It is difficult to imagine a house in which there are no windows or doors. In order to make them, structures are needed to cover the openings.

Reinforced concrete lintels are used for this purpose. Their main function is to transfer the load from the ceiling and brickwork to the side sections of the walls (piers).

The main materials for making jumpers are:

- Reinforced concrete - due to its affordable price and high manufacturability, is widely used in capital construction;

- Steel (I-beam or channel) is used to a limited extent to cover wide openings where windows and doors are subject to heavy loads.

The markings and overall dimensions of reinforced concrete structures are specified by GOST 948-84 . This building standard divides all industrially produced lintels for window and door openings into several basic types:

- PP - slab (width more than 25 cm).

- PB - block (width less than 25 cm).

- PG - L-shaped beams are equipped with a protrusion designed to support floor slabs.

- PF - façade (used for openings in which the masonry protrudes more than 25 cm from the wall surface).

Depending on the size of the working load, all prefabricated lintels are divided into load-bearing and non-load-bearing. The former perceive and transmit to the walls the weight of the ceiling and the upper part of the wall. The latter can only withstand the load from the wall and their own weight.

The load-bearing capacity of reinforced concrete lintels ranges from 100 to 3,700 kg/m. Concrete provides these structures with the necessary compressive strength, and steel reinforcement absorbs tensile forces.

Lintels for window and door openings: types, sizes, installation features

It is difficult to imagine a house in which there are no windows or doors.

In order to make them, structures are needed to cover the openings. Reinforced concrete lintels are used for this purpose. Their main function is to transfer the load from the ceiling and brickwork to the side sections of the walls (piers).

The main materials for making jumpers are:

- Reinforced concrete - due to its affordable price and high manufacturability, is widely used in capital construction;

- Steel (I-beam or channel) is used to a limited extent to cover wide openings where windows and doors are subject to heavy loads.

The markings and overall dimensions of reinforced concrete structures are specified by GOST 948-84 . This building standard divides all industrially produced lintels for window and door openings into several basic types:

- PP - slab (width more than 25 cm).

- PB - block (width less than 25 cm).

- PG - L-shaped beams are equipped with a protrusion designed to support floor slabs.

- PF - façade (used for openings in which the masonry protrudes more than 25 cm from the wall surface).

Depending on the size of the working load, all prefabricated lintels are divided into load-bearing and non-load-bearing. The former perceive and transmit to the walls the weight of the ceiling and the upper part of the wall. The latter can only withstand the load from the wall and their own weight.

The load-bearing capacity of reinforced concrete lintels ranges from 100 to 3,700 kg/m. Concrete provides these structures with the necessary compressive strength, and steel reinforcement absorbs tensile forces.

Technological characteristics

Industrially manufactured products are checked for compliance with the standard (reinforced concrete lintels GOST 948-84, 13015-2003) for each of the specified parameters:

- frost resistance – F35/F200;

- crack resistance, strength, rigidity;

- concrete strength M200 and higher;

- moisture content of concrete upon delivery – no more than 13%;

- thickness, type, quality of anti-corrosion coating;

- dimensional and quality characteristics of steel for embedded elements, hinges, fittings;

- fire resistance;

- seismic resistance;

- accuracy of geometric parameters.

Standard size range, weight and marking

The GOST dimensions of reinforced concrete lintels are as follows:

- length from 103 to 596 cm;

- height from 12 to 44 cm;

- width from 14 to 38 cm.

The weight of these structures directly depends on the dimensions and can range from 20 kilograms to 2 tons.

Reinforced concrete lintels are mounted on cement mortar. Cutting of these structures for the purpose of adjustment is not permitted. If the wall thickness is large, the opening is covered with several timber lintels, laying them parallel to one another.

Special markings help you understand the wide range of these products. It consists of three groups of alphanumeric symbols separated by a dash.

The first digit indicates the GOST number of the section. It is followed by two letters indicating the type of jumper and two numbers of its length (in decimeters). The second group of numbers contains information about the design load in kN/m. The third group of marking symbols is service and contains data on the degree of concrete density, the presence of mounting loops, the degree of seismic resistance or the class of reinforcement.

