There is very high competition among companies that install plastic windows. Unfortunately, among them there are many unscrupulous market participants. When choosing a contractor, it is very easy to fall for deception, even after thoroughly studying the issue of installing PVC windows and types of glazing. After all, many defects can only be recognized after a time when the warranty has already expired.

Among the frequent mistakes of the client is the reluctance to delve into details from the very first contact with the window company. Before setting a price, a conscientious specialist will tell you about the parameters that make up the price: the dimensions of the opening, the type of profile and glass unit, the size of the window sill, the configuration of the sashes, additional options. But many clients shrug it off and want to know the price right away. Another common mistake is choosing to install a window based on a promotion that is too tempting.

A modern plastic window is not only a number of components from different manufacturers, with a wide range of parameters, quality and cost. Measurement with assessment of the situation, compliance with assembly and installation technologies of structures also affect the service life and reliability of windows. Therefore, only a combination of characteristics allows one to judge the integrity of a window company.

Materials and components

You can stumble across a scam at almost any stage of window selection, and every element of the window can turn out to be a fake.

Profile

One of the favorite advertising techniques is to emphasize the German origin of the profile. After all, let’s be honest, the Russian consumer has low confidence in domestic products. But if we think logically, then a window profile made and brought directly from Germany will be very expensive. This is not beneficial for either the company or the client.

What is a German profile in Russia?

In fact, German origin is the use of German technologies in the production of profiles in Russian cities. At the same time, factories, as a rule, are official partners of the brand and operate under the control of its representatives. This means that production is regularly certified for compliance with the production and assembly technology of products.

Factories of the largest brands are located in the following cities:

- REHAU - Ramenskoye, Moscow region;

- VEKA - Moscow and Novosibirsk;

- KBE - Voskresensk, Moscow region;

- THYSSEN - Serpukhov, Moscow region;

- GEALAN - St. Petersburg;

- ELEX - Krasnodar;

- Salamander - Brest, production for export to Russia and Ukraine;

- TROCAL - Voskresensk, Moscow region.

When choosing a window company, we advise you to pay attention to whether it has a certificate of compliance with German requirements. There is no doubt about the quality of the European product: the guarantee for it lasts at least 40 years, the material is durable (does not crack) and color-resistant (does not turn yellow in the sun). We do not recommend choosing Turkish and Chinese profile systems. They are produced to completely different standards, and, accordingly, have different quality, while the price is about the same.

Before purchasing plastic windows, ask the company for a quality certificate!

Fake

Another trick that unscrupulous companies resort to is the production of counterfeits. Scammers copy or buy a cheaper profile, then change the protective film, and buyers mistake the product for a higher-level brand. Most often used for these purposes:

- BRUSBOX, MONTBLANC, PLAFEN, ARTEC - similar to REHAU profiles;

- NOVOTEX, KRAUSS, PROPLEX, WINTECH, EXPROF, RIGAP - similar to KBE.

In addition, unscrupulous companies may use a profile for non-residential premises instead of the usual one. Outwardly, they are almost the same, but the object profile is made of recycled plastic, and the thickness of its walls is thinner than the required 3 mm. The cost of such a profile is much lower, which is a “bait” for the buyer.

Poor quality window profiles

Remember, it is strictly forbidden to use an object profile for residential premises! The design of such windows is not strong enough, thermal conductivity is not up to standard, and the plastic can emit an unpleasant odor. An unreliable company, of course, will keep silent about the real purpose of the product.

How to spot cheating? There are usually no inscriptions on the profile protective film, or there are the words “object”, “object”, “engine”, “tender” and similar in meaning. Pay attention to this and do not agree to install such windows.

Saving on raw materials

Another fraudulent method to reduce the cost of metal-plastic windows is inserts made from recycled materials. How to recognize them? By a darker shade on the front surfaces. Also, the glazing bead and the profile should normally be identical in color. If recyclable materials were mixed at the plastic production stage, the shades of the elements will differ - most likely, the glazing bead will be darker or yellower

Accessories

The cost of fittings makes up a significant part of the price of a metal-plastic window. Unscrupulous companies know how to save money in their favor.

