The balcony of any apartment can serve not only for storing things, but also as a place for relaxation and work. In this case, it is necessary, first of all, to insulate it. In any case, it is not enough to simply install metal-plastic windows; it is necessary to take measures to insulate the floor. The ideal option is an insulated floor on joists.

Let's take a closer look at the arrangement of decking on the balcony using logs.

Advantages of flooring on joists

The feasibility of using a floor on joists is due to the following positive aspects of this design:

- high thermal insulation;

- communications can be carried out under the floor on joists;

- the floor breathes, and the air layer under the joists retains heat;

- the highest point of the floor rises, promotes air circulation, heat retention, and extends the life of floorboards;

- the floor level is leveled;

- along with laying the floor, vapor barrier and waterproofing measures are carried out, thanks to this the balcony base is protected from moisture and other atmospheric influences;

- a wooden floor looks great with any type of wall decoration, be it plastic or wood;

- ease of installation (one person who does not have deep construction skills can cope with this work).

- quick installation;

- You can do the work at any time of the year at any temperature.

Arranging the floor on joists helps level the floor without installing a concrete screed.

Floor operating conditions

Even taking into account the fact that wood is a widespread building material, its ability to withstand the destructive effects of the environment is taken into account. Wood lumber lasts well for decades if it is exposed to dry air. High humidity quickly causes fungal diseases and rotting of boards.

Therefore, the issues of ventilation, waterproofing and vapor permeability of the floor structure should be given the closest attention. Its service life directly depends on ensuring correct installation, and it makes sense to install a wooden floor on a balcony only after its glazing has been completely completed.

In this regard, it is convenient to use sliding plastic windows, which you can install yourself. They are well adapted to protect a balcony or loggia and provide sufficient amenities to residents. However, they cannot completely protect wood from environmental influences. But this is not required.

Short-term penetration of moist air during precipitation is not dangerous if the wood is impregnated with special solutions that protect the wood from rotting and fungi.

When installing the floor, ensure that the joists are secured to the concrete base through a layer of waterproofing so that the moisture penetrating onto them flows down and is additionally ventilated by natural ventilation.

Materials and tools for laying floors

To lay the floor on joists, you need to prepare tools and purchase material. Of these we will need:

- perforator;

- drill or screwdriver;

- wood saw or grinder;

- roulette, level;

- anchors, screws, dowels, nails;

- stapler, staples;

- dry timber 50 x 50 mm thick;

- waterproofing and vapor barrier material;

- antiseptic for wood processing;

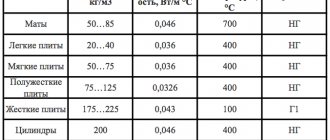

- insulation polystyrene foam or mineral wool of the same thickness as the logs.

If you use wet wood when laying the floor on joists, it may move when drying and the floor will become deformed.

Finishing of floorboards

Wood is a fairly soft material, so it wears out easily. In order for the floor to last long enough, it should be covered with varnish or coloring compounds. The paint coating will reduce the ability of wood to absorb moisture, and this in turn will prevent it from swelling and the formation of rot.

To finish wooden floors, paint and varnish compositions intended for outdoor use are used. If the boards are well sanded and have a beautiful texture, it is better to coat them with a tinting varnish that penetrates deeply into the structure of the wood. Floor painting is used in cases where new boards of different sizes are not used for flooring. A solid coat of paint will hide unevenness in the wood texture.

Preparatory work

Inspect the balcony slab for defects.

If the balcony will be glazed, first install the balcony frame, then level the slab on the balcony, and only after that proceed to laying the floor on the loggia or balcony.

To prepare, you must perform the following procedure:

- We inspect the stove and determine the need for repair.

- If there are cracks in the slab, then through them we look at the condition of the reinforcement inside the slab. If everything is in order and major repairs are not required, we remove debris from the base, remove all exfoliated building materials, seal all cracks with cement or polymer mortar and wait for it to dry completely.

