It seems that just recently simple windows with a wooden frame and one glass were familiar to us. Only now they have almost everywhere been replaced by more complex structures - double-glazed windows. Of course, such a quick replacement did not happen just like that. The improved type of window frame has many advantages, if only because it does not need to be insulated every fall and the traces of insulation need not be washed off every spring. At the same time, when there is a need to order a double-glazed window or replace it, questions arise: how to correctly determine the size of the canvas inside the plastic frame? Before answering it, let's figure out what kind of structure it is and what it consists of.

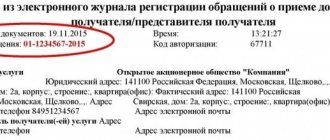

Distinctive and common features of our products and foreign analogues:

| Parameter | Meter "Profi" LIZM.RU | Meter "Start" LIZM.RU | Imported devices* |

| Price | Below | Below | Higher |

| Optical power of laser emitter | 5 mW | 5 mW | less than 1 mW |

| Strap clip | + | + | — |

| Risk of the device accidentally falling out during measurement | — | — | + |

| Risk of the scale falling out and being lost | — | — | + |

| Scale numbering order from left to right | + | + | — |

| Availability of spare parts | + | + | — |

| Anti-glare filter | + | — | — |

| Taking instrument readings in direct oncoming sunlight | + | — | — |

| Automatic on and off | + | — | — |

| The need to hold the button during operation | — | + | + |

| Batteries | 2 AAA elements | Small capacity disk batteries (CR 2032) | Small capacity disk batteries |

* The closest imported analogue of our device, suitable as a sample for comparison: MERLIN LAZER article BOHLE BO 5164701.

Devices of this type can determine the presence and location of:

How to measure a double-glazed window yourself

New Year is a time of family fun, noisy games and, unfortunately, broken glass. We have already noticed that the majority of requests to replace broken double-glazed windows occur during the New Year holidays. The saddest thing is that window companies do not work and customers simply have nowhere to turn.

What to do? Try to take the dimensions yourself and on the first working day after the New Year send a request for production; in two or three days the double-glazed window will be delivered to you.

So, in order:

1. If you still have warranty cards or a window passport, then you do not need to determine the thickness of the double-glazed window; it is indicated in the above-mentioned documents (as a rule, the formula is 4*16*4, 4*10*4*10*4, 4*14 *4*14*4And and more). If the documents have not been preserved, you will have to take three measurements: width, height and thickness.

2. Using a tape measure, measure the width and height; to do this, you need to take the size from the junction of the glazing bead and the frame

in width and height

For example, the measurement result is a width of 500 mm and a height of 1250 mm, to determine the size of a double-glazed window you need to subtract 1 cm (10 mm) on each side, we get the size of the double-glazed window 490 * 1240 mm.

3. It remains to determine the thickness of the double-glazed window; only a specialist can visually do this without measuring. You also need to remove the beads in order to take the measurement correctly. We start with the vertical elements, take a chisel and a hammer, try to make a gap between the frame and the bead

then remove the vertical beads

It remains to remove the horizontal beads

Be sure to hold the glass unit, otherwise it may simply fall out; it is better to work with gloves, as there is a possibility of cutting yourself. Carefully remove the straightening plates

and remove the glass unit

Using a regular ruler, measure the thickness

and the distance between the glasses. All that remains is to determine the formula of your package and you can contact a window manufacturing company. The size is not rounded, the thickness is usually a multiple of two (24 mm, 28 mm, 30 mm, 32 mm, etc.)

And lastly, we have in our warehouse a pack of double-glazed windows that were erroneously ordered by customers. To avoid mistakes, you can always contact the specialists of our company to measure the broken double-glazed windows.

How is the size of a plastic window calculated?

The first thing to do when updating windows is to determine the size of the opening where the new structure is planned to be installed. The success of all further installation steps depends on how correctly the measurements are taken. Measurements are taken not only from the inside - it is necessary to take measurements from the outside. Double measurements of the opening will allow you to determine the parameters of the required product correctly, avoiding possible distortion of the opening and complications of installation.

