Cold aluminum profile is the basis for glazing unheated rooms that do not have strict requirements for thermal insulation. Unlike its warm counterpart, it does not have polymer inserts that thermally separate the outer zone of the structure from the inner one. The main advantage of a cold profile is its reasonable price, due to the minimum range of materials and ease of production.

The scope of application of structures is extremely wide and includes the construction of shopping, entertainment and business centers, industrial buildings and structures, sports facilities, exhibition complexes and pavilions. Installation of an aluminum profile allows you to improve the appearance of buildings whose facades require cosmetic repairs at low cost.

VIDNAL VP 01/03

hinged “cold” glazing

To learn more

VIDNAL VP 02

"cold" door system

To learn more

A cold aluminum profile is made from a special alloy, which is heated to 600 degrees and “pressed” through a special matrix with holes. As a result, extrusion technology allows us to obtain a durable and lightweight structure with precise parameters of length, width and thickness. After creation, it is coated with paint under the influence of electric current or using powder coating. Moreover, the designs have no restrictions on colors.

Systems of this type are lightweight, so they look more elegant. In addition, they are much cheaper than warm analogues, because they have only one double-glazed window. Cold aluminum profiles are used, as a rule, for glazing unheated rooms: loggias, terraces, verandas, balconies, winter gardens. The material is in demand for arranging partitions in office buildings, for zoning premises, organizing vestibules and producing door structures. Quite often, cold aluminum profiles are used for the manufacture of sliding systems. Due to the small weight and dimensions of the guides, these structures are thinner, which means they allow the use of a small area.

No. 1. Main advantages of aluminum windows

Aluminum window profiles are made by hot pressing from an aluminum-based alloy , which includes additives such as magnesium and silicon , the latter sometimes replaced by copper. Thanks to these components, the finished material acquires the necessary strength, rigidity and the ability to withstand heavy loads. The wall thickness of an aluminum window profile is usually 1.5-2 mm , but there are also lightweight systems with walls of 1.2-1.3 mm.

Aluminum windows are widely popular due to a huge number of advantages:

. Thanks to the use of the additives described above, it is possible to obtain a profile that can withstand double-glazed windows of almost any weight and configuration. This has become a competitive advantage of aluminum profiles;

strength- reliability . The profile withstands impacts well, it is resistant to abrasion, it is easy to care for, and if dents appear, they are easy to remove, so we can talk about a high degree of maintainability ;

- resistance to negative environmental factors . The aluminum profile is not afraid of rain and snow, sunlight, temperature changes, and even acid precipitation will not damage it. Coating with special paints and varnishes only increases the stability of the material;

- ease . Sometimes the weight of the window structure does not allow the implementation of bold design solutions, as it creates an excessive load on the load-bearing supports. With an aluminum profile you can easily install the largest windows;

- durability _ Many manufacturers provide guarantees for aluminum windows for 50-80 years. According to this indicator, the aluminum profile is ahead of other materials;

;

fire safety- environmental friendliness . Aluminum is a natural element, the production technology does not involve the use of toxic materials, so the finished profile will not emit any harmful substances into the air;

- plasticity . This property of aluminum allows us to produce windows of any shape. These can be oval, round, polygonal and other fancy designs;

- good design . Until recently, aluminum windows were rarely installed in residential premises due to their low aesthetics. Today the situation is diametrically opposite. The profile can be painted in any color using powder coating or anodizing, it can be decorated to resemble wood, and very precisely.

Among the main disadvantages it is worth highlighting:

. The price of aluminum windows is not the lowest, but taking into account the durability and strength of the structure, such expenses are more than justified;

price- high thermal conductivity of aluminum . This means that on a hot day the profile quickly heats up, and on a cold day it freezes. This problem, fortunately, has long been solved - manufacturers use a layer of heat-insulating material , due to which the structure receives excellent heat and sound insulation characteristics;

- the aluminum profile does not allow air to pass through, so you will need to take care of a reliable ventilation system .

Characteristics of Provedal P400 and PROVEDAL C640 profiles

| Provedal P400 | Provedal C640 | |

| Profile type | cold | cold |

| Frame mounting depth | 40 mm | 60 mm |

| Installation depth of sash/impost | 47 mm | 22 mm |

| Apparent size of the sash in daylight | 70 mm | 52 mm |

| Structural thickness | 64 mm | 64 mm |

| Fill thickness | glass 3-7 mm, double glazing up to 16 mm | glass 5 mm |

| Soundproofing | up to 27 dB | up to 12 dB |

| Water permeability | class E2 | class E2 |

| Breathability | class A3 | class A3 |

| Sealant | elastomers meeting the EPDM standard | elastomers meeting the EPDM standard |

| Profile | extruded from aluminum alloy 6063 (UNE 38/337) | extruded from aluminum alloy 6063 (UNE 38/337) |

| Types of sashes | blind, swing | sliding |

No. 2. Cold or warm aluminum profile?