For example, let’s decipher the standard designation of a reinforced concrete jumper: 2PB22-3-p:

- 2 — section number (indicated in the GOST table);

- PB – bar lintel;

- 22 – length in decimeters (220 cm);

- 3 – bearing capacity (design load, 3 kN/m);

- p – the product has mounting loops.

To increase the load-bearing capacity of lintels, prestressed reinforcement is used. Such structures can be distinguished by the type of reinforcement indicated at the end of the marking. For example, 5PB21-27-AtV. In this case, AtV is a type of prestressed reinforcement.

Approximate prices and selection features

The most popular length of lintels used in residential construction is from 1.2 to 2.2 meters. The estimated cost of slab-type structures (width 38 cm) ranges from 600 to 4000 rubles. Bar lintels of similar length can be purchased at prices ranging from 250 to 1,700 rubles per piece, depending on the selected width and height.

When choosing the type of lintel above the windows, do not forget that slab lintels can only be installed in a non-load-bearing wall (on which the floor slabs do not rest). Bars can be installed in any type of enclosing structures (non-load-bearing and non-load-bearing).

The width of all manufactured reinforced concrete lintels is a multiple of the width of the masonry. Thanks to this, they are easy to choose for any object. For example, for partitions with a thickness of half a brick (12 cm) and one brick (25 cm), there are more than three dozen standard sizes of products ranging from 1 to 6 meters in length on the market. For thicker walls (1.5 bricks or more), the industry produces slab lintels.

For installation in non-load-bearing walls, it is more profitable to use slab lintels, because their width is equal to the width of the wall. In this case, you will have to use several pieces of timber beams.

When purchasing, you must take into account the support of the lintels on the wall - the main criterion for the reliability of the ceiling. If the area of the supporting part turns out to be less than the standard, then destruction of the material on which this structure rests may occur. To restore the load-bearing capacity of the pier, you will have to do the labor-intensive dismantling of the lintel, dismantling and re-laying the destroyed area.

In general, for a load-bearing brick or aerated concrete wall, the depth of embedding (support) of the lintel should be at least 25 cm. For a self-supporting wall, the size of its supporting part can be reduced to 12 cm. The lintel above the doorway should extend its ends onto the wall no less than 20 cm.

The height of the lintel is selected based on the calculated load on the opening. The developer does not need to perform complex strength calculations, since the full specification of these structures, indicating the dimensions, is contained in the design documentation. During independent construction, you should not engage in amateur activities with the selection of jumpers. It is better to contact the designers for advice.

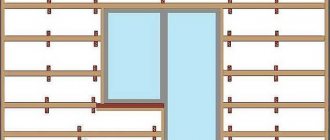

The technology for installing lintels over openings is determined by the type of wall (load-bearing or non-load-bearing). In the first case, a powerful reinforced concrete beam is placed under the slab. Two other smaller sections are placed in the middle of the wall. The outer one goes down one row of bricks, forming a quarter.

In a non-load-bearing wall, the lintels are the same size. The outer one is lowered by a quarter, and the rest are placed at the same level.

Possible mistakes

Difficulties and mistakes made when laying aerated concrete partitions can arise in the following cases:

- Purchasing low quality material that does not have labeling, certification or warranty from the manufacturer.

This applies to gas blocks, cement, glue and all other consumables. Blocks must have a high D density. - Errors in calculating the shape of the wall, its thickness and external load.

A well-drawn professional drawing from a local architectural bureau of urban planning or a construction company that provides this type of service can protect against this problem. - Lack of waterproofing, anchoring and construction technology. Such errors will contribute to the rapid destruction of the partition or the appearance of cracks on the wall, which will require additional financial costs to eliminate the problems, with additional time spent.

- Failure to comply with temperature conditions. Recommended temperature for indoor work is +5 °C. At warm temperatures, work proceeds quickly, and solutions and glue harden well.

- Construction of walls immediately after pouring the foundation. It is necessary to comply with the technical conditions for starting work, in accordance with GOSTs, so that there is no destruction or cracks in the future.

In order to avoid errors in work, it is necessary to adhere to the following standards when working with gas blocks:

- GOST 21520-89;

- GOST R 57334-2016/EN 771-4:2011;

- SP 339.1325800.2017;

- STO 501-52-01-2007;

- STO NAAG 3.1–2013.