Precise measurement of the opening and taking into account the obtained indicators during further production will allow you to eliminate end-to-end distortion. If errors in measurements are identified at this moment, it is important to correct them immediately, because later installation will become possible only after reworking the current opening.

Already at the measurement stage, you can make a preliminary calculation of the amount of mortar for plastering work that will be required when sealing cracks and gaps. Correct measurements and taking into account the obtained dimensions will minimize the volume of material, and, consequently, installation costs.

When taking measurements, it is recommended to adhere to the following sequence:

- Measure the opening as accurately as possible. To avoid problems with incorrect calculations, it is recommended to contact specialists who have experience in such work.

- Determination of the exact dimensions of the future structure, made to order.

- The selection of additional elements that give increased functionality to the window (mosquito net, window sill) is determined by the size of the ebb.

- The quality of the binding, the style of the product, the shape and color of the structure, the special characteristics of the fittings, the type of glass unit and their quantity are agreed upon.

- Bringing window sizes to uniform values.

- Preparation of documents for installation, production of products, specifications and other accompanying papers.

How to correctly measure double glazing in a plastic window

Determining the dimensions yourself - width and height - will not be difficult, even without removing the glazing beads.

To find out the width of a double-glazed window (SP), you need to measure the width distance between the glazing beads, including them (along the glazing groove). Measurements are made with a regular tape measure, but accurate to the nearest millimeter.

You need to subtract 10 mm from the resulting value. This is the size of the deformation gap between the glass and the frame to freely adjust the structure and prevent its destruction as a result of expansion of materials under the influence of temperature fluctuations.

For example, if the width along the glazing groove is 475 mm, then the width of the double-glazed window itself will be 465 mm (475-10). The height is determined in a similar way.

Sometimes when ordering, it is enough to indicate the width and height along the glazing groove, and the craftsmen involved in manufacturing will then take the required value themselves.

Guide to calculating the size of window structures

When taking measurements, it is recommended to use a tape measure, the length of which allows you to take the necessary readings. The best option is a roulette with a digital display . Measurements are also taken using existing special protrusions and quarters.

Expert commentary

Vladislav Dobronravov

Leading technical specialist at Okna-Media company

First of all, take readings of the height of the opening from both sides. Width data is taken once - at the bottom. If there is a suspicion of unevenness, a level is used to identify deviations.

It is also necessary to take into account how far the frame extends into the plastic product - no more than 2 cm exceeding the measurements. The location of the frame in the upper quarter should take into account the possibility of installing a mosquito net. In the absence of a vertical or top part, the approach indicator is within a couple of centimeters. Additional centimeters will be required to organize insulation in the structure.

When replacing a balcony sector, first take measurements of the window and measure the door structure separately. Then the values of the entire balcony compartment are measured. When taking measurements, take into account that the hinged sashes should not be less than 40 cm. If large windows are installed, upon delivery it must be taken into account that the dimensions of the product must fit into the doorways and means of transportation.

It is necessary to take into account the weight of the plastic structure and its dimensions, coordinating them with the permitted indicators from the design documentation of the structure. When choosing an option for a private home, it is especially important to take into account the stylistic combination of the structure with the overall design and interior.

How to measure the thickness of a glass unit?

Of course, in the arsenal of every glazier there is a certain set of auxiliary measures that help, with a certain degree of convention, to create a basis for drawing conclusions about the structure of the double-glazed window. But the result obtained in some situations may not coincide with the data of the double-glazed window being measured, and often comes down to a lottery: “you guessed it right or you didn’t guess it right.” Accordingly, the question arises: the modern level of progress is simply obliged to help in such situations at an accessible level, but are there any implemented solutions, or is there nothing besides theory? Of course, there are ready-made solutions.

Window sill measurement

Everything is simple here - measure the required length of the window sill and add 10 cm to it so that the window sill is recessed into the wall on both sides. The width of the window sill is measured taking into account the width of your wall, sorry for the taftology. The window sill should protrude slightly. I will not give any specific advice here, since this parameter can vary and is calculated individually. Let’s say, personally, in one room I have a normal window sill with a protrusion of 3 cm, and in the other bedroom there is practically no protrusion, since it rests on a metal heating pipe.