Poor quality fittings

Substitution

The simplest way is to install cheap fittings instead of the high-quality fittings promised in the advertisement. A little math: the difference in price between a cheap Turkish Vorne kit and a good German Roto can reach 65% for one window. The Austrian brand MACO has a factory in China - it is quite difficult to determine the country of origin. The average window company produces about 250–400 units of products per month. Can you imagine how much they win from such illegal “savings”? Customers, in turn, will have to repair the fittings at their own expense in a few months.

Be careful when concluding a contract: if it does not indicate the brand of fittings used, they can install anything. Most likely, the quality will differ from what is stated in words or in advertising.

To determine the quality of the fittings, you need to test them in action. Try turning the window handle: if you have to apply force, and the mechanism operates with a creaking or jerking sound, then the part is unlikely to last long. If a spring effect appears when locking, this is a sign that the metal power elements have been replaced by plastic ones and bend when the handle is turned. This may also be evidence of improper assembly or under-assembly - missing screws.

Savings on packaging

In addition to handles, window fittings also include other elements on which the service life of the window depends. High-quality fittings protect the doors from sagging and the room from drafts.

Another type of deception is that some parts may simply not be included in your window package. Although your contract will indicate that it will be the Roto kit that will be supplied.

- Before purchasing and after installation work, you should definitely check for the presence of an erroneous action blocker. It prevents the sash from hanging on the lower hinge when switching from swing to tilt mode. This is not only an important contribution to the service life of the window, but also a guarantee of safety. If the lock is not installed, the hinge may fail and the sash will fall out of the frame.

- The package must include a strike plate. It is needed for a tight fit of the sash to the frame and is installed along the perimeter of the internal contour of the frame, at least one on each side, that is, 4. Possibly more, depending on the size of the window. The dishonest approach of some companies is to limit themselves to two strikers per sash. This leads to drafts and even drafts in the area of glass and window sill, which indicates significant losses in tightness and thermophysical parameters.

Be sure to check the operation of window handles and other fittings before acceptance!

Double-glazed windows

Unfortunately, this parameter also provides a lot of opportunities for deceiving clients. Unscrupulous companies practice the following:

- reduce the amount of sealant or use a cheap product;

- For the initial sealing and fixation of a double-glazed window, instead of polyisobutylene, double-sided adhesive tape is used, which contradicts the requirements of the technology;

- for secondary sealing, instead of polysulfide, use a one-component sealant (silicone, hotmelt;

- replace the desiccant (phonosorb) with silica gel or another cheap analogue;

- use insufficient amounts of phonosorb or abandon it altogether.

If the window chamber fogs up or becomes covered with condensation, this indicates mediocre quality and is a reason to file a claim with the company. Sealing problems are covered under warranty.

Consider the sealing layers - they are clearly visible through the glass. The black color of the first layer is a good sign. White or transparent is a sign of savings on primary sealant. After a few years, the thermal insulation qualities of a double-glazed window will significantly decrease and it will last a shorter period of time. You should also pay attention to the second layer - it must be at least 5 mm, otherwise over time the glass unit will lose its integrity. In addition, along the entire internal contour, both layers must be of uniform thickness.

Above we looked at technological violations. In addition to them, replacement or absence of glass unit elements is often encountered.

- M1 float glass is replaced with ordinary glass. If you look through it at a slight angle at a neighboring building or other structure with straight lines, distortion will be noticeable: straight lines will be wavy and begin to “float” as your gaze moves along the plane of the window.

- There is no internal glass in a double-glazed window. Although it is difficult to notice visually, there is a way to check: you need to hold a lighter to the glass and count the number of flame reflections. Three glasses will give 6 reflections, two – 4.

