If you need to create an even and neat hole in a glass surface, it is not necessary to contact experienced and qualified specialists, whose services are quite expensive. This procedure can be performed with your own hands in a home workshop, but, of course, to do this you need to know how to drill glass, what tools, consumables and equipment to use.

To drill glass, use one of the methods discussed in this article

We understand the features of the material

Before asking yourself the question of how to drill glass at home, you should at least get acquainted in general terms with the characteristics and features of this material.

The glass production process is quite complex. It is performed at industrial enterprises equipped with special equipment. The main stage of this process is the preparation of a melt, which includes several components. Such a melt for glass is subjected to sudden supercooling, and the crystallization process is not completely completed.

To prepare the melt, the mixture of components that make up the future glass is subjected to significant heating - up to 2500°. Depending on the chemical basis of the melt, glasses are distinguished:

- oxide category;

- sulfide;

- fluoride type.

Oxide glass (aka silicate) is used to make bottles.

Glass, which can also be opaque, is divided into various types depending on the main characteristics of the material. So, glass is distinguished:

- quartz, which is obtained by melting quartzite, also known as “rock crystal” (this material can be of natural origin and is found mainly in places where quartz deposits have been exposed to lightning);

- optical type, used for the manufacture of basic elements of optical instruments (lenses, prisms, etc.);

- highly resistant to aggressive chemicals and elevated temperatures;

- industrial use (the most extensive category of glass, also used in everyday life).

The question of how to drill a hole in glass most often arises when using the latter type of product. Industrial products, in turn, are also divided into several categories:

- potassium-sodium type (such glasses, characterized by a clean and light internal structure, have a relatively low melting point, so they are often used for the manufacture of glass products of complex shapes);

- potassium-calcium type (glass of this type has a surface without a pronounced shine, is highly hard and difficult to melt);

- lead type (such glasses have a pronounced shine, which makes them very similar to crystal, high fragility with a fairly high plasticity of the internal structure, significant specific gravity and a higher price when compared with the cost of products of other types);

- borosilicate (they are highly resistant to temperature changes and mechanical stress and are quite expensive).

In most cases, drilling of window or display glass is required

There is also a classification of glass according to purpose. Thus, various types of glass are used for:

- glazing of windows and other translucent structures;

- manufacturing of containers;

- reducing radiation levels;

- fiberglass production;

- protecting smartphone screens;

- making dishes;

- production of thermometers capable of measuring temperature in the range from –200° to +650°;

- manufacturing laboratory glassware (such glasses are characterized by high thermal stability);

- production of medical products (ampoules, tubes, containers for medicines);

- fireplace screens and ovens (in such cases, heat-resistant glass is used);

- manufacturing of electric lamps (in this case, so-called electric bulb glasses are used);

- production of incandescent lamps, X-ray tubes, ignitrons (this requires vacuum glass);

- creation of elements of optical instruments - cameras, microscopes, telescopes, etc.;

- manufacturing thin-walled chemical containers and other products that require high resistance to chemical and thermal effects (for this, quartzoid glasses, also known as Vicor, are used).

Drilling thick glass is best done on a machine

Tools

0 votes

+

Vote for!

—

Vote against!

If it is necessary to drill glass surfaces, many prefer to entrust this task to professionals, turn to special services, spend money, and most importantly, time. We’ll find out how to drill glass at home and what you can use to drill glass.

Table of contents:

- Types and features of glass

- Types of drill bits for drilling glass

- Preparing glass for the drilling process

- How to drill glass with a regular drill

- How to drill glass at home using sand

- How to drill glass with your own hands using a homemade drill

- Tips for drilling glass at home

- Working with glass using a glass cutter

- Unconventional methods of drilling glass

Types and features of glass

The formation of glass occurs during supercooling of a melt from several components, while the speed of this process is quite high and the crystallization process does not have time to complete.

Glass is a fragile material that is often used for human needs. Glass is formed at a fairly high temperature from 200 to 2500 degrees. Not all glasses are transparent; this property is not a general characteristic of this material.