Some practical tips

Friends, handymen, we have reviewed with you the measurements of windows both with and without a quarter. In principle, there is nothing complicated here and you can do all the work yourself, but if your hands are shaking and your eyes are afraid, then qualified workers will come to your aid. By the way, you can only order window measurements, and do the installation work yourself - here it’s up to you and only you!

If you have read the entire article to the end, then you probably already understand the principle of measurement, but there are a few more nuances that I would like to pay attention to.

Friends, even if you have to install ten windows, measure each one separately; you should not take average values. This is especially true for private houses, where the difference between adjacent windows can reach 20 cm.

Pay attention to all the little details - if you have heating made of polypropylene and sewn into the walls, then this is good, but if, like mine, 100 pipes are welded, then you need to make sure that they do not interfere with the installation of window sills, you also need to look at the jumpers - will it be possible remove them or you will have to adapt to them so that the window opens normally.

Let me remind you that all dimensions, or better yet, tolerances and fits may differ significantly from yours, since each of you has your own situation, your own openings - concrete, brick, cinder block, adobe, etc.

Also, before starting measurements, you need to clearly determine the type of windows you will install. Types of window profiles - 3, 4, 5 chamber. Types of double-glazed windows - 1, 2, 3 chamber. All these characteristics affect the thickness of the window, which is important when measuring windows correctly.

Accuracy of measurements

At the manufacturing stage, the device undergoes the necessary calibration of glass thickness measurements and glass intervals. The error during operation is no more than 1-2% of the measured values, and, among other things, may be associated with the temperature dependences of the measured materials, which does not affect the accuracy of the readings taken. Measuring the thickness of glass with a nominal value of 8 mm using a caliper. The actual result is 7.7 mm:

Measuring the thickness of two layers of the same glass with a nominal value of 8 mm and an actual thickness of 7.7 mm using a laser device:

Measurements can be carried out over a wide range of glass thicknesses, from 1 mm to multi-layer triplex of bulletproof protection classes.

In the photo: measuring laboratory glass 1 mm thick

This device is suitable for measuring all types of glass, as well as for organic materials such as acrylic glass and monolithic polycarbonate, as well as other transparent materials with a refractive index that does not have critical deviations from the calculated value used for glass.

How to measure yourself

To accurately calculate the size of the window along the opening, you will need a special tool - a laser level. This device helps to see if there is a deviation of the walls from the horizontal or vertical. In case of deviation, measurements should be taken along the beam.

It is better to take a 3.4 meter tape measure with an error of 1 mm.

With a quarter

The width is measured along the external slopes, then 4-6 cm is added to the resulting value so that the finished structure fits into a quarter on all sides. In the case where the wall is strongly curved, the increase is less than 2-3 cm.

The resulting width should be less than the distance between the internal parts of the walls. You should also make sure that the measured width is less than the distance between the points at which the internal slopes connect to the frame.

The height of the product is the distance from the lower base to the upper outer slope minus 1-2 cm for the mounting foam. 2-3 cm is added to the height so that the window structure extends into a quarter.

If during the design such components as a window sill and ebb were provided, a stand profile 3 cm thick is used to secure them. Therefore, the previously obtained height value is reduced by this amount.

In the final version, the product will be 7-8 cm smaller than the original parameters of the existing technological hole.

Straight

If the house has a regular straight opening, the measurement is carried out 4 times, first taking the width measurements at the bottom and then at the top. Then, similarly, measurements are taken in height on the left and right sides.

Of the two sizes, take the smallest value and subtract 2-4 cm from it, taking into account the gaps for the foam on both sides. Additionally, subtract the height of the stand profile (3 cm). The resulting number will be the width of the plastic window.

During work, it is necessary to take into account the recommendations for taking measurements for various openings.