Aerated concrete blocks are a lightweight and very practical material that is easy to construct, following technological rules.

How to choose lintels for brick walls?

Purpose of the lesson: to consolidate theoretical material, learn how to select lintels over window and door openings to brickwork.

Contents of the lesson: on A4 graph paper at a scale of 1:100, draw up a plan diagram for the list of lintels according to the given options, fill out the list of lintels in Form 1 and the specification of precast reinforced concrete elements (Appendix A).

Initial data: diagrams of floor plans (based on materials from practical work No. 1). Jumper types are given in Appendix B.

Procedure for conducting the lesson:

1) Before proceeding with the selection of lintels, it is necessary to complete the floor plan diagrams for the list of lintels. An example plan is shown in Figure 6.1.

To do this, we schematically draw the floor plan of the house with the designation of openings, observing the scale. An example of the circuit is given in Figure 6.2.

2) Assign each opening a position (mark), which is assigned in accordance with the width of the opening and the static function of the wall - load-bearing, self-supporting or non-load-bearing. An example is given in Figure 6.3.

3) Determine the size of the opening: (width and thickness).

4) Select cross-sections of lintels, combining them from several bars or a combination of bars and beams. In load-bearing walls, place “load-bearing” lintels in places where the slab (beam) is supported, and fill the remaining width of the walls with “non-load-bearing” lintels. An example is given in Figure 6.4.

Section diagrams are drawn in table form 2.1 GOST 21.501-93.

Figure 6.1 1st floor plan

Figure 6.2 Layout of the 1st floor

Figure 6.3. Marking of openings

Figure 6.4 Diagram for installing lintels over openings in external load-bearing brick walls

For ease of work, keep a count of the required length of jumpers next to the sheet. To do this, we add to the width of the opening the value of the minimum support of the lintels on the wall: “non-load-bearing” lintel + 240 mm (120 mm on each side), “load-bearing” lintel + 500 mm (250 mm on each side). The brands of jumpers are indicated by positions on the section diagram. The “non-load-bearing” lintel takes only the weight of the masonry, and the “load-bearing” lintel takes the weight of the masonry and the floor resting on it.

5) Select “load-bearing” and “non-load-bearing” jumpers according to Appendix B.

6) In load-bearing, self-supporting walls and partitions, use only “non-load-bearing” lintels.

7) If a quarter is required, lower the external reinforced concrete lintel by a quarter amount equal to 65 mm.

The selected brands of lintels are indicated in the specification of prefabricated lintel elements (Appendix A)

An example of selecting lintels in a building with brick walls

Guidelines: An example of selecting lintels in a building with brick walls. The thickness of the external walls is 510 mm, the internal walls are 380 mm.

Stage I. According to the plan, Figure 6.5, determine load-bearing and non-load-bearing walls

Along the axis, 1-window opening is 910 mm (load-bearing wall 510 mm thick).

Along axis 2 - doorway - 910 mm (load-bearing wall 380 mm thick).

Along axis A - doorway - 1010 mm (curtain wall 510 mm thick).

Along axis B there are 2 window openings – 1510 mm (curtain wall 510 mm thick).

There are two window openings of the same size on the building plan, so they will have the same lintel markings.

All openings have different widths, which means that the marking diagram should have four types of lintels: PR-1; PR-2; PR-3 and PR-4.

Figure 6.5 1st floor plan

Stage II . Draw a diagram of the 1st floor plan (Figure 6.6), indicating the positions of the openings. In the task it will look like this:

Figure 6.6 Scheme of the 1st floor plan with markings of openings

Stage III. Select “load-bearing” and “non-load-bearing” jumpers and sketch their diagrams:

1) To block an opening in a wall 510 mm thick, you will need four 120 mm wide timber lintels: 120 mm x 4 = 480 mm,

plus three 10 mm seams (10 mm x 3 = 30 mm). Thus, we get: 480 mm + 30 mm = 510 mm - a size equal to the thickness of the wall.

We have determined that the wall is load-bearing, so the outermost lintel on which the wall rests must be “load-bearing”.