In relation to the main material used during glass production, glasses are distinguished:

- oxide,

- sulfide,

- fluoride

Depending on the type of application, there are:

- quartz type glass - made by melting quartzite or rock crystal, this material can be natural, it is formed when lightning strikes the location of quartz deposits;

- optical glass is used to make lenses or prisms;

- Chemical type glass is characterized by high resistance to chemicals and temperature changes;

- Industrial glass is widely used in the manufacture of various things that people use.

Industrial glass is:

- potassium-sodium type - characterized by a low melting point, different shapes can be easily obtained from it, has a clean and light structure;

- potassium-calcium type - has high hardness and is difficult to melt, does not have a pronounced shine;

- lead type - similar to crystal, very fragile and shiny, more expensive, heavy, but at the same time quite soft;

- borosilicate type - resistant to temperature changes, exposure to foreign substances, quite expensive.

In relation to the area of use, glass is distinguished:

- window,

- containers,

- radiation resistant

- fiberglass,

- protective,

- dishes,

- crystal,

- thermometric,

- heat resistant,

- medical,

- heat resistant,

- electric bulbs,

- electrovacuum,

- optical,

- chemical,

- quartzoid.

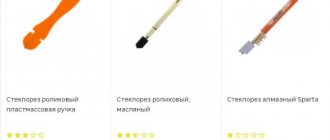

Types of drill bits for drilling glass

The process of drilling glass requires a good, and, most importantly, suitable drill and material that will instantly cool the glass during the drilling process. Let's look at the main types of drills that are suitable for glass:

- drill in the form of a spear or feather - made of hard alloys, the diameter of such devices ranges from 3 to 12 mm, if you have the skills, drilling glass with such a drill is quite possible, but you cannot do without the formation of small chips;

- spear-shaped drills with diamond coating - characterized by softer drilling, no chips;

- tubular or round drills are used to cut circles or rings on glass surfaces; this process is most conveniently carried out using a drilling machine;

- brass type glass with diamond coating requires mandatory cooling through the supply of water or turpentine;

- A tubular diamond type drill is used to drill a hole in glass, it has the form of a crown with a shank, the end of the crown is diamond coated, and requires cooling.

Preparing glass for the drilling process

1. Before you start drilling glass, you should prepare the surface for this process.

2. Using alcohol or turpentine, be sure to degrease the surface and then wipe with a dry cloth.

3. The glass sheet is not allowed to slip or shrink on the surface.

4. The glass sheet must be placed on the base.

5. It is better to mark the drilling point using construction tape or a marker.

6. If you do not have the skills to work with glass drilling, it is better to practice on small fragments so as not to ultimately spoil the material.

7. Drilling glass takes a long time; do not press hard on it to speed up the procedure.

8. Hold the drill bit at a right angle to the glass surface. Do not drill one hole at a time; stop periodically to allow the glass to cool.

9. When drilling is completed, when the hole is almost ready, you should turn the glass over and drill a hole from the back side. This procedure will help avoid chips or cracks and make the hole the desired shape.

10. To remove small roughness or unevenness on the glass surface, use fine sandpaper.

How to drill glass with a regular drill

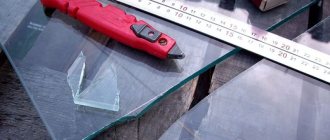

To complete this process, you must have:

- drill, which is used for drilling metal or ceramic surfaces;

- screwdriver or low-speed drill;

- plasticine,

- turpentine,

- alcohol solution.

The glass must lie on a completely flat surface. Pay attention to the placement of the glass; the edges should not hang over and the glass should not wobble.

Set the screwdriver or drill to the minimum rotation speed. Insert the glass and check whether the device breaks the glass; if there is significant runout, it is recommended to replace the drill.

Using cotton wool and alcohol, degrease the glass and make a recess out of plasticine in the place of the future hole. Pour turpentine into it and begin the drilling process. To avoid the appearance of cracks, you should not exert much force during this process. Hold the device lightly and without pressing over the glass.

The minimum rotation speed for drilling per minute is 250, and the maximum is 1000 cycles.

