A double-glazed greenhouse helps create comfortable conditions for growing seedlings. In structures with high light transmission, both vegetable and ornamental crops develop and grow well. Gardeners appreciated the thermal insulation qualities and resistance to gusty winds of this design. By installing a double-glazed greenhouse on your site, you can be sure that the construction costs will be repaid with a hefty harvest. By following installation tips, you can avoid common mistakes.

What is double glazing

A double-glazed window, which is popularly called a plastic window, is a building structure made of several sheets of glass and a metal-plastic frame. The glasses are located close to each other, and all the free space between them is filled with dry air. It turns out to be a kind of “package”, hence the name.

Important! A double-glazed window retains heat no worse than brick.

Double-glazed windows are used for various purposes, as they are durable, not afraid of frost, do not allow noise or drafts to pass through, and are completely sealed. They produce several types of windows:

- single-chamber;

- two-chamber;

- three-chamber.

The greater the number of glasses in the package, the better the quality of the window. Two-chamber and three-chamber structures are used to create winter greenhouses. The thermal insulation properties of such double-glazed windows are much higher than conventional ones.

Building frame

To build the frame we need beams. You need to install beams on top of the anchors and connect the corners. Then we make markings for the vertical supports. We install intermediate supports, checking them with a level. We attach the frames to the frame using screws.

When working with a hammer, there is a risk of damaging the glass. The last step is to seal the cracks.

Features of a double-glazed greenhouse

To build greenhouses, you can use not only new, but also used double-glazed windows. They are no worse, they have the same properties. The popularity of such designs is growing every year and there is a logical explanation for this.

A double-glazed greenhouse can be of any shape, but most often a standard design is made in the form of a rectangle with a gable roof. However, craftsmen can also do it with a pitched roof, in which case one of the sides is the wall of a building.

The roof for the greenhouse can be made from the same double-glazed windows or other available materials, for example, polycarbonate. Although experienced summer residents do not recommend this option. It is better to make it entirely from plastic windows, it will be more reliable.

Since double-glazed windows are the basis of the structure, the purpose of the building also depends on their choice. As already mentioned, for winter use you will need two- and three-chamber windows. If you plan to grow only seedlings or summer vegetables, then a regular double-glazed window is sufficient. However, planting in such a structure is possible only at positive temperatures.

Attention! Assembling a greenhouse from double-glazed windows is easier, they are stronger and more reliable.

When planning the construction of a greenhouse, you also need to decide on the height of the structure. These can be low or high buildings, where you can walk at full height and grow tall crops. You also need to remember about ventilation; some windows are ordered with vents.

Self-installation steps

The installation of a greenhouse structure is carried out in stages, and all actions must be carried out in strict accordance with the construction technology and drawings of such structures.

Arrangement of the base of the structure:

- assembly of a frame from boards treated with special means in accordance with the dimensions of the future greenhouse structure;

- installation of a wooden frame on a flat piece of land;

- checking the diagonality of the installed wooden frame and installing pieces of reinforcement at the internal corners.

Installation of fastenings for frame PVC arches:

- cut fourteen reinforcing sections with a length of seventy centimeters;

- marking the frame along the long sides at intervals of ninety centimeters;

- deepening the reinforcement sections from the outside of the frame in accordance with the markings made;

- marking the frame along the width with the mark of the area for the doorway, followed by a deepening along the completed mark of the reinforcement.

Manufacturing of PVC arcs for greenhouse construction:

- welding two three-meter pipes with the installation of a cross, which makes it possible to obtain internal frame arches;

- production of external elements of arcs using welding and straight tees;

- finished arch structures must be placed on reinforcement fixed in the ground.

Installation of stiffeners:

- cutting sections of PVC pipes with a size of 8.5 centimeters;

- welding of cut sections between the cross and the central tee, which can significantly strengthen the structure frame;

- fastening on a wooden frame and making horseshoe-shaped clamps from a strip of metal.

- fastening the PVC frame using self-tapping screws to the base of the boards.

Construction of door and window openings:

- draw a straight line from the reinforcement, buried along the width of the wooden frame, to the outermost PVC arc;

- inset at the level of these marks of oblique tees.

If you plan to use a material such as polyethylene film as a covering, then you should fasten the tensioned covering to a wooden frame using a regular wooden lath and nails. Greenhouse doors and vents can also be made from PVC profiles and tees. They need to be covered with film and installed in the openings.

When arranging a greenhouse frame with a coating based on polycarbonate sheets, you should perform the following steps:

- place wooden blocks on a wooden frame base between the stiffening ribs;

- fastening polycarbonate sheets using self-tapping screws with thermal washers.

You may also be interested in an article about building a year-round greenhouse.

Advantages and disadvantages

With your own hands, you can undoubtedly make a high-quality greenhouse from PVC windows, which will have many advantages over industrial polycarbonate structures:

- beautiful design and appearance;

- good thermal conductivity properties;

- resistance to loads, winds, snow;

- complete tightness, which allows you to retain moisture in sufficient quantities;

- durability.

