST 948-84.

It is allowed to use jumpers that have a technological slope along the side and end faces, the dimensions of the permissible slopes are:

- Up to 8 mm. in width.

- Up to 20 mm. by lenght.