Aluminum profiles, depending on the design, can be of two main types:

- cold;

- warm.

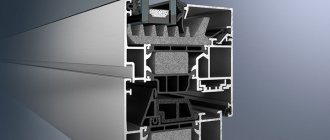

Cold is a single-chamber aluminum profile that does not use any insulating materials. Such structures have the minimum possible weight and are used only in non-residential premises : parking lots, verandas, unheated loggias, utility rooms, etc. Since the heat transfer coefficient of aluminum is 1000 times higher than that of plastic and wood, such a profile instantly cools or heats up, so a warm profile was developed for residential premises.

A warm aluminum profile is a more complex system. Between the two profiles there is a layer of polyamide 1.5-4.5 cm thick. This is an excellent heat insulator. The structure is assembled using special rolling devices, the ridges of the polymer fit tightly into the grooves of the profile, and later they are soldered. The two external aluminum profiles are not connected to each other anywhere in order to provide the room with maximum thermal insulation. A polyamide insert is popularly called a thermal break, which quite accurately reflects its function. It turns out that there are three chambers in a warm profile, but sometimes the heat insulator is additionally divided into several chambers , due to which the manufacturer increases the level of insulation and strength.

Polyamide is a layered composite containing up to 25% glass fiber. The thickness of the thermal break determines how far the aluminum profiles will be spaced apart from each other, which directly affects the degree of thermal insulation. For most regions of Russia, the polyamide layer should be at least 2.5 cm.

Manufacturers continue to improve the design of aluminum windows to make them even more energy efficient. On sale you can find designs in which the aluminum profile is filled with polymer foam material . Polyurethane is often used. Thanks to this technique, convective flows inside the profile are reduced and it is possible to increase the level of sound insulation.

Advantages of cold frames

The structure of cold frames is homogeneous and inseparable. The integrity of the structure makes it as airtight as possible. It protects the room from precipitation, dust, and moisture. Heat loss with such glazing is significant due to the absence of a polyamide insert. However, a cold aluminum profile has a number of advantages:

- Light weight, which makes it possible to install windows even in structures without load-bearing walls and a solid foundation;

- Ease of assembly, which makes cold metal structures relevant for arranging a veranda or outbuildings;

- Cheapness. Therefore, such designs are especially in demand for non-residential premises, for example, loggias, unheated technical structures.

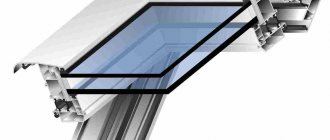

Cold-type aluminum profiles are also installed as interior partitions, office screens, skylights and doors in the winter garden.

No. 3. What type of glass should it be?

In aluminum windows, a particularly important role is assigned to the double-glazed window, which must reliably insulate the room from temperature and noise influences. That is why aluminum windows are often equipped with 3- and 4-chamber double-glazed windows , because the more chambers, the better thermal insulation and noise protection the design provides. Do not confuse the number of chambers with the number of glasses: a chamber is the space between the glass panes of a double-glazed window. Typically the glass thickness is 4 mm , but in double-glazed windows with two or more chambers the outer glass can be 6 mm thick to improve sound insulation . For the same purpose, double-glazed windows are used in which the distance between the glasses is unequal.

To make the window structure even more reliable protection from external negative factors, special glass can be used in double-glazed windows:

- triplex consists of several glasses laminated with film. Triplex is difficult to break, it has good sound insulation properties;

- Selective glass differs from ordinary glass in the presence of a low-emission layer, thanks to which it is possible to retain heat in winter and cool in summer;

- Tempered glass receives additional strength characteristics due to thermal or chemical treatment. Even if such glass is broken, there will be no sharp fragments;

- colored glass is colored in bulk and allows you to create a cozy atmosphere in the apartment. It is recommended to install such glasses when the window faces south, as they reduce light transmission.

Consumer Reviews

Here are the opinions of several buyers who bought aluminum windows:

- Eduard, 30 years old, Simferopol. To be honest, when I first saw an aluminum window, I was pleasantly surprised. The appearance of the structure is quite nice. After consulting with the seller about the technical characteristics, I bought it without hesitation.