Self-measurement of double-glazed plastic windows

Any, even the most expensive, plastic windows do not last forever. This applies to double glazed windows and seals . We'll talk about seals later, but now about glass and double-glazed windows. All glass tends to break, and the reasons can be very different, from a soccer ball, or a severe draft, a stone deliberately thrown at the window, and much more. One way or another, the glass unit is damaged.

Our Company will promptly replace it with a new one. But before you order a glass unit replacement, you need to measure it. You can entrust this procedure to a specialist, or you can handle it yourself, since this process is not complicated.

Many people believe that in order to measure an old double-glazed window, it must be removed from the opening, but this is not so. There is a method for determining the size of a double-glazed window without dismantling it.

First, you need to visually see the line between the window frame and the glazing bead - this is the net size of the seat for the double-glazed window. But this pure size in itself is not needed - we will use it exclusively to determine the optimal size of the double-glazed window.

The glass unit is measured vertically and horizontally. The glass unit itself is pressed with a glazing bead. The bead is easy to identify; it has a seal (black or gray rubber) along its entire length. The glazing bead is inserted into the window frame or sash using the groove-to-groove system. And the measurement is made exactly from the place where the glazing bead is attached to the window profile.

In the photo you can see in which places you need to measure, and to what level. If you measured the height and width of the glass unit according to these instructions, then you need to subtract a centimeter on each side - this centimeter will provide a deformation gap (0.5 cm on each side of the window frame). A loose fit of the double-glazed window to the frame will not only allow for its adjustment, but will also prevent premature failure of the double-glazed windows as a result of thermal expansion of the materials.

In addition, it is necessary to measure the thickness of the glass itself, and the distance between the glasses (in order to determine what kind of double-glazed window you had installed - single-chamber, double-chamber, energy-saving, noise-insulating, shockproof - they are all different in size). These dimensions must be in mm and should not be rounded under any circumstances.

With the dimensions obtained as a result of measurements, you can safely contact a company that sells and installs plastic windows and order a new double-glazed window from them with delivery to your home. If you wish, you can order its installation or do it yourself.

Common Mistakes

When measuring a window opening, it is necessary to take into account common mistakes.

- It is important to check whether the walls are even and there are no large chips or distortions in the horizontal and vertical planes.

- Many people forget to take into account that the distance between the walls increases when dismantling the old product.

If incorrect or inaccurate endpoints are determined, the following problems may arise during the installation phase.

- The appearance of significant gaps along the perimeter. To correct the defect, you will have to purchase an additional bottle of polyurethane foam. During operation, the frame deforms and it begins to let in cold air and dust. A double-glazed window will not protect the room from humidity, which can lead to the appearance of fungus. Mold causes various diseases, such as allergies or asthma.

- A mistake can lead to an increase in the size of the profile and a frame made to your dimensions simply will not fit. Correcting this defect is much more difficult. To do this, you will have to remove part of the wall, and this is a labor-intensive process, noisy and dirty type of work, which increases the repair time and its cost. Special equipment is required to remove concrete or masonry.

Over time, the frames in the apartment do not close well, the plastic does not look so snow-white, and the deformed fittings creak. To replace them, it is necessary to measure the plastic windows. This stage is very important, as well as installation.

Main types and tasks of an element

The thickness of the glass unit of plastic windows plays an important role, since it determines how strong the glass unit will be, how well it can insulate heat and noise, and how much the structure will weigh. The main functions of the window are assigned to the double-glazed window.

The types of these structures are as follows:

- Single-chamber double-glazed windows are the simplest and most affordable. The thickness of a single-chamber double-glazed window usually does not exceed 4 mm. It also happens that in one package there are two glasses, the thickness of which is different. It is easy to find out about this by reading the product labeling. The manufacturer resorts to this technique to make the window cheaper. This double-glazed window is suitable for warm climates; The middle zone and more northern regions of the country are not suitable for using such windows for installation in residential premises, since they are not able to withstand severe frosts.

