The main idea of almost any design solution in terms of decorating an apartment or house is the separation of rooms from each other and the formation of separate compositions within each. The most important element of dividing space is naturally interior doors. Now we will talk about how to install an accordion door with your own hands.

Until recently, most people associated this type of door with a cheap option for those situations where, in a small home, it is necessary to save and preserve every square meter of space. In their modern form, accordion sliding doors are already a separate design element, and not a forced compromise. There are many different variations of accordion doors on the market with a wide variety of design styles. The basis for such doors can be either PVC or MDF strips. The differences are not even so obvious at first glance. In both cases, the appearance of the doors appears pleasant and harmonious.

Plastic is naturally much lighter and less susceptible to both damage and contamination. It is easy to clean and can last quite a long time. The downside is again its somewhat excessive lightness. After all, when using such a door, there is a certain feeling of its flimsiness. However, the latest versions of PVC slats are made with a more sophisticated system of stiffening ribs, so they only seem flimsy. In terms of installation, plastic accordion doors are somewhat easier. Firstly, the door elements are very easily clicked together manually and are easily adjusted in size to the required dimensions of the doorway. Secondly, setting up such doors is much easier, as well as correcting possible flaws during the installation process.

Doors made of MDF are already much more massive, and this affects their ease of use. This does not add any difficulties in opening and closing, but the noise insulation and stability of the door is clearly better than in the case of plastic. The installation of such doors is complicated mainly by the weight of the door and the need to especially strictly observe all levels and markings during installation. Among other things, MDF accordion doors should be secured much better.

What is required to install the door?

The doors themselves are sold with all the necessary spare parts and fasteners. In high-quality products, there are always several spare strips to be able to increase the width of the door.

typical configuration of an accordion sliding door.

From materials it is also necessary to purchase and prepare everything necessary to prepare the doorway itself. Any suitable extensions and platbands are suitable for this. It is only important that the thickness of the material is at least 15 mm in order to withstand the weight of the door and, accordingly, all the loads during operation.

The following tools and building materials will be needed:

- hammer drill;

- hammer drill (if you need to expand the existing doorway);

- roulette;

- plumb line and bubble level;

- construction corner;

- hacksaw;

- miter box;

- bars or wooden bowls;

- polyurethane polyurethane foam.

Sliding grilles for windows: advantages and disadvantages, do-it-yourself manufacturing and installation

Of all types of window protective devices, sliding grilles stand out to a large extent - they work on the accordion principle and, when open, take up virtually no space. But the most important thing is that these devices fully comply with all necessary safety requirements. In this article, together with the website stroisovety.org, we will look at the advantages and disadvantages of sliding window bars, study their varieties, consider the possibility of making them ourselves and pay attention to the issue of their installation.

Sliding grilles photo

Preparing the doorway

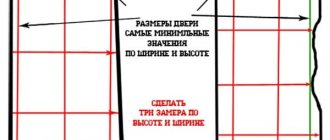

You can, of course, mount an accordion door inside an existing door frame. However, this will significantly reduce the usable width of the opening. It is best to completely dismantle the old door along with the frame and knock down the mortar underneath them down to the base (brickwork or concrete wall). After this, you can take measurements of the resulting opening and check the list of nominal door sizes for different numbers of elements. Such a list is included in the instructions for the door. It is only important to take into account the width of the extensions. As a result, it becomes clear whether it is necessary to slightly widen the opening or, conversely, to reduce the dimensions to the required parameter with the help of extensions, polyurethane foam and bars.

The prepared extensions are cut to form a box without a threshold. In this case, the upper crossbar is attached with its ends to the upper edge of the vertical extensions and fastened with self-tapping screws.

Important: In order not to damage the material, you should first drill holes in the place where the self-tapping screw is installed with a drill of a smaller diameter (2 mm) and only then screw in the self-tapping screws.

After the box is ready, it can be inserted into the doorway and secured with blocks and other wooden supports as wedges. For reliability, it is better to use several bars equal in width to the doorway, form spacers in the center and along the bottom edge so that the extensions do not bend during the installation process. To secure the extensions to the wall, long anchors are used, installed three on each side and at least two on top.

Once the anchors are tightened, you can foam the gap between the extensions and the wall. After the foam has dried, you can proceed directly to the installation of the sliding accordion door.

What are window bars made of?

The most common, time-tested material for window grilles is steel. But it can be processed and presented in a variety of ways: round and square or multifaceted sections, thin strips of steel or a combination of rods of different shapes.

If you take the issue of choosing a material for gratings seriously, then it is best to choose structural steel, since it can be welded better than other types.

When greater strength is needed and if there is a risk that they will try to saw through the gratings, alloy steel is suitable, but it is rarely used. As a rule, at the individual request of the customer.