- Alevtina, 25 years old, Yekaterinburg. When my husband told me that he had bought aluminum windows, I was disappointed, to put it mildly. The image my mother described of angular frames with a scary appearance immediately popped up. The delivery service delivered the windows in two hours. Going down to the street, I was amazed at the beautiful design.

No. 4. Profile design

The profile surface is painted at the factory using powder coating. No solvents are used, so this technology is completely safe. The coating is so durable that it is not affected by any weather conditions, and the original color remains for years.

The profile can be painted in any shade , have a matte or glossy surface. Moreover, with the help of powder painting you can imitate the texture of any type of wood : first the main color is applied, and then the texture pattern. In the same way, the profile can follow the structure of stone or any other material.

Another way to decorate a profile is electrochemical anodizing . The technology involves “growing” a thin oxide film on the profile surface, which literally grows into the material itself and is therefore highly durable. Before compaction, the film can be tinted, thanks to which you can obtain a golden or black coating, imitate the color of old birch, etc.

Since previously aluminum windows were criticized for their primitive design, today manufacturers are trying in every possible way to radically change the perception of these structures, and they are doing a good job. One of the most popular solutions at the moment is an aluminum profile trimmed with wooden overlays : it is very difficult to distinguish such windows from wooden ones, but the lightness and strength of the aluminum structure are preserved. To create such aluminum-wood structures, high-quality wood of expensive species is used.

Manufacturer's choice

There are many companies producing aluminum insulated windows, but not all of them are able to meet the demands. For specific purposes, you need to contact different manufacturers - not all of them have a large selection of windows and prices.

The German company Schuco has long established itself in the window profiles market. They have been around for 60 years and operate in 80 countries. Their windows are considered the highest quality and most durable. The products of this manufacturer have only positive reviews.

In addition, Schuco offers its customers a variety of types, shapes, and sizes of window structures. They offer a range of 20 thousand aluminum profiles and their components. Such diversity allows the company to collaborate with the most interesting and unusual objects and carry out orders for complex architectural projects. The prices are not the lowest, but you can also choose a window for domestic use.

The Russian analogue is Alutech. Their big advantage is their low price. But compared to their German competitors, they offer little choice.

They produce high-quality products; according to this criterion, they are not much inferior to Schuco. Moreover, Alutech creates profiles according to the requirements of the Russian climate. If you choose a window for an apartment or your home, this is excellent value for money.

No. 5. Which seal is better?

The seal ensures complete tightness of the entire window structure, protects against drafts and heat loss. The following seals are used for aluminum windows:

- EPDM seal based on natural rubbers - this is the most popular option, used by most manufacturers. It is resistant to negative environmental factors, behaves normally under temperature changes, in frost and heat, does not lose elasticity, and is inexpensive. Its cross-sectional shape is not so important; it is better to pay attention that not only the internal and middle insulation contour is used, but also the external one;

- rubber compressor Although it is cheap, at low temperatures its elasticity is lost, and therefore its basic properties. For domestic harsh winter conditions, this option is not very suitable;

- silicone sealant is a leader in performance characteristics, it is durable, not afraid of frost, temperature changes, and sunlight, but is very expensive, so it is used extremely rarely;

- Thermoplastic elastomer has properties similar to rubber, but softens at high temperatures. It is used infrequently, since its performance qualities are far from ideal, and the cost is higher than that of a rubber seal.

Checking the material for practicality

Photo: Mixall. For large-format glazing, it is best to use aluminum frame profiles in combination with anti-vandal triplex and reinforced fittings. In this case, it is necessary to provide convectors built into the floor - otherwise the windows will fog up in cold weather

The material for the thermal insert is glass fiber reinforced polyamide. This plastic is quite durable, and in addition, it hardly expands when heated, which allows it to “coexist” peacefully with aluminum alloy. The metal parts of the profile are connected to the thermal insert using a longitudinal crimp lock on the rolling line.

Photo: BG-Lengo. Thanks to the strength and stability of aluminum frames, the roller mechanisms for moving the sashes do not jam or jam

The thermal insulation characteristics of the frames (or, in the language of specialists, the non-transparent part) of an aluminum window depend mainly on the configuration of the thermal break, and the dimensions and cross-sectional shape of the metal parts have almost no effect on the thermal insulation.

Photo: Finstral, Hörmann. In the West, not only windows, but also doors made of “warm” aluminum are extremely popular, for example, folding terrace models (a) and burglar-resistant entrance doors with an anti-panic handle (b)

Aluminum windows are equipped with two or three sealing contours made of elastic and durable terpolymer. Thanks to this, as well as the precise geometry of the frames, they provide excellent protection against drafts.