- The thickness of double glazing is usually more satisfactory for the northern regions of Russia. Three glasses are installed in a double-glazed window, the thickness of which is on average 4 mm. Usually all the glass in the design is the same; due to the larger number of glasses, an additional air chamber appears. Due to this, condensation forms only at a temperature of -20 degrees, if the chambers are filled with air, and -25, if an inert gas is enclosed between the glasses.

- Three-chamber double-glazed windows are perfect for northern regions. For central Russia and the south of Russia, installing such windows is irrelevant. The thickness of the three-chamber double-glazed window allows you to easily withstand severe frosts, which do not occur in the middle zone. Such a window costs much more than a two-chamber window and has a larger mass.

- Exclusive options. At the request of the customer, many manufacturers are ready to produce double-glazed windows with from one to five chambers; less often, six are offered. The thickness of the glass in double-glazed windows can also vary. For an additional fee, you can always install glass with a thickness of 6-8 mm or more.

Quarter window measurement

Friends, according to GOST, when installing and measuring windows with a quarter, the windows should extend 30 - 60 mm per quarter, so when calculating the width of the window, you must calculate it so that the window is larger than the quarter, but smaller than the walls.

We measure the height of the window and a quarter. It's done like this. First, measure the distance from the bottom of the window opening to the quarter and add 2 cm to it so that the window goes beyond the quarter. If you order windows with a window sill and ebb, then you should take into account the fact that they have a support profile, the width of which is 30 mm.

After all the calculations, it is necessary to subtract from 30 to 60 mm for the polyurethane foam and, in principle, the calculation can be considered complete.

In order to correctly measure the width of a window and a quarter, it is necessary to add 40 - 60 mm to the external size between the quarters so that the window extends beyond the quarter. When measuring, you also need to take into account that you will need a distance for the mounting foam.

IT IS IMPORTANT TO KNOW!

Friends, you should not recess the window too deeply into a quarter, as this can ruin the aesthetics of the window and also complicate the subsequent installation of the mosquito net.

We looked at the measurement of windows with and without a quarter. It is necessary to understand that all this work is carried out in warm weather and implies the already completed dismantling of old windows, but if this is not possible, then window measurements can be carried out even if there is an old window. Everything is simple here - you take the outer dimensions of the window frame as the initial size.

How to understand product labeling?

If you carefully examine the product, you will notice a set of numbers on it: for example, on single-chamber double-glazed windows you can often see the following values: 4-16-4 - this means that the package includes two glasses, the thickness of which is 4 mm. The distance between the glasses is 16 mm.

The following markings are typical for double-glazed windows: 4-10-4-10-4. This means that the design includes three glasses, the thickness of which is 4 mm, and the distance between them is 10 mm.

Scope of work performed

To date, we have produced about 200 thousand products for premises in different parts of the capital and region. Buyers choose us thanks to our modern service, which includes the following services:

- consulting professionals to select the optimal window system, components and fittings;

- calculation of the approximate cost of the product;

- accurate measurements using a professional measurer;

- careful delivery;

- high-quality installation of window systems, slopes, window sills, etc.

How to measure the thickness of a glass unit

Dimensions must be indicated in millimeters and with an accuracy of 1 millimeter!

Then, subtract 10 mm from the resulting dimensions. Both width and height.

S of the finished double-glazed window = S along the bead – 10 mm

H of the finished double-glazed window = H along the bead – 10 mm

Example: bead width = 475 mm (see figure), which means the width of the glass unit = 475-10 = 465 mm

Bead height = 1130 mm (see figure), which means the width of the glass unit = 1130-10 = 1120 mm

We transfer the size to production: 1120 x 465

Metering

Step 1. Measure the opening. Calculating the size of a plastic window.

| Rice. 1: Window opening without quarter. | Rice. 2: Window opening with a quarter. |

Measuring the opening without a quarter.

First, we measure the width of the opening (Wpr), i.e. distance between side walls. To calculate the window size (Wо), it is necessary to subtract the gaps for the mounting seam (Wm) from the obtained value of Wpr. As a rule, 20-30 mm are left under the mounting foam on each side.