We get: three jumpers – “non-load-bearing” and one – “load-bearing” (Figure 6.7)

Figure 6.7 Diagram of jumpers in a load-bearing wall 510 mm thick

2) To determine the length of the lintel to the width of the opening, add the value of the minimum support of the lintel on the wall (Figure 6.8 and Figure 6.9)

“non-load-bearing” lintels: 910 mm + 240 mm (120 mm on each side) = 1150 mm.

Figure 6.8 Scheme of supporting a non-load-bearing lintel over the opening

Using the table in Appendix B, we select the required size of the jumper, the size of which will correspond to the calculated length (in our example, 1150 mm). This turned out to be a jumper with the name 2PB13-1, the length of which is 1290 mm, height – 140 mm;

“load-bearing” lintel: 910 mm + 500 mm (250 mm on each side) = 1460 Figure 6.9 Scheme of supporting the load-bearing lintel over the opening

We find the required lintel in the table and do not forget about the design load (Appendix B), since the floor slab rests on the “load-bearing” lintel. We get a 3PB16-37 jumper, the length of which is 1550 mm, the height is 220 mm;

Jumpers PR-2, PR-3, PR-4 are selected using the above method.

When selecting a PR-4 lintel, it is necessary to take into account the wall thickness - 380mm.

In this case, 3 lintels with a width of 120 mm are laid above the opening:

120x3 = 360 mm; 360 mm + 20 mm (two seams of 10 mm each) = 380 mm.

3)We fill out the list of lintels according to form 6.1 - Figure 6.10, putting down positions in the section diagram, then fill out the table of specifications for prefabricated lintel elements (Appendix A). Examples of filling are given in tables 6.1 and 6.2.

Form 6.1 GOST 21.501-93

Figure 6.10 Jumper List

Table 6.1 Example of filling out the list of jumpers

Table 6.2 Example of filling out the specification of jumper elements

You will only need four parameters that you know well:

– width of the opening to be closed;

– type of wall brick (silicate or ceramic);

– whether the wall is load-bearing (whether the floor slabs rest on it).

Four simple steps:

- Step 1: width of the opening to be covered. Enter the width of the opening in meters. The program is designed for openings with a width from 0.8 to 2.7 m; if you enter a larger width, lintels of 2.7 m will be calculated. The calculator does not care which opening is being considered: a window or a door.

- Step 2: type of brick masonry walls. The program selects lintels for buildings from the following materials: ceramic single brick GOST 530-2012 “Ceramic brick and stone” with a height of 65 mm;

- silicate one-and-a-half brick GOST 379-95 “Silicate bricks and stones” with a height of 88 mm.

- All! By entering these four values, you will get a layout of lintels over one opening. In addition, the calculator will provide a specification indicating the brands and GOST standards of jumpers, the required number of jumpers per opening and the weight of each of them. Follow the same procedure for all openings of your house or cottage, and you will receive materials for a comprehensive order of all precast concrete lintels for the site. Thus, you will receive all the necessary information for purchasing jumpers free of charge. More details

After entering the data, you will see a diagram of the layout of the jumpers along the opening. If necessary, you can go back any number of steps and change any of the parameters. The layout scheme will be recalculated immediately.

The program lays out only timber lintels of PB grades in accordance with GOST 948-84 “Reinforced concrete lintels for buildings with brick walls.” This standard applies to reinforced concrete lintels made from heavy concrete and intended to cover openings in brick walls of buildings for various purposes.

The jumper brand consists of alphanumeric groups. For example, the brand of jumper 5PB27-37 is deciphered as follows: 5 – jumper with a cross section of 250×220 mm; PB – bar lintel; 27 – length of the jumper in decimeters, rounded to the nearest whole number (in this case 2720 mm); 37 – design load taking into account its own weight, rounded to the nearest whole number (in this case 37.3 kN/m). In brands of jumpers that have sling loops, a lowercase letter “p” has been added. For example, 5PB27-37-p.