For domestic needs or institutions that do not store something incredibly valuable, structural steel is also suitable; it is also not easy to saw through, especially if you use thicker rods for the sliding grille. Attackers will have to tinker for a long time, and the point is not in the material, but in the movable structure, consisting of small parts connected to each other. So, if we talk specifically about sawing, a sliding grille is a much more difficult obstacle for it than a static one. In addition, from the rhythmic movement of the cutting object, be it a mechanical or electrical tool, the entire lattice structure begins to shake, which will greatly slow down the sawing process.

Installation of guides

In order not to make mistakes in the calculations, it is better to start with the installation of guides and other fasteners. The set of accordion door parts includes a guide profile. According to the instructions, the required length of the profile is measured and the excess is cut off. It is advisable to use a miter box to ensure a perfectly even cut.

In the same way, according to the instructions, a profile is cut to attach the blind part of the door and the counter on the side of the handle of the future door. After this, we check all the dimensions, but only by placing the profiles, without securing them. Holes for self-tapping screws are made in the profiles in advance. In the upper profile, holes with a diameter of 3 mm are drilled every 5-7 cm, and on the side profiles every 15-20 cm.

If the profile is designed for fastening using special clips, then you can already begin installing the clips around the perimeter of the doorway. Typically, the same clips are used for the top guide (rails) and the profile on which the blind part of the accordion door leaf will be attached. On the side where the finishing groove and magnetic lock will be installed, slightly different smaller clips are used.

The top guide should be strengthened so that the clips are located at a distance of approximately 5-7 cm from each other. On the sides, you can limit yourself to installing only 4 or 5 clips evenly in height.

Materials used

In order to make your own folding door, you can use a wide variety of materials. Guides and runners can be purchased at hardware stores. As for the sashes, their manufacture will not be difficult.

First of all, you need to decide for what purpose and type of room you need such a structure. So, for more durable and massive models, you can use wood, plywood or MDF. The latter is the most popular material, its properties satisfy various needs, and the external design is practically unlimited; it can be covered with PVC film, laminate, natural or artificial veneer, etc. The wood must be treated with an antiseptic and varnished.

MDF is the most popular material for making sashes

For rooms with high humidity, you can limit yourself to plastic. The choice of such material today is much larger than before, so you can easily find a suitable option. You can also use glass, but only if it is pre-treated: hardening, reinforcement, gluing a protective film, etc. Such doors are more suitable as a partition.

Assembling the door leaf and mounting the rollers

All strips from which the door leaf will be made should be cut so that they fit in height. In this case, the reserve for the roller system on top, which is inserted into the rail, is taken into account. There should be a ventilation gap of approximately 7-10 mm at the bottom of the door, as is the case with any interior door.

How to assemble an accordion door is described in detail in the instructions supplied with it from the manufacturer. It is very important to comply with all the necessary assembly points, because different manufacturers have their own design features.

In a simple version, the plastic strips of the door leaf are connected directly using grooves or using additional spacers. In this case, the two parts to be connected are shifted and connected at the edges, after which one part is pulled along the second to the end.

In the case of MDF, a method is often used in which the strips are connected using a long axle, which is threaded alternately through the eyes on each of their parts.

After all the elements are connected and the door leaf is completely assembled, you should place the rollers and other accessories that come with the kit. As in the previous case, everything is done strictly according to the instructions.

Designs of sliding grilles for windows

Whatever the specific purpose of the gratings, they can be made in a variety of options, subject to the general principle of operation.

The rods are round or faceted, of different thicknesses, and they are held together by a moving part like a hinge. The gratings usually move according to the scissor principle. This design is the most durable and has proven itself in operation.

The mobility of the sashes is ensured by a hidden roller mechanism or due to the upper suspension.

Final assembly and fastening

Now all that remains is to install the folding interior accordion door inside the prepared doorway. The door leaf is threaded with rollers into the guide profile. When all elements are inserted, the door folds and is located in the center of the profile. In this condition, it is most convenient to install the guide in the doorway.

final view of a typical accordion door assembly

If clips are used, the guide snaps onto them. If necessary, use a rubber mallet to securely click. In other options, self-tapping screws are used, which first fasten the rail along the edges, and then along the entire length every 5-7 cm.

The next step is to attach the side profiles and attach the blind part of the door leaf to the corresponding profile. At this stage, the ease of movement of the door and the tightness of its fit to the counter profile on the handle side are checked.

If everything is fine, then the handle is installed. When the door is closed, the location of the lock mate is marked and the latch with a magnet is screwed onto the door frame.

Practical recommendations

They will help those who are thinking about how to make an accordion door with their own hands:

- To make planks, you can use thin boards, multilayer plywood, chipboard, fiberboard, and PVC siding. It is necessary to take into account the location of the intended installation. Plastic is more suitable for installing an accordion in the openings of built-in wardrobes or for curtains, for example, in showers. But you shouldn’t use it for an interior door - it’s difficult to fit into the interior. If the lamellas are attached only at the top, this is definitely not an option - the slightest draft will lead to spontaneous movement of the folding sash.