- Instead of reinforced or energy-saving glass, ordinary glass is installed. The lighter will also help identify this violation: the reflection of the flame in the energy-saving glass will be different in color (purple, not red).

- Absence of inert gas stated in the contract. Can only be checked using a spectrum analyzer. The problem is that not everyone has professional equipment for this test in their home, and it is not cheap.

- Use of cheaper seals. Unfortunately, it is impossible to determine a replacement by appearance.

Drain bar

This element is needed to protect against water ingress during rain, when the sash is switched to tilt mode, and is mounted on the outside of the window. Many companies neglect to install a drainage strip, although this is a mandatory requirement according to the standards.

Slopes

Slopes of decent quality are made of insulated sandwich panels 10 mm thick. The material is warm and tough, fungus does not form on the surface. Cold wall panels of mediocre quality are used as a cheap replacement.

Errors when finishing slopes

Normally, joints are lubricated with liquid plastic during installation. It is similar to PVC in structure and has an equal expansion coefficient, so it does not differ in color from the profile and does not crack. But instead of liquid plastic, silicone can be used - after a few weeks it will turn black and fall off. As a result, the appearance of the window suffers, energy efficiency decreases, and fungus may appear.

Which plastic windows are best to buy?

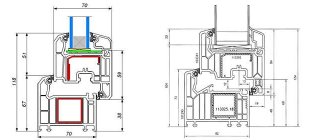

When choosing a window, they are primarily guided by the geometry of the profile, because almost all the characteristics of a PVC structure depend on it:

Installation width. The higher this indicator, the more reliable the design and the higher its energy efficiency.

- It is usually recommended to take a profile of at least 70 mm.

- For northern regions, the threshold value shifts to 80 mm and above.

- In the south of the country, it is permissible to use a profile with a width of 58-60 mm.

The thickness of the glass unit, as well as the number of layers in it, depends on the width of the profile. All this together determines the energy efficiency of the window structure.

The thickness of the outer walls of the profile affects the strength of the frame. Don't forget to check this figure when ordering budget models. Experts recommend choosing windows with external walls no thinner than 2.5 mm.

The number of air chambers in the frame usually ranges from 3 to 8, depending on the chosen modification. The more chambers, the more internal air “pockets” that reduce heat loss.

Thickness of the reinforcing insert - in a high-quality window, the metal core of the profile must be made of steel with a thickness of at least 1.2 mm. And from 1.5 mm for windows with massive double-glazed windows.

The shape of the reinforcement also matters:

- The best option is an insert with a rectangular (square) cross-section;

- The U-shaped one is only slightly inferior to the square in rigidity;

- The L-shaped insert is used in economy series windows.

Manufacturing technology

Violation of technological requirements in the manufacture of windows is also a fairly popular type of deception. It leads not only to economic losses, but also to a questionable level of structural safety.

+7 (499) 647-50-50

Call

Order windows at a profit!

Until the end of the week, 30% discount on windows and balconies!

I want a discount

Reinforcement

The plastic profile needs to be reinforced - otherwise the product will deform and the window will become unusable.

To avoid window deformation, the PVC profile needs to be reinforced inside the structure. This is achieved by using a metal profile - that is why they are called metal-plastic. According to technological standards, the metal profile must be protected from corrosion. The minimum thickness of a closed section (square) is 1.5–2 mm, and at least two screws must fit into it - then the sash will not sag over time.

Where could the deception lie? Usually this is a deviation from production technologies:

- the profile section is too thin - 0.75, 1 or 1.2 mm;

- use of ferrous metal unprotected from corrosion;

- U-shaped reinforcement without a closed section. In addition, violations are possible during the installation of reinforcement:

- selective location (only in mullions, shulpi and turns);

- too short or composite metal profile;

- complete lack of reinforcement (often found in new buildings).

How to check reinforcement for compliance with standards?

- Using a magnet. Run it along the entire length of the frame and sash - there should be attraction everywhere. If it is not available anywhere or in some areas, you have the right to refuse the product.