In addition, fungi and pathogens of many diseases cannot live in plastic, so there is no need to treat the greenhouse; it is enough to wash the double-glazed windows. In addition, it is much easier to repair such a structure.

But be that as it may, greenhouses made from double-glazed windows have disadvantages. First of all, this is the high cost of materials. After all, even a small building will cost a tidy sum. And the construction of such a structure is only possible on a foundation, which makes it impossible to move the greenhouse to another site. The design is bulky and heavy.

What are they?

Double-glazed windows are an ideal design for creating a greenhouse effect. What it is?

On a sunny day, the transparent coating of greenhouses allows short-wave solar radiation to pass through. It is absorbed by dark surfaces (ground, equipment, plants), turns into long-wavelength and remains inside the structure. This very transformation occurs with the release of heat, due to which a greenhouse effect is created in the greenhouse.

So, double-glazed windows perfectly transmit the sun's rays into the room and almost completely block back radiation, preventing it from escaping outside. In other words, glass, unlike film, is the most heat-saving material, and this is one of the main signs of a good greenhouse.

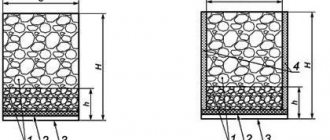

Sectional view of single- and double-chamber double-glazed windows.

Double-glazed windows are manufactured in two versions:

- Single-chamber.

- Two-chamber.

All packages consist of two or three glass sheets glued together and inserted into a frame. The bags are hermetically sealed at the ends with a special compound, the gaps between the glasses are filled with either air or inert gas, and are supplied with a moisture absorber. Therefore, between the sheets the air or gas remains dry, which eliminates fogging of the glass inside the bag, as well as freezing in winter.

They are quite heavy, so if you are installing a double-glazed greenhouse with your own hands, then you must handle the products very carefully and carefully. Nowadays, scientists have developed fundamentally new double-glazed windows, in which the air or gas between the glasses is replaced by a vacuum, and the glasses themselves are not inserted into a frame, but are connected to each other by soldering or welding.

Vacuum double-glazed windows are the near future for gardeners.

As a result of these developments, the seal life is extended to 50 years, the thermal insulation properties are increased 10 times compared to single glazing, and energy costs for heating such a greenhouse are reduced by up to 90%.

With all this, the thickness of the double-glazed window is 4–5 mm, and the heat-insulating properties increase by 5–10 times, which is equal to a brick wall 0.5–1 m thick! But such new products are still very expensive, and not everyone can afford to glaze a greenhouse with such unique double-glazed windows.

How to make a greenhouse from plastic windows

Having decided to build a greenhouse from double-glazed windows, you need not only to choose high-quality metal-plastic windows, but also to think through all the little things and details. The operation of the structure will depend on this. There is no need to skimp on materials, because the structure is being built to last for many years.

Materials and tools

First you need to draw up a plan for a greenhouse from a PVC profile, decide on the size of the double-glazed windows, outline the vents, and choose the type of roof. Draw a design or select a suitable drawing, slightly adjusting it to suit your building.

Based on all the details, decide on a set of tools and materials. In addition to the double-glazed windows themselves of the required sizes, the following will be useful for building a greenhouse:

- timber 50*50 for the frame;

- sand, slag, cement;

- concrete mixer;

- boards for formwork;

- roofing material;

- hacksaw or metal scissors;

- construction foam;

- screwdriver;

- screws and fasteners.

In addition, you need shovels, stakes for marking, cords, and a construction tape.

Site selection and preparation

To build a greenhouse, you need a perfectly flat area. Plastic windows should be evenly illuminated from the south, southwest or southeast side. The construction site should not be flooded by melt water or rain. The ideal soil is sandy. If there is clay on the site, then the place needs to be prepared in advance. To do this, the area is covered in layers with gravel and sand, after which fertile soil is added.

After preparing the site, you need to mark the future structure. This is done so that the ridge of the greenhouse is located from north to south. Then there will always be uniform lighting inside the structure. For these works, stakes, cords, and tape are used. All dimensions are carefully checked against the plan.

Foundation structure

The structure of a plastic greenhouse weighs a lot, so that over time the double-glazed windows do not warp, it is installed on the foundation. Plus, it will help retain more heat. Experienced craftsmen claim that 10% of heat loss can be saved.

The foundation can be made of timber. But it is better not to use this option. When watering, the tree gets wet and quickly becomes unusable. And the double-glazed structure itself can last 40 years or more, so the foundation is poured from concrete. Do this according to the instructions:

- A trench 35-40 cm deep and about 30 cm wide is dug along the perimeter of the greenhouse.

- A 5 cm layer of gravel is poured onto the bottom of the trench and metal stakes are driven in. It is necessary to drive in not too rarely or often. This is called foundation reinforcement.