- We treat the surface of the floor and walls on the balcony with a primer and antifungal mixtures. The primer makes the surface more durable.

- After the primer has completely dried, we find the zero level on the floor. We select the highest place on the slab and mark it on the wall. We place marks, focusing on this height, along the entire perimeter of the walls.

We carry out all work using a water or laser level. How even the floor will be will depend on the correct markings.

How to determine the level of a clean floor?

When the material has been decided, another question arises: to what level should the floor be leveled? You can use a water level (spirit level). To do this, place a line on the balcony wall in an arbitrary place, and use a spirit level to make marks at the same level on other walls. A line (horizon) is drawn along the obtained points. In the highest places of the floor (determined visually), measure the distance to the horizon. From the smallest measurement, subtract the thickness of the floor structure and set aside the resulting distance from the horizon to the floor. Based on this point, using a water level, o.

An easier to use laser level. It is enough to install it in the highest corner of the balcony, turn it on, and it itself, using laser dots or a line, will indicate an even horizontal line. This is what you need to measure up to when installing the floor.

Home craftsmen often use a regular bubble level to create a horizontal line. You need to act like this: determine the highest corner of the room by eye and place a mark near the floor. The height of the floor structure is measured from the resulting mark upwards. Using a level, draw a straight line along the mark, extending it along the perimeter of the balcony. However, this method has too large an error, so it is not used for high-quality alignment.

For open balconies, it is recommended to make floors sloping towards the street (away from the wall of the house) to ensure the drainage of atmospheric moisture. A 1 cm slope per 1 m width of the balcony is enough.

Insulation and floor laying

On open balconies there is no need to insulate the floor. It is recommended to lay thermal insulation material on glazed loggias to increase the thermal insulation properties of the room.

The insulation can be polystyrene foam, mineral wool, polystyrene foam, expanded clay, or polyethylene foam. It is recommended to lay a waterproofing layer on an unglazed balcony; it will protect the slab from destruction.

We cut the longitudinal and transverse beams to the required length. We prepare the beams for laying, drilling holes in them for dowels or screws. We apply the beam to the floor, drill a hole in the slab.

When using a powerful hammer drill, you can drill holes in the timber and the slab simultaneously. We drive the locking part of the anchor into the hole in the slab, then bolt the beam to it.

Stages of work:

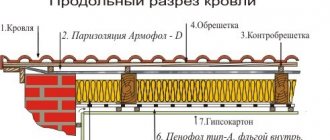

- We lay waterproofing material. You can apply bitumen-based mastic with a brush or secure the film with adhesive tape. You can also use roofing felt, special paint, waterproof plaster, liquid glass and rubber as waterproofing. The waterproofing material should extend onto the walls 70-100 mm from the floor level.

- We treat the bars with impregnation to protect them from atmospheric influences, insects and mold.

- We lay the floor on the logs on the balcony. We lay the logs longitudinally at a distance of 500 mm from each other, the height of the sheathing should correspond to the previously made marks. We attach the floor sheathing to long dowels or anchors. Where the height of the timber is not enough, we raise it to the level, placing timber of the required thickness. First, the outer beams are laid, then a cord is pulled between them and, focusing on the height of the cord, we lay the logs in the middle.

Lay the joists at a distance of 500 mm from each other - We lay insulation between the joists. You can use sheet or bulk. Sheet insulation (foam plastic, expanded polystyrene, mineral wool) must fit tightly to the bars; the joints are blown with foam or treated with mastic. The thickness of the insulation should be the same as that of the timber. If we use expanded clay, then pour enough of it between the joists so that it does not interfere with the laying of the next floor level.

- We lay a vapor barrier material over the insulation. If it is expanded polystyrene or polystyrene foam, then laying a vapor barrier material is not necessary. If insulation is not placed on mineral wool, it can become damp and lose its properties.

- We mark and cut the plywood or OSB board to size, taking into account that you need to leave a gap of 3 mm on the sides.

