Miscellaneous

During renovations in an apartment, the question of replacing the door frame and installing interior doors often arises. It must meet modern requirements: functionality, design, aesthetics. There are various offers. The question arises: PVC doors or eco-veneer, which is better? Therefore, remember their characteristics, advantages, disadvantages.

Eco-veneer doors

Types of interior door bases

When choosing, some focus on price and choose cheap models, while others focus on exclusivity and aesthetics, choosing expensive types. The choice takes into account indicators for purpose, style, shape, and fittings.

There are 2 types of interior doors: glued, solid. The latter is considered the best option for creating a cozy environment. It is made from natural eco-friendly material, which provides sound insulation, retains heat, and closes tightly. These species have pockets of resin and small cracks.

Models made from laminated wood are an economical option. They are assembled according to a scheme of several parts. After assembling such doors, lighter areas are noticeable on the surface. This is due to the combination of materials.

Veneered doors, which ones are better?

The term itself, veneered door, reflects only the material of the protective and decorative coating of the door. In this case, it is natural veneer. The specialist, seeing the name of the model, will automatically think further. The fact is that all manufacturers of veneered doors adhere to the same technology for their production. In essence, the design is a four-layer sandwich, in which:

1st layer – inexpensive solid pine; 2nd layer – MDF panels (for leveling and giving hardness and scratch resistance); 3rd layer – natural veneer; 4th layer – varnish, for decorative variety and increased protection from moisture and dirt.

How to choose veneered doors, which ones are better in design, construction, quality?

The design depends on the type of wood:

- Pine veneer: rarely used, more often solid pine covered with veneer from expensive species is used;

- Walnut veneer: light gray color, pronounced wood texture, high price;

- Maple veneer: white, suitable for tinting;

- Wenge veneer: excellent design, wide palette of colors (depending on the specific cut location - closer to the core or edge), from cream to almost black;

- Oak veneer: high strength, beautiful shades and patterns, one of the most expensive and widespread types.

Veneered doors are “charged” with natural energy. If you need a cheaper model, look at the fine-line option.

Doors finished in Fine-Line veneer in bleached oak

Veneered door design

The vast majority of veneered doors are presented in the section of paneled structures. This is the most “classic classic”, with blind or glass inserts. Which veneered doors are better is rather a matter of taste, financial capabilities and manufacturer responsibility. What colors and decorative elements are used on the surface of the door - the same should be repeated in the interior. This is the only way to achieve harmony in the interior design style.

The price difference appears for several reasons:

- Due to the use of veneer of different classes: in elite models, sheets from 4 mm thick are used;

- What's inside - honeycomb filling or solid MDF: the former do not protect against loud sounds, but are cheaper and lighter. The latter are stronger, quieter, heavier, but more expensive;

- The responsibility of the manufacturer is precisely realized in the level of quality. Read on to find out how to check it.

Door coated with natural ash veneer

How to choose a high-quality veneered door, take note of some useful tips:

- Look at several doors - the pattern should not be repeated even on two models. Otherwise, it is not natural veneer, but an artificially created film (eco-veneer);

- The varnish coating must be uniform; blurry or cloudy spots are unacceptable; they indicate that low-quality varnish or undried wood was used;

- The top ends will tell you a lot: don’t buy a door whose veneer comes off the door when you just try to pick it off with your fingernail;

- The ends must be perfectly straight, no figure-of-eight distortions. In the near future, the geometry of the canvas will be disrupted even more and you will have difficulty closing;

- The door should not smell strongly of chemicals - this indicates the low quality of the varnish;

- Take a measuring tape with you and measure the length along both diagonals. The error may be up to 1 mm. If more, it means that the manufacturing process was disrupted. This will negatively affect the service life;

- If the door has glass, try opening and closing the door several times. You should not feel that the insert is moving, no rattling is allowed;

- Take a closer look at the surface - look at it from several angles. It should be smooth, without depressions or bulges.

- Veneered doors are cheaper than solid wood panels - on average their price is in the range of 6-20 thousand rubles. Which one is better - choose according to the style in the interior, look at the quality.

Features of choosing door leaves

The main functions of interior doors include the separation of rooms, an attribute of housing design. The duration of use and the preservation of a presentable appearance depend on the cladding material. When choosing which doors are better, pay attention to the following properties:

- Strength;

- Appearance;

- Weight;

- Environmental friendliness of the material;

- Resistant to changes in humidity, temperature, and ultraviolet radiation.