How to drill glass at home using sand

At a time when there were no screwdrivers and drills, this method of drilling glass was used. To drill glass using sand you will need:

- sand,

- gasoline,

- tin or lead,

- gas burner,

- metal vessel, preferably a mug.

Be sure to degrease the surface with gasoline, and pour a mound of wet sand onto the site where you intend to drill. Next, using a sharp object, you should make a funnel the size of the hole.

Pour a pre-prepared mixture of tin or lead into this form, after a few minutes, remove the sand and remove the frozen part of the glass, which should easily come off the surface.

To heat lead or tin, use a metal vessel and a gas burner. If there is no gas burner, replace it with an ordinary stove.

Such a hole is perfectly smooth and does not require additional processing effort.

How to drill glass with your own hands using a homemade drill

The drill used in the work process consists of a diamond roller, which is placed in the simplest glass cutter, and a metal rod.

You need to cut a special hole in the rod into which the diamond roller is placed. The roller is installed in such a way that it is stationary.

Attach the drill bit to a drill or screwdriver and start drilling.

This drill is a modification of conventional diamond-coated drills, so if you cannot buy such a drill, make it yourself.

Another option for making a drill involves drilling glass with a small hole diameter of up to 50 mm. Take any ordinary drill. Turn on the gas burner, clamp the drill with pliers and hold it over the flame for several minutes. When the tip of the drill turns white, cool it quickly by dipping it in sealing wax. After it has cooled, remove the drill and remove drops of sealing wax from the surface, if any. This glass has become tempered and is excellent for drilling glass.

Tips for drilling glass at home

1. A little honey or turpentine should be applied to the place where the hole will be drilled in order to prevent the appearance of cracks and splits.

2. Do not press the drill from above.

3. The interval between drilling is 5-10 seconds. It is advisable to dip the drill in a vessel with water during breaks to prevent the glass from melting.

4. You cannot rock the drill from one side to the other.

5. If possible, it is better to use a screwdriver; this item is more gentle, as it has low speed.

6. The cost of drilling glass in a professional setting starts from $10, so by using these tips you can save a lot of money.

7. Not only alcohol, but also acetone is perfect for degreasing the surface.

8. When working with a drill, do not forget to follow safety precautions, wear goggles and gloves

9. The distance between the edges of fragile glass should be at least 1.5 cm, for ordinary glass 2.5 cm.

10. The best surface for working with glass is wood.

Working with glass using a glass cutter

1. In order to make a hole in glass of large sizes or unusual shapes, a glass cutter is suitable.

2. Using a felt-tip pen or marker, make a marking along which the drilling will be carried out.

3. When working with a glass cutter, you should not make sudden movements; pressure should be smooth and have the same force.

4. Using the handle of a glass cutter, tap the glass so that the cut part falls out.

5. To remove excess glass, use special tongs.

6. Pay attention to the condition of the tool before starting work. The location of the roller should be central, it should rotate smoothly and evenly.

Unconventional methods of drilling glass

1. To drill through carbide type glass, you should prepare a cooling liquid. To do this, take acetic acid and dissolve aluminum alum in it. If they are not available, mix turpentine with camphor in a one to one ratio. Treat the glass with one of the solutions, and only then start drilling.

2. If there is no drill, use copper wire, which must be inserted into the drill. In this case, drilling occurs using a specially prepared solution. One part camphor and two parts turpentine, add coarse sandpaper type powder to this mixture. Place the mixture in the place where you want to drill a hole and start working.

3. There is another method using this solution. Use a piece of metal tubing that is inserted into the drill. Make a plasticine ring and attach it to the surface of the glass. The height of the ring is 10 mm, and the diameter is 50 mm. Apply a solution of turpentine, camphor and emery powder into the recess.

4. Take a tube made of aluminum, copper or duralumin, the length of which is about 5 cm. Drive a wooden plug into one end, and cut out the teeth with a hex file at the other end. Screw the self-tapping screw into the end on which the wooden plug is located, and saw off its head. Attach two circles pre-cut from cardboard, the diameter of which is the same as the diameter of the future hole, to the inner and outer parts of the glass. Place the glass on a rubber surface and sprinkle abrasive powder on it. Place the place where the self-tapping screw is attached, with the cut off head, in a drill or screwdriver; treat the back side of the so-called drill with turpentine solution. Drill the third part of the hole from one side, and then turn the glass over and finish the job.