Wо = Wpr – 2*Wм

Rice. 3: Calculation of the window width for a quarter-less opening.

| Then we proceed to measuring the height of the opening (Hpr), i.e. distance between the lower and upper wall. From the resulting height we subtract gaps of 20-30 mm at the top for the installation seam (Nmv) and 40 mm at the bottom for installing the window sill (Nmn). As a result, we get the window height (Ho): But = Npr – Nmv – Nmn |

| Rice. 4: Calculation of window height for a quarter-less opening. |

Measurement of the opening and a quarter.

Unlike the quarter-less version, in this case measurements are taken both from the street and indoors.

We measure the opening from the street side (Wul) and the opening width in the apartment (Wkv). The width of the plastic window (Wo) should be 20-50 mm more than Wul and 40-60 mm less than Wsq.

Rice. 5: Calculation of window width for a quarter opening.

We also measure the height of the opening from the street side (Nul) and indoors (Hkv).

If there is a quarter at both the top and bottom, then the height of the window (Ho) is calculated using the formula:

But = Zero + (10…30 mm) – 15 mm

If the quarter is only at the top, then the height (Ho) is calculated using the formula:

But = Zero + (10…30 mm) – (40…60 mm)

| Rice. 6: Calculation of window height for a quarter opening | Rice. 7: Calculation of window height for a quarter opening (without lower quarter) |

Step 2. Measuring the ebb and window sill.

The length of the ebb is determined by the width of the opening on the street side. Allowances of 30-40 mm on each side are added to the width of the opening. The size of the flashing is measured by the depth of the external wall (from the frame to the edge of the wall), plus 20 mm of penetration under the frame, plus 30-40 mm of the projection of the flashing from the edge of the wall.

The length of the window sill is measured by the width of the opening on the side of the room. To this value, allowances of 100 mm are added on each side. The width of the window sill is determined by the depth of the inner wall (from the edge of the wall to the frame), plus 20 mm of overlap under the frame, plus the amount of protrusion of the window sill from the edge of the wall.

When measuring the window sill, it is very important to take into account that it should not cover the heating radiator by more than 1/3. Otherwise, obstruction to the free circulation of warm air may result in the formation of condensation on the glass.

When measuring the tide and window sill, you need to remember that the frame of the new plastic window will be narrower than the old wooden frame. Therefore, the window sill and ebb will be larger in width.

Step 3. Measuring the width of the internal slope.

The width of the slope is determined by the depth of the inner wall from the frame to the edge of the wall. A minimum of 20mm must be added as a trim allowance.

When measuring the slope, you need to remember that the frame of the new plastic window will be narrower than the old wooden frame. Therefore, the resulting slope will be wider.

These measuring instructions will help you determine the preliminary parameters of the window and components to calculate the approximate price.

You can find out the price by calling +7(495) 229-39-71 (multi-channel).

Differences in thickness

The thickness of glass in double-glazed windows can be from 4 to 8 mm, depending on whether you install a standard double-glazed window or order an individual double-glazed window. Most often, the entire structure has a width of 32 mm if we are talking about a two-chamber structure. The standard width of a single-chamber window is 18-24 mm.

Thickness may depend on the manufacturer. Inexpensive windows usually have glass thickness of about 3 mm, as this makes their price more affordable. Better quality manufacturers produce glass with a thickness of 4 mm. Professional expensive windows have a glass thickness of 6-8 mm.

Especially for our readers, we have made a rating of manufacturers of plastic profiles, which you will find in the article “All brands of plastic windows - choose to taste!”

How to find out the thickness of a glass unit

Of course, it is better to have all the necessary dimensions determined by a specialist, since this is fraught with costs for re-manufacturing the double-glazed window of the correct dimensions and may cause the glass in it to crack. If you can’t invite a specialist, you can find out the thickness in several ways.

How to find out without disassembling the window

The next important measurement for replacing a double-glazed window is its thickness. You can find out in several ways:

- View the contract for window installation. It will indicate the thickness of the joint venture (for example, “Single-chamber 24 mm”) or its formula (for example, 4-16-4).