Eco-veneer doors

When choosing which models are better, the characteristics of the door leaves are important:

- Raw materials for door leaf;

- Exact dimensions of the opening;

- Facing material.

Attention. When choosing a door manufacturing company, choose one that guarantees product quality.

The choice of facing material is wide; the following are most often used:

- laminated;

- veneered;

- PVC coating;

- eco-veneer

Each type has advantages and disadvantages. They differ in price. To choose the appropriate option, consider in detail whether PVC-coated doors or veneer doors, which are popular with consumers, are better.

Eco-veneer based on polypropylene

Polypropylene is a waterproof material, similar in composition to polyethylene or plastic, only less dense, but more resistant to abrasion. It is chemically resistant and is exposed only to strong oxidizing agents. Compared to polyethylene, it is more heat-resistant (max. operating temperature 120-140 C). When boiled or treated with steam, it does not deform, but is not frost-resistant, becoming brittle from −5 to −15 C.

Polypropylene is a high-quality material. It does not contain environmentally harmful substances and has several advantages compared to other coatings. Characteristics of polypropylene doors

Advantages:

- 3D - eco-veneer is indistinguishable from natural coating, very high quality of texture and color;

- Tactilely, the surface of the coating is warm, there is no feeling that the canvas is covered with artificial material;

- The coating is resistant to mechanical damage (abrasion, chips, scratches). This strength is achieved through an additional varnish-based coating with electron beam curing;

- New technologies and the peculiar properties of polypropylene make it possible to maintain the original appearance of the coating for many years. This material significantly extends the life of the door block, compared to natural veneer, which requires more careful care and operation;

- Environmentally friendly coating;

- Affordable.

Flaws:

- Becomes brittle at −5 C.

What is eco-veneer: characteristics of doors

The doors have a hollow wooden frame, onto the surface of which a thin layer of eco-veneer is applied. It has the second name CPL, which translates as subject to long-term pressing. During manufacturing, a mixture of wood fibers with a synthetic binder material is pressed. As a result, the structure of the material has a volumetric effect that misleads the consumer. It is often confused with veneer.

The material is produced from waste from the wood processing industry, which is broken down using special equipment. Small fibers are dyed, mixed and glued together. This technique of coloring wood fibers eliminates differences in the color of the finished product, gives any shade, and imitates wood. Often produced in the following forms: wenge, ice cream, bleached oak and others. Each pattern is unique.

Different shades of doorways

The material is pressed gradually with increasing force. This makes it possible to squeeze out small air bubbles from the mixture. As a result, ekopchon sheet material is formed, which is supplied in rolls to factories for the production of interior doors, where it is applied to the products.

When to choose doors with eco-coating

Natural wood is a rather capricious material, inferior to eco-veneer in terms of durability and practicality. At the same time, the polypropylene layer imitates wood so well that it is increasingly difficult to distinguish them from each other. Eco-veneer coating for interior doors is chosen in the following cases:

- When operating conditions are far from greenhouse conditions. Thick propylene film will be the best solution if there are pets and little fidgets in the house.

Classic with frosted glass insert Source site-media.eu

- If you are looking for a bathroom door. This room usually has a modest volume, so moisture easily condenses on all surfaces.

- For the interior, it is important that the doors are as similar as possible to natural wood, but it is necessary to fit within a narrow budget.

- It is assumed that the end of the doors will be in contact with something. In this case, technology due to which there are no edges on the product is a winning option.

PVC interior doors

In terms of characteristics, PVC doors are most similar to veneer. Polyvinyl chloride is a special film made from thermoplastic with stabilizers, various modifiers, and pigments. To obtain interior PVC doors, a wooden frame is created, the gaps are filled, and the surface is coated with a special glue. Next, PVC film is glued onto the wooden canvas using vacuum pressing technology, while the heated film is pressed tightly.

PVC film

PVC is resistant to chemical attack from acids, solvents, alcohol, and alkalis. Such products are considered an excellent option for interior design, since they select any shade and apply a pattern. Photo printing is possible. PVC film is not afraid of exposure to sunlight or temperature changes. Such models are installed in the kitchen, shower, and bath. They are suitable for hospital, store and other places.

Practicality and complexity of care

Veneer . Wooden doors often require special care, since chemically active cleaning agents are contraindicated for them. As a result, it is better not to install them in places with a lot of people traffic.