How to drill glass video:

What tools are used to drill glass?

To prevent glass drilling from ending in cracking and complete destruction, it is very important to know not only how, but also how to drill glass correctly. There are many tools on the market today, some types of which can be used to create holes in glass.

- A drill, the working part of which is made of hard alloy and has the shape of a feather or spear, allows you to make a hole in glass with a diameter of 3–12 mm. Using such a drill requires certain skills. However, even their presence and maximum care when performing work will not help to drill glass with this tool without small chips.

- A diamond glass drill, the working part of which also has the shape of a spear, allows you to drill holes better. Such a tool, the cutting part of which is coated with diamond, provides softer drilling.

- Glass drills, made in the form of a tube, are used in cases where it is necessary to make a large diameter hole in the glass. It is more convenient to use a tubular drill complete with a drilling machine.

- When using brass drills, the cutting part of which is coated with diamond, it is necessary to take care of their high-quality cooling, for which water or turpentine is supplied to the processing zone.

- Tubular glass crowns, made with diamond coating on the cutting part, also require high-quality cooling. If you don't know how to cut a large hole in glass, this tubular drill bit will help you solve the problem.

Main types of glass drills

What should a drill be like?

A diamond-coated drill bit can cut a cylinder out of glass, and if handled correctly, its working capacity is determined by 100 linear millimeters of drilling. However, be careful, as sometimes you can buy a fake under the guise of such drills. Their appearance is practically no different from a high-quality drill, but immediately after the first drilling, diamond chips simply fall off. The tube itself, as well as the material from which it is made, is also important. If the drill is made of brass, then most likely it will bend when clamped in the chuck.

There is another type of drill that can be used to make holes in glass - conical ones. However, experts prefer to use tubular drills, since conical drills have limited thickness and turn all the glass drilled into dust. In addition, tubular drills can be purchased at almost any hardware store, and they are inexpensive. In addition, they have a fairly large selection of different diameters.

Product preparation

When wondering how to cut a hole in glass so that the hole formed in it is as neat as possible, and the glass itself does not crack, it is important to know how to properly prepare it for processing. To drill glass with your own hands, you need to perform the following preparatory steps:

- The surface of the glass that needs to be drilled is degreased with alcohol or turpentine. After this, it must be wiped with a dry cloth.

- The glass sheet or mirror must be placed on a surface that will prevent the product from sliding during processing.

- The surface on which the glass sheet or mirror will be placed must be larger than the product itself. The edges of the sheet should not be allowed to protrude beyond its limits.

- It is advisable to stick masking tape or a piece of plaster on the place that needs to be drilled to prevent the tool from slipping.

- The center of the future hole is indicated using a regular marker.

- If you are familiar with drilling glass at home only from videos, then to gain practical skills it is better to first practice on unnecessary glass shards. This training will allow you to subsequently drill glass efficiently.

- Drilling holes in glass should be done as carefully as possible, without unnecessary haste. In this case, minimal pressure should be applied to the tool used.

- The glass and ceramic drill that will be used for processing should be positioned strictly perpendicular to the surface of the product.

- You should not drill holes in glass in one pass; you must periodically stop the process to allow the tool to cool completely.

- When the glass sheet or mirror is drilled almost completely, you should stop the process, turn the workpiece over and continue on the other side of the product. This approach will allow you to drill a hole in a mirror or glass sheet with the highest quality possible and minimize the risk of chips and cracks.

- To make the edges of the hole you drilled even neater, you can further sand them with fine sandpaper.

Tricks when working with glass

When working with glass, there are some nuances and tricks that will help facilitate the process of creating a hole in the glass.

We have already figured out how to drill glass, now let’s move on to useful tips:

- Many people have experienced that when drilling glass, chips and cracks occur. This can be avoided by simply smearing the glass near the future hole with honey and turpentine.

- During the drilling process, you need to apply literally minimal effort, and in no case put too much pressure on the glass. You need to set the drill speed to minimum.