If necessary, we are ready to provide documentation with initial data and specifications of selected jumpers completely free of charge. Specify the email address to which we will send the required document, which also contains information about the organization that carried out the selection of jumpers, the name of the responsible specialist and a link to the approvals of our organization that allow us to carry out the specified type of design work. An example of document formatting is provided at the link. s Laying out reinforced concrete lintels is one of the stages of designing a cottage. Other important steps include designing foundations, laying out floor slabs, designing basement walls and staircases. From us you can order a project for the load-bearing structures of a cottage or house, which will be completed by experienced designers (see “our team”). In our work we use modern software systems for calculations and design of load-bearing structures.

How to calculate the load

Technically, the lintel at the top of the opening is a regular beam and the calculation for it is carried out in a similar way. There are two main requirements that this part must satisfy:

- The sections of the walls on which the lintel rests must adequately bear the load.

- The residual deformation (deflection) of the lintel under load should not exceed the permissible values for windows or doors installed in the opening.

It is always necessary to take into account the self-supporting properties of the wall. Very often, when constructing masonry, opening lintels perform their function only for the first 2–3 weeks after their installation, and then they simply remain in the walls without any need. This applies to those openings over which a masonry pillar is preserved, equal in height to the length of the span. Here, a lintel is not needed at all - the wall will support itself, and the larger the blocks used for masonry, the smaller the height of the pillar should remain.

In other cases, the jumper is calculated based on the applied load, including:

- own weight of the jumper;

- the weight of the wall taking into account its self-supporting capacity (the height of the masonry above the opening);

- distribution of the weight of the wall (for summer masonry, only 1/3 of the width above the opening is taken into account, for winter masonry - the entire wall);

- the load caused by the support of beams or floor slabs on a given section of the wall.

The linear dimensions of the jumper are also important. Its width is determined by the thickness of the wall, its height by the required load-bearing capacity. The length of the lintel corresponds to the width of the opening plus twice the depth: from 10 cm for brick walls and up to 30 cm for loose porous blocks.

In most cases, to determine a suitable lintel, it is enough to make a selection from tables with standard prefabricated concrete products (series 1.038 for standard and 1.225 for very wide openings). The required product is determined by the width of the opening, taking into account the depth of the filling. If the required lintel is thinner than the wall, you need to install several of these, or at least two of them.

Of course, no one insists on purchasing finished products. You are free to cast reinforced concrete lintels yourself, as well as replace them with wooden or steel ones at your discretion, having first performed a calculation of the lintel for deflection.

Installation of lintels in stone buildings

The easiest way to decorate the upper part of the opening is to avoid using a lintel, increasing the height of the window right up to the reinforced belt. This is not always possible, because the length of the span imposes its own limitations, especially for load-bearing walls, and besides, it is impossible to bring doors right up to the ceiling. And yet you should know that between the opening and the reinforced crown there must be at least two rows of large-format blocks, or 5-7 rows of bricks, or there should be nothing.

It is easiest to arrange the upper part of the opening in walls on which the ceilings do not rest. If the height of the masonry above the opening does not meet the requirements for self-support, the upper rows are reinforced with reinforcement. Between each brick of the row covering the opening, “clips” are laid - clamps made of 4 mm wire, which protrude above the row of masonry, forming a kind of ears. Under them, longitudinal reinforcement is inserted and tied, one 10 mm rod for every 10 cm of wall thickness, extending 15–20 cm onto the pillars on the sides of the opening.

Strengthening an opening in load-bearing walls made of solid blocks of lightweight concrete is even easier. The masonry above the opening is carried out using a temporary support from below. After this, a groove up to 20 cm deep and 25–30 mm thick is cut in the center of the blocks above the opening. Flat reinforcement is inserted inside - a mesh of 12 mm reinforcement, and then the groove is filled with sand concrete. If it is clear that such strengthening does not meet the strength requirements, use U-shaped trays made of porous concrete in the manner of permanent formwork.

Reinforced concrete lintels are very significant cold bridges. Their use is required only in exceptional cases, when a very wide opening is planned in the load-bearing wall. Such lintels are cast flush with the wall, tamping the panel formwork from the inside, outside and below. The lintels are reinforced in two rows, one 12 mm rod for every 60–80 mm of wall thickness. Depending on the length of the span, another 2–3 reinforcement bars can be added to the bottom row of reinforcement. To prevent heat migration, a pair of EPS slabs with a total thickness of 50–70 mm are installed in the center of the formwork, while the reinforcement is distributed to form protective layers of 40 mm.