- According to the distance of the screws along the end of the frame. Normally, they should be spaced with a maximum of 50 cm indentation in a regular profile, and 30 cm in a colored profile.

- Based on the strength of the screws, try unscrewing them. If you can't, that's a good sign.

Assembly

Only a large company that has a considerable amount of money for technical re-equipment can afford to fully equip an assembly line for plastic windows. It must be operated by trained specialists, which also involves costs for staff development. These components make it possible to ensure reliable assembly according to the technology.

Firms that cannot afford high-quality and at the same time expensive equipment with the ability to evaluate the quality of welding end up with a window that has incorrect geometry, lets in cold air and fittings that quickly fail, which, of course, suffers from the client. It is almost impossible to identify such defects visually. Check with the window supplier who serves as the manufacturer. A small organization in a small city is not your option.

Ask the seller where exactly the products are manufactured!

Manufacturing of arched plastic windows

The production technology of arched windows involves performing an order of magnitude more operations than in the production of plastic Euro-windows. One of the most important processes is PVC profile bending. This process is carried out in accordance with a given radius under which it is necessary to produce a double-glazed window. In addition, the production of arched windows involves welding on a machine with one welding head. Given the additional processes involved, the cost of producing arched plastic windows is usually higher. In addition, the price is affected by the production time.

Rice. 8. Arched window production process.

Installation

Even if you are confident in the characteristics of the product, it is too early to relax; poor installation can negate its advantages. Pay attention to the materials that the company’s specialists use:

- You should use specialized mounting foam for translucent structures (for example, Tytan).

- It is worth using vapor-permeable PSUL (pre-compressed sealing tape). It will guarantee protection from sunlight and remove excess moisture.

- External slopes and flashings will provide PSUL protection from ultraviolet radiation.

Results of savings on window installation

What else you need to pay attention to when accepting work:

- There should be metal plates along the end on three or four sides. If you don’t see them, it means that metal fittings with plastic elements, or completely plastic, are installed. It will last until the end of the warranty period, but there is no guarantee that it will serve you faithfully for a long time.

- Close the window. Check the seal. The gaps and loose fit guarantee you a draft in winter.

- The seal should contract when the window is closed. A flat seal will not protect you from the cold, as it will not fit tightly enough to the frame.

Try to be present in person during window installation!

Prices and discounts

When advertising plastic windows, they often announce the price of a standard product, despite the unique parameters of each order. What is a standard window:

- double-leaf structure 1300 mm wide and 1400 mm high with a vertical impost in the middle;

- one sash is tilt-and-turn, the second is blind;

- single-chamber double-glazed window 24 mm wide with formula 4-16-4;

- mosquito net; window sill 250 mm wide and 1400 mm long;

- ebb 150 mm wide and 1400 mm long.

Companies often purposefully “simplify” the package in order to stand out from numerous competitors. This leads to the fact that when placing an order, you are faced with the fact that the mosquito net is not included in the price, the width of the window sill is reduced, or a double-glazed window with the formula 4-10-4 is taken into account, which, by the way, is generally not suitable for glazing residential premises in the middle zone Russia. Of course, when calculating the “normal” configuration, it turns out that there is no benefit.

Discounts are a separate issue. It seems that everyone understands that the company will not work at a loss or for free. But a trusting buyer cannot miss the offer of free delivery or installation.

Remember: there are no free services - you will pay for them anyway! These are just marketing gimmicks that are created in order to attract buyers with unique offers. The size of the discount may result in work not included in the estimate or will be compensated for by the inflated cost of components. Orders from companies that do not offer discounts or promotions are often more profitable.