- Some people will ask: is it possible to drill glass by swinging the drill from side to side? This is a very bad idea. Cracks will be inevitable. The drill must be held strictly perpendicular to the surface of the glass.

- We periodically take breaks of literally ten seconds to let the glass cool down.

- In this case, the drill also needs to be cooled in water so that it does not melt the glass.

- To degrease the glass surface before drilling, you can use not only alcohol, but also acetone.

- You cannot drill holes at a distance of less than one and a half centimeters from the edge of the glass.

Non-standard methods of drilling glass

In fact, there are even more creative ways to drill through glass, even compared to using sand. How else can you make a smooth hole in a glass surface?

Using copper wire

If you don't have a drill handy, you can try taking a drill and fixing copper wire in its chuck. But you won’t be able to drill a hole without a special mixture (two-thirds turpentine, one-third camphor and a little abrasive powder). This mixture is applied to the drilling site.

Metal tube

The method here is the same. We fix the tube with a smoothly sawn end in the chuck, and apply the same mixture to the drilling site as in the previous paragraph.

Serrated metal tube

And again - the same method and the same mixture of camphor, turpentine and abrasive. But this time we take the tube not with a smooth cut, but with teeth cut at one end (it is worth remembering that they must be the same).

And finally, it’s worth mentioning how to drill tempered glass. Remember: it is better not to do this at home. It is worth contacting specialized companies.

Drilling glass using a regular drill

Many home craftsmen are interested in the question of how to drill glass or a mirror, using not a tubular or other special drill, but a regular tool. In order to perform this procedure, you will need the following tools and supplies:

- a drill, which is usually used to drill metal, ceramic and tile materials;

- low-speed drill, instead of which you can use a screwdriver;

- a piece of ordinary plasticine;

- turpentine;

- alcohol solution.

The edge on the plasticine glass is needed to hold the coolant in the drilling area

The drilling itself is performed in the following sequence:

- The glass sheet or mirror must be laid on an absolutely flat surface, and the edges of the workpiece must not protrude beyond its limits.

- The area of glass that needs to be drilled must be degreased using cotton wool soaked in an alcohol solution.

- After fixing the drill bit for tiles and glass in the chuck, the minimum number of revolutions is set on the drill. Before starting work, you need to check the degree of runout of the drill: if it is too large, then the tool should be replaced with another one.

- On the surface of the glass that needs to be drilled (in the place of direct processing), it is necessary to fix a piece of plasticine, in the middle of which a small depression is made in the form of a funnel. Turpentine is poured into such a recess, through which holes are drilled in the glass.

- To avoid throwing away the cracked object after drilling, this process should be carried out as carefully as possible, without exerting much effort. The minimum rotation speed of the drill chuck should be 250 rpm, and the maximum cannot exceed 1000 rpm.

How to drill glass at home?

Glass is a very fragile material that breaks very easily, so when performing work involving it you need to be extremely careful and attentive. That is why many, faced with the need to drill through this material, are lost, not knowing how best to do it. Today I will share with you three methods that will answer the question of how to drill glass.

First method (the easiest)

To drill a hole in glass we will need: a flat surface (board, table or other), a screwdriver or low-speed drill, plasticine and turpentine.

So, first, place the glass on a prepared, flat surface so that it lies stable (does not “play” on the surface) and its (glass) edges do not hang down. Now we insert the drill into the drill (screwdriver) and set the minimum possible drilling speed.

We scroll in the air, determining the “runout”; if it is large, then you should choose another drill. Having selected a drill, degrease the surface of the glass with alcohol and sculpt a boundary circle on it from plasticine, into which we pour turpentine (a small amount).

Now you can drill, the main thing is not to use much force so that your glass does not crack under pressure.

Second way

So, we take the glass and degrease it with alcohol, after which we sprinkle it with wet sand, in which we make a funnel of the required diameter with a sharp object. Then we pour pre-molten tin or lead into this funnel. We wait two minutes, remove the sand from the surface and remove the frozen solder, obtaining the desired smooth through hole.