Laminate . They tolerate wet cleaning well, but since the laminate layer is usually quite thin, it is better not to use abrasive substances when cleaning it.

Eco-veneer . Manufacturers do not impose any restrictions on care products for doors covered with eco-veneer, but you should remember that they have a textured surface, so you should not use very rough cleaning products. They also tolerate the effects of detergents well.

PVC film . Surfaces coated with it can be washed with any cleaning products - other than that, they do not require any maintenance. The PVC surface has no pores, so it can be easily washed with detergents.

The easiest way to care for doors is with an external coating based on polyvinyl chloride - their dense surface prevents dirt from penetrating inside and it is easily washed off with any available means. However, on this same surface various traces of sweat and fat are most visible.

Advantages of PVC facing coatings and eco-veneer

The question that arises for all consumers after familiarizing themselves with these types is one: which is better - PVC interior doors or eco-veneer? You can get the answer if you find out the advantages and disadvantages of each type of material. The advantages of eco-veneer include the following:

- High wear resistance, durability, practically indestructible;

- Withstands sudden changes in humidity and temperature;

- Prevents scratching and impact;

- Does not fade under the influence of ultraviolet radiation;

- Environmentally friendly as it does not contain chloride;

- Imitates the structure of different tree species;

- The cost of eco-veneer is lower than that of models made from non-artificial veneer;

- Easy to care for the surface of eco-veneer doors;

- Does not peel off during use;

- Large selection of shades;

- It is easy to restore the coating if it is damaged.

The advantages of PVC doors include:

- It is difficult to ignite, has the ability to go out, and has high fire safety;

- Eco-friendly material, used even in children's rooms;

- Not subject to destruction from lime, alkaline, acid solutions;

- Maintenance is easy thanks to PVC film;

- They do not rot, the panels do not delaminate or warp;

- Not affected by temperature changes;

- They are durable and not subject to mechanical damage (cracks, scratches, chips);

- Lightweight design;

PVC opening - inside view

- The color does not fade or fade from the sun's rays;

- Drawings and photo printing are applied to the surface;

- They have low cost.

Response to humidity and climate change

Here it is necessary to take into account not only the finishing, but also what the door frame is made of - an array of glued blocks of wood or chipboard and MDF. In the first case, the influence of humidity and temperature will be much more noticeable.

Veneer . In any case, it is not recommended to install such doors in rooms with high humidity. If the frame is made of solid wood, it will be susceptible to temperature changes.

Laminate . It tolerates moisture well, but if the outer layer is damaged it will begin to deteriorate.

Eco-veneer . The material is not susceptible to moisture and temperature changes. Such doors are recommended to be installed in the bathroom and toilet.

PVC film . Plastic does not absorb liquid at all and is not subject to deformation under the influence of temperature, so it can be installed not only in damp, but also in technical, unheated rooms. Under conditions of variable humidity and temperature, such doors will retain their shape unchanged.

In terms of this parameter, artificial materials win, and there is no particularly noticeable difference between them.

Disadvantages of PVC and eco-veneer doors

It is impossible to answer unequivocally which models are better: PVC-coated or eco-veneer, without understanding the shortcomings of the cladding material.

Attention. Making a decision to buy this or that model only based on positive aspects is wrong.

After all, shortcomings can outweigh the best positive qualities. The disadvantages of eco-veneer include:

- The lightness of eco-veneer has a negative impact on performance indicators: it breaks due to shocks and blows.

- The damage cannot be repaired.

- Low sound insulation, as there is emptiness inside the door.

- Synthetic binders reduce the quality of air exchange, so the room must be ventilated frequently.

- Proper surface care is required.

- It is impossible to make doors with curved parts.

The disadvantages of PVC coating include:

- Insufficient sound insulation, thermal insulation;

- Contains chloride;

- The surface is cold to the touch;

- Not exactly a respectable look;

- The material does not withstand frost (-15 C);

- When PVC is disposed of, toxic substances are released.

It is difficult to determine which option is better than eco-veneer or PVC; such options have both pros and cons. To make the right decision in choosing interior doors, find out what the priority is. Any model of interior doors finds its buyer.