Thermal insulation. Most often, a thermal break consists of two plastic bridges 18–25 mm wide, forming (together with aluminum walls) one air chamber. The disadvantage here is that an intense convective flow is formed inside the chamber, which helps to cool the inner aluminum part of the profile. The heat transfer resistance coefficient (R0) of products of this type usually does not exceed 0.45 m2 • °C/W. In practice, this means that even in moderate frost (slightly below –10 °C) and normal air humidity in the room (45–50%), condensation will form on the internal surfaces of the frames.

Photo: "YUKKO". When glazing unheated rooms, cold profile systems are used - both conventional hinged (a) and sliding (b). Such designs are designed for the installation of single glass or single-chamber double-glazed windows.

To minimize the risk of freezing, convection must be stopped. To do this, the thermal break chamber is filled with foamed polyethylene or polyurethane. In terms of heat and sound insulation characteristics, such products are comparable to budget plastic and wooden ones (R0 = 0.55–0.57 m2 • °C/W).

Photo: Finstral

In the most advanced designs, the thermal break is 30–40 mm wide and is often made of a multi-chamber fiberglass profile - such frames have a heat transfer resistance of up to 0.62 m2 • °C/W and are suitable even for passive houses.

It is worth noting that the heat and sound insulation properties of a window depend not so much on the frame parts, but on the glass unit - its type and thickness; from this point of view, aluminum structures are superior to plastic ones, in which it is not always possible to install a heavy double-glazed window (for example, a double-chamber soundproofing glass with an outer glass 6 mm thick).

Due to their high strength and low coefficient of thermal expansion, aluminum profiles are ideal for large-format window structures and facade glazing.

Strength and burglary resistance. Aluminum parts of the profile are subjected to heat strengthening, and corner connections of frames and sashes are made using metal embedded elements, and the corners are inserted into both the internal and external chambers of the profile. The weakest point of the structure is the polyamide thermal insert, but it also has significant strength: according to the technical specifications (GOST), a section of a profile 10 cm long must withstand a transverse breaking load of at least 600 kgf.

Thanks to this, the sashes rarely sag or play, and their maximum dimensions depend only on the calculated wind loads on the glass unit. A large-format aluminum structure will cost at least a third more than a wooden one (made of pine), but it is more reliable, since even engineered solid wood changes in size due to changes in humidity and can warp slightly.

Photo: Schüco

According to tests, aluminum windows can withstand theft's hand tools for more than 10 minutes (unlike most PVC products, which are not burglary-resistant). If it is necessary to increase the burglary resistance of the structure, hidden hinges and special locks with hook bolts are used, while the fittings are additionally protected from breaking out and drilling by steel plates or liners in the profile chambers. In Europe, similar products equipped with anti-vandal glass are assigned class RC 4 according to the DIN EN 1627:201 standard, that is, they are capable of resisting opening with a plumber and compact electric tools for more than 10 minutes.

Functionality. An aluminum window can be equipped with any modern fittings - rotary (with opening inward or outward), tilt-and-turn, parallel-sliding, etc. There will be no problems with installing a window ventilation valve, although the service will cost one and a half to two times more than in case of PVC windows.

No. 6. Aluminum window fittings

The fittings in aluminum windows are fixed either in the Eurogroove cavity or inside the profile. Despite the external similarity of such windows with wooden and plastic ones, the fittings here have a number of features . Since the aluminum profile is more rigid, durable and reliable, fewer locking elements can be used, making the mechanism simpler, lighter and cheaper.

The features of the fittings used for aluminum windows make it possible to implement several methods of opening sashes : these are not only traditional swing, tilt, turn-tilt and parallel-sliding, but also mid-turn. In the latter case, the window leaf rotates around an axis passing through the middle of the window. This option is often implemented for opening round and oval windows.

Accessories also include handles . They can be made in any shade, have both the most ordinary and non-standard shapes. As for functionality, you can choose the most ordinary handle, which is responsible only for opening and closing, and if necessary, you can choose handles with a lock or removable handles, which will become a safety element for families with small children. Anti-burglary handles are used to protect against unauthorized access.

The loops can be made in a standard overhead way or hidden. Since the ease of use of a window largely depends on the fittings, sufficient attention should be paid to its selection. It is better to give preference to fittings from well-known manufacturers: Roto, Savio, Siegenia and others. Some large manufacturers of aluminum windows have their own production and all the necessary fittings.