- Formwork is installed around the perimeter of the entire structure.

- A mixture of sand, cement, slag and water is prepared in a concrete mixer for pouring. They fill the trench with it.

- When pouring the foundation, the frame and fastening elements are placed. They are immediately fixed with concrete.

The greenhouse can be without a frame if single-chamber double-glazed windows are used. They are lightweight and can withstand light loads. For a permanent structure, a frame made of timber is provided, otherwise the ends of the double-glazed windows will corrode over time.

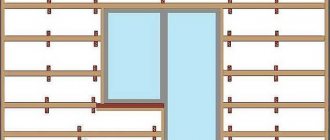

Making a frame and erecting walls

A metal frame is more reliable and durable, but to install it you need to have the skills of a welder or call a specialist. A timber base is not much inferior to a metal one, but you can completely assemble it yourself.

The foundation needs at least a month to harden. Only after this do they begin to build the frame:

- The timber is cut to the size of the greenhouse and treated with preparations against fungus, mold and pests. Let it dry.

- Pieces of timber are laid out around the perimeter of the foundation, after laying waterproofing. You can use pieces of roofing felt.

- The ends are connected with metal corners and self-tapping screws. The bottom trim is ready.

Next, the bursas are prepared for the construction of the walls of the greenhouse, between which double-glazed windows will be installed. The racks are secured with a metal corner and bevels. At the same time, walls of windows are being installed. The inside of the bottom trim is sewn up with boards to hide unnecessary gaps.

The upper harness is carried out similarly to the lower one. After that, all the cracks are filled with polyurethane foam. Fixation of double-glazed windows will be reliable, and thermal insulation will increase.

Roof installation

To make a roof for a greenhouse from double-glazed windows with your own hands, cut a beam of the required size. A frame is made according to the dimensions indicated in the drawing, which is installed on the greenhouse. The ridge is assembled separately on the ground and only then mounted.

Attention! Cross beams on the roof need to be placed frequently so that it can withstand heavy loads. Such a structure is not afraid of snow drifts.

After all the preparatory stages, the roof is covered with the material provided for in the project. The easiest way is to make it from polycarbonate; it is attached to the frame with self-tapping screws. You can make a roof from double-glazed windows, but it will be heavy, and installing windows is not such an easy task.

At the final stage of greenhouse construction, doors, ebbs, heating and water supply systems are installed.

Do-it-yourself greenhouse from window frames: step-by-step instructions with photos

If there is not much space, then the structure can be made in a mini format; such a greenhouse can even fit on a balcony. The walls of the structure will be made of wooden planks, and the roof will be made of window frames. During the day it can be opened for ventilation. The width of the frame must correspond to the size of the greenhouse. It is more convenient if it has the shape of a rectangle.

If the greenhouse is installed in an open area, then installation proceeds as follows:

| Photo | Manufacturing |

| Make markings and dig wooden blocks in the corners. Make shields from boards. | |

| Attach the top layer to the lower shields, which should be higher on one side of the structure and lower on the other. Thanks to this, the roof will have a slope and moisture will not linger on it. Secure the panels to the supports with nails. | |

| Position the frames at a 90 degree angle to the high side. Secure the windows to it with hinges. | |

| Attach a rail between the windows so that there is no hole between the frames and one frame rests on this rail.. | |

| Mount handles on the roof to make it convenient to open and close. | |

| Install clamps on the short side. Build a small plank that will serve as a support for the open frames. |

This completes the construction of the mini-greenhouse. The work usually takes a maximum of 2-3 hours.

The difference between a summer greenhouse made of double-glazed windows and a winter one

A greenhouse is a closed space for growing plants, which creates a favorable microclimate and greenhouse effect. Due to the fact that weather conditions are different at different times of the year, the temperature inside the structure fluctuates greatly. That is why a summer greenhouse is very different from a winter structure.

The inside of the winter greenhouse is arranged differently. It needs to be heated and lit, so the project provides a system for supplying heat and light. Maintaining such a greenhouse is an expensive pleasure and quite labor-intensive.

In addition to high-quality three-chamber double-glazed windows, you will have to spend money on:

- heating radiators;

- electric soil heating;

- automated drip irrigation system.

All this is necessary to avoid sudden changes in temperature inside the greenhouse. Only in this case will it be possible to grow healthy plants and reap a good harvest.

Comment! You can grow vegetables and berries in a winter greenhouse all year round.

Ideas for double-glazed greenhouses

You can make a greenhouse entirely from windows so that they reach right down to the ground. This will allow the plants to be evenly illuminated from all sides. You can grow crops directly in the garden beds.

The option of plastic windows and doors, where most of the walls are covered with plastic, is suitable for mixed growing. Some crops are planted in the garden bed on the side where the windows come from the ground. And the rest of the plants are placed on shelves.

A winter greenhouse made of double-glazed windows looks good, where the foundation and part of the walls are made of brick.