Double-glazed windows with a hole for air conditioning

Double-glazed windows with a hole are usually used to provide outlet for a mobile or floor-standing air conditioner. The need to install such air conditioners is usually dictated by the lack of other outlets for the air conditioner. The reason for installing such a double-glazed window may be the reluctance to disrupt the appearance of the building, the inappropriateness of the costs of installing a split system, etc. Among the features of such double-glazed windows, it is worth noting that the holes in the glass are cut individually in accordance with the size of the air conditioner hose. In addition, such double-glazed windows are manufactured exclusively in factory conditions, in which it is possible to maintain the safety, strength and tightness of the glass.

Rice. 9. Double-glazed window with a hole for air conditioning.

Guarantee

You can often hear from a company about a 25-year warranty, but in the contract it turns out that the warranty period is 1-3 years. Can such cases be considered fraud?

Not really. Each part of the window belongs to a specific manufacturer and has its own service life. Technical testing of the profile can show that the structure will last for several decades, so the product will receive a 15-year guarantee. The warranty for fittings is usually 10 years, for double-glazed windows - 25. In advertising you hear a guarantee for the profile structure, not for all windows as a whole, as is stated in the contract.

Read the contract carefully and check the terms of the guarantee!

A few more tips

- You should not change all the glazing in an apartment or private house at once. It's better to make a mistake with one product than to replace all of your windows, especially if you're on a tight budget.

- There is no connection between the number of sealing circuits and the absence of a draft, so you should not overpay.

- The recommended profile thickness is 58–60 mm. Such a design can freeze if the temperature remains low - a so-called “cold bridge” will appear in the places where the fittings are attached. It is better to choose a profile with a thickness of 68–84 mm and a thicker double-glazed window. The brands REHAU, VEKA, KBE have such systems. The difference in cost will be insignificant, but the result will be tangible.

- It often happens that companies insist on a window design with a large number of chambers, justifying this by the fact that such a double-glazed window will retain heat in the house much better than its counterparts with fewer chambers. If we consider a budget option for double-glazed windows, this will give almost nothing. Most often, the energy efficiency of a profile with 3 chambers is sufficient. 4-, 5- and 6-chamber systems prove themselves in houses and apartments with individual heating.

- Don't give up energy-saving glass. They help retain heat in the room and are not much more expensive.

- Plastic windows require maintenance. The fittings must be periodically lubricated with silicone grease or technical petroleum jelly. The seal will also have to be maintained from time to time. It is best to entrust this task to specialists.

Of course, not all window companies set themselves the goal of deceiving the client, but where there is a lot of money and high competition, the likelihood of making a mistake with the choice is not so small. In some cases, it is simply impossible to detect fraud without special knowledge and equipment.

How to protect yourself? It is better to contact a large, trusted company, which will not benefit from compromising itself on the service market. Ideally, if one of your friends has already ordered glazing from it and is ready to share their experience of cooperation with you.

is an official partner of REHAU and offers only high-quality plastic windows and doors at manufacturer prices!

Double-glazed windows with a hole for a fan

It is also possible to produce double-glazed windows with a hole for a fan. Such double-glazed windows are also manufactured to individual orders. It is worth noting that such double-glazed windows have no analogues, since it is impossible to make a hole in a finished product due to loss of structural integrity. In addition, the seal of the glass will also be compromised. The manufacture and installation of double-glazed windows with a hole requires jewelry work that can only be performed by a master. Therefore, you should not install such windows yourself, but entrust this process to professionals.

Rice. 10. Double-glazed window with a hole for a fan.

Reviews from our clients

Customer review #1

Our apartment had a very cold balcony. The house is located in such a way that the wind blows all the time. We decided to install windows, on the advice of the Rehau Grazio master. The drafts have disappeared, the windows don't let anything in at all. 100% satisfied

Customer review #2

I ordered Diamond windows in the shape of arches. Everything is thought out to the smallest detail, the windows are made perfectly. Installed quickly and without problems. Thanks for bringing the original design to life!

Customer review #3

When buying an apartment in a new building, we decided to immediately change all the windows, because... developers often save on this. We replaced everything with Rehau Thermo windows and made an insulated balcony. We were satisfied with the work, nothing blows through, very warm.