- Its weight can be artificially reduced in order to simultaneously facilitate installation and decorate the canvas according to the principle of paneled doors. That is, provide inserts made of thin glass, plastic, film or original grilles. Focusing on a specific opening, choosing the best option is easy.

- To avoid skewing of the canvas panels and possible snags, it is recommended to leave a gap of about 2.5 mm between them.

- The accordion design is designed so that it is slightly wider than the opening for which it is intended.

If the installation principle is clear, then installing the door, regardless of its modification, will not cause any difficulties. The main thing is to properly prepare the opening, taking into account all the features of the wall material. And what kind of accordion to choose (make) is up to the owner to decide.

Completion of work

When everything is finally secured and checked, you can begin installing platbands around the perimeter of the doorway on both sides. Using a hacksaw and wort, excess parts of the trim are cut off at an angle of 45 degrees, limiting their length. The platbands can be attached using either liquid nails or special furniture nails with countersunk heads or without them at all.

At this point, the installation of the doors can be considered complete. We can also say that according to these instructions, a folding door-book is also installed. The only difference is the process of assembling the door leaf itself.

Artistic

Artistic designs are those designs of sliding window grilles that are decorated with decorative imprints on the bars. They are installed when there is no need for increased protection, but there is a desire to make the house more attractive. Sliding artistic grilles are also used in cafes and restaurants to decorate the interior and provide protection.

To produce artistic designs, you need special equipment that allows you to create, depending on the design solution, the effect of hand forging or fantastic wicker patterns. With the help of acrylic paints, sliding grilles can be turned into a real work of art.

Sliding bars on windows: advantages and disadvantages

If we compare sliding metal bars for windows with similar stationary structures, we can identify a number of advantages that are unique to these protective products. They are few, but they are significant. These unique advantages include the following features.

- Versatility - with equal success they can be installed not only on windows, but also on doors and even on display cases, thus protecting goods from intruders. In addition, unlike swing gratings, they are quite convenient to use.

- It's no secret that according to all fire safety standards in both residential and public buildings, windows serve as an emergency exit, to which there must be free access. Sliding bars solve this issue in the best possible way, providing both protection of the premises from intruders and, if necessary, free passage through the window (they open with one movement of the hand). It is thanks to this combination of qualities that this type of grating is widely used in banking institutions.

- From the point of view of design and appearance, one can note the fact that, despite their non-solid design, they look like a single product. In addition, due to their design, they can have larger dimensions than ordinary stationary grilles.

Sliding metal grilles photo

In principle, advantages can be sought further, but there is no particular point in this - the advantages described above are quite enough to determine the scope of their use. The only thing that can be added is that in apartments, sliding bars will be the best option - in some ways they can be compared with roller shutters, which can be locked at night and opened during the day, when everyone is at home (so as not to look at the world, like from a prison cell).

Stages of correct installation

When performing self-assembly and installation of the door book, you must follow the sequence of installation steps. After preparing the opening, the canvas is assembled. A step-by-step description of the process will help you do everything right.

Installation of a suspended folding door structure

The canvas is attached to the box. The direction of folding is determined in advance. It is recommended to use 3 sets of hinges in the installation so that the mechanism can support the weight of the panels. During the work, it is necessary to correctly integrate the loops into the canvas so that the gap between the extensions and the canvas is uniform. If the conditions are not met, misalignment may occur, which can lead to deformation and subsequent repairs.

Installation of hanging fittings

Sliding mechanism fittings:

- Aluminum rail.

- Carriage with rollers.

- A roller guide with which the carriage with rollers is attached to the door.

- Self-tapping screws.

- Limiters.

The books use a standard sliding panel movement system. An aluminum rail with a built-in groove for the carriage and moving rollers is installed at the top. The work is done using a level. This is necessary so that the rail is attached horizontally without distortion. The roller carriage should move freely and easily inside. Stoppers are built into the edges of the rail to prevent the rail from hitting when sliding. The next step is to install a roller guide to one of the canvases. The roller carriage and guide are fastened together.

Installers insist on lubricating the mechanism with oil after assembly is complete. This will make the move smoother and protect the structure from corrosion.

Installation of additional fittings

Doors are used daily and are subject to increased load, so the installation of strong fittings is required. These are special clamps, locks, handles.

For “books”, it is recommended to install handles built into the canvas. This option does not damage the adjacent door panel when folded. A handle that protrudes and is installed in a narrow opening is dangerous for people passing by.

Closers are used in heavy, large structures made of solid wood or glass that require smooth closing. For lightweight materials there is no need to install a closer.

The folding device is in most cases installed on hinges. Manufacturers mark their attachment points, so all that remains is to secure them correctly with self-tapping screws.

It is more difficult to install the slats. For accurate installation, be sure to make markings for the guides, according to the instructions.