When installing jumpers of any type, it is important to be able to properly prepare the “shoulders” on which they rest. As a rule, wood, solid brick or grade 300 cement mortar are used for this.

Strengthening openings in frame buildings

For a frame building, the presence of lintels in the upper part of the openings is strictly necessary. The requirements described below are valid for frames made of both metal and wood.

If the width of the opening does not exceed two steps for installing the frame racks, the nearest side rack elements are connected by two horizontal crossbars, and then two vertical spacers are added between them, setting the required width of the opening.

If the opening width is equal to three or more distances between the frame posts, it is decorated with crossbars in the same way. For additional support of short racks above the opening, they are unloaded onto adjacent ones using diagonal braces running from the center outward. In all cases, the cross-section of the crossbars should not be less than the size of the rack elements of the frame.

If the opening exceeds the width of five times the distance between the posts, the verticals closest to it should be double. The internal pair is connected to each other by a horizontal jumper, and the external one is the same, but higher by half the height of the opening. The space between two horizontal crossbars is filled with a diagonal stiffening mesh based on the principle of floor trusses.

Foam concrete is

Foam concrete is an airy, spongy material, one of the types of cellular concrete.

Many people do not see the difference between a foam block and a gas silicate block, because... they are similar in their airiness. But this airiness is provided to the materials in two different ways, and as a result, they have different characteristics and areas of use.

When making foam blocks, sand, water, cement and a specialized foam additive are used. Gas silicate is obtained through chemical reactions. For these reasons, aerated concrete has through pores, and foam concrete has closed ones. Therefore, foam block is more popular, it has good waterproofing and thermal insulation.

How to make and strengthen openings in load-bearing walls

When remodeling, it may be necessary to make an opening in a load-bearing wall. Such actions in the public sector can only be carried out in agreement with the housing stock, while private developers can act at their own peril and risk.

According to the project, the boundaries of the future opening are marked on both sides of the load-bearing wall. To ensure complete coincidence, after marking, four strictly perpendicular holes are drilled on one side in the corners of the opening and connected with lines.

Along the upper border of the opening, a horizontal trim is made about 10 mm wide and 20 cm longer than the opening in both directions. A piece of angle steel is placed into the resulting groove on each side. Its cross-section can be determined by bending calculations, but more often the embedded parts are made with great excess strength. In general, a steel angle 100x100x8 mm will be more than enough.

Above the nested corners, one hole is drilled for every 25 cm of the opening width; smooth fittings are inserted into them, through which the corners are connected to each other. The lower ligament is made with overhead steel plates 100x8 mm. After installing the lintel, the opening can be cut out and removed piece by piece.

In the lower part of the opening along the plane of each wall, two pieces of corner steel with dimensions of at least 50x50x4.5 mm must be laid. They need to be inserted into the wall at least 50 mm on each side. Vertical side corner covers are inserted between the lower and upper corners. They are usually chosen to be equivalent in size to the top frame.

On the inside, the side corners are connected with overhead plates. In the wall, the harness is secured with pins made of 12 or 14 mm profile reinforcement, which are driven into holes drilled at an angle of 45° to the wall plane every 35–40 cm. The pins are secured to the corners by welding, cut to 60–70 mm, and then tightly are bent to the plane of the frame and thoroughly scalded.

Calculation of reinforced concrete lintels.

When erecting brick walls, it inevitably becomes necessary to install a reinforced concrete lintel over the window opening. They are reinforced concrete beams with different sections and lengths, manufactured at the factory. To select the required standard size of the product, it is necessary to make preliminary calculations that will take into account such data as the load on the lintel and the width of the opening. Calculation of reinforced concrete lintels.

At the same time, when talking about the load, they mean the dead weight of the lintel combined with the weight of the wall and ceiling. In the case of residential buildings, where the loads are not so high, all cases are usually divided into three groups:

- The ceiling rests on the wall.

- The ceiling does not rest on the wall, and the wall itself is self-supporting.