- You can measure the width of the window frame, and from the resulting value subtract the distance from the edge of the window frame to the glass outside and inside. In this case, a slight deviation of 3 mm up or down is acceptable. It is important to remember that the thickness is usually a multiple of two.

- Sometimes, you can determine the thickness of a double-glazed window without measurements; it will be enough to just look at the spacer bar. It will contain dimensions, formula SP, GOST, date of manufacture, individual number. You will have to inspect the entire perimeter of the plastic window, since the inscription can be in absolutely any place.

- Use a laser device to determine the thickness of the glass unit and glass. This method has a significant drawback: the price of even domestically produced devices is incomparably high compared to the cost of the part being measured. It is not advisable to buy it for one-time use.

Distance bar

How to properly remove a glass unit to measure its thickness

If none of the above methods failed to check the thickness of the joint, then you will have to remove it from the frame. The sequence of actions in this case will be as follows:

- Insert a spatula or other flat, sharp tool into the gap between the window frame and the bead.

- Using loosening movements, make sure that the glazing bead begins to come out of the grooves. You need to remove the glazing beads in a cross order: first the vertical ones (right, left), and then the horizontal ones (top, bottom), so the glass won’t fall out or break.

- Take out the straightening plates (distance pads). Be sure to remember their location so that after determining the required dimensions, install them in their places.

- After all the manipulations, tilt or remove the joint from the frame, and use a regular ruler to measure its thickness.

- Since it is unsafe to be in a room with a window without glass, you need to repeat all the steps in reverse order and return the joint to its place before replacing it.

You don’t have to remove the joint, but after removing the beads, insert an unbent paper clip into the gap between it and the window frame until it stops. The depth to which it entered will be the desired value.

Advice! When disassembling a PVC window, you should wear gloves, so the glass will not slip off your hands; if there are cracks or chips on it, there will be less chance of cutting yourself.

Measuring the glass unit yourself

Before ordering a glass unit replacement, you need to measure it. You can entrust this procedure to a specialist, or you can handle it yourself, since this process is not complicated.

Many people believe that in order to measure an old double-glazed window, it must be removed from the opening, but this is not so. There is a method for determining the size of a double-glazed window without dismantling it.

Measuring the opening: a guide to action

The rectangular shape of the product requires the following measurements:

- width of the opening at the bottom;

- width of the plastic product;

- height of the opening on the left and right sides;

- total height of the window product.

When specifying dimensions, take into account the gap for installation work. The installation seam can reach 4 cm, this value should be taken into account when determining the dimensions of the product.

Measurements of window structures also take into account the need to install a support profile. The working height of the profile is taken into account when calculating the height of the product. Very rarely does an opening have ideal rectangular parameters, so after taking measurements it is necessary to once again measure all the values for control using a building level, a plumb line and a tape measure. These measures will allow you to take accurate measurements and produce a plastic product of the required size.

Blitz survey: What are “fixed” windows? From the previous article you can learn about fixed plastic windows and their features.

The next step will be to measure the thickness of the wall where the opening is located and determine the position that the window will occupy during installation. When determining the dimensions of a plastic product, the required ratio is taken into account - window installation is carried out at 2/3 of the thickness. Moving the structure too far towards the outside spoils the thermal insulation properties, leading to greater heat loss.

After determining the position of the structure, the length of the external ebb is measured at several points, due to the possible distortion of the indicator along the entire length. Then you need to find out the length of the window sill, which cannot be identical to the width of the structure. This rule is due to the fact that the installation of plastic slopes is carried out after the structure has been installed and the opening has been finished. If the length of the window sill matches the width of the PVC structure, it will be impossible to install the window sill.

Measurement of slopes from the inside and outside occurs after determining the dimensions of the window sill. The material for slopes and window sills is most often plastic. If the shape of the product is in the form of an arch or trapezoid, the process of measuring dimensions will be more complicated, so it will not be possible to do without professional help.