Third way

Let's take a glass cutter and remove a diamond roller from it; we will need it to make a homemade drill. We fasten this roller with a rivet to a metal rod (in which a slot must first be cut) so that it cannot rotate and sits rigidly in the seat.

We insert the homemade drill we made into the drill chuck and drill the glass surface in the usual way.

Source: https://podmasterij.ru/poleznye-sovety/kak-prosverlit-steklo-tri-neslozhnyx-sposoba.html

How to make a hole in glass using sand

Few people know how to make a hole in glass using ordinary sand. You will need:

- the sand itself;

- petrol;

- a small amount of tin, which can be replaced with lead;

- gas-burner;

- a metal vessel, which can be used as an ordinary mug.

The surface of the glass that needs to be drilled is degreased, as in all previous cases. A mound of wet sand is poured into the area where the center of the future hole should be located, in which, using a sharp object, a recess is made with a diameter corresponding to the cross section of the hole being created.

Making a hole with molten solder

Molten tin (or lead) is poured into a depression formed in a pile of wet sand, after which it is necessary to wait a few minutes. Then the sand is removed from the surface of the product, and a piece of metal alloy with glass, the dimensions of which fully correspond to the geometric parameters of the hole being formed, is easily removed from the material being processed. A gas torch and a metal mug are used to bring the tin or lead to a molten state.

The cut made using the method described above is of high quality and does not require additional modification.

How to drill glass

Drill for glass

In industry, this process is performed quite easily on special equipment using tools typical for this type of work. Naturally, there are no such opportunities at home. Therefore, the work methodology is somewhat simplified.

First you need to understand which drill is best to perform such an operation. Simple drills designed for working with metal or wood are not suitable, as they will simply crush the glass. To make holes in glass, you must use a special drill. Its tip has a characteristic shape, somewhat reminiscent of an arrow. This type of drill has a special coating that allows it not to pierce the material during operation, but to gradually scrape off layers of the surface, gradually making it thinner at the drilling site. Another type of drill for such work is tubular. With its help, you can easily drill through both tiles and glass material. The edges of such a drill are coated with diamond in the form of fine chips.

Drilling bits

Note!

This type of drill is recommended for cases where it is necessary to drill a hole with a large diameter.

Glass drilling work is performed with an electric drill. The only condition is that the tool must have a speed control function. This is due to the fact that glass drilling should be performed at low speeds.

Using a homemade drill

You can drill glass by making your own tool, the design of which includes a diamond roller from a glass cutter and a metal rod. The diamond roller, which will act as the cutting part, is tightly fixed in a slot made on the end part of the metal rod. By fixing such a tool in the drill chuck, you can drill any glass product, and the result will be of sufficient quality.

Homemade drill from a glass cutter

By hardening a regular drill, you can give it the ability to drill through glass. To do this, the working part of the drill must be heated white-hot using a gas burner, and then cooled by dipping it into sealing wax.

Regular drill

Drilling with a regular drill

When using a regular drill for small holes, you must follow these recommendations:

- Harden the drill. To do this, the drill, clamped in the pliers, must be thoroughly heated over a gas burner.

- Then you should immediately place it in sealing wax (or machine oil) to cool. It should be kept until the wax mass stops melting and cools completely.

- The drill can be removed and any wax particles stuck to it can be removed. The tool has been hardened and work can begin.

Practical recommendations

How to drill glass correctly to get a high-quality result? To solve this problem, it is enough to adhere to the following recommendations:

- To minimize the risk of cracks and splits at the drilling site, the glass can be treated with honey and turpentine.

- The pressure exerted on the drill from above should be minimal.

- The drilling process itself must be performed for 5–10 seconds, after which it is necessary to cool the tool in a vessel with water.

- The drill should not be moved from side to side.

- The distance between the center of the hole and the edge of the workpiece must be at least 1.5 cm.

Naturally, before drilling the glass, you must degrease it and lay it on a flat surface, which is best used as a wooden base.

Useful tips

- To avoid cracks and chips, it is recommended to apply a small amount of honey or turpentine to the area where the hole will be made.

- When drilling, take short breaks of 5-10 seconds. At the same time, dip the drill in cool water to enhance the effect, otherwise it may melt.