- Using self-tapping screws, we attach plywood, OSB board or floorboard to the joists.

We overlap the sheet waterproofing material and seal the joints with tape. Spread the bulk insulation in a layer of at least 3 cm.

We raise the floor to the level of the balcony threshold

If you decide to make an insulated room, you can raise the floor on the logs on the balcony to the level with the threshold. To learn how to make a threshold on a balcony, watch this video:

A thicker layer of insulation can be laid under such a floor.

- As in the first option, we lay waterproofing and insulation on it.

- We select devices with which we will increase the height of laying the logs:

U-shaped holders made of thick metal, into the socket of which we install and secure logs. You can attach the beam to the upper end of the holders, you can immerse it inside to the required height, and cut off the edge of the holder with a grinder;

Metal studs are available in different heights; they have threads with which the height can be adjusted. Before purchasing studs, measure the height from the floor to the threshold and subtract the width of the beam. Holes are drilled in the timber every 200 mm and placed on studs. The studs from below are secured to the slab.

Corner metal stands, height adjustable. They are attached first to the timber, then to the slab.

Plastic stands similar to furniture legs with threads, made on the basis of polyvinyl chloride. A hole must be drilled in the slab for each leg. They are the cheapest, but plastic is not a very strong material; if the leg breaks, you will have to redo the floor.

- We install fasteners that will raise the sheathing to the desired level. We retreat from the edges so that the insulation fits there. We cut holes in the insulation for fastenings, and put it on top. In this option, you can cover the entire floor with insulation.

- We fasten the logs, lay plywood or OSB board and flooring.

The floor on the logs on the balcony is ready, all that remains is to attach the baseboards.

We install fastenings for joists first at the edges of the floor, then in the middle; it is not recommended to install plastic legs.

Wood flooring

Although floorboards have many advantages, they are not always suitable for balcony design. For example, if the balcony is attached to the room or there is a study in it, made in modern styles, linoleum or carpet is more suitable for finishing the floor. In this case, it is better to use solid wood boards for laying the subfloor: OSB, chipboard, plywood.

The logs are installed in the same order as for plank flooring. The only difference is that the step between the transverse bars is 40 cm. The cut slabs are laid on logs with a minimum temperature gap (1-2 mm) and nailed (if it is plywood) or screwed with self-tapping screws (OSB, chipboard). The joints of the slabs should rest on the joists, and not hang from them, otherwise the edges of the slabs will sag under mechanical load. After applying a protective layer of drying oil, the floor covering is laid on the wood-based flooring.

Advice. The slabs should be cut in such a way that there are as few joints as possible on the floor surface.

Flooring materials

Tongue-groove system

If you decide to lay laminate flooring on balcony floor joists, lay a backing underneath it on plywood or OSB board.

We lay the floorboard with a gap of 10 mm on the sides. We fasten them together into a tongue-and-groove connection. We attach the boards to each block using self-tapping screws or dowels, recess the head deep into the board, and putty on top. The boards need to be treated with two layers of varnish or paint on top to protect them from moisture and increase their service life. For more information about flooring, watch this video:

We lay the linoleum on top of the OSB board and install the skirting boards.

Flooring on joists can be installed easily, quickly and inexpensively. With proper installation and treatment of materials against atmospheric influences, such a floor will last a long time, creating comfort on the balcony.

Surface finishing

The boards were well cut on the sawmill and equally dried. They lay down tightly and formed a flat floor. All we have to do is sand the outer surface a little and treat it with clear varnish.

Grinding

The Bosh multi-tool was well suited for this operation.

It made it possible to smoothly sand the joints of the boards and bring the floor surface to an ideal state.

During the process of sanding the wood, the sandpaper had to be replaced.

The treated floor surface is shown in the photo below.

Painting

A clear varnish was chosen to treat the outer surface of the boards. After applying it, the floor on the balcony acquired a completely finished look.