PVC doors

Comparing eco-veneer and PVC in cost, PVC film takes the lead. This option is suitable if you plan to renovate and replace the doors in 7 years. In terms of durability, they prefer doors made of eco-veneer, the texture of which is similar to natural material. To select the optimal option, the interior, material, service life, and cost are taken into account.

Strength and wear resistance

This is one of the main parameters that determines the service life of doors. Typically, manufacturers try to improve this indicator by introducing new technologies.

Veneer . The main protection for such doors is provided by a layer of varnish that covers them, but in any case, scratches and dents that may appear are quite difficult to repair or disguise.

Laminate . Originally designed as a floor covering, it is durable enough to resist cuts and dents. But inexpensive doors often use a material with a thin protective layer, which can be susceptible to abrasion.

Eco-veneer . Since it is created on the basis of polymer materials, the wear resistance of the surface treated with it is at a high level - it does not crack, is not susceptible to chipping or deformation. While natural veneer can change its appearance over time, eco-veneer will retain its original appearance for two to three decades. Unlike products made from natural wood, eco-veneer is not susceptible to cracking and fading from ultraviolet radiation.

PVC film . According to the technology, this material is literally baked on the surface, creating a durable coating. But when exposed to sharp objects, the film can easily be damaged. Subsequently, it may lag behind the base.

If you do not take into account the quality of the materials used, eco-veneer and laminate are clearly the leaders in this category.

How to install interior doors made of eco-veneer

In most cases, specialists are invited to install interior doors, but if you decide to save money and are confident in your abilities, you can try to do it yourself. We will tell you the stages of work and what needs to be prepared.

Preparation

The preparation process involves the selection of tools and materials that are necessary in the work process.

You will need:

- hammer;

- hacksaw;

- perforator;

- screwdriver;

- chisel;

- tape measure, level, corner, pencil;

- pliers;

- screwdriver;

- plastic wedges, screws, dowels, plugs;

- polyurethane foam.

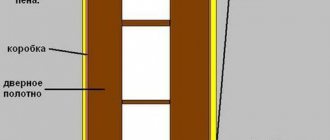

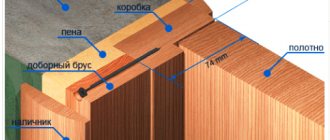

Box installation

Installation steps

The whole process can be divided into several stages:

- Installation of the door frame in a pre-prepared doorway;

- Installation of an eco-veneer door;

- Finishing work related to finishing and foaming the voids on the sides of the box.

A door frame is installed in a doorway that has been prepared in advance from debris and dust. Pay attention to the side gaps between the box and the wall. Your task is to make them the same. In addition, make sure that the bottom of the box coincides with the floor level, otherwise you will have a threshold, which is not always convenient.

After installing the box, attach it to the wall. Next, spacers are installed in the door frame between the side doors and the side gaps are foamed. After the sealant has completely dried, its excess can be cut off and the screws and dowels used to attach the jumpers removed.

Please note that for better adhesion of the sealant to the surface of the wall and door frame, both surfaces are moistened with water.

Now they begin to attach the hinges, which will hold the door leaf. First, markings are made, the canopies are applied and the depth to which they need to be recessed in the frame is determined to ensure precise contact between the door leaf and the door frame. Using a chisel, remove part of the wood. Mark the holes and drill them.

The second part of the canopy is attached to eco-veneer doors in a similar manner. After attaching the awnings, the doors are hung. All that remains is to check if you did everything correctly. To do this, the door leaf is opened and closed, checking the tightness of the connection and the absence of distortions.

Masking scratches

Natural veneer or eco-veneer, what is the difference?

It’s more convenient to start with the similarities between these materials - they exist, but they are few:

- Both are used for protective and decorative coating of interior doors;

- They are a thin film;

- Externally they repeat the texture of wood of different species.

They have the same purpose, but different properties. We offer to compare veneer and eco-veneer according to 4 parameters - strength, moisture resistance, design and price.

Veneered doors

Natural veneer is a natural material obtained by cutting from the surface of wood. Any breed can be used. The coating is divided into classes depending on the cutting method and thickness:

| Way | Width, (mm) | What breeds do they come from? |

| Peeling | 0,1-10 | pine, alder, birch, oak |

| Sawing | 1,0-10 | fir, cedar, spruce |

| Planing | 0,2-5,0 | acacia, oak, beech, walnut, mahogany, yew, elm, Karelian birch, ash |

Rotary veneer is the cheapest and most common. Sawn wood, on the contrary, is the most expensive, but it is mainly used in the production of musical instruments. Elite doors are made from sliced veneer, selecting a tangential, radial, radial-tangential or tangential-end cut to obtain a specific pattern.