Tables of standard window sizes with estimated prices

| Opening dimensions, mm. | Standard window sizes, mm. | Cost, rub. | ||

| Height | Width | Height | Width | |

| 500 | 500 | 470 | 470 | 1 700 |

| 600 | 600 | 570 | 570 | 1 800 |

| 600 | 900 | 570 | 870 | 1 900 |

| 900 | 600 | 870 | 570 | 2 200 |

| 900 | 900 | 870 | 870 | 3 000 |

| 1 200 | 600 | 1 170 | 570 | 2 000 |

| 1 200 | 900 | 1 170 | 870 | 3 600 |

| 1 350 | 600 | 1 320 | 570 | 3 200 |

| 1 350 | 900 | 1 320 | 870 | 3 900 |

| 1 500 | 600 | 1 470 | 570 | 3 400 |

| 1 500 | 900 | 1 470 | 870 | 4 200 |

| Opening dimensions, mm. | Standard window sizes, mm. | Cost, rub. | ||

| Height | Width | Height | Width | |

| 1 200 | 1 800 | 1 170 | 1 770 | 6 000 |

| 1 200 | 2 100 | 1 170 | 2 070 | 6 600 |

| 1 350 | 1 800 | 1 320 | 1 770 | 6 800 |

| 1 350 | 2 100 | 1 320 | 2 070 | 7 600 |

| 1 500 | 1 800 | 1 470 | 1 770 | 7 400 |

| 1 500 | 2 100 | 1 470 | 2 070 | 8 200 |

| Opening dimensions, mm. | Standard window sizes, mm. | Cost, rub. | ||

| Height | Width | Height | Width | |

| 600 | 1 200 | 570 | 1 170 | 3 100 |

| 900 | 1 200 | 870 | 1 170 | 3 800 |

| 900 | 1 350 | 870 | 1 320 | 4 000 |

| 900 | 1 500 | 870 | 1 470 | 4 300 |

| 1 000 | 1 000 | 970 | 970 | 3 700 |

| 1 200 | 900 | 1 170 | 870 | 3 800 |

| 1 200 | 1 000 | 1 170 | 970 | 4 100 |

| 1 200 | 1 200 | 1 170 | 1 170 | 4 500 |

| 1 200 | 1 350 | 1 170 | 1 320 | 4 800 |

| 1 200 | 1 500 | 1 170 | 1 470 | 5 300 |

| 1 350 | 1 000 | 1 320 | 970 | 4 100 |

| 1 350 | 1 200 | 1 320 | 1 170 | 4 800 |

| 1 350 | 1 350 | 1 320 | 1 320 | 5 300 |

| 1 350 | 1 500 | 1 320 | 1 470 | 5 700 |

| 1 500 | 1 200 | 1 470 | 1 170 | 5 200 |

| 1 500 | 1 350 | 1 470 | 1 320 | 5 700 |

| 1 500 | 1 500 | 1 470 | 1 470 | 6 100 |

Formula SP

Width is the size of the glass unit of a plastic window, affecting the number of glasses and their thickness, the width of the spacer frame, and the number of cameras. In other words, everything is part of its formula.

For example, the formula for a two-chamber joint venture with two energy-saving glasses and chambers filled with argon will look like this:

4i-14Ar-4-14Ar-4i, where

- 4i – energy-saving glass 4 mm thick;

- 14Ar – chamber made of a 14 mm spacer, filled with argon;

- 4 – ordinary glass 4 mm thick.

The notations used in the formulas are given in the table:

| Designation | Decoding |

| Designation before the glass unit formula | |

| SPO | single-chamber SP |

| SPD | two-chamber SP |

| Glass designations | |

| M1 or without designation | regular polished glass of the highest quality |

| M2, M3, M4 | glass of lower quality, very rare |

| AND | low-emissivity glass from which energy-saving glass is made |

| Br | armored glass |

| Refl | tinted glass, its color can be additionally specified |

| A | self-cleaning |

| M.F. | multifunctional with sun protection and energy saving |

| AMF | multifunctional self-cleaning |

| Designations for spacers | |

| no markings | regular aluminum spacer |

| TGI or TR | plastic warm frame |

| Ar | argon gas in the chamber |

Also, different manufacturers may have other designations for glass and spacer frames.