- Do not swing the instrument in different directions.

- Instead of alcohol, you can use acetone.

- When working, do not forget about safety precautions: use safety glasses and gloves.

- The hole should be located at least one and a half millimeters from the end of the glass sheet.

- It is advisable to work with glass on wood surfaces.

Application of glass cutter

You can drill through a glass sheet not only with a tubular drill or a tool for processing ceramic tiles. A regular glass cutter is also used to create holes in this material. How to drill (cut) glass using such a tool? Simple rules should be followed: you cannot make sudden movements with the glass cutter, while gentle pressure is applied to it, and during the processing process, the cut being formed is tapped with the handle of the tool.

A compass is used to cut round holes of large diameter with a glass cutter.

Using a glass cutter

This tool is great for creating large, oddly shaped holes. The sequence of work will be as follows:

- Using a marker, select the contours that will be processed.

- When using a glass cutter, do not make too sharp manipulations. You need to apply pressure on the device smoothly and as evenly as possible.

- To make the cut piece fall off, gently tap the tool handle on the surface.

- To get rid of excess material, use special tongs.

- Check the condition of the device in advance. The cutting roller must be located strictly in the middle.

Non-standard glass drilling methods

Non-standard methods for making a hole in glass include the following:

- using copper wire as a cutting tool, a solution consisting of one part camphor and two parts turpentine, to which abrasive powder is added;

- using a metal tube as a cutting tool, which is also used together with a special solution and abrasive powder;

- drilling using a piece of tube made of aluminum, copper or duralumin, on which cutting teeth are previously made (drilling using this method is also carried out using a special solution and abrasive powder).

Drilling glass with a copper tube

We have discussed many ways to drill glass, and in conclusion we offer you to watch a detailed master class on making a hole using a diamond crown.

Marking and preparation

The usual method of marking the center of the hole with a cross will not work for marking. To drill glass, you need to draw a square that will describe the hole. Remember that a tubular drill cannot be centered, so you will need a stand that will allow you to guide the tool in a strict vertical line. If there is no such frame, then distortions may occur.

In addition, starting the drilling itself will be quite problematic. It is possible that the drill will slip and scratch the surface of the glass. In this case, you can use a piece of plastic or wood. They are pre-drilled and attached to the surface of the glass with tape, and then using the same drill, a hole is made in the glass itself. If you have enough experience, you can do without plastic. Then you need to make an approach with only one side of the drill, gradually bringing it to the normal.

Preparing for work

- Before you drill glass at home, you need to prepare it for work: use turpentine or alcohol to degrease the entire surface, and then wipe it with a dry soft cloth;

- Do not allow the glass sheet to slide during operation.

- The sheet must be completely positioned on the base.

- The place where you decide to drill a hole should be marked with a marker or construction tape.

- If you do not have the skills to drill holes, we advise you to practice on small pieces so as not to spoil the main sheet.

- Drilling glass at home is not fast. The process will take quite a long time. While working, do not press too hard to speed up the work.

- The drill should be positioned at right angles to the plane. One hole should not be made at a time. From time to time you need to stop and let it cool a little.

- When you are in the final stage, i.e. When the hole is almost ready, you need to turn the glass sheet over and drill a hole on the other side. This operation allows you to avoid cracks or chips, and you will also get a hole of the correct shape.

- In order to get rid of small irregularities or roughness on the glass surface, take fine sandpaper and sand the sheet.

Preparing the workplace and tools

- The workplace for drilling glass should be comfortable and safe:

- special premises (preferably non-residential);

- a stable and level table (or workbench) with a non-slip surface;

- availability of free space around the table (or workbench).

- Ensuring worker safety:

- special safety glasses;

- gloves made of thick fabric.

- Tools and consumables:

- classic drills for metal and ceramics of the required length;

- drill (can be replaced with a screwdriver, but not recommended);

- liquid soap (or equivalent);

- hot water;

- foam sponge;

- turpentine for degreasing or other similar chemicals (alcohol, solvent, acetone, etc.);

- a piece of soft, dry flannel fabric.