The maximum thickness of eco-veneer is 0.4 mm. In addition, this is not wood, but a mixture of cellulose or wood fibers with polypropylene. Externally, the coating is difficult to distinguish from natural, but its strength is inferior to its natural counterparts. Of course, thin film also has its own margin of safety, but it is not so great that we can talk about 50 years of operation and ideal preservation of the external gloss after many years.

Moisture resistance - according to this parameter, both perform at the same, quite good level, with only one caveat - if the manufacturer has tried and efficiently covered the natural veneer with several layers of varnish. In this case, both models have the same chances of resisting water. If we take unprotected surfaces, then eco-veneer wins, which is obvious, because natural wood absorbs moisture like a sponge, unlike polymers, from which moisture simply drains.

Veneered door in the bathroom

Design: you've probably already read on many websites that the materials are identical in appearance, that there is almost absolute similarity between them, which is reflected in the appearance of the doors. Don't believe it - the suppliers are lying. Well, the door of the Premium segment cannot be no different from the door of the Economy class. Yes, the pattern and texture of eco-veneer are similar to natural wood, but it still does not have that aristocratic gloss and composure that veneer has.

As for the design, there are significant differences here too: natural veneer is more often used when finishing classic paneled doors. Eco-veneer is mostly modern designs obtained by constructing prefabricated frame (tsar) models.

And yet, a door made of natural veneer is one of a kind, because, just as people have no two identical fingerprints, there are no identical wood patterns. Ecoveneer is a mass product. It is worth buying if you need to install canvases that are absolutely similar to each other in a room.

Oak veneer door

Price: doors made of natural veneer are more expensive, and this is also obvious. And it’s not just the cost of the coating – the reason is the design of the structures. Inexpensive eco-veneer products are made from solid pine; a honeycomb filler is placed inside, which hardly affects the increase in strength and insulating qualities. Doors made from natural solid wood are produced using the same sandwich technology, only instead of honeycomb filling, solid MDF is used, and this increases strength, heat and sound insulation, and accordingly affects the price.

Repair of eco-veneer doors

Even such doors sometimes have to be repaired. There may be several reasons to restore the integrity of the coating:

- swelling of the coating;

- the appearance of scratches and chips.

The first reason is the most harmless, all you need is a slightly heated iron, which is applied to the problem area for 5 seconds.

Removing scratches can be entrusted to a wax pencil matched to the color of the canvas. Pre-clean the problem area, heat up the wax pencil and cover the scratches. After hardening, remove excess material and coat the restored area with varnish.

For more serious damage, patches are indispensable. The damaged area is cleaned. The required fragments are cut out of individual veneer sheets, identical in texture and color to our door leaf. Afterwards they are carefully glued, smoothing the joints. The restored coating is also varnished for durability.

Selection of interior door leaf:

Voted over 257 times, average rating 5

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Miscellaneous Installation of a threshold for the front door in a private house: we select and do it ourselves The threshold under the front door prevents entry into the house...

Miscellaneous What to do if condensation appears on the front door? During the off-season or winter, owners of private houses face...

Miscellaneous How and with what to lubricate a metal entrance door if it creaks? A door that squeaks is a nuisance, especially if it...

Miscellaneous Varieties and manual installation of seals for interior doors No matter how good and expensive an interior door is, its ...

Eco-veneer based on cellulose

Laminate or finishing film - textured paper with a pattern and wood color applied to it, applied to MDF (hardboard). 3D paper is impregnated with special natural melamine resins, which increase its density and protect the coating from mechanical damage and moisture. The material is simply applied and does not require the use of expensive technologies and adhesives. Of all the varieties of eco-veneer, finishing film is the most inexpensive coating. It is mainly used to cover doors in the economy segment, frame structures with honeycomb filling. Such doors are called laminated, they are: plain, 3D with wood texture.

Characteristics of doors covered with finishing film

Advantages:

- Relative cheapness;

- Large selection of various textures and shades;

- The coating is not exposed to ultraviolet radiation and does not fade;

- Safe for health.

- Flaws:

- Of all the coatings, laminate has the worst wear resistance;

- The coating does not protect the canvas from moisture;

- Small thickness.