The secret of durability and freedom of architectural solutions

The appearance on the market of aluminum profiles with high thermal insulation characteristics has opened up wide opportunities for designers and individual developers to create unique houses. Modern architecture finds its expression in simple and laconic forms, open spaces and large areas of glazing. What previously could only be seen in pictures in real estate magazines has become accessible to a large number of people. If you want panoramic glazing - please, glass walls - no problem!

No other technology provides such opportunities in glazing as aluminum profile systems. The static stability of the material, combined with the strength of the joints and fastening elements, makes it possible to create structures from ALT W72 and ALT W62 profiles that are significantly larger in size than wood or plastic.

At the same time, the profiles of ALUTECH systems do not oxidize or deform, which allows them to maintain an aesthetic appearance throughout their entire service life. Compared to plastic and wood, aluminum windows are perhaps the most durable solution that provides savings in the long term. Don’t forget about the environment: aluminum, unlike plastic, is an absolutely safe material from this point of view, which is an important advantage.

In general, aluminum windows based on the ALT W62 and ALT W72 systems are distinguished by great diversity due to the variability of sizes, shapes, as well as different apparent profile widths. At the customer's request, the window structure can be made in any color that is in harmony with both the interior and exterior of the house. Thus, all of the listed advantages of the ALT W62 and ALT W72 window and door systems from ALUTECH allow architects, designers and private developers to realize the most daring ideas, creating houses that are always warm and cozy.

No. 7. Ventilation systems

High-quality aluminum windows have a high level of tightness; in fact, thanks to this characteristic, they are widely used in houses and apartments. Old wooden windows, due to the presence of cracks, ensured the flow of the required amount of fresh air, and when installing a new aluminum window, you will have to take care of the ventilation system. Typically, one of the following systems is used:

- ventilation limiter with fixation in a certain position. This is something like combs that are used for plastic and wooden windows, but for aluminum windows the limiter has a slightly different shape, since ordinary combs are not suitable in design and method of fastening. As a rule, such limiters can be installed in 10-12 different positions, providing the required level of ventilation;

- vents , which were used for ventilation everywhere a couple of decades ago, today can be part of the design of an aluminum window. This is a simple and reliable option, but due to the presence of additional profiles and sashes, the flow of sunlight into the room will be reduced;

- ventilation supply valves Air-Box Comfort S type are located at the top of the window, allow fresh air to pass through, but trap dust and provide reliable protection from noise. This system is regulated by turning the knob, so you can control how much fresh air will enter the room.

Why glaze a balcony?

Sliding aluminum frames are a good option

Before deciding to glaze a balcony structure, the homeowner should consider all options for the type of system (plastic warm glazing or cold), and understand what benefits he will receive by using aluminum or plastic glazing.

By the way, those who decided to assemble and install such a translucent structure with their own hands should understand that this is associated with a number of difficulties.

Practice and calculations show that this operation allows you to increase the temperature in the room facing the balcony or loggia by several degrees.

So, the obvious advantages include:

- increase in room temperature;

- creating protection from the effects of precipitation and the environment, including noise;

- The use of glazing allows you to create additional space on the balcony.

If an old grille is used as a parapet, then aluminum glazing will not provide any insulation effect.

No. 8. The best manufacturers of aluminum windows

The production of aluminum windows is a rather complex technology that requires the use of specific equipment, so it is better to trust your choice only to trusted manufacturers. They provide a guarantee for their products and, moreover, constantly delight with innovations that increase the functionality and energy efficiency of the design. Let's look at the best manufacturers of aluminum windows.

Schuco

This German company is a leader in the aluminum window market. Operating since 1951, it was at the forefront of the production of aluminum profiles, and today Schuco windows are used all over the world. These are convenient, well-thought-out and practical designs that have an excellent design and can be painted in any color according to the RAL map. The company's aluminum windows have energy efficiency at the level of a passive house. During production, double-glazed windows and fittings from trusted manufacturers are used.

Provedal

The well-known Spanish company has also been present in the aluminum window market for a long time. The main feature is that anodizing is used in production, so the coating is as durable as possible. The company's windows are in high demand in dozens of countries around the world.

Reynaers

Reynaers is a company from Belgium that is constantly expanding its range of products. The manufacturer is distinguished by a wide range of profile colors, high durability of products, their functionality and thoughtfulness. Not long ago, wood-aluminum windows were introduced into the range, which are in great demand in the domestic market.

Profilco

The Greek company Profilco has been operating since 2001, but during this time it has managed to establish itself as a reliable professional who quickly responds to market demands and is ready to constantly present new solutions. The company includes a large research and development center; all products meet the most stringent global requirements for quality and safety. The network of sales offices is widely developed, so domestic buyers can order products from a leading European manufacturer.

ALUMIL SA

This is one of the largest aluminum extrusion companies in South-Eastern Europe. Production facilities are located in countries such as Greece, Romania, Bulgaria, Albania, and Serbia. The holding includes branches and sales offices all over the world. The research center is constantly working to improve aluminum systems, and strict quality control of products is carried out. The company offers several options for aluminum windows and a lot of profile color options.

ACG Windows & Doors

The Chinese leader in the production of aluminum windows has long been widely represented in the domestic market. The company's products are characterized by an affordable price and a high level of quality. The profile can have any color, so it will fit into any interior style. The products are in demand not only in the domestic market, but throughout the world.

Realit

The Realit aluminum profile plant has been operating since 2002, is equipped with the most modern production lines, and today can offer high-quality aluminum profiles, which are subsequently used for the production of aluminum windows. The range includes profiles for cold and warm windows. Profiles for warm aluminum windows are equipped with two heat insulator inserts.

What to look for when choosing a warm aluminum company?

Every year the demand for windows made of warm aluminum is slowly but surely growing. However, not all manufacturers have learned to work with products that are complex to design and manufacture. This is not plastic!

When choosing a company, you should pay attention to the presence of:

- High-precision equipment for the production of high-quality aluminum structures;

- A staff of qualified designers who can make calculations on the strength of the object’s glazing. Select solutions that can withstand large static loads and provide the customer with the opportunity to choose for various tasks and budgets.

Photo: installation of warm aluminum structures is not easy! Special equipment required! © Artem_Volkov

- Special equipment for delivery, lifting and transportation of large, heavy structures around the site.

- Assortment of profile systems. If, for example, only Provedal is available, then the company is unlikely to be able to make high-quality glazing from warm aluminum.

I hope my advice and experience in SEC Window Continent will help you make the right choice and find a company that will make your dreams come true.

Advantages and disadvantages

Glazing verandas and terraces with sliding frames has undoubted advantages:

- aluminum frames cost twice, and sometimes even three times less than plastic or wooden analogues;

- in the open position, such structures do not take up space inside the veranda;

- installation of aluminum systems takes less time than installation of PVC analogues;

- the material from which the profile is made ensures the rigidity and strength of the system;

- elements of the aluminum structure (frame, sashes) are lightweight, so they do not overload the foundation;

- frames made of this material are not subject to fire;

- the profile is equipped with locking mechanisms, which protects the windows from burglary;

- To keep structures clean, it is enough to remove dirt from glass and guide profiles.

Sliding glazing of the veranda and terrace allows you to install large windows of various shapes.

Along with numerous advantages, sliding systems also have some disadvantages:

- sliding doors on skids are a less practical option than swinging counterparts;

- aluminum structures do not require room insulation because they have a low heat saving rate;

- frames made of this material also have a rather low level of noise insulation (however, this drawback is insignificant, since it is always quieter in the country than in the city);

- in the off-season, frames and glass are covered with condensation, and in frosty weather - with frost.

Warm glazing of the front balcony

The warm glazing of the front balcony creates a cozy and comfortable atmosphere in the house. An integral part of many apartments is a balcony, without which it is difficult to imagine any living space. Most often, this area of living space takes on the temperature shock and all weather fluctuations. A well-designed balcony with a warm glazing system can withstand persistent frosts and maintain optimal indoor temperatures.

Unique interior with warm facade glazing

- You can install warm glazing on balcony facades and create an exclusive design using colored canvases.

- The only limitation is the owner's imagination.

- The frame can be of any color, which allows you to combine the facade with the interior design of the balcony.

If the design involves non-standard window sizes, then the frame is assembled from a metal or aluminum profile. All work is carried out using a thermal insulation system, which is suitable precisely in cases where it is necessary to increase the living space. Glazing can have a panoramic view, which will visually expand the square footage and provide a flow of sunlight.

Installation of any window opening system

Warm glazing of a front balcony using an aluminum profile has a number of advantages. This type of glazing is distinguished by its ability to support any window opening system. The stained glass window can be assembled using tilt-and-turn fittings, which will provide the balcony with ventilation. The facade can be equipped with a sliding system, which ensures ergonomics of the room and complete ventilation of a small living space.