Thus, thanks to two tiers of joists, we were able to raise the level of the wooden floor to the height of the door threshold, and also position it strictly on a horizontal plane, sand it and varnish it while preserving the original appearance of the wood.

In addition to the topic of the article, we recommend watching the video of the owner Dmitri Koblikov “Laying floorboards on joists”

We remind you that now it is convenient for you to ask questions in the comments and share this material with friends on social networks.

Installing sheathing on walls

Installation work depends on the material and design of the balcony parapet (fencing). If it is brickwork, which is quite rare, it is enough to screw bars of the appropriate section to it with dowels (the height depends on the intended insulation). For leveling, just like on the ceiling, you should use spacers or secure them with galvanized hangers.

In case of large differences, we attach them to drywall hangers

A more common situation is when a welded metal structure is installed as a fence, insulated with glass wool and sheathed on the outside with flat slate (built during the USSR). In such cases it is necessary:

It is not always necessary to disassemble the outer casing; in such cases, installation work will be limited to points 2 and 4.

If there are door or window openings to be lined, the sheathing should be installed along their entire perimeter (except for the floor), as well as on slopes.

Installation of galvanized profile sheathing

On the side of the walls, at the corners of the balcony and on the door/window openings, U-shaped guides are mounted vertically. A rack profile is inserted into these guides (thus it is fixed at the edges). The profile is fastened along its entire length on mounting hangers using special self-tapping screws at intervals of 40-50 cm.

For more tips on installing beam sheathing, watch our video:

Source

Leveling the floor with a self-leveling solution

If the existing unevenness on the concrete floor is less than 3 cm, then it is not advisable to apply a regular cement screed. Most likely it will crack. There is a more reliable way to make a thin, absolutely flat and smooth surface - use self-leveling solutions. The thickness of such ties can vary from 3 mm to 3 cm.

To install a self-leveling screed, you need: a primer, a self-leveling mixture, a spatula, a brush or roller (for priming), a needle roller (for deaerating the screed) and a mixer.

The alignment goes like this:

- The floor is cleaned of chips, paint, grease and oil stains. Cracks in the floor, between the slab and the walls are repaired. Dust the surface with a vacuum cleaner - construction or household.

- The cleaned floor is primed with a brush or roller. According to the instructions, the primer takes 4-6 hours to gain strength. It is advisable to maintain this interval before moving on to the next stage of work. Despite the fact that the primer dries much faster - in the summer in 1-2 hours.

- Add the leveling mixture with water and mix with a mixer until it becomes liquid and flowing.

- Pour the mixture onto the floor, trying to distribute it evenly. Level the screed with a metal spatula.

- Roll over the liquid surface with a needle roller to remove air bubbles from the mixture.

- This screed hardens in 1-2 days, after which you can walk on it. Finishing is carried out only after 1-2 weeks, according to the recommendations of the manufacturers of specific mixtures.

How to level the floor using this technology, watch the video:

Laying laminate flooring on the balcony

Photo of laying laminate flooring on the balcony.

Laying the laminate is done after the internal wall cladding. To avoid squeaking and knocking, we use a soft substrate, starting with a whole strip along the balcony. From the edge of the covering to the walls around the perimeter we leave a gap of 5 mm. To set it up, you can use half-centimeter bars chopped or special plastic wedges.

Interior decoration of balcony with wooden floor.

The laminate is pressed along the edges with a plastic plinth and gives the floor a finished look.

Assembling the floor sheathing

The installation of the sheathing should begin with the floor (if you plan to insulate it), after which they proceed to the ceiling and only then to the fence and walls.

The timber, pre-treated with an antiseptic, is cut to size. The length of the blanks depends on the direction of the finishing material and the configuration of the balcony.

Logs with a minimum cross-section of 40x40 are attached along the bottom slab of the balcony (parallel to the fence). An 80 mm long anchor with a diameter of 8-10 mm is used as fasteners.

Fastening frequency – not less than 50 cm; drilling depth – 50 mm.