- The lintel is laid in a brick partition 12 cm thick.

Briefly about the main thing

When building a house, you need to pay special attention to the creation of window openings, for which special lintels are used. If the wall is load-bearing and a multi-story building is planned, then it is advisable to use monolithic lintels with high strength

In places with small window openings up to 1.7 m wide, conventional masonry can be carried out using temporary support.

If the wall is load-bearing and a multi-story building is planned, then it is advisable to use monolithic lintels with high strength. In places with small window openings up to 1.7 m wide, conventional masonry can be carried out using temporary support.

Ready-made high-strength jumpers are purchased in advance. Until the moment of use, they are stored together with other building materials in a place protected from rain.

Types of reinforced concrete lintels.

Before we begin the calculations, let's take a little look at the types of jumpers themselves. To understand what options are available to you, you should open the website of any reinforced concrete manufacturer and see what types of reinforced concrete lintels are present in their product range. By clicking on the link, you will see a long list of standard sizes with their characteristics. To learn how to quickly navigate it, you should learn to decipher the markings. Let's do this using the example of a 2PB 16-2 jumper:

- 2PB - this part of the marking means that the product belongs to a certain type and type of section. In this case, a timber lintel of the second type of section . Bar lintels (PB) can have a width of 120 or 250 mm, which makes it necessary to use several products at once in cases where the thickness of the partition exceeds 120 mm. They also produce slab lintels (PP), the width of which is 380 and 510 mm.

- The second type of section (2PB) has dimensions of 120x140 mm. Other types have the following dimensions: 1PB - 120x65 mm, 3PB - 120x220 mm, 4PB - 120x290 mm, 5PB - 50x220 mm.

Now, knowing the variety of reinforced concrete lintels, you can proceed directly to the calculation.

Installation benefits

The advantages of using gas blocks are as follows:

- Ease and high speed of masonry, as well as processing (surface grinding, chipping, sawing with a hacksaw).

- Good thermal insulation and sound insulation characteristics.

- Economic benefit and practicality.

- Excellent combination with reinforcement.

- Environmental friendliness and fire protection.

- Possibility of using any finish.

The disadvantages of using gas blocks are:

- Allowing only minimal operating loads.

- Arrangement using flexible and rigid anchoring (tapes), which must be performed several times.

When characterizing aerated concrete partitions, buildings have more advantages than disadvantages.

How to select reinforced concrete lintels.

Calculation of reinforced concrete lintels. So let's first enter some initial data. Let's say we need to calculate which lintel should be used to cover a span of 1350 mm wide in a self-supporting wall 240 mm thick with a wall height above the opening of 800 mm. Construction is being carried out in winter conditions.

A wall thickness of 240 mm means that we will need two lintels 12 mm wide. In winter, a load from the height of the wall equal to the design span is taken on the self-supporting lintel. The design span is calculated as follows:

1350 + 2*100/3 = 1420 mm

100 mm in this case is the minimum depth of support for the lintel. Since the height of the masonry turned out to be less than the design span, in future calculations we will use exactly this height - 800 mm.

Next, we determine the load per 1 linear meter of the product:

0.24*0.8*1.8*1.1/2 = 0.19 t/m = 190 kg/m

In these calculations, 1.8 t/m3 is the weight of the brick, 1.1 is the safety factor, 2 is the number of lintels. So, we need to choose a jumper from those whose load index is at least 2.

As we said above, the minimum support depth for these jumpers is 10 cm, which means the smallest possible length of the jumper in our case is:

1350 + 100*2 = 1550 mm

From the list of standard sizes, a 2PB 16-2 jumper with a length of just 1550 mm and a design load of up to 200 kg/m could suit us. However, we still need to take into account the load from the beam’s own weight, which is 70/1.55 = 45 kg/m. That is, the total load will be 190 + 45 = 235 kg/m, which exceeds the maximum permissible for this jumper.

In our case, a 2PB 19-3 jumper is suitable. Its own load is 80/1.94 = 41 kg/m. Then the total will be equal to 190 + 41 = 231 kg/m, which does not exceed the permissible 300 kg/m for this beam. The length of the lintel is 1940 mm, and this is also